For this weeks assignment we had to produce a In-System Programmer (ISP) which we will be using for the rest of the class to flash other electronics. For this I learned how to use the Roland Modella CNC machine and how to properly solder surface mount components

Milling

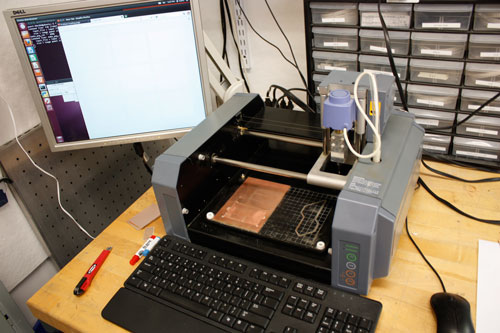

To machine the PCB I used the Roland Modella CNC machine with the FAB modules. To position and setup the machine I undertook the following steps:

1) - Place the PCB on the bed using double sided tape.

2) - Press down firmly ensuring that it's level

3) - Select the required bit (1/64" - Track, 1/32" - Outline)

4) - Using the Allen key release the bit

5) - Replace bit and allow it to sit on the surface of the PCB

6) - Lock in the bit using the Allen Key

7) - Machine following the FAB Module instructions

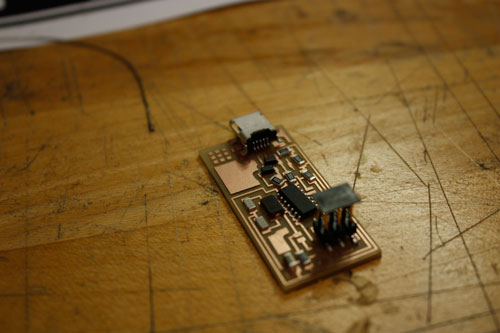

The board is pretty small as you can see in the image below, and becuse of this it might look intimadating to stuff it.

This was my first time soldering. It takes some practice to get the hang of. A helpful tips to working with such small components. Place a bead a solder on the pad before placing the component on the board. This allows the component to easily be placed without moving around to much.

When stuffing the board, it is recommended to start from the center and move outwards.

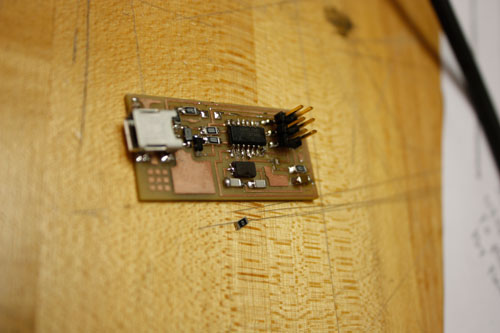

After stuffing the board, you have to program the board using the following steps:

- USB power

- make clean

- make hex

- (sudo) make fuse (check programmer in Makefile, may need to repeat)

- (sudo) make program

- desolder SJ1 and SJ2

- make IDC ISP cable, connecting header pin 1 to pin 1

you can download the files here:

interior

traces

firmware.zip