Computer controlled machining

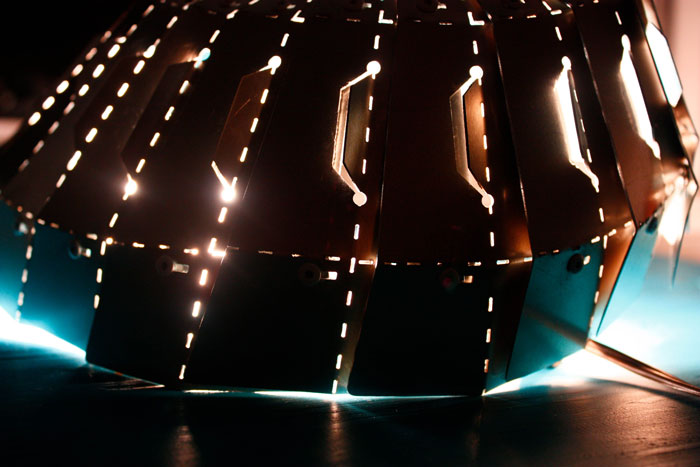

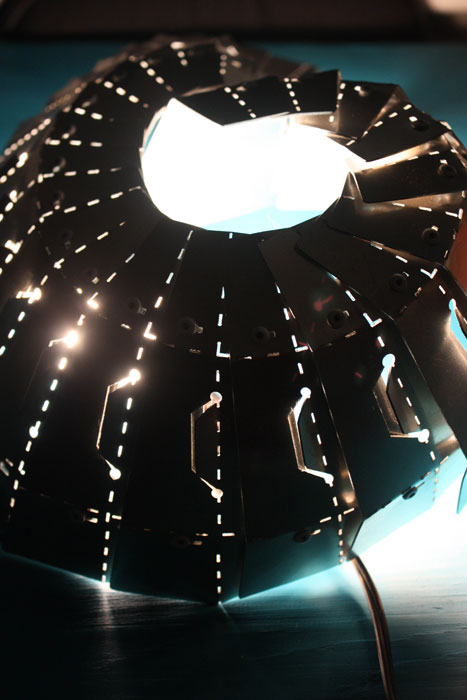

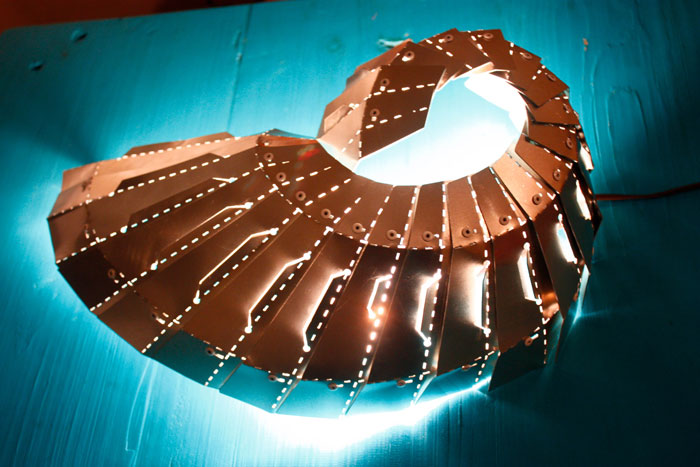

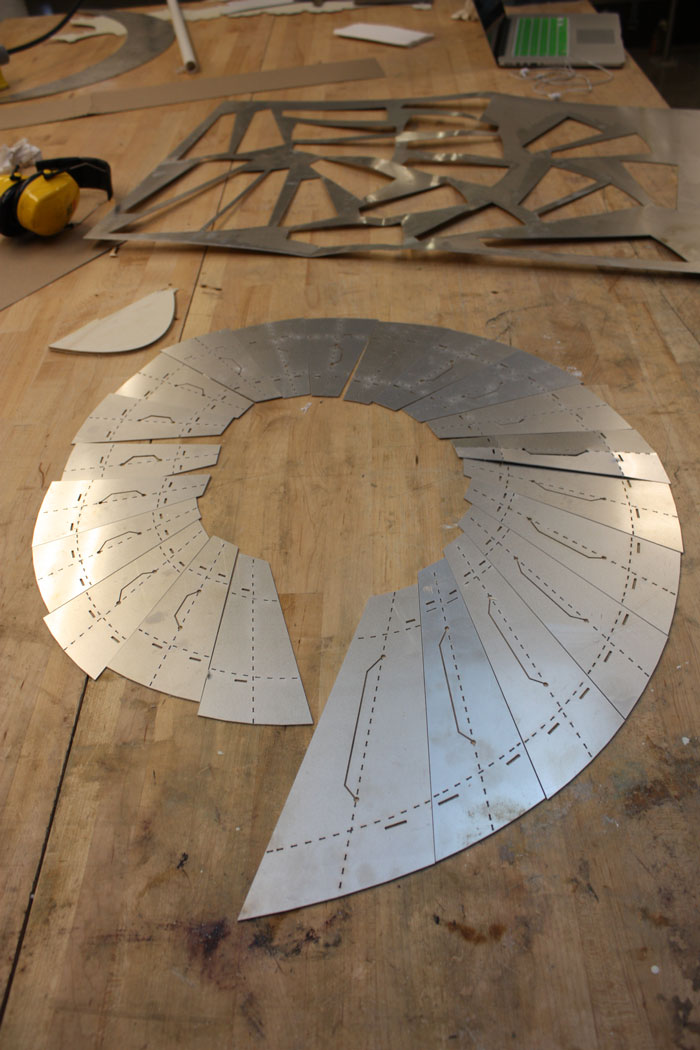

The goal in this project is to make a surface that is capable to adjust its curvature using an aluminum sheet. I looked at different system that dealt with this problem and how they negotiated a solution. I ended up using the same logic that medieval armatures makers used back in those days. To make the fabrication process easier, the doubly curved surface of the torus was simplified into develop-able sections. These sections can be flattened, and manipulated without greatly changing the original shape.

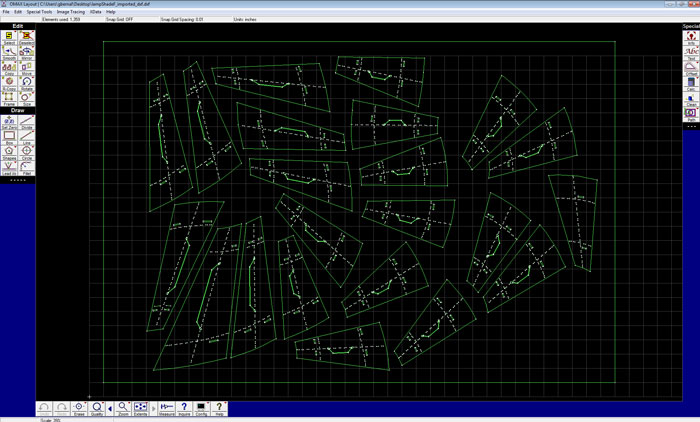

I began by sketching the form in rhino. Once I had a shape that I was happy with, I used to unroll-surface to generate the cut files

Once you I had my file ready, I exported the line work as .dxf file. It is very important to select arc and lines from the dropdown menu in your export settings.

Once you I had my file ready, I exported the line work as .dxf file. It is very important to select arc and lines from the dropdown menu in your export settings.

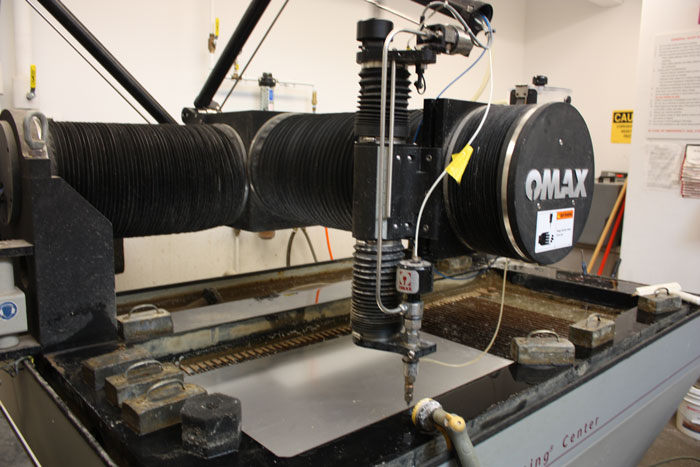

The software used to create a toolpath is Omax layou and make,

Once the toolpath is made, the stock was placed in the water bed and zero.

In order to keep the stock in place a few lead brick are put in locations where there is no cutting

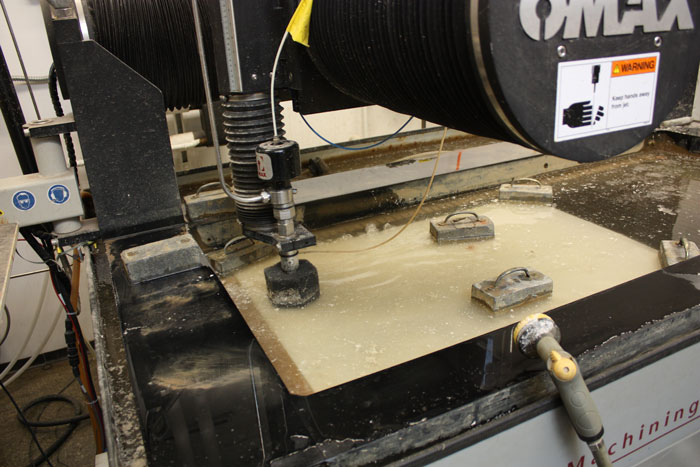

In order to keep the stock in place a few lead brick are put in locations where there is no cutting

The reason why the image above looks so dirty is because of the mixture of water and garnet.

The reason why the image above looks so dirty is because of the mixture of water and garnet.

Once all the pieces had been cut, the only thing left to do is fold them a connect them using rivets