Electronics Design

This week required taking an existing board design from the fab site, adding a component or two, milling it on the Modela, and programming it to do it's basic functions. This was really more of a 2-3 week success project, because it really took that long to debug the many issues you could encoutner when doing this before you really feel like you get it. The biggest setback was that our HTM Section never received notice that we were supposed to program our FabISP during the Electronics Production week so we were struggling with that learning curve before even getting to the point of being ready for this week.

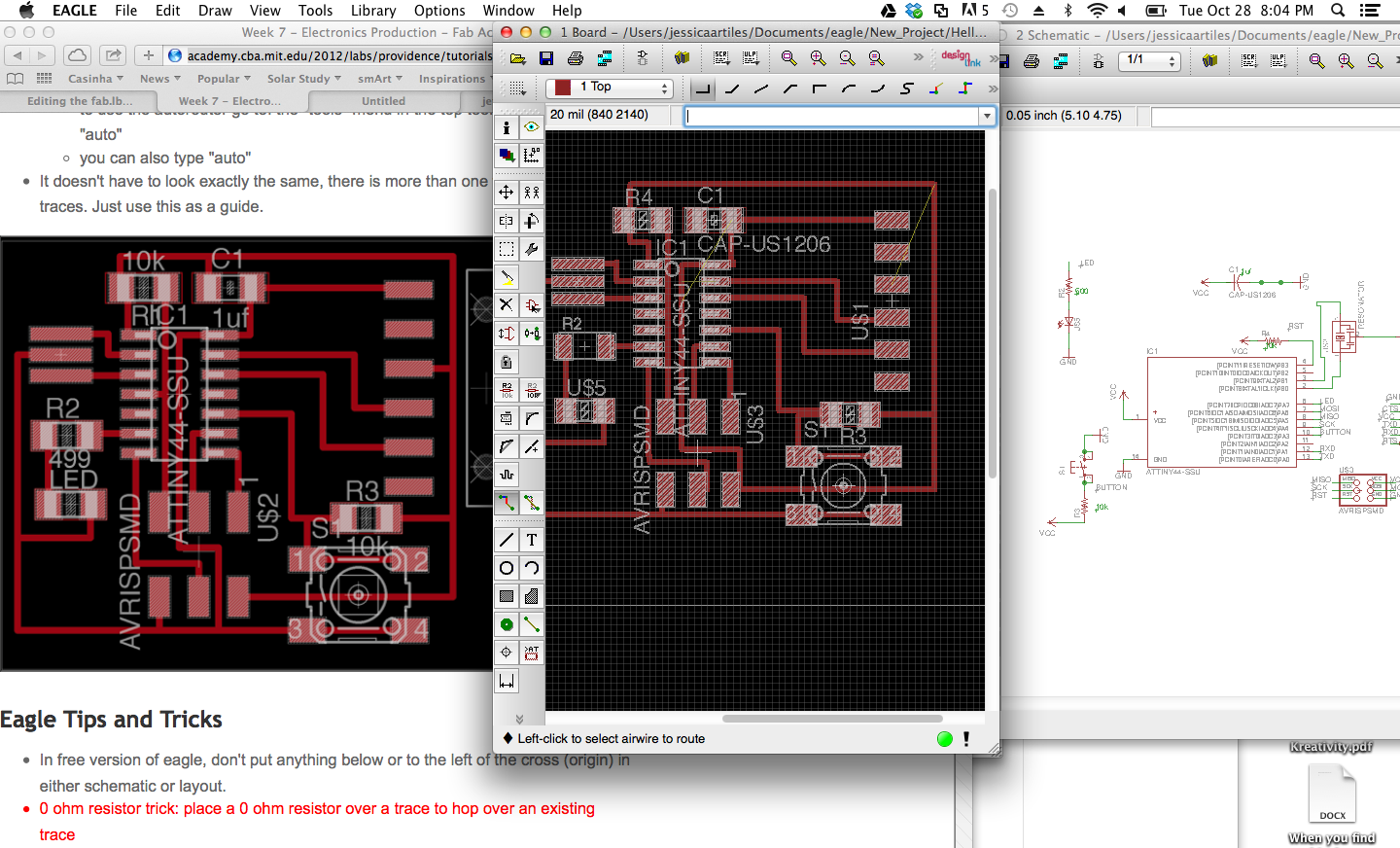

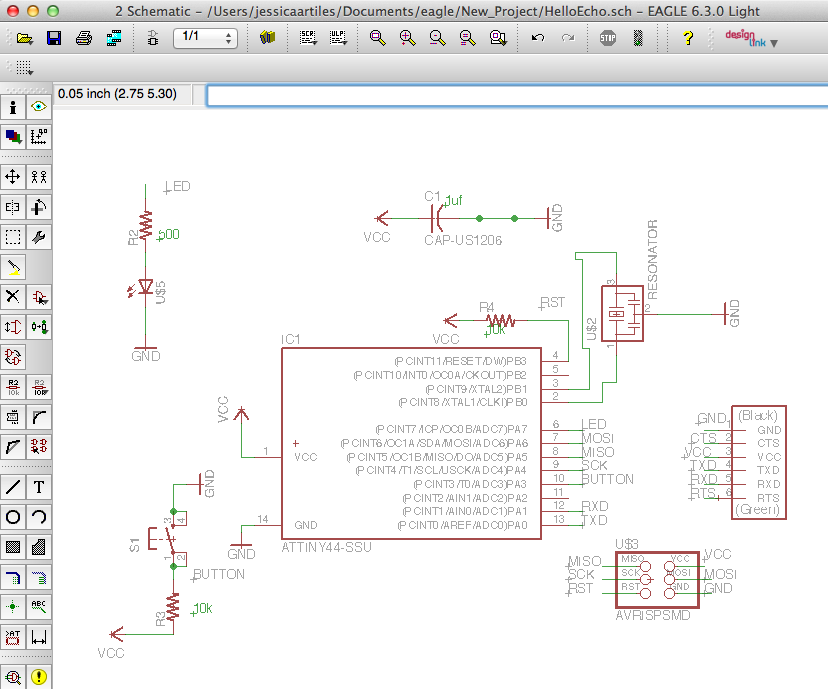

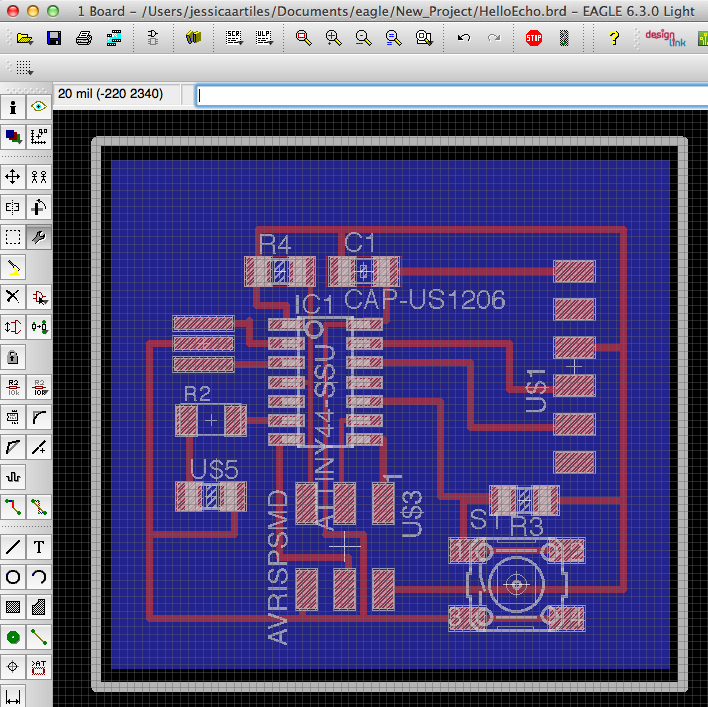

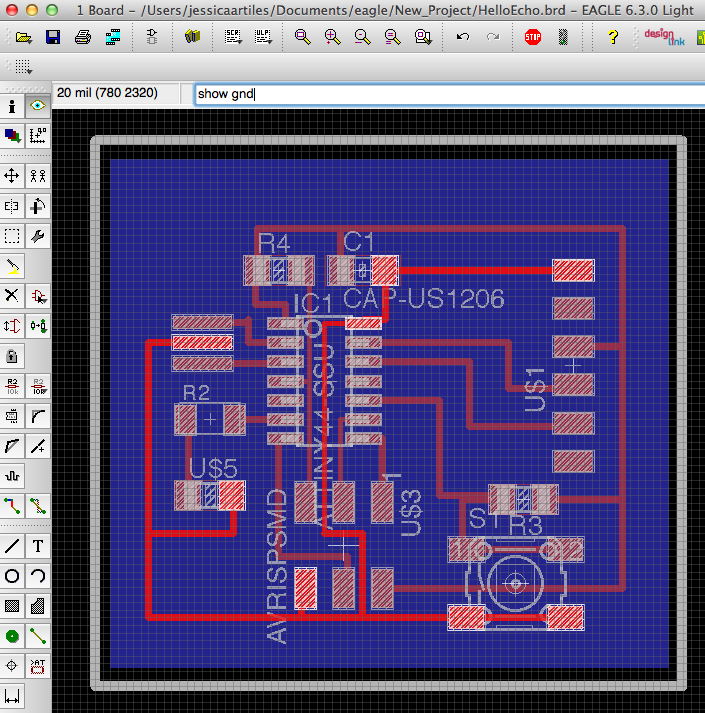

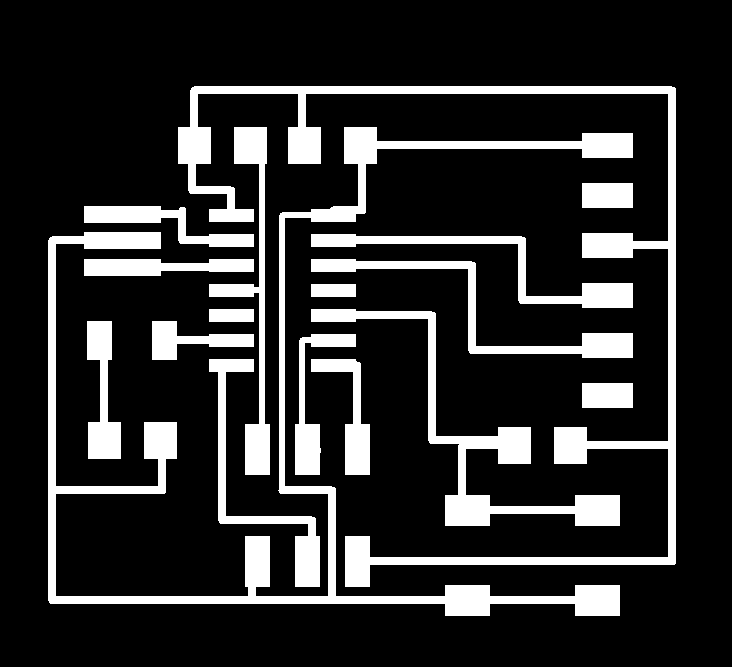

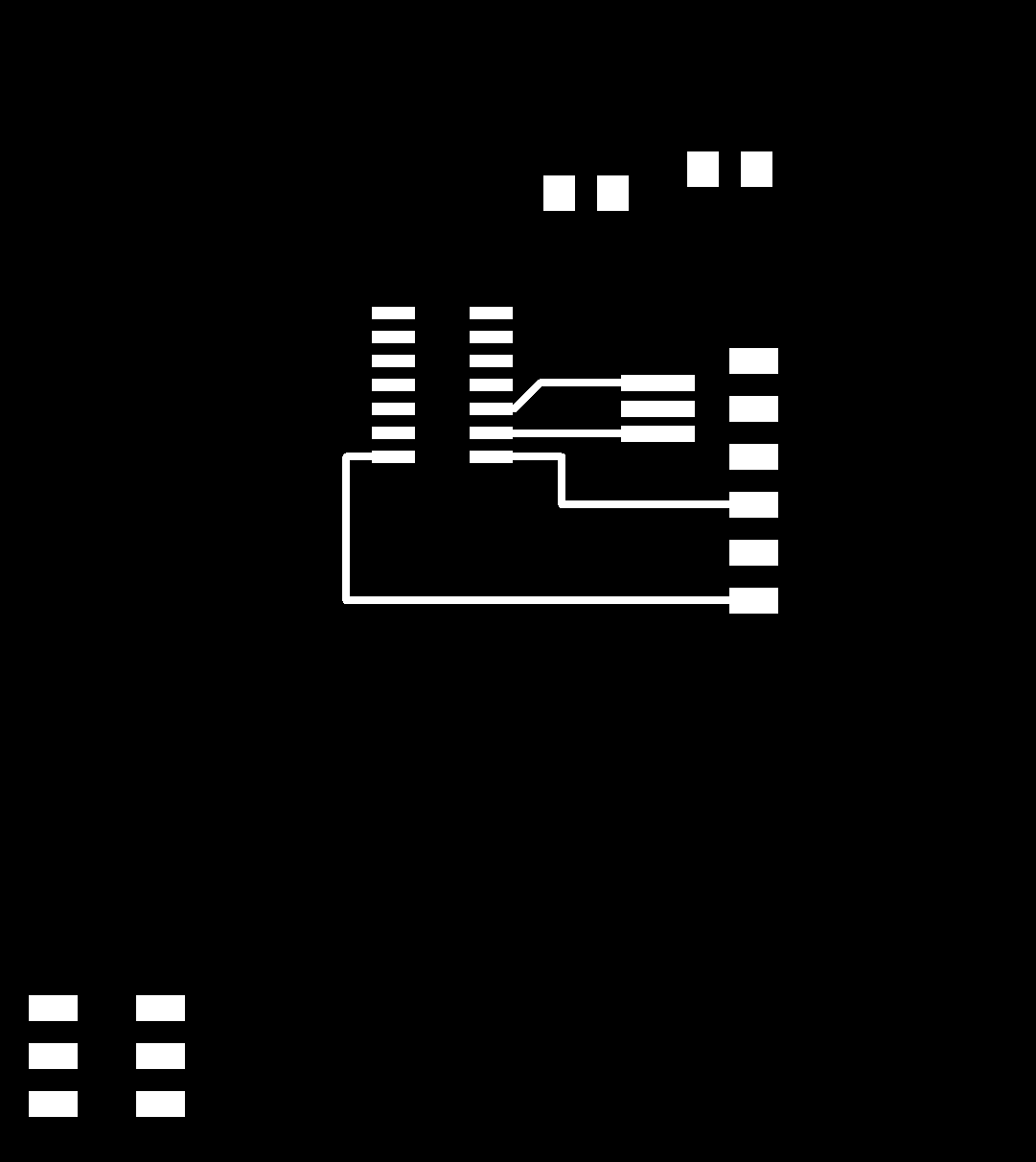

Below are screenshots of the process on the Eagle side that occured during the week to complete the assignment. Below that are the conceptual notes that came in between, but mostly after the week, as we looked back and tried to understand what we were actually programming in our hands!

Circuit Schematics and Boards on Eagle

This week really tested our ability to remember useful shortcuts on non-ubiquitous programs like Eagle. Some lessons learned:

Programming my echo board

Firs I tried my echo board on Morris’s setup with his FabISP, and my LED automatically turned on, used the Voltmeter to debug connections and learned that the left line is probably connected to some micro controller pins, unfortunately.

Instead of running to lab to use the copper braid and de-solder the IC chip, I instead tried to program Morris’s echo board using his working FabISP off of my computer. This will at least get me to the point where my computer is ready and set up to program other boards (using Arduino/make files).

The plan was to then go back and try to make my echo board work by debugging the electrical solder connections. Do this with a FabISP that works (AVRISP or Morris’s FabISP).

I tried to make my FabISP programmed by an AVRISP or other working FabISP using this tutorial.

While doing it I used Jeff's tutorial, which links to Irene's tutorial. Another great resource was the FAB Academy Tutorial Page.

For some reason the echo board didn't want to be programmed that day. I suspected the Makefile vs. .make file as the culprit. There was some awkwardness in making the make file…but then I got it! I needed to get my makefile to not say makefile.txt and instead just say makefile.

That’s why it’s called an ECHO BOARDDDD!

Then I used Kate's code and it blinked!