Week 2 - PCB production, and soldering components

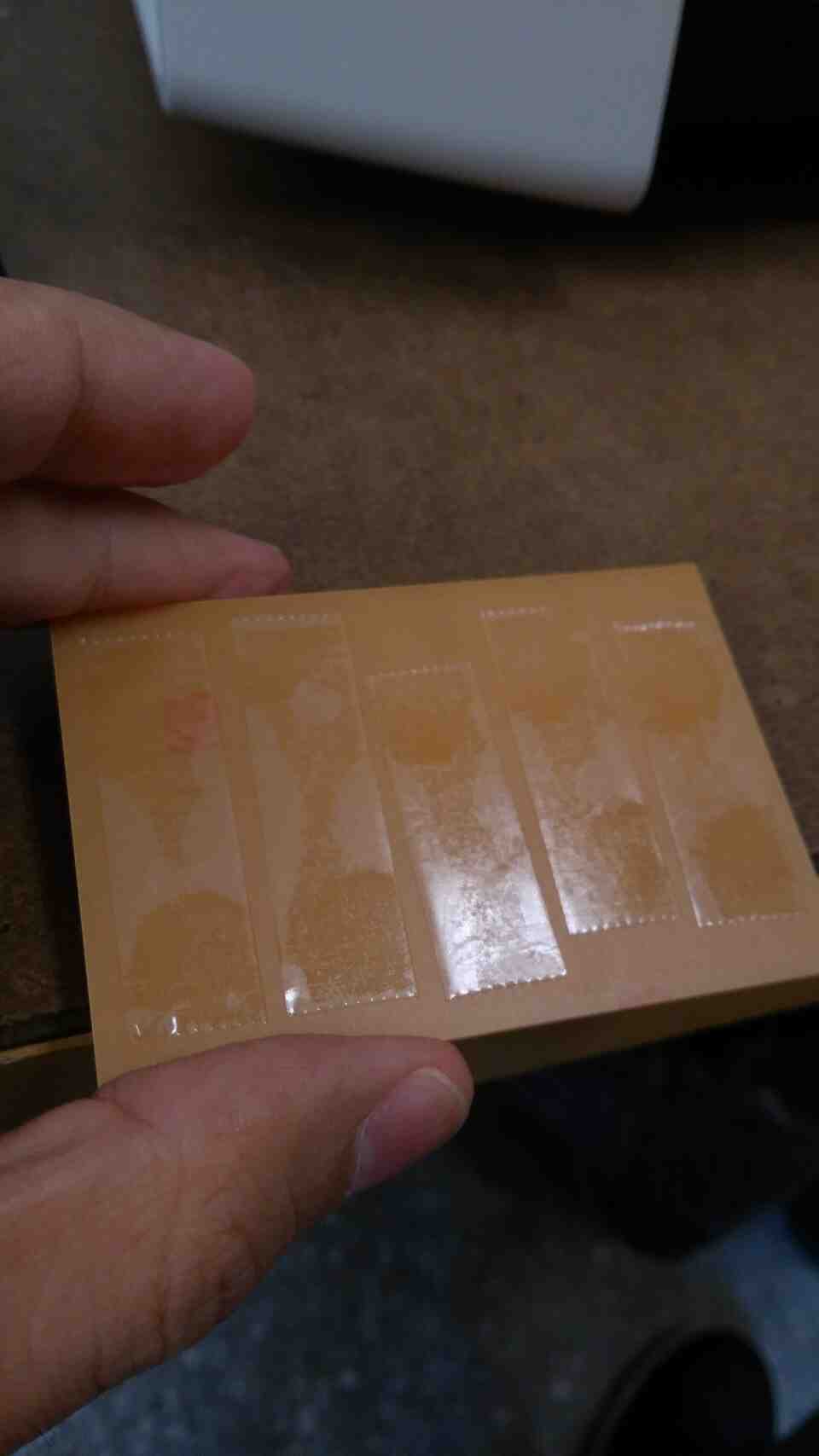

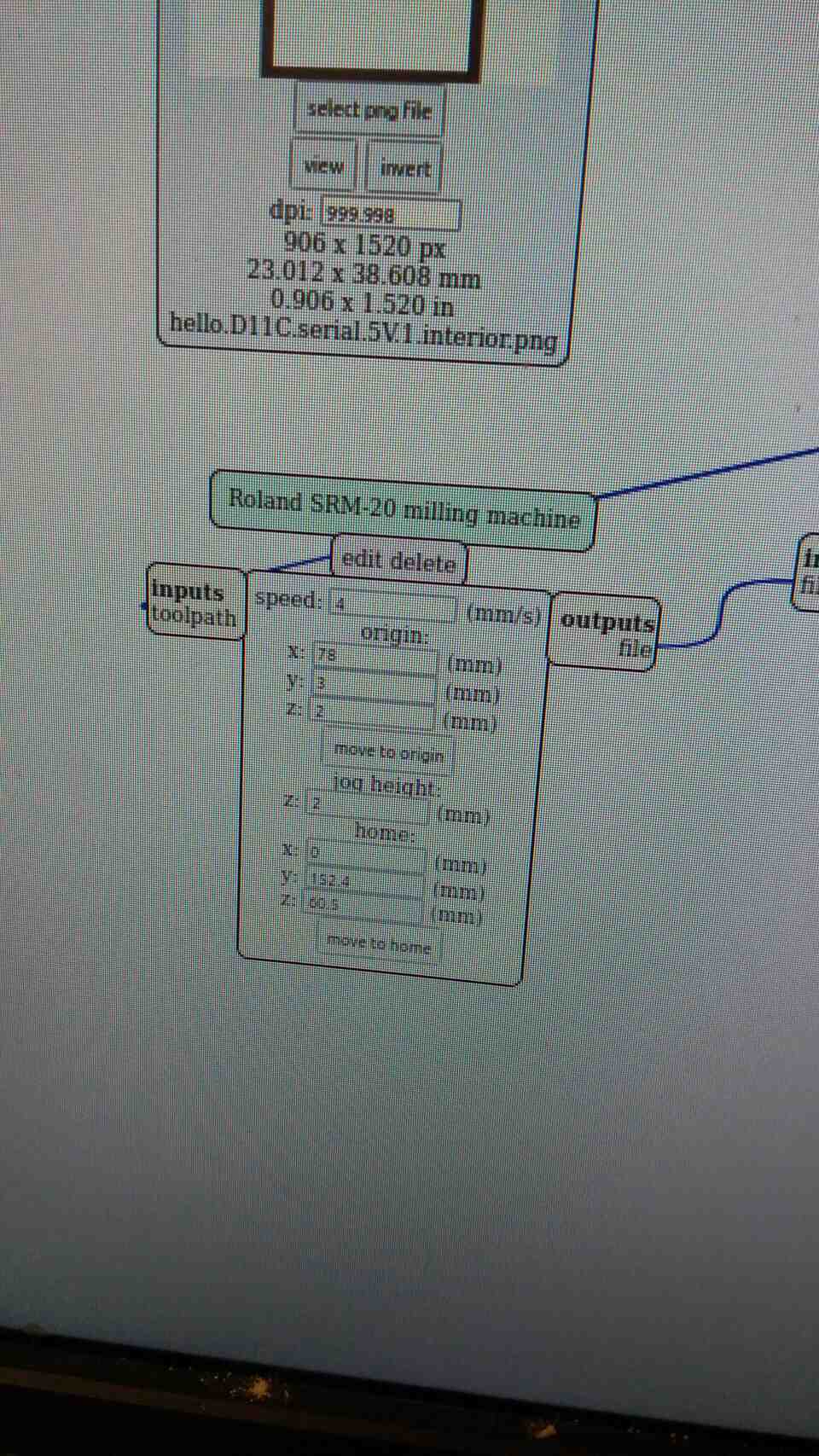

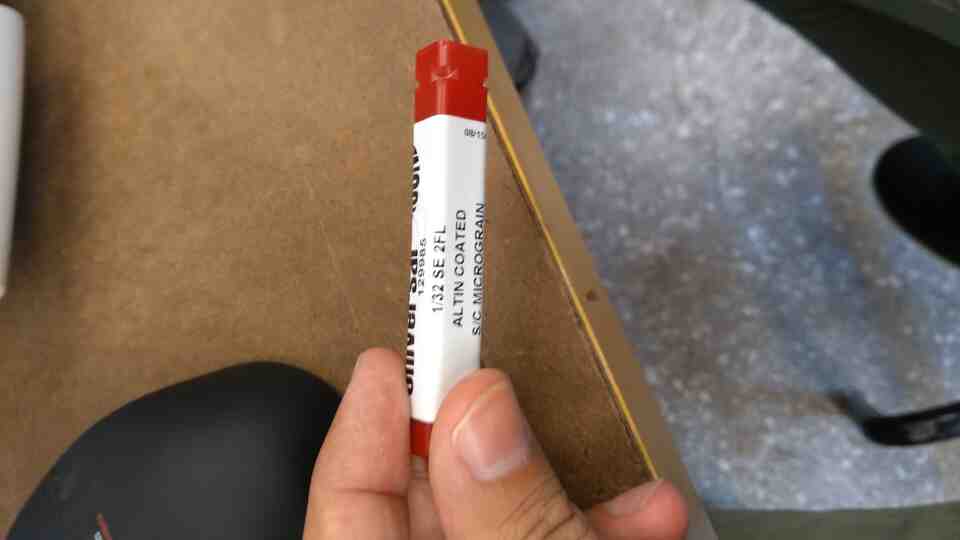

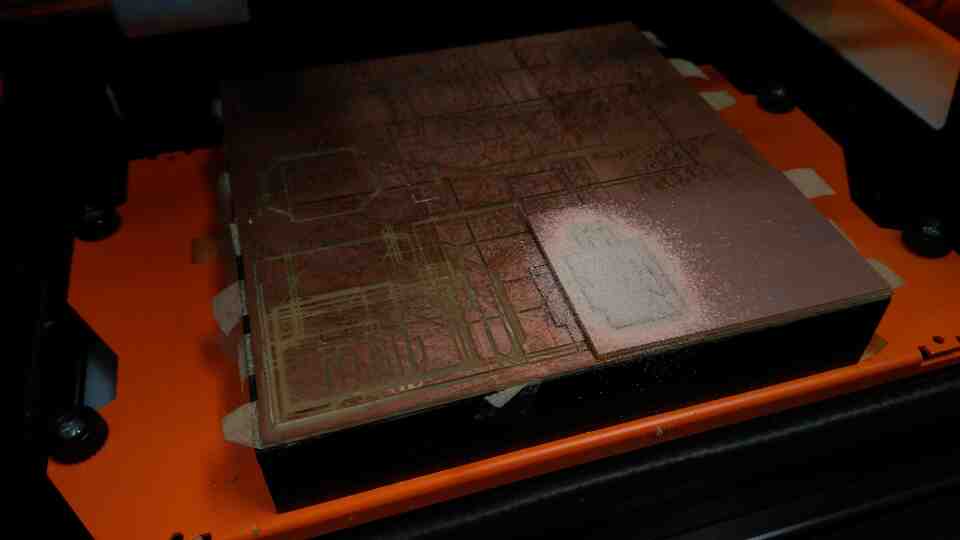

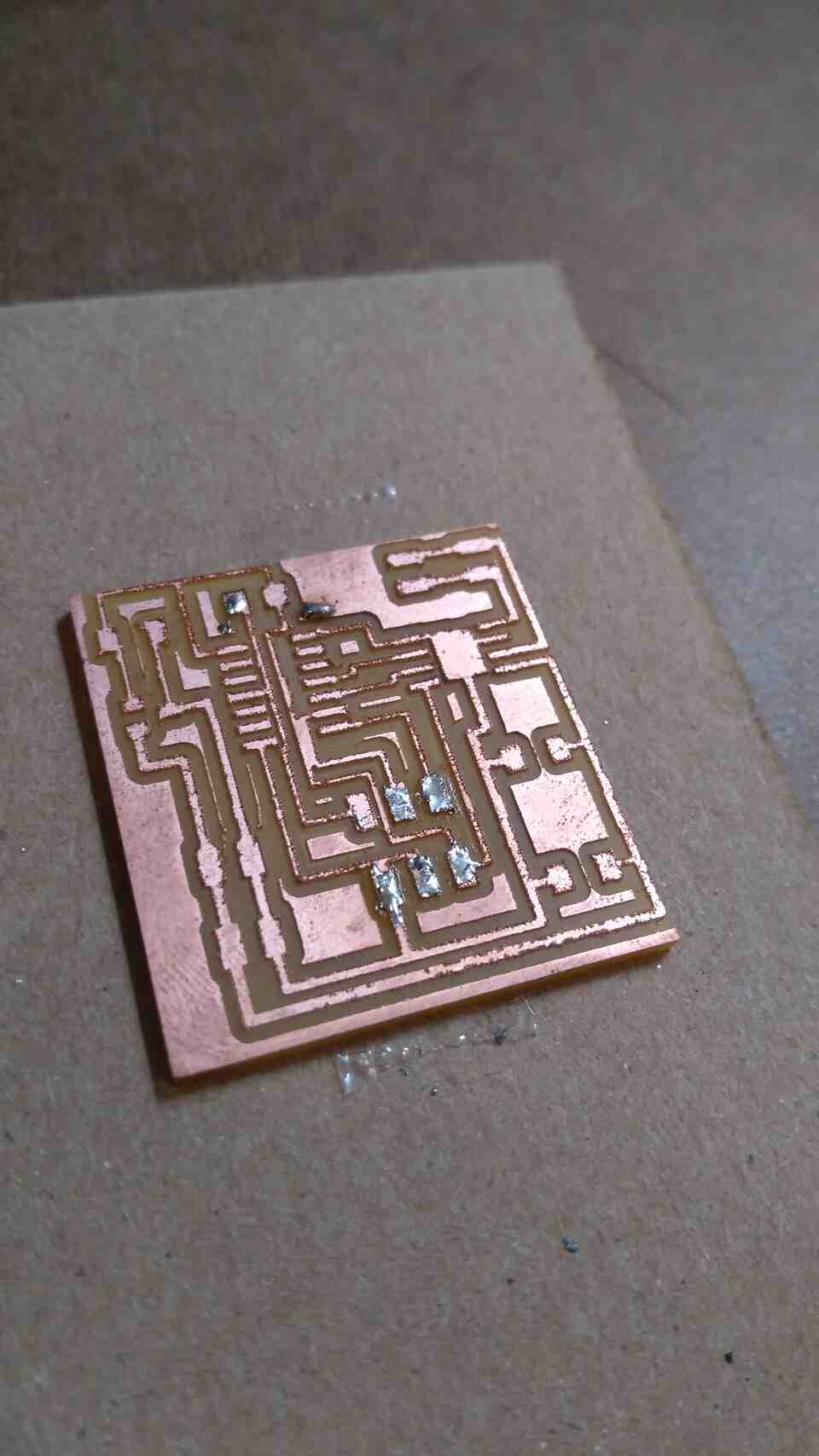

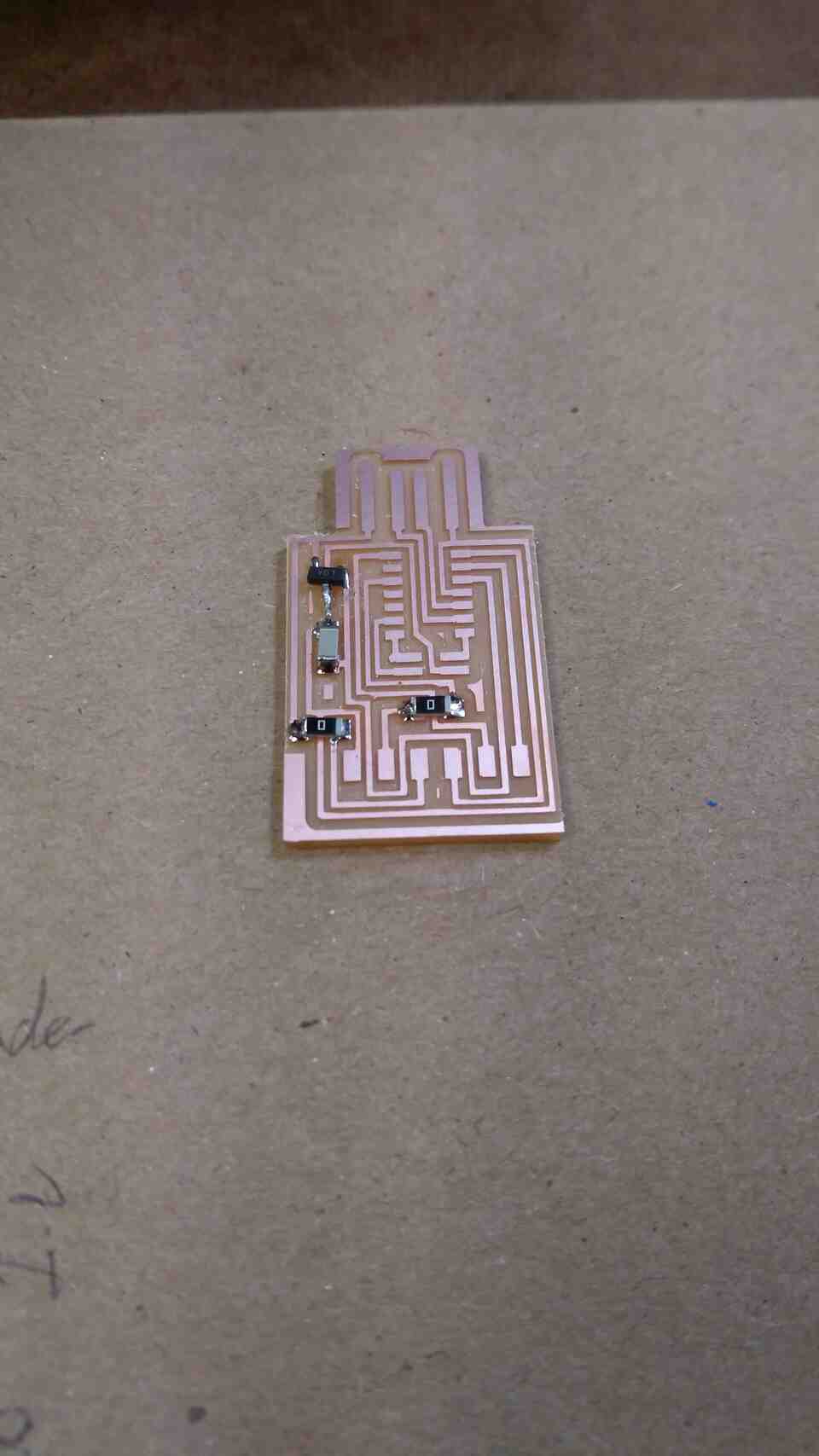

To create printed circuit boards (PCB) with a Roland SRM-20, I used double sided tape to attach a copper and silicone board to the bed.

It is important to create a clean, flat, and stable surface for cutting. Moreover, remember to keep a note of the origin position used for cutting the interior, to use the same values for silhouette cutting.

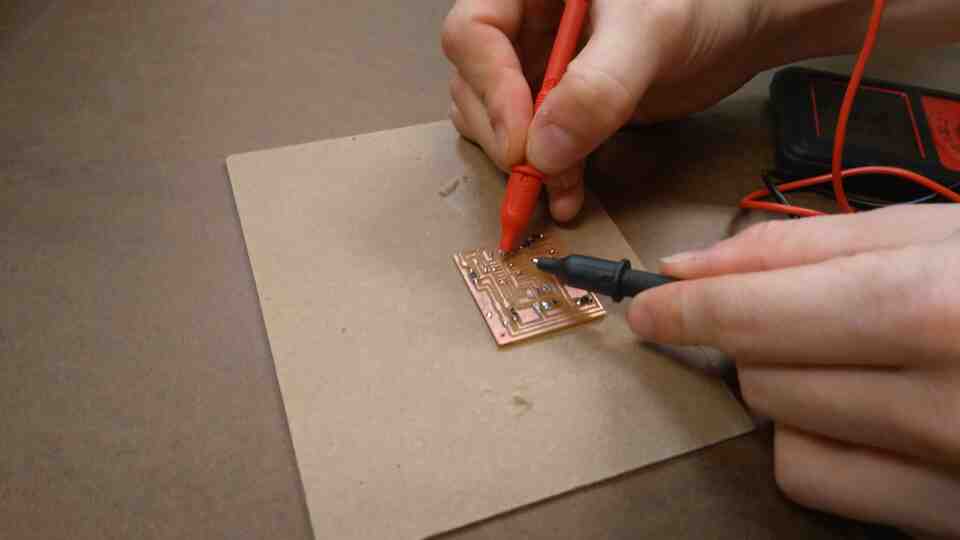

Next is to try soldering on an old board. The point the soldering iron touches is where the solder flows toward. Excess solder can be removed by a braid or a vacuum pump. I have little success with the braid but managed better with the pump.

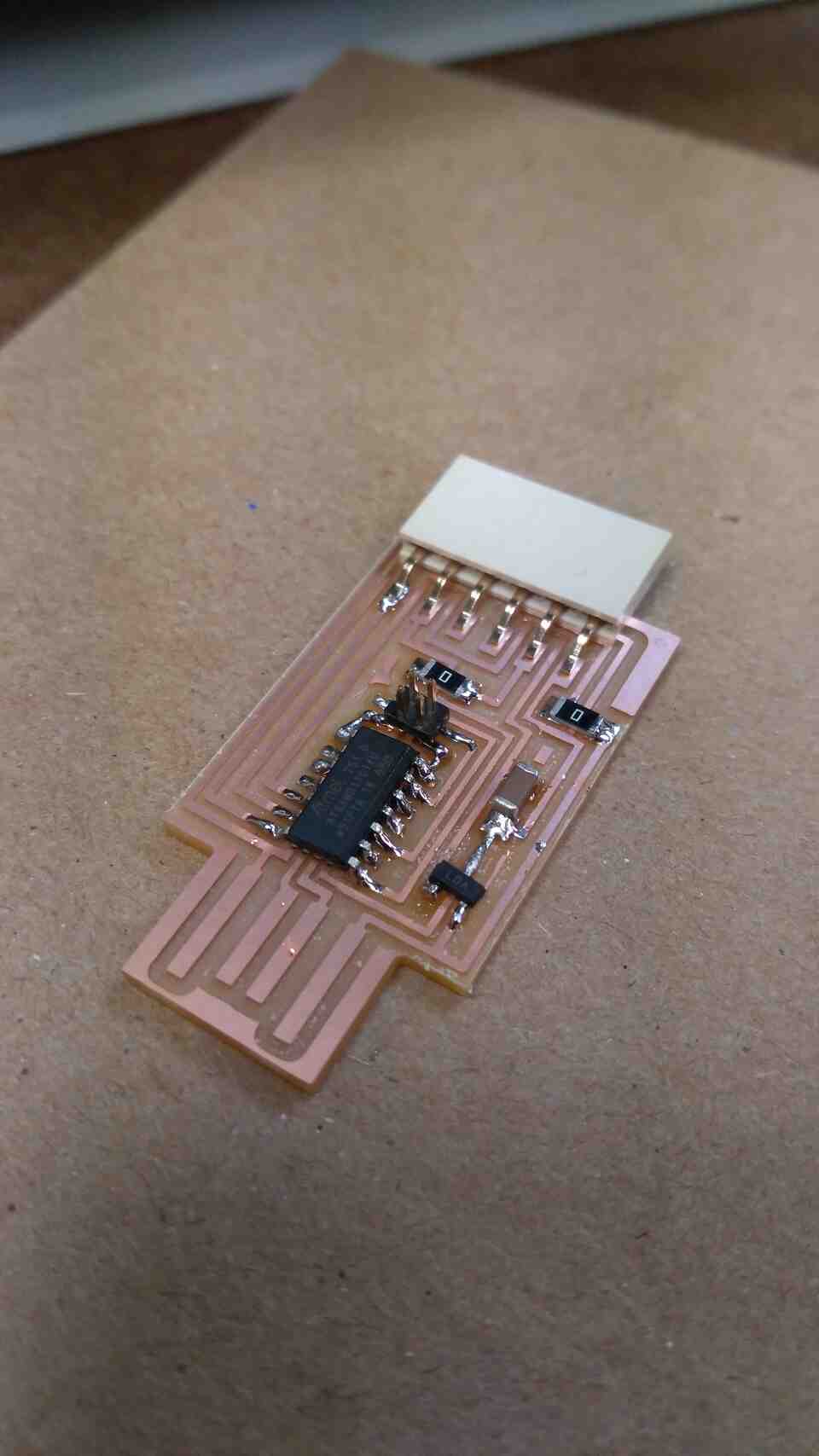

I followed up with soldering parts into my own board, and testing (thanks to Ganit).

Files (from "cba.mit.edu")

hello.D11C.serial.5v.1 boardhello.D11C.serial.5v.1 components

hello.D11C.serial.5v.1 top

hello.D11C.serial.5v.1 interior