2:30am on a tuesday night.

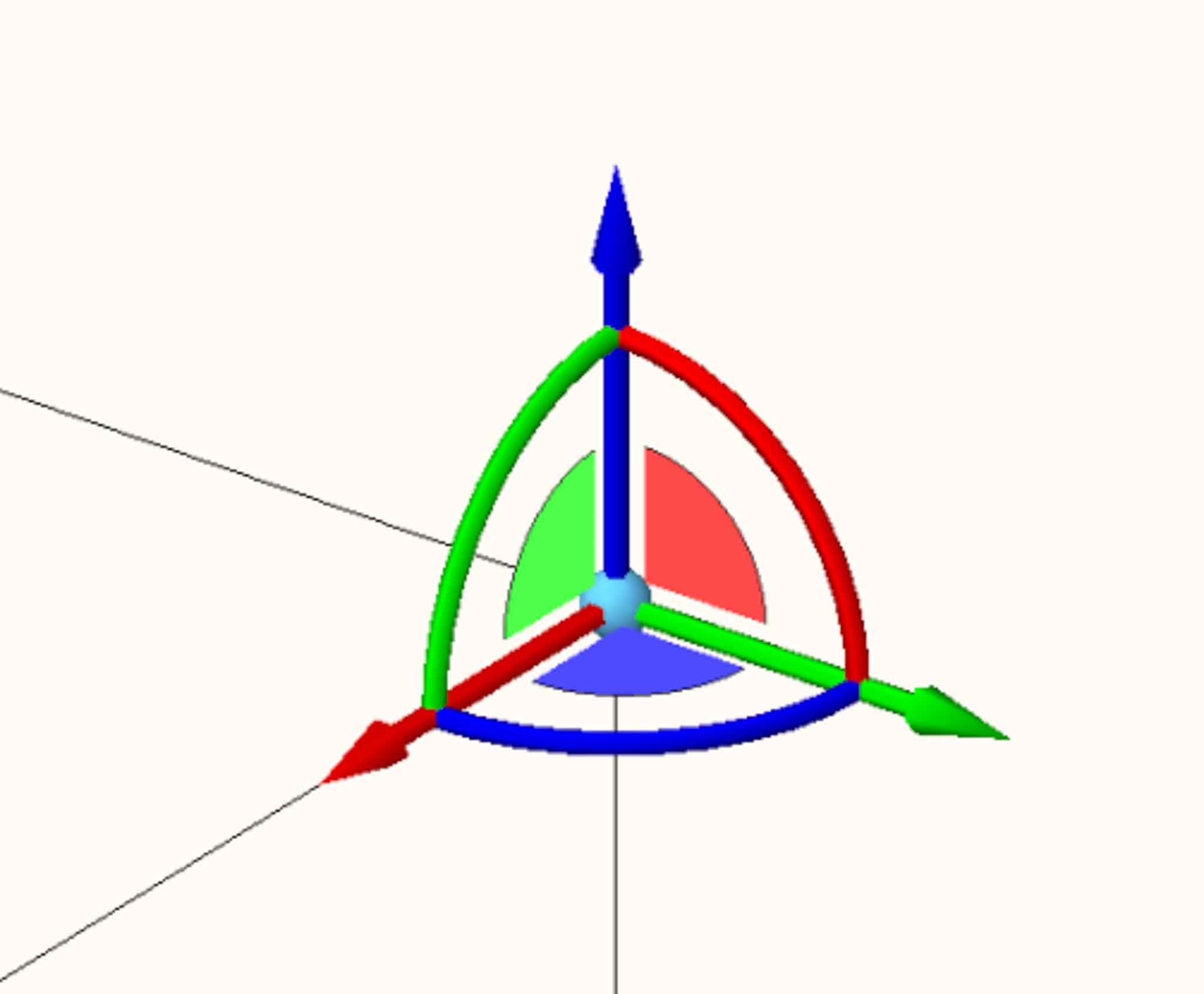

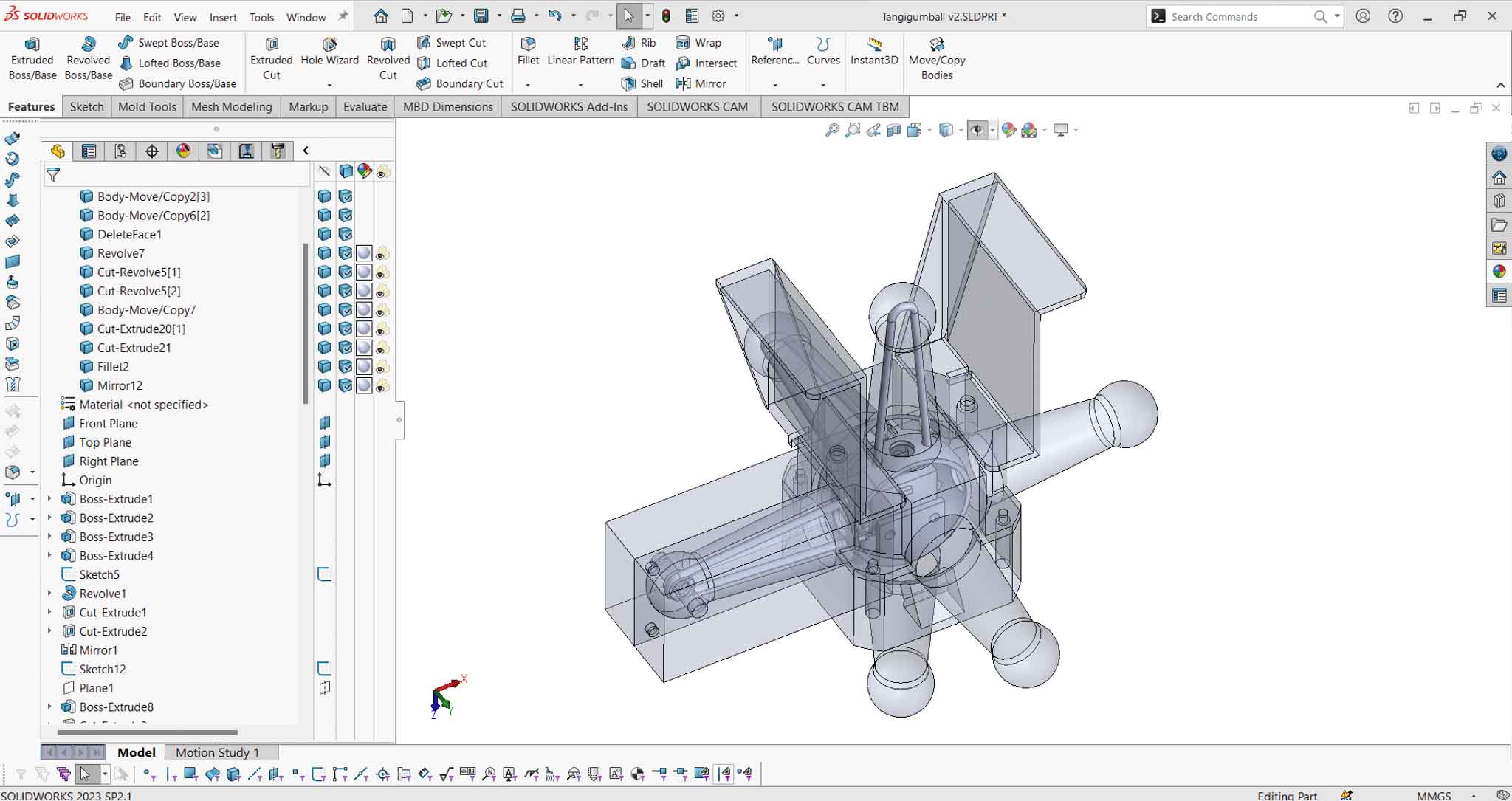

For casting, I made a physical version of the gumball tool commmonly found in computer molding software like Rhino.

My goal is to make a input device that is used the same way as the tool works on screen.

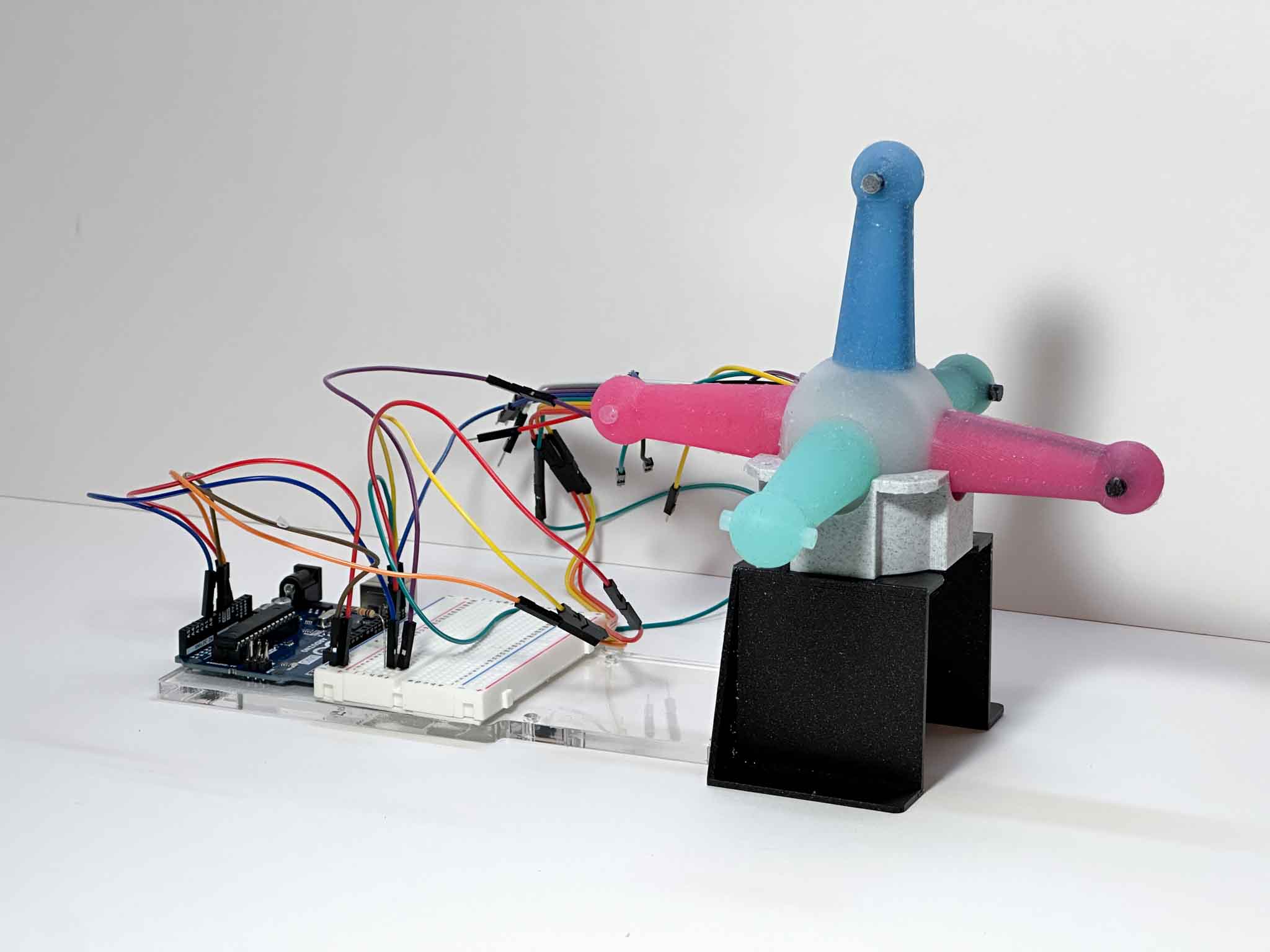

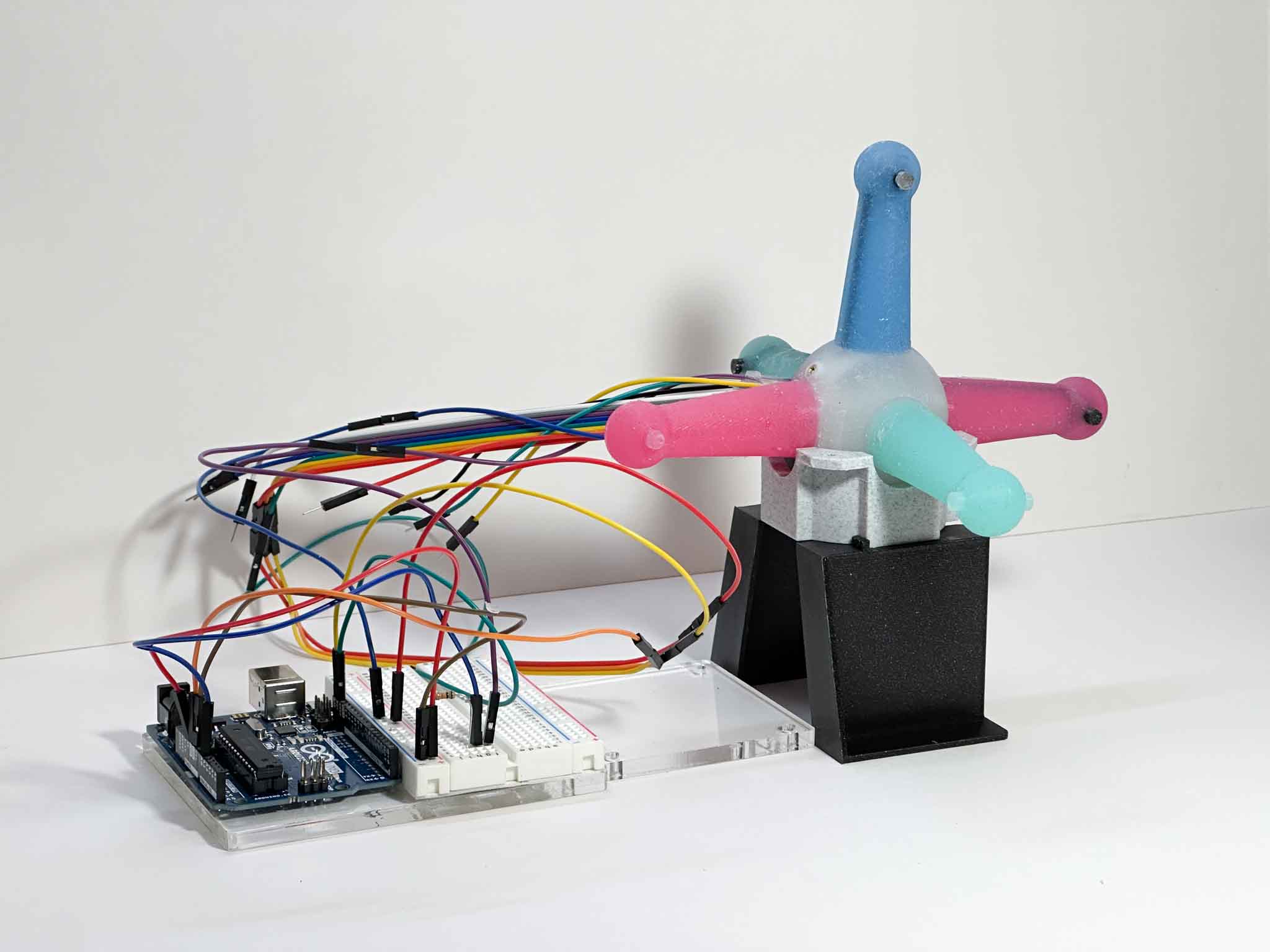

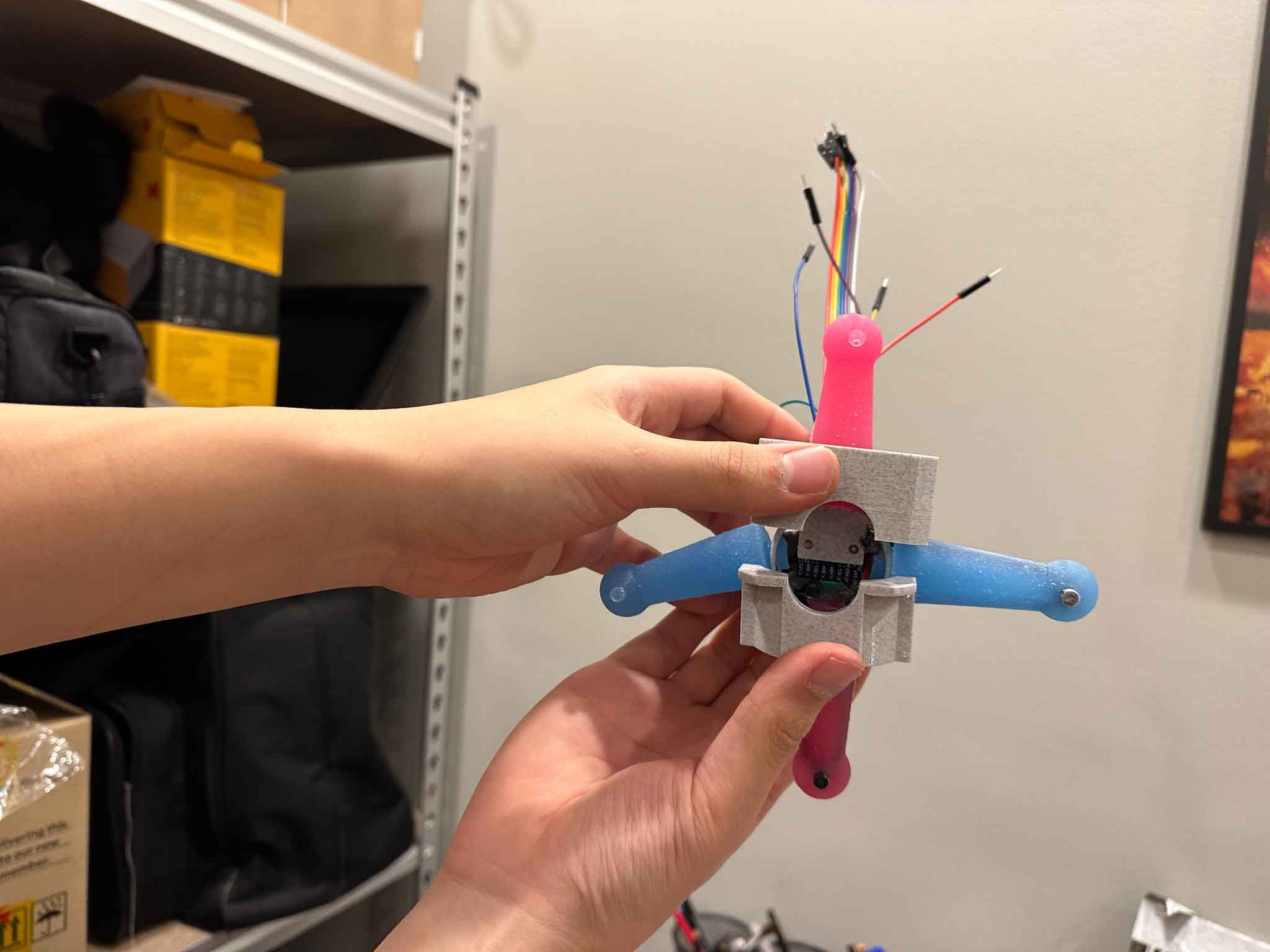

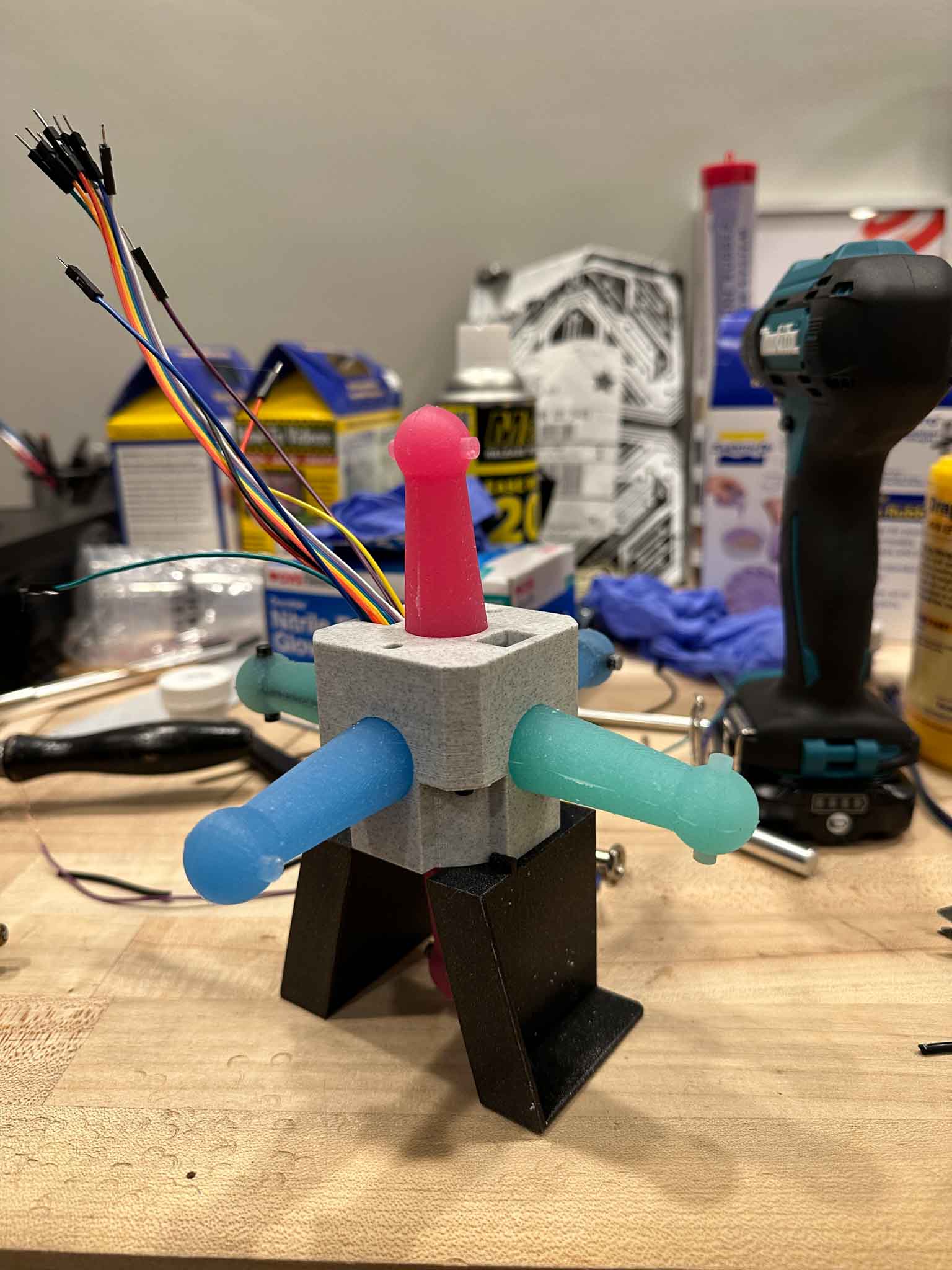

Here is the final prototype (please ignore the messy wires, will clean up later). Here is a short demo of how it works: as the user rotate the gumball the orientation of their computer counter-part rotate as well. When one axis is streched so is the model.

Process:

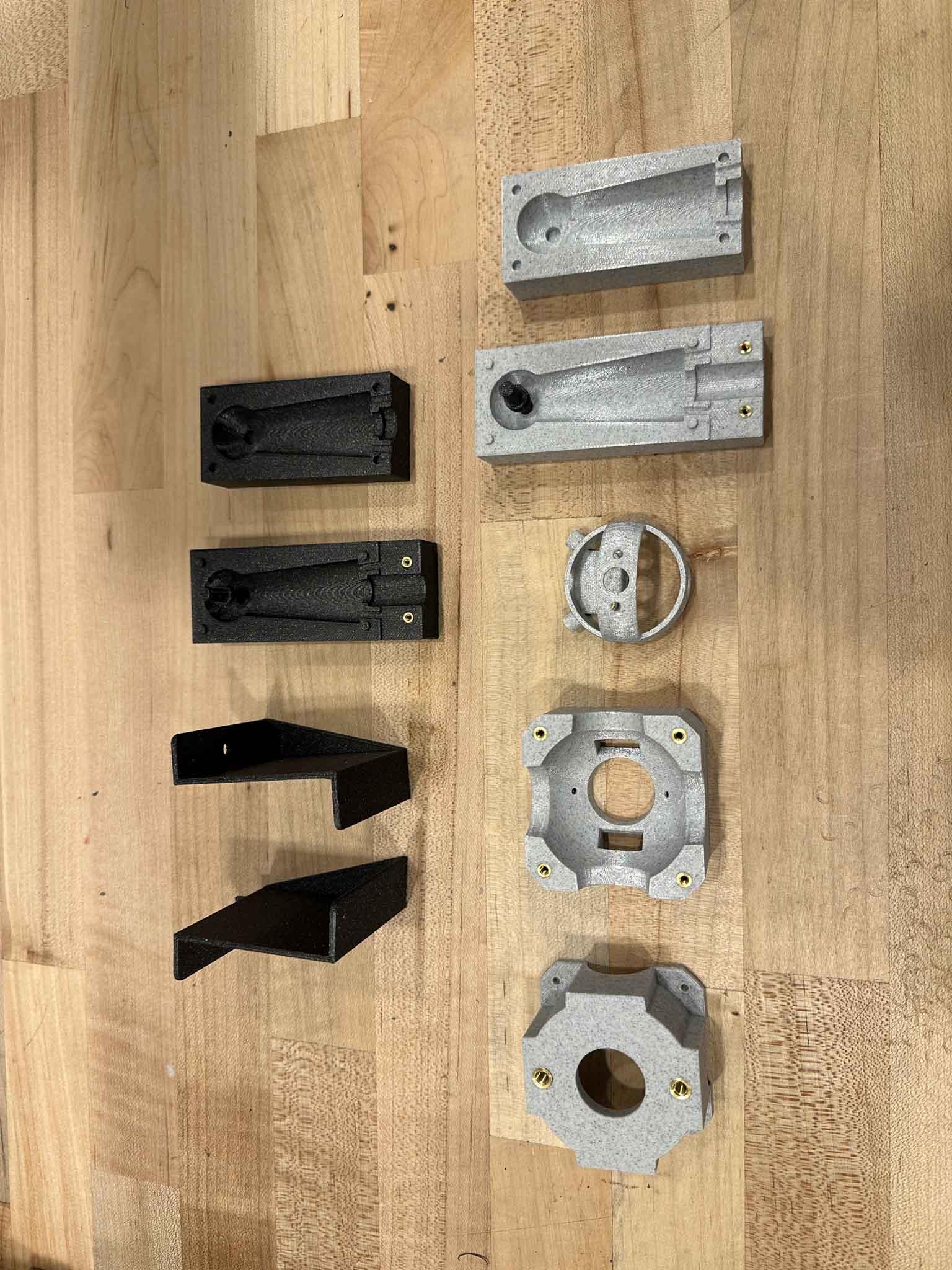

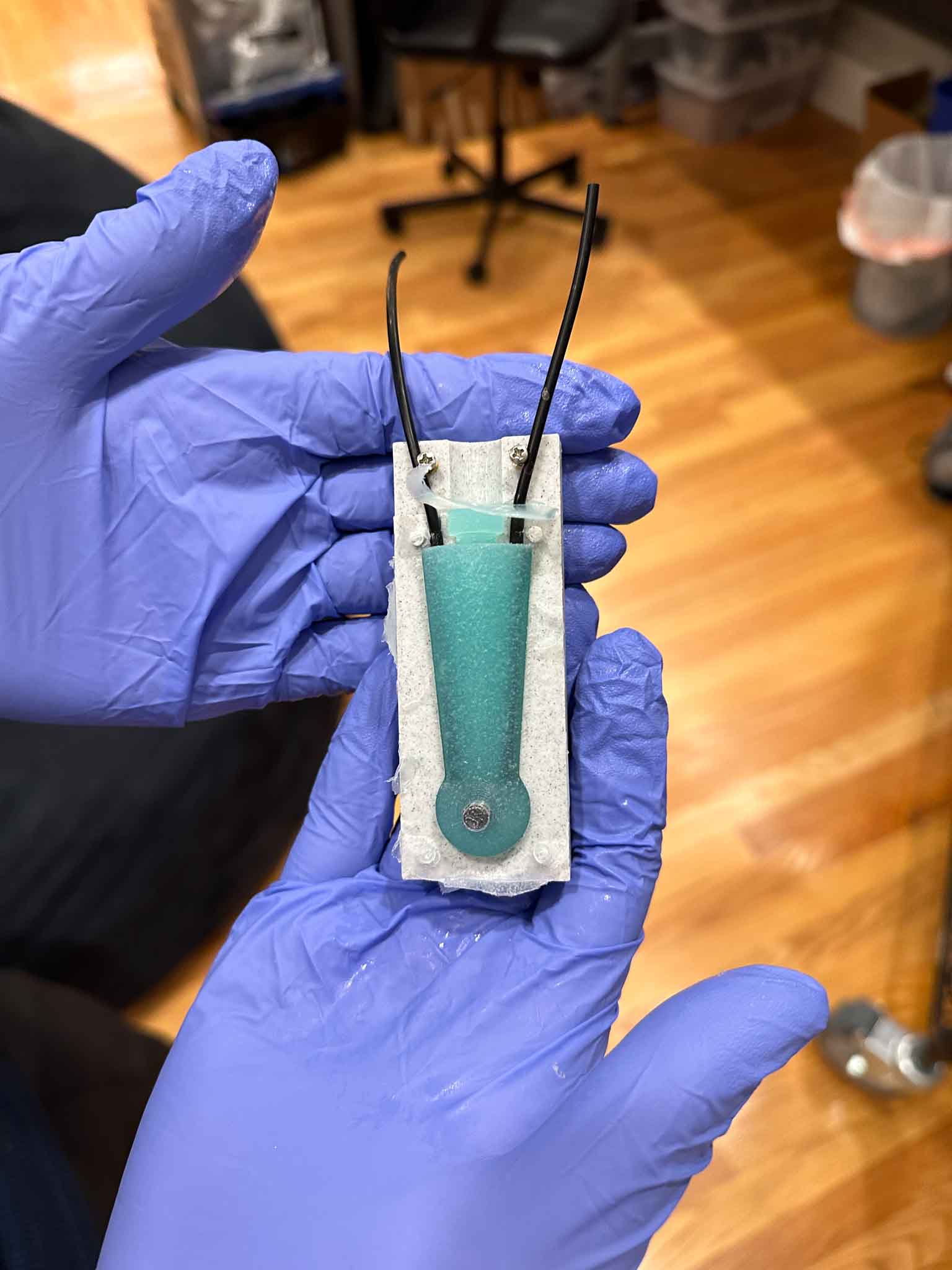

I started by ordering and testing this conductive rubber material, which basically acts as a resistor. As it is streched, the resistence change, allowing it to be read as values for input. I modeled the gumball in the size I want and the mold geometries for casting.

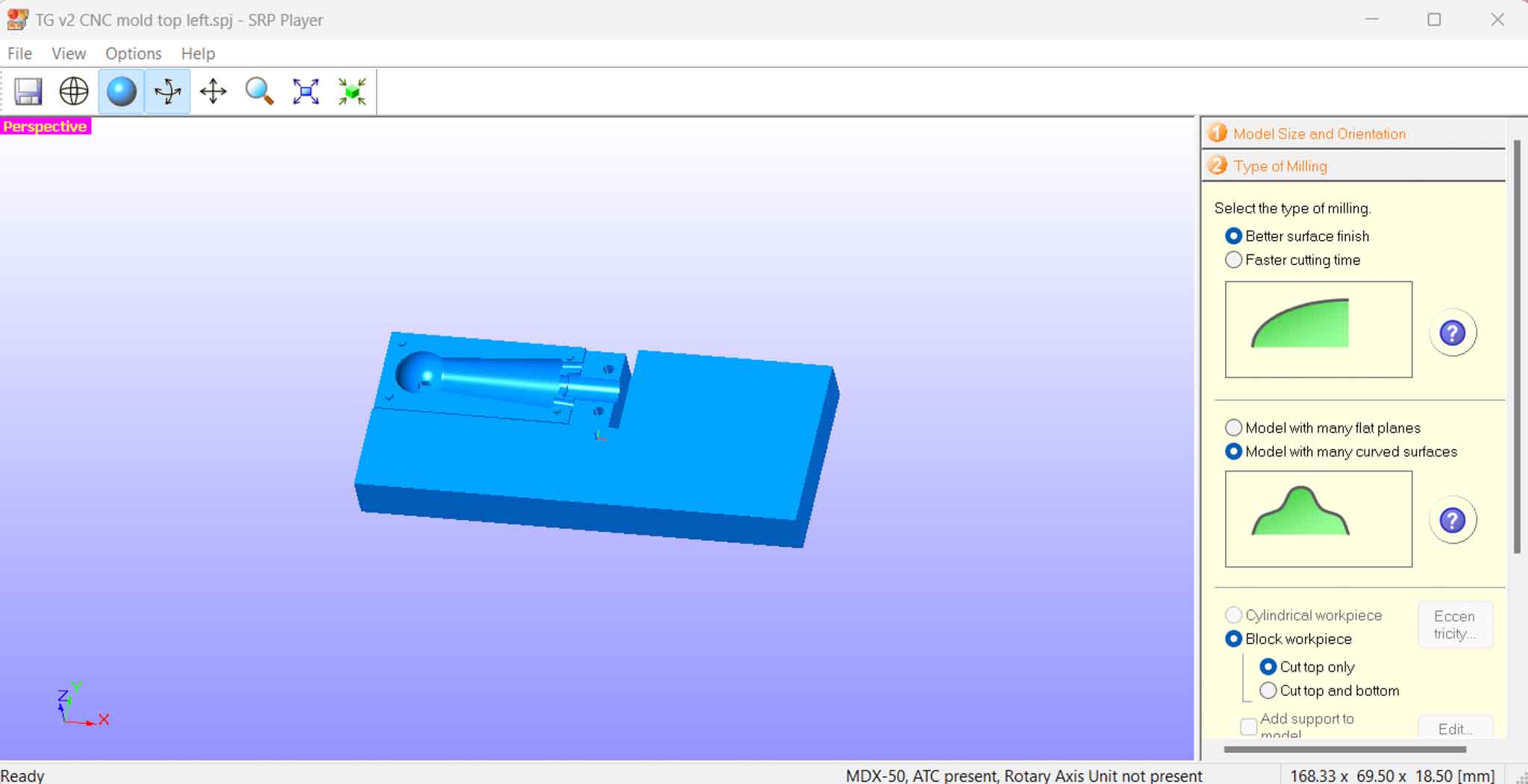

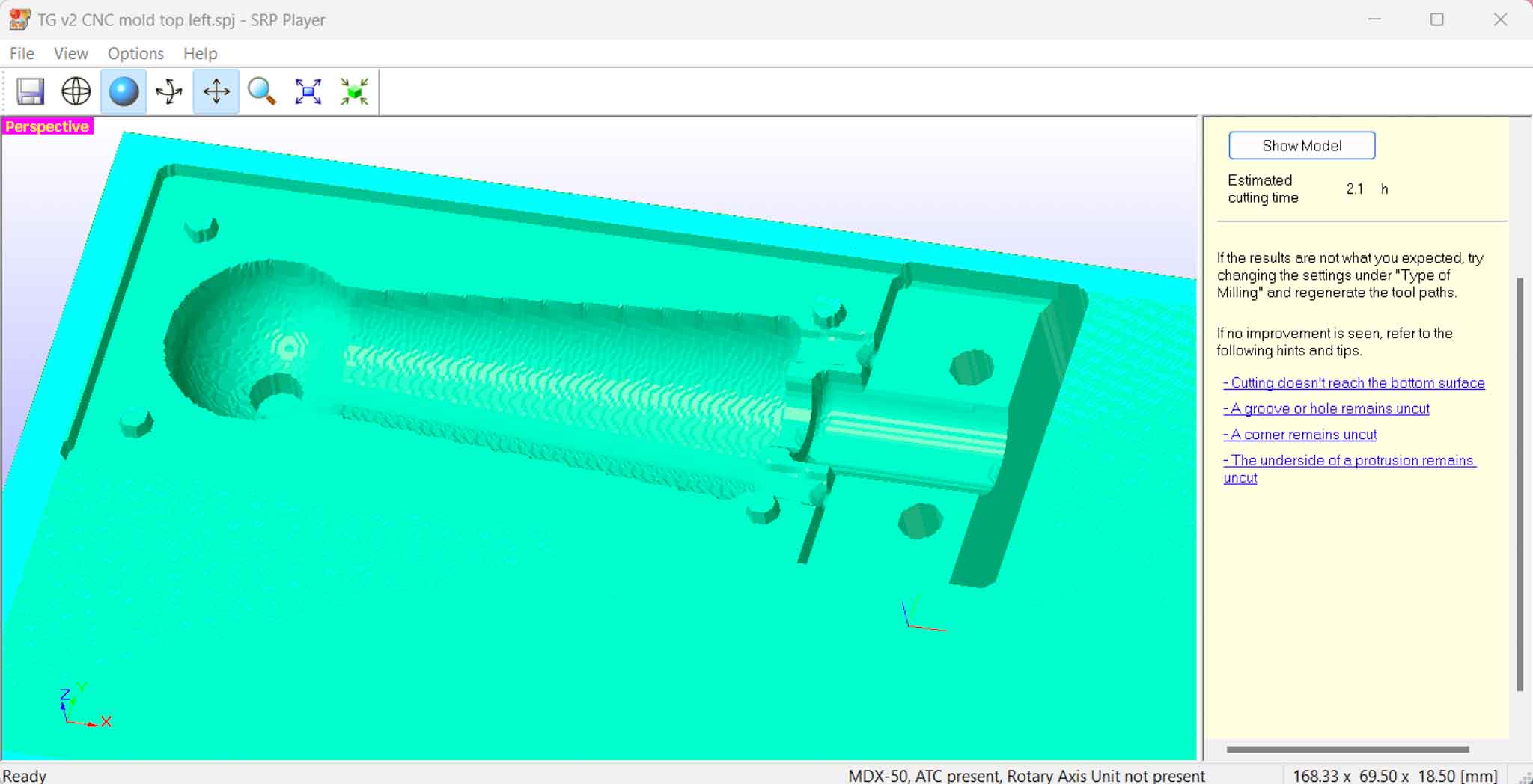

For cutting the mold, I learned how to use SRP player, a toolpath software from Roland to calculate my rough path and finishing path.

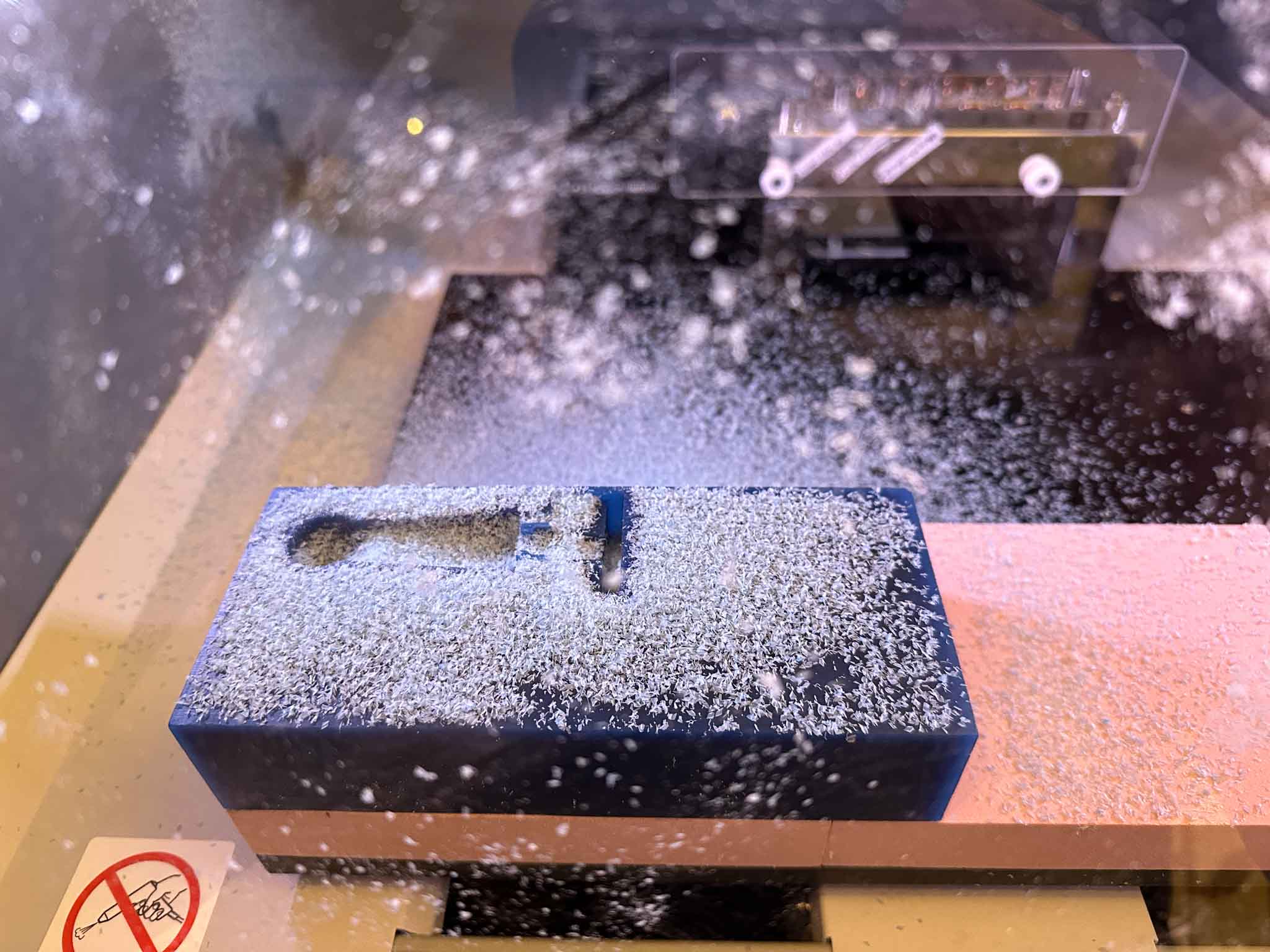

Mold cut inprogress:

After the cut:

The cutting took close to 4 hours using a 1/8inch flat mill and a 1/8inch ball mill.

I realized that because I am casting several legs, I might need to either cut more mold or 3D print a few to speed up the process.

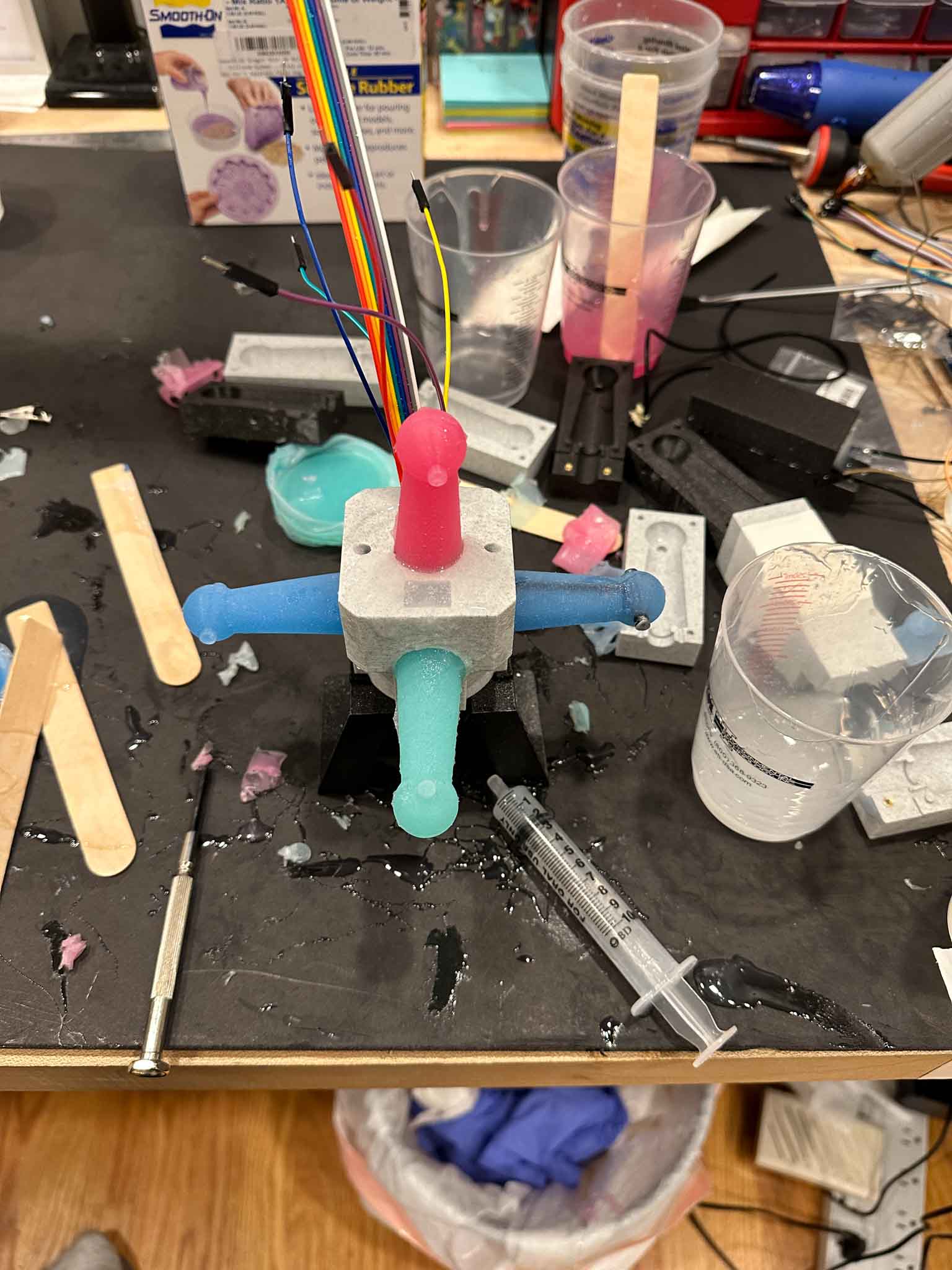

The process to cast the conductive rubber material inside the silicon can be a bit trouble some.

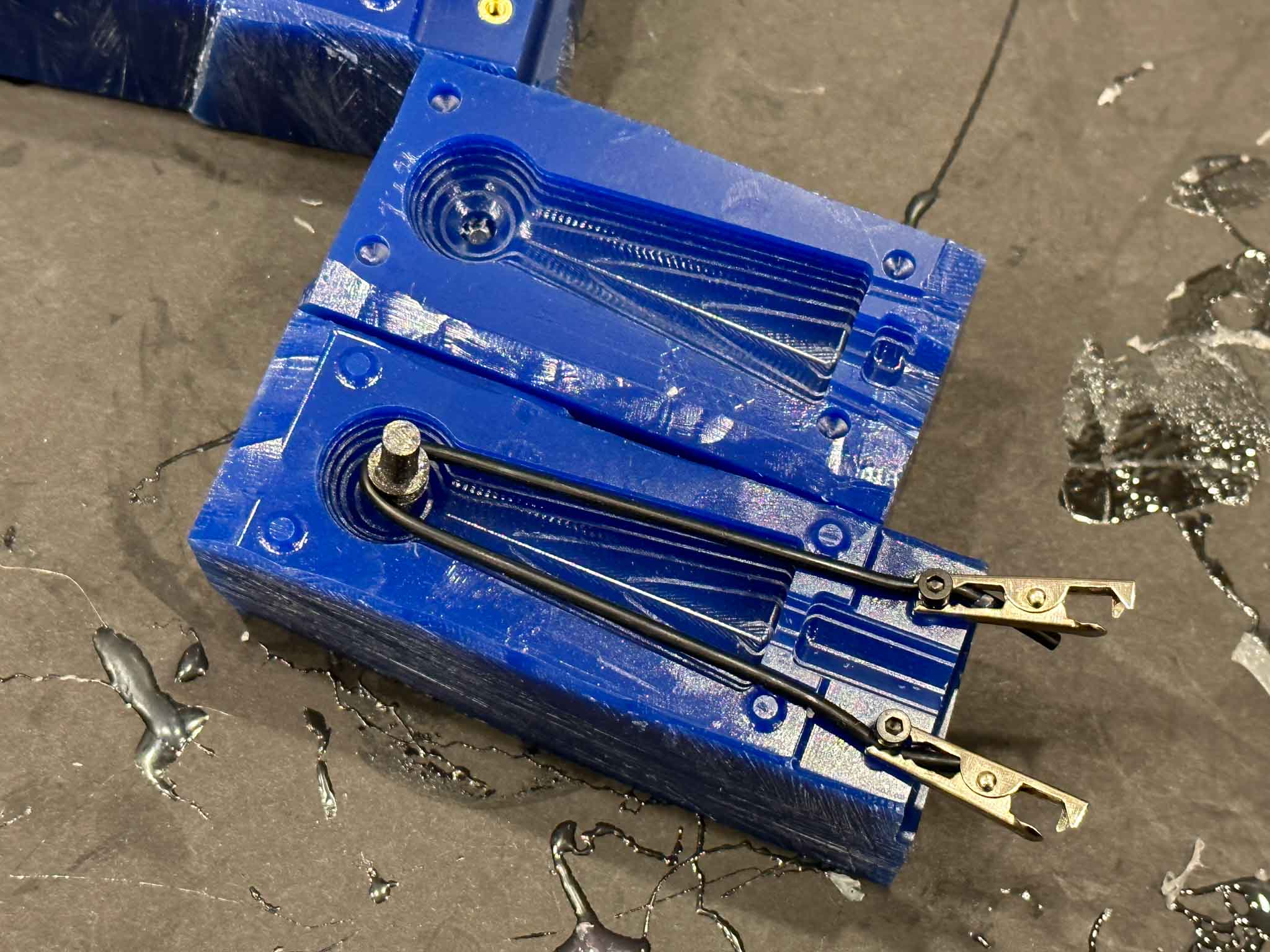

I first clamp the ends of the rubber material throught the mold with a insert spindle holding it in place. This way I can ensure that when I pull on the leg of the gumball, the conductive rubber material will not slip or move.

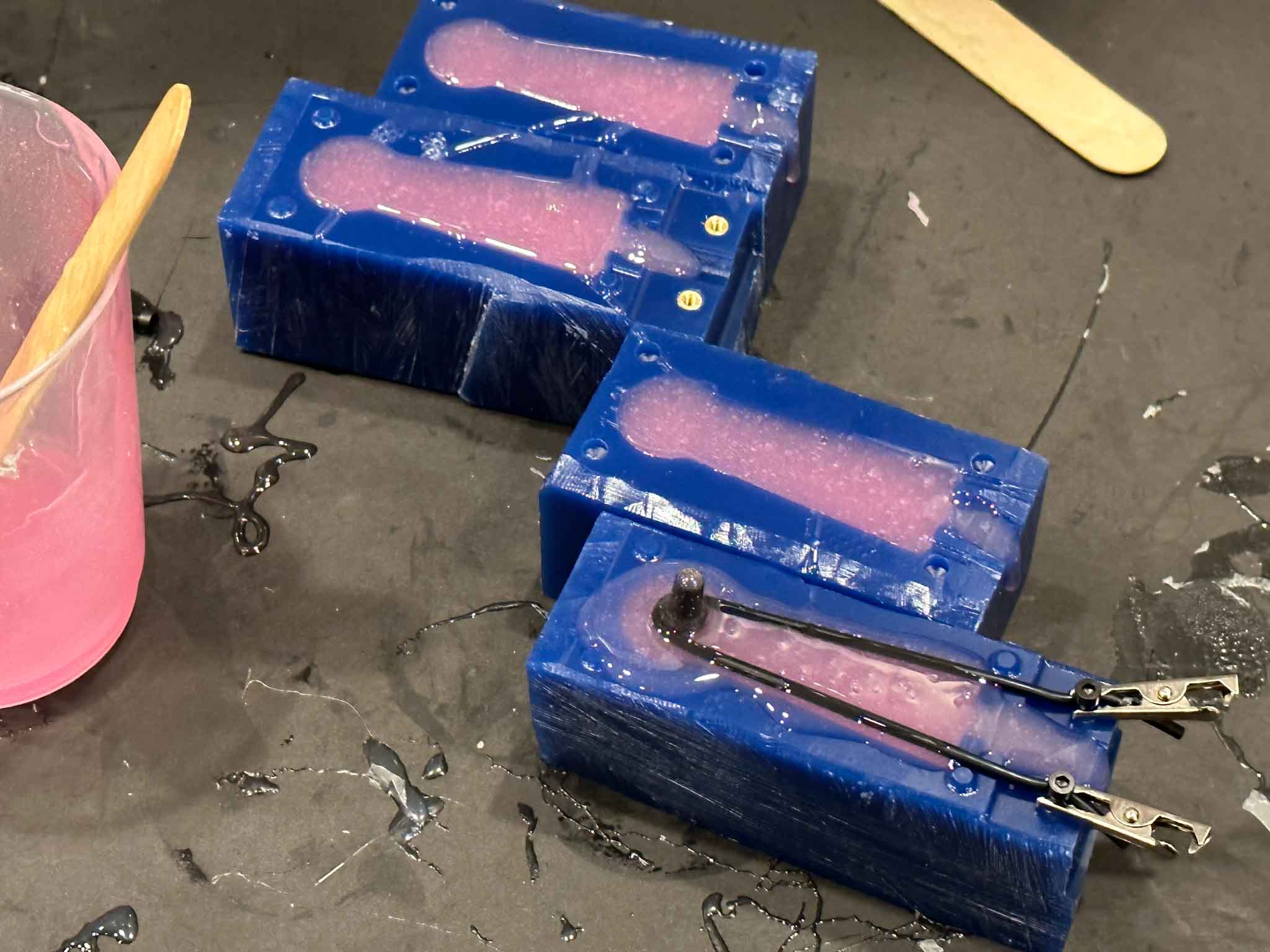

I realized due to the size of my mold and the lack of venting holes, I have to pour silicon into both have the molds before quickly clamping them together. I was able to get away with this because the silicon material is very sticky.

Because I ran out of time to cut another set of molds on the cnc, I printed some molds to cast the rest of the gumball legs.

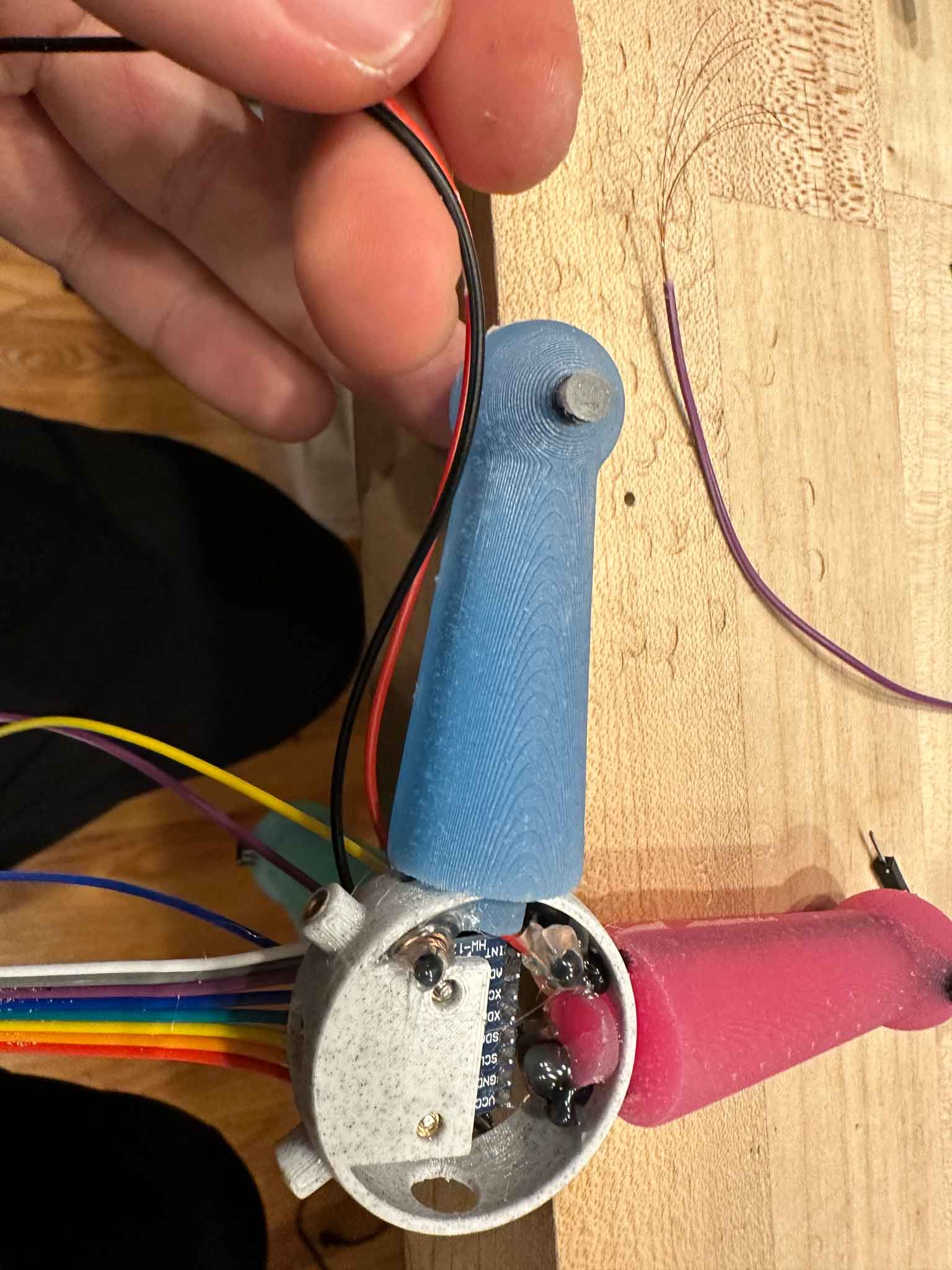

There are some 3D printed skeletons that are casted inside the gumball to hold the electronics and mount the conductive rubber.

After casting the legs, I assembled them inside the main body mold and attached the wires to each of the legs with conductive rubber material. I also added a MPU6050 gyroscope inside the main body.

Pouring the final cast.

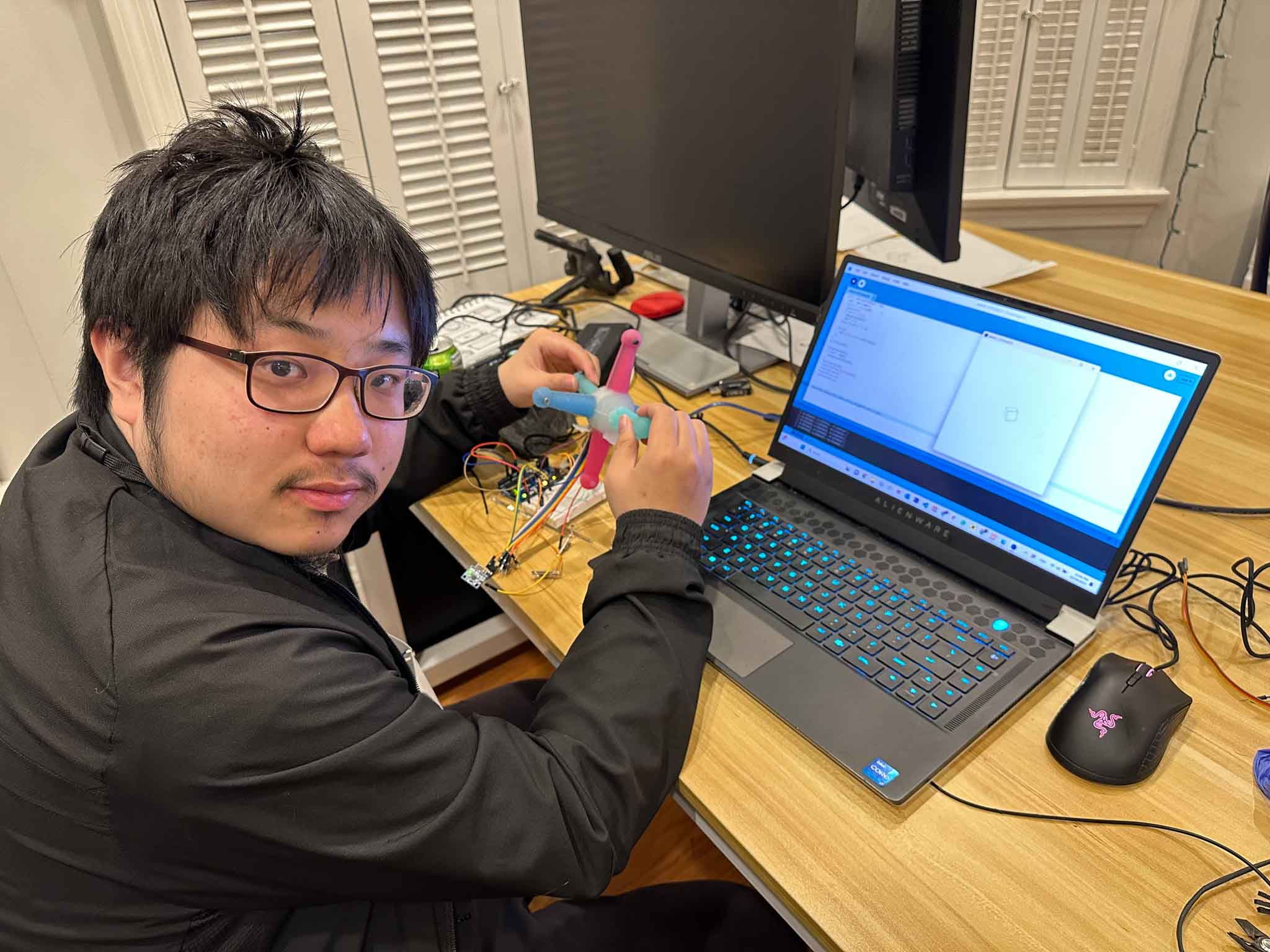

I removed the mold to be greeted with a relatively successful cast. My friend Lingdong help me wrote visualizer that the gumball controll.

Final gumball, have fun streching!