Mechanical and Machine Design

Group Assignment

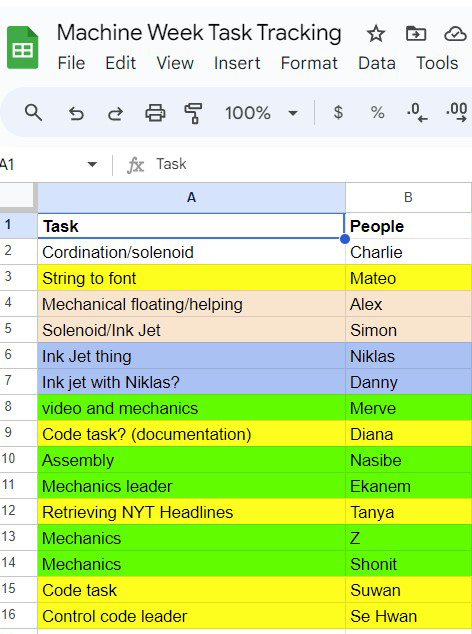

Fig. 1A. Architectural drawing of our machine.

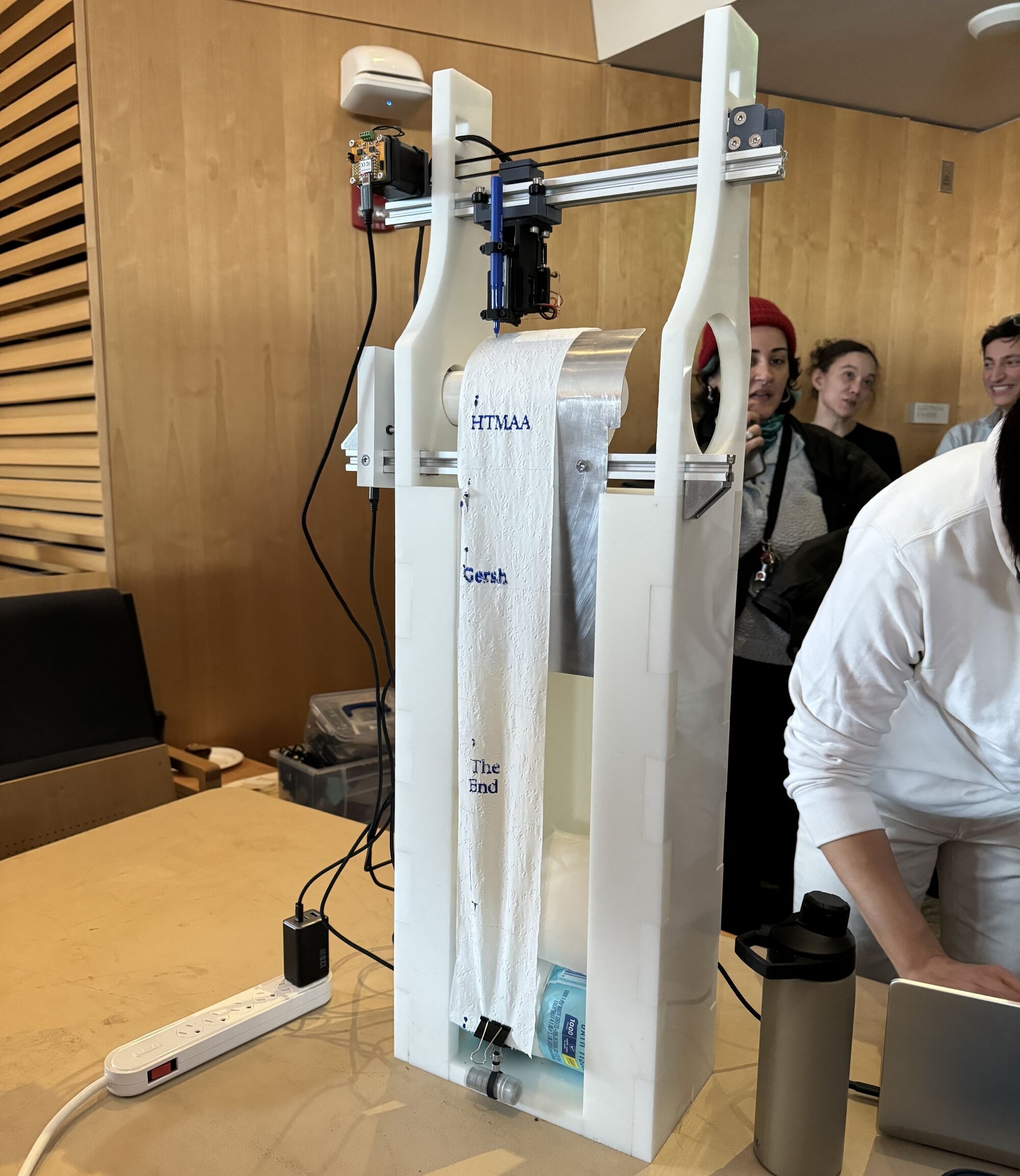

This week was a group project, where I worked with the rest of the Architecture section to design and build a machine. After discussing ideas, we settled on making a machine that would print the newspaper headline each day on a toilet paper roll. This fun idea turned out to be a huge amount of work, but in the end we learned a lot. The components of the machine can be seen in the architectural drawing we made (Fig. 1A).

The initially assigned role I was given was to take part in the coding, particularly in text to Times New Roman font conversion to makesure the pen will print on the toilet paper in particular this font.

However, this matter was resolved by other member of the group in charge of coding, so I spent time dedicating in 3D printing, testing the toilet holder mechanism for iteration, and documentation of the process and the website.

Fig. 1A. Architectural drawing of our machine.

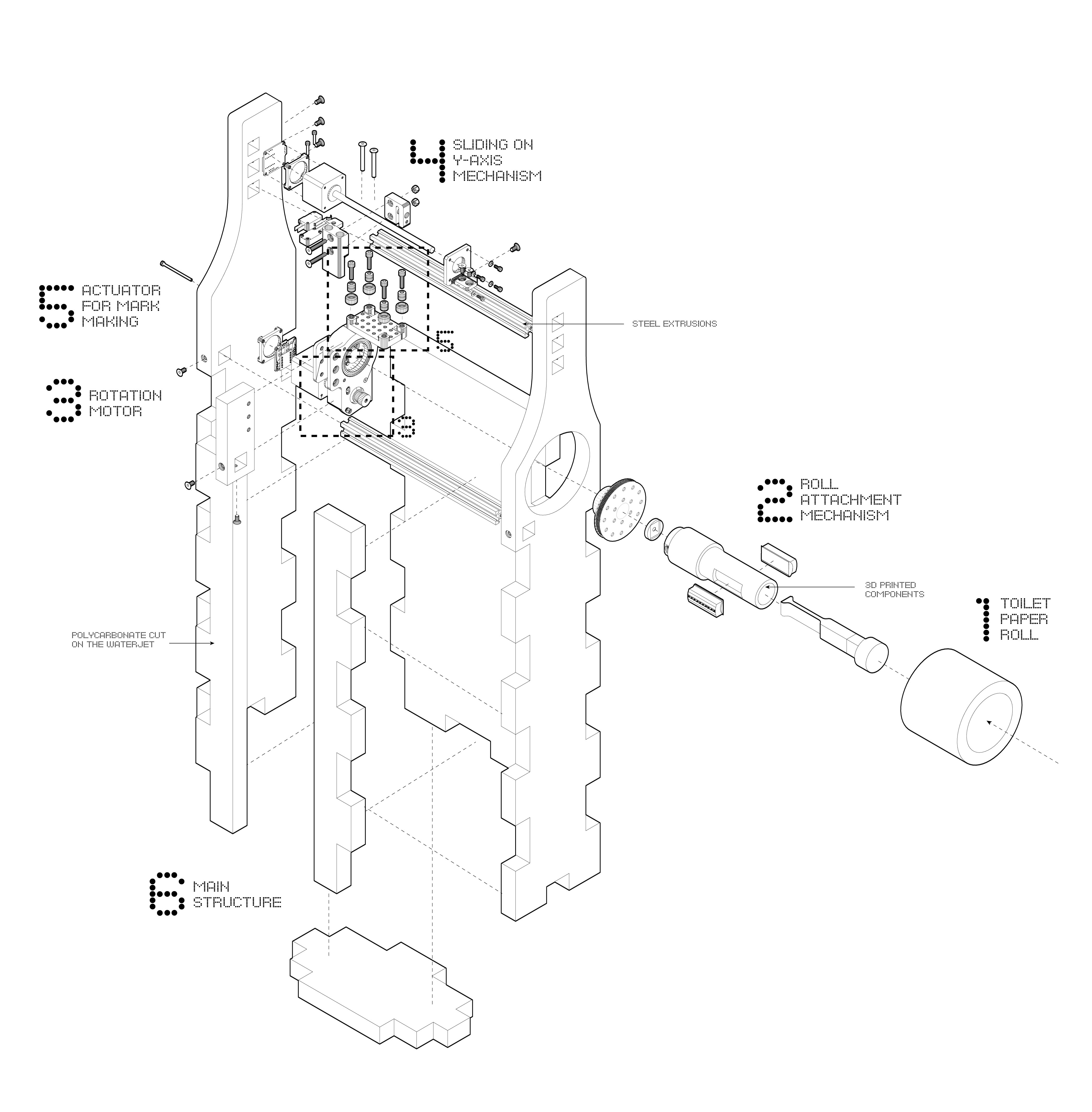

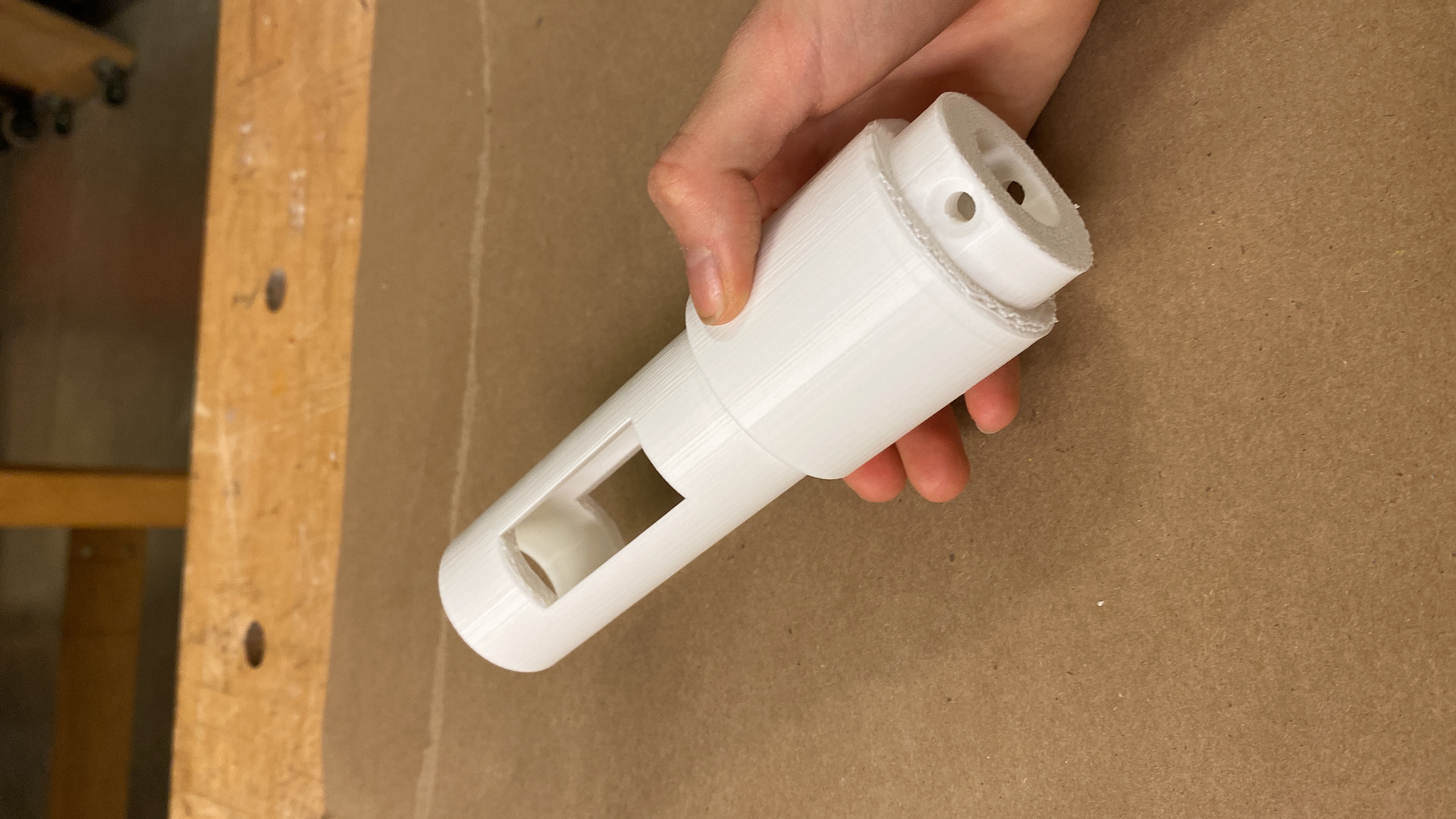

We needed a way to secure the toilet paper roll to the machine so that it would not rotate on its own, but insted, only rotate from our rotary motor. We came up with several early concepts and 3D prints to create this mechanism.

Fig. 1B. Initial test prints

In creating these prototypes, we saw an opportunity to make the mechanism simpler, removing the need for external components such as the spring in the slide-based mechanism. This simple push-based mechanism became the design for our Roll Holder.

Fig. 1C. Roll Holder design process.

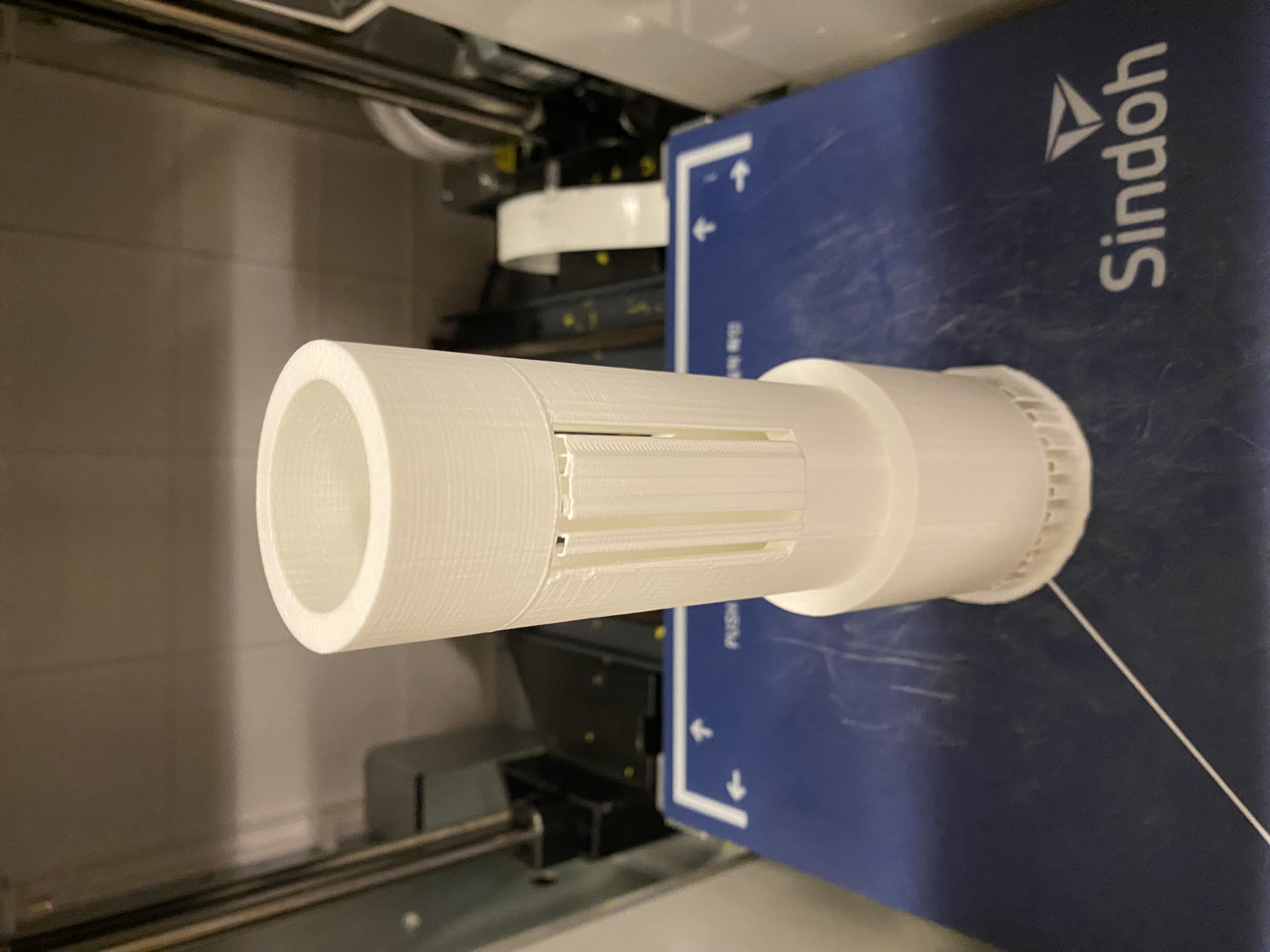

The updated roll holder mechanism printed above. Most of our components for the machine was printed in PLA printer. We have debated about printing with ABS printer which prints in a much higher resolution with a lower failure rate.

However, by the time we were finalizing the design mechanism, it was already around Friday, making it late to submit for the ABS and to run the job.

Also, we had to keep in mind that the support from the ABS printer has to melt overnight in a chemical tank which would delay our plan to finish the project.

As shown in the image above, the print turned out fine.

Fig. 1D. Roll Holder design process.

The parts printed with some rouch edges and surfaces, so I refined the surfaces sanding them with a sand paper.

Fig. 1E. Mechanism in action.

Fig. 1G. The complete 'Daily Paper' machine in action

Fig. 1H zz Plant

Towards the end of the machine week, we were working at the arch student lounge in the evening with this cute ZZ Plant placed on the table.

I was playing with the leaf of the plant, didn't wash my hands afterwards, and went home.

30 min later, I had such an intense reaction to the plant which turned out to have toxic property and got my whole face and body swollen up.

30 min later, I found myself on an ambulance.

another 30 min laer, I was in an ER room where I spend he night and did not get to see the machine getting assembled on the last day. Very sad.

An important lesson learned: Do not mess around with an unknown plant.

Fig. 1H. little man

Although the machine week turned out to be the most hectic and dramatic week out of all the other weeks, I was very proud take part in this week long project.

It was an incredible feeling to see how everything came together and to actually see a pen plotting letters on a toilet paper.

Additionally, it was a meaningful week to get to know and work with everyone from our section.