+ Different compounds can be used for injection molding

+ Both the liquid and the mold will be hot, so plastic can flow easily

+ Vacuum Forming: wrapping aroiound plasic and sucking

+ Blow Molding: blow a test tube, and it formes the model

Irriversible vacuum forming, vacuuming lego bricks (paradox!), inflating inside, commonly used for packaging. Lego has engineered injection molding well, they have optical finish tech!

|

Plastic letters are made by injection molding. (Click on the picture to see larger.) |

+ Feed with ABS plastic dies from the back ,you can add colored ones for playing with color .

+ Align the plate with base, adjust the amount of the plastic, by turning the knob. Adjust Rear zone heat, fron zone heat, mozzle heat. if there is more material the n it can take in, it will come out form the sides.

+ Engage the carriage, inject, and extrude up.

+ There is a black knob for pressure adjusting , counter clockwise to lower the pressure.

|

Another view. |

|

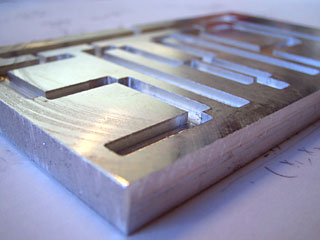

Details of the plastic letters. |

|

It was not easy... the amount of the plastic and the intervals in molds can be tuned after several shots. (Click on the picture to see larger.) |

|

The liquid plastic has injected into this mold. (Click on the picture to see larger.) |