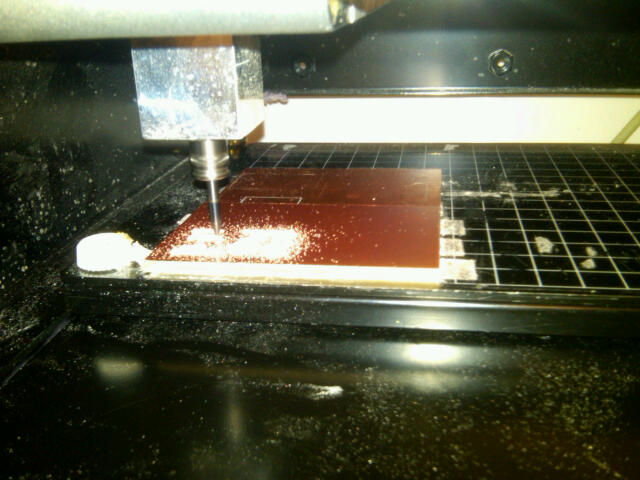

Milling & Soldering

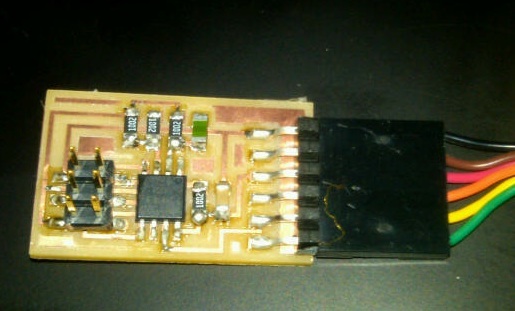

I made a temperature sensor, which I plan to modify to detect useage of kerosene lamps.

Milling went fine - board cut nicely and cut out neatly.

I used lead-free solder, which was somewhat more difficult to work with than the lead-based solder - it did not melt as easily,was harder to desolder, and did not finish as shiny as the lead-based stuff. Still, fewer toxins, right?

Here is one of the completed boards.

Programming

I programmed the board in C using the hello.temp.45.c code, and visualized the output with the hello.temp.45.py script.

I tested it out on cold and warm temperatures. It maxed out quite quickly just sitting on my laptop and placing it on a refrigerated item took it below the threshold.

For my kerosene lamp application, this may be okay, as we don't need a precise temperature, but rather an "on" or "off", and so long as it won't be getting that warm when the unit is off, the low heat threshold won't be a big problem, but I will probably tweak it to be safe. I also will probably make this again on the vinyl cutter, as that will enable me to stick the circuit to the lamp. I will also have an extended thermistor (e.g. attached via a wire to the board) rather than sitting on the board itself, so the rest of the device does not need to be exposed to the warm temperatures. Finally, I need to find a way to store some data (and a battery) as I don't want it to have to run off the computer.