Week03 - Electronics Production

This week THRILL as NovySan spins the tale of endmills and sacrifices his eyesight to the tiniest soldering job on earth.

The adventure this time is to mill, stuff, and program a FabISP micro-controller programmer. Anticipating building machines that build other machines, and perhaps with a nod to the blacksmith who could make any tool he needed as long as he could make a pair of tongs and a hammer, the job of this little droid is to tell other droids what they should be doing.

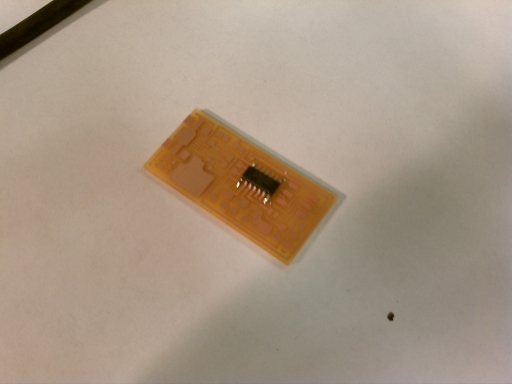

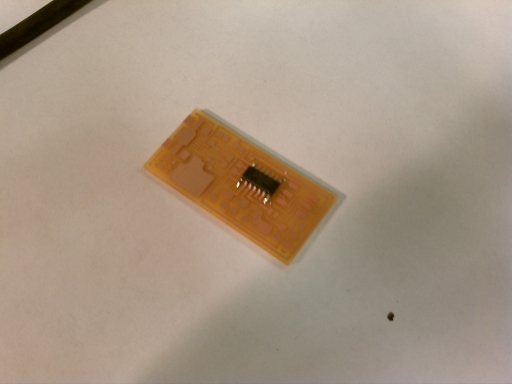

Once the board was milled on the Modelo (like the beer!) using a 1/64 for the traces and a 1/32 to cut the board free, we collected the treasures we would need to create our little droid brain.

The adventure this time is to mill, stuff, and program a FabISP micro-controller programmer. Anticipating building machines that build other machines, and perhaps with a nod to the blacksmith who could make any tool he needed as long as he could make a pair of tongs and a hammer, the job of this little droid is to tell other droids what they should be doing.

Once the board was milled on the Modelo (like the beer!) using a 1/64 for the traces and a 1/32 to cut the board free, we collected the treasures we would need to create our little droid brain.

For those keen of eye, that's 1/4" ruled graph paper (courtesy of Jesse Thorne at Max Fun Con. Thanks, Jesse!). Some of the components were 1/16" or smaller and had writing on them needed to indicate proper orientation. Thank god for LASIK and the loupe which allowed me poor ol' eyes to see what I needed to do without going mad or blind. And speaking of mad or blind, turn on your fume extractor while working with solder. You'll thank me later.

Below is the first few legs of the tiny44 micro tacked down. Notice the shininess and lack of bridging. I think I fell in love with the flux pen and have been trying to put flux on other things in my life so they flow where they need to more easily. It's better than The Secret™. In fact, it may BE The Secret™.

Below is the first few legs of the tiny44 micro tacked down. Notice the shininess and lack of bridging. I think I fell in love with the flux pen and have been trying to put flux on other things in my life so they flow where they need to more easily. It's better than The Secret™. In fact, it may BE The Secret™.

The remaining THREE HOURS were spent placing everything where it needed to go. After a while I discovered Neil's method of "tinning" the pad with a bit of solder, placing one leg of the part down on it, then holding the part down with the tweezers while heating the previously applied solder would cause the solder to "sit down" sharply and make excellent contact. Once one leg was down the rest were a breeze. If I re-worked the solder too much (OCD? Me? What gives you that idea? 90 degree angles are IMPORTANT!), I discovered I could apply a touch of flux, hit it one more time, and a perfect shiny blob would result.

Once everything was onboard, it was time to fire it up and tell it how to tell other pics how to do their job. Kinda like a union supervisor but with fewer paid personal days.

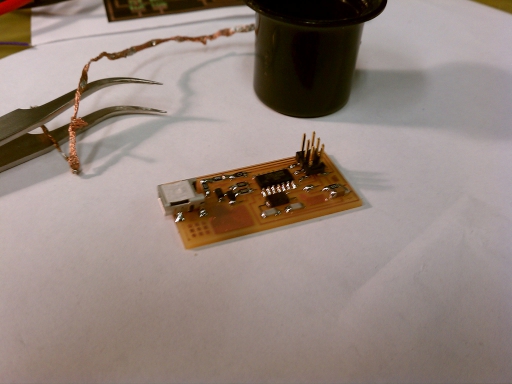

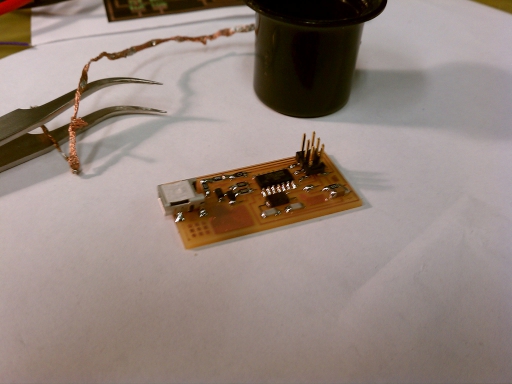

Everything programmed like a breeze and then all that was left was to remove a "solder jumper" and a 0 ohm resistor that then pulled the chip out of programmable mode making it capable of programming other pics. I've included in the final pic an homage to tools I could not have finished this assignment without. The loupe, the tweezers, and the braid to pull solder away when you've shorted some legs or simply put too much on.

Once everything was onboard, it was time to fire it up and tell it how to tell other pics how to do their job. Kinda like a union supervisor but with fewer paid personal days.

Everything programmed like a breeze and then all that was left was to remove a "solder jumper" and a 0 ohm resistor that then pulled the chip out of programmable mode making it capable of programming other pics. I've included in the final pic an homage to tools I could not have finished this assignment without. The loupe, the tweezers, and the braid to pull solder away when you've shorted some legs or simply put too much on.

I'm really looking forward to the coming weeks when I will use this tool to program other tools I make. There is a deep sense of satisfaction knowing I did it myself and can now do it when ever I need to.

Until next time then, Space Cadets! NovySan, OUT!

Until next time then, Space Cadets! NovySan, OUT!