Week04 - MAKE SOMETHING BIG! aka Computer Controlled Machining

Or, perhaps, Make Something Big(GER!)

This week, two weeks actually given that Sponsor Week so rudely interrupted our lives last week, was all about computer controlled machining, such as the ShopBot and OMAX Waterjet Cutter, a machine I shall love until my dying days.

This week, two weeks actually given that Sponsor Week so rudely interrupted our lives last week, was all about computer controlled machining, such as the ShopBot and OMAX Waterjet Cutter, a machine I shall love until my dying days.

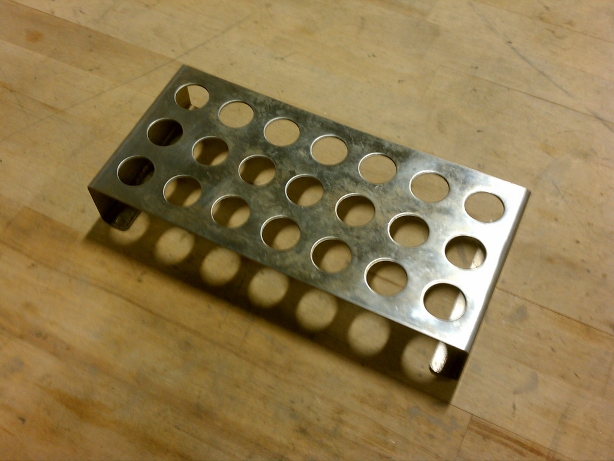

The above implement is the inspiration for my project. It exists for one reason. TO MAKE BACON WRAPPED, CHEESE STUFFED JALAPENOS. It's drawback is obvious. It is small. Very Small. It can make only 21 delectable bites at a time. This will not stand, Sirrah. I needed a way to make many more in a single oven cycle for events where I am called on on Cocktails and Appetizers, a situation that seems to occur semi-regularly in my life. Off to the waterjet cutter!

After quickly purchasing cookie sheets and jelly roll pans (to contain the dripping. the lovely, lovely drippings), I grabbed an older grad student and headed toward OMAX, who in my mind is the god of waterjet cutters and is vaguely mechano-Mayan in appearance. Someday I'll draw a picture. I was able to design and fabricate directly on the cutting computer so no USB SneakerNet either.

Here you see 35 perfect holes cut by water pressure and garnet. As someone who has before had to cute many perfect holes with a UNIbit and a hand drill, I cried with glee as the machine happily went about punching holes in a perfectly good cookie tray.

Here you see 35 perfect holes cut by water pressure and garnet. As someone who has before had to cute many perfect holes with a UNIbit and a hand drill, I cried with glee as the machine happily went about punching holes in a perfectly good cookie tray.

Thirty-five was simply not enough, being really not that many more than twenty-one, so I made TWO. The beauty of CNC Machining became apparent. Reset the origin and Z depth for the new piece of material and simply cut another one with the same file open on the machine. If I'd built a jig to hold material in the same position, I could've run off as many copies as I needed without even having to re-origin. Someday I see Kinkos having laser cutters and waterjets, at least the Kinkos on Mars.

I can now make SEVENTY BACON WRAPPED, CHEESE STUFFED JALAPENOS at one time.

Below you can see the result fresh out of the oven, including the jelly roll drip tray.

I can now make SEVENTY BACON WRAPPED, CHEESE STUFFED JALAPENOS at one time.

Below you can see the result fresh out of the oven, including the jelly roll drip tray.

Proper presentation!

Easy clean up. The waterjet was so precise it didn't shatter the non-stick surface on either edge of the hole. Or course there's bare metal on the interior, that can't be helped, but properly seasoned it shouldn't be a problem.

Again, note the drip containing tray. It's not my fault if you skip this step and burn your kitchen down.

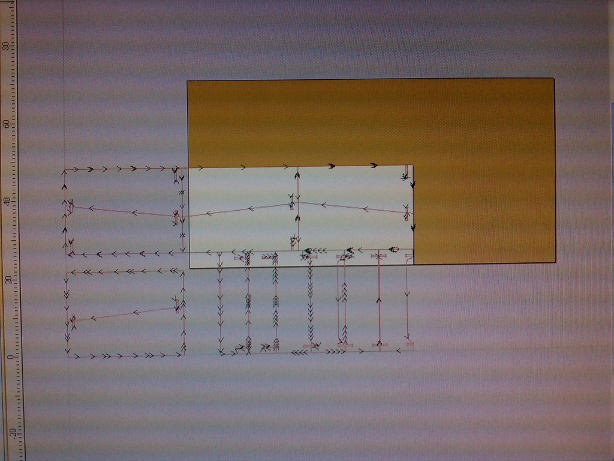

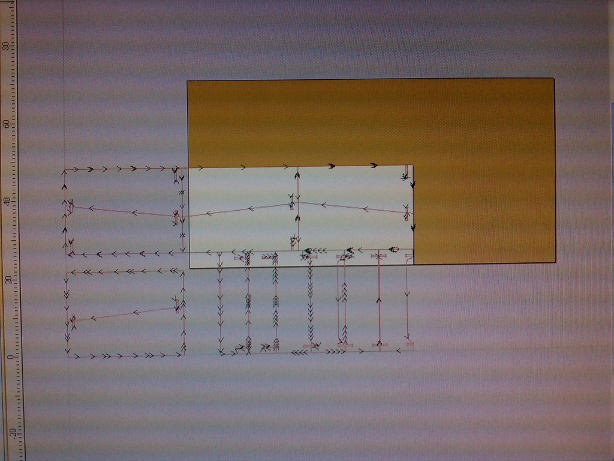

Next, came the ShopBot, perhaps the high point of the class so far. Although the task was to build something BIG, we were limited to one sheet of OSB. Luckily Andy went to Home Depot for Sponsor Week and I ended up with a sheet of 1/2" ply, much better suited to building furniture. The process was smooth sailing right up until this:

Next, came the ShopBot, perhaps the high point of the class so far. Although the task was to build something BIG, we were limited to one sheet of OSB. Luckily Andy went to Home Depot for Sponsor Week and I ended up with a sheet of 1/2" ply, much better suited to building furniture. The process was smooth sailing right up until this:

Easy clean up. The waterjet was so precise it didn't shatter the non-stick surface on either edge of the hole. Or course there's bare metal on the interior, that can't be helped, but properly seasoned it shouldn't be a problem.

Again, note the drip containing tray. It's not my fault if you skip this step and burn your kitchen down.

No one could figure out why it was doing this in the preview of the ShopBot 3 software. Eventually, it was decided by the powers that be to ignore the preview, and "run it in the air" from the set origin to see what it did. Luckily the tool path was correct and the machine responded as expected and we could proceed to actual cutting.

I found a hand drawn image in a book from the 70's that creates two slotted plywood chairs from a single piece of plywood. I redesigned the chair for our material, drafted it up in Partworks and created the tool paths. Completed the chair looks like this. My wife will choose a material at the fabric store to make the "sling" that spans between the cross pieces. You get two chairs for each piece of plywood.

No one could figure out why it was doing this in the preview of the ShopBot 3 software. Eventually, it was decided by the powers that be to ignore the preview, and "run it in the air" from the set origin to see what it did. Luckily the tool path was correct and the machine responded as expected and we could proceed to actual cutting.

I found a hand drawn image in a book from the 70's that creates two slotted plywood chairs from a single piece of plywood. I redesigned the chair for our material, drafted it up in Partworks and created the tool paths. Completed the chair looks like this. My wife will choose a material at the fabric store to make the "sling" that spans between the cross pieces. You get two chairs for each piece of plywood.

Debate and consideration of the FINAL PROJECT continues. I believe creating an armored pinata that hits back would require pneumatics and machine vision technologies beyond the scope of this class. I am leaning very much so toward the Moby Dick pancake dispenser, although other brilliant ideas keep presenting themselves. Decisions must be made NOW.

Until next time then, Space Cadets! NovySan, OUT!