Concept

A press-fit chair cut out of OSB on the ShopBot.

Design

I started out making the chair in SolidWorks, but I had a terribly time making splines - they were always either under-defined or over-constrained.

As an experiment, I decided to switch to Inkscape for this assignment. It went okay, and I documented tips and tricks in the content archive.

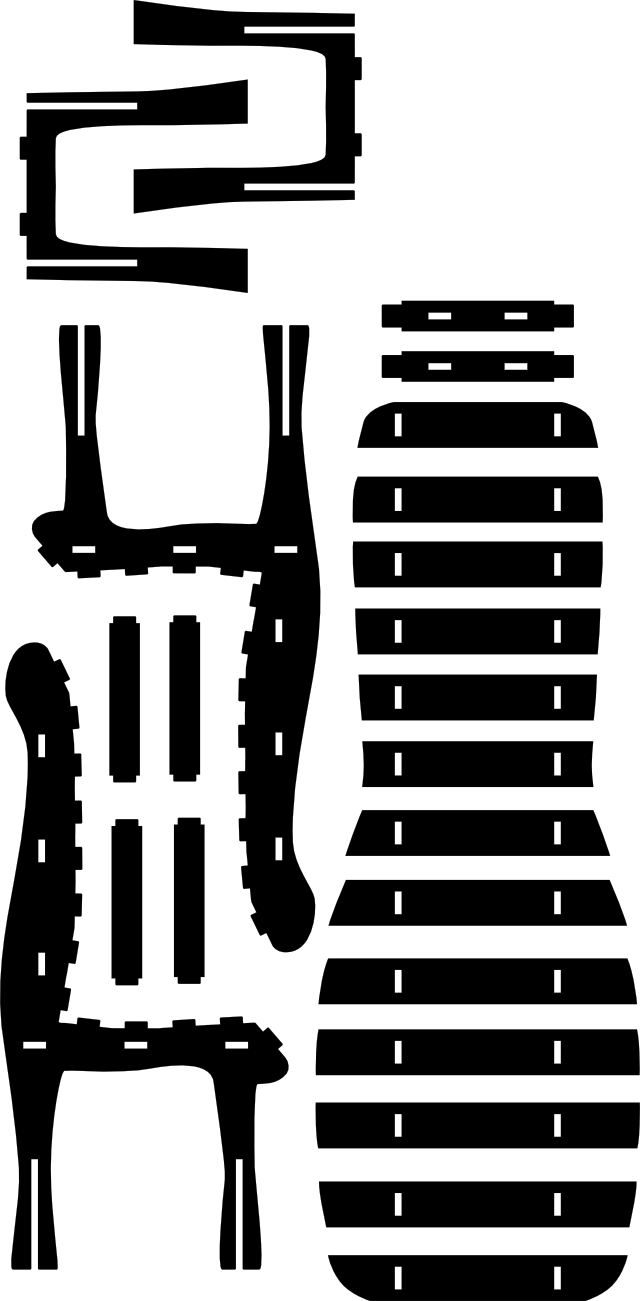

Final part sheet:

T-bone fillets were later added to all of the inner slot/tab corners using PartWorks 2D.

T-bone fillets were later added to all of the inner slot/tab corners using PartWorks 2D.

Cutting

I learned a few valuable lessons about the ShopBot:

- If the PC-side software crashes due to communicating errors, static could be the cause. Vacuuming up the dust near the cables seemed to fix this strange issue.

- If the ShopBot software crashes mid-cut, make sure to lift the cutting head up before you attempt to move it horizontally. Otherwise, you could break the milling bit.

- If you're trying to resume a job after a software crash, it's possible to manually edit the ShopBot cut file, which is simply a series of instructions. When the software crashes, make a note of what line it is on. Then, delete the code between the initialization stuff (line 12 or so) and the line that it failed on.

- If you've edited code in this way, make sure that you're at a reasonable x/y position before starting the job. If the head is at [10, 10, 2] and the first point in modified job is [80, 80, -0.5], the cutting head will make a long diagonal traverse, cutting through anything in its way - this is probably not what you want.

Assembly

The missing slat had a misplaced slot; I recut it on the laser cutter.

The missing slat had a misplaced slot; I recut it on the laser cutter.

Back view:

Clever interlocking joints:

Results

Source

SVG file

Note: this lacks fillets and needs to be rotated 90° before cutting.