How To Make Almost Anything

David Yamnitsky

Final Project

Quadcopter

This week I made a quadcopter. I designed a frame and cut it from aluminum on the waterjet, then added brushless motors and controlled them with a bluetooth microcontroller using readings from an IMU.

Computer Controlled Machining

Press Fit Standing Desk

This week we covered large format machining. I used the brand new Onsrud 8'x4' router in N51 to make a press fit standing desk.

Embedded Programming

AVR Oscilloscope

This week I made an oscilloscope with an ATMega328. The scope can measure between -10V and 10V and uses the internal ADC and comparator for triggering. It samples at around 150ksps and sends the data over USB.

Output Devices

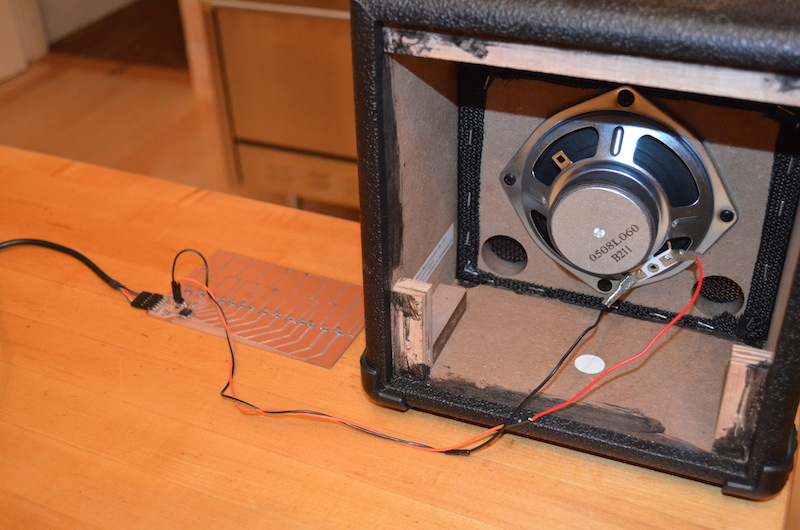

Capsense Piano

This week I finished the Capsense Piano project that I began in Input Devices Week and added a Speaker to it that I salvaged from an old guitar amplifier.

Molding and Casting

MIT Logo

This week I molded and casted an MIT logo. I milled a positive mold with machining wax, cast a silocone negative in it with Oomoo, and then cast the logo out of Hydrostone.

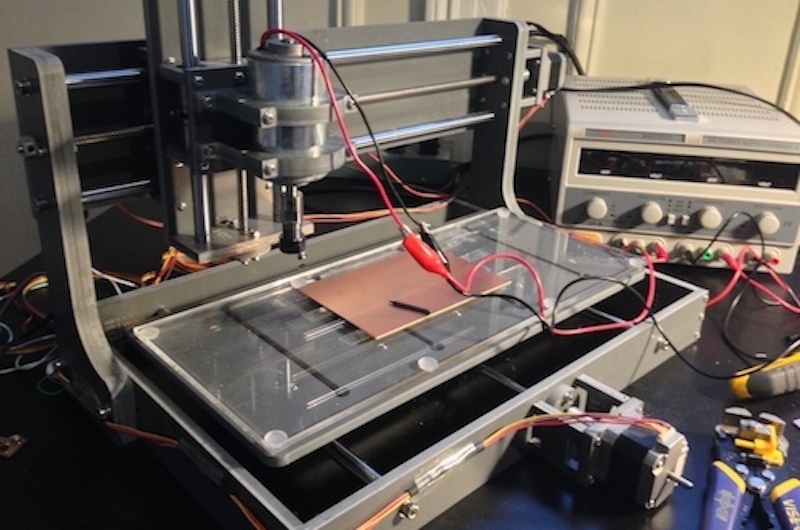

Electronics Design

PCB Mill Components

This week I used the CNC I had leftover from my 6.115 Final Project to mill its own limit switches and control board.

Computer Controlled Cutting

Press Fit Flying Saucer

This week I made a press fit flying saucer by laser cutting cardboard. I used 123DMake from Autodesk to slice a 3D model into press fit pieces.

3D Scanning and Printing

Press Fit Flying Saucer

This week I 3D Printed a sailboat in a block on a Form 1 and made a touch probe 3D scanner.

Networking

Bluetooth Door Lock

This week I made a door lock that opens via Bluetooth with an app on my phone.

Application Programming

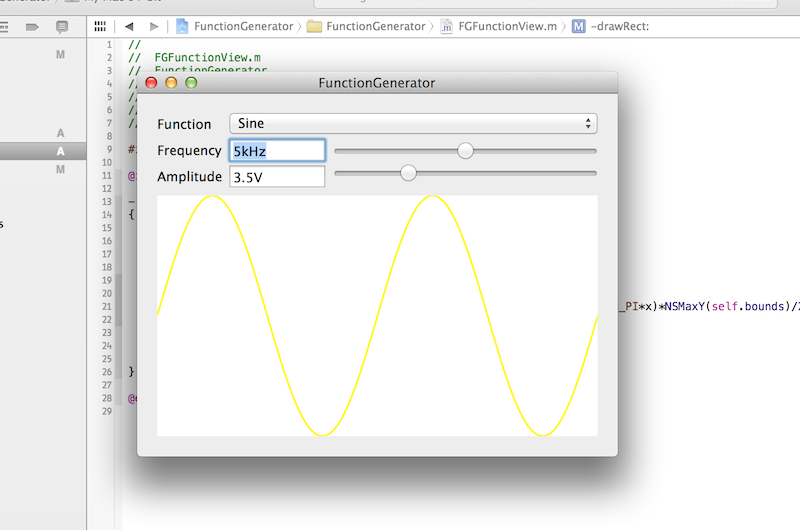

USB Function Generator

This week I prototyped a USB function generator with a PSoC 5LP and a Cocoa app to control it.

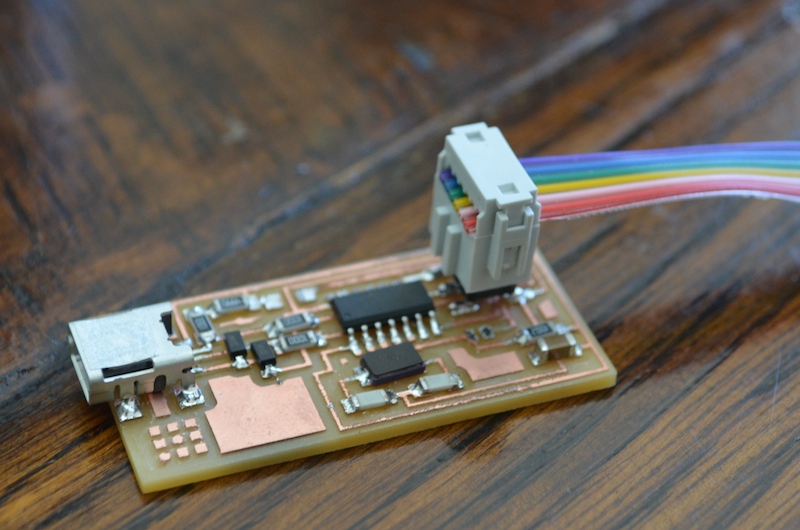

Electronics Production

FabISP

This week I milled a FabISP in-system programmer using the Roland Modela and learned how to solder surface mount components.

Input Devices

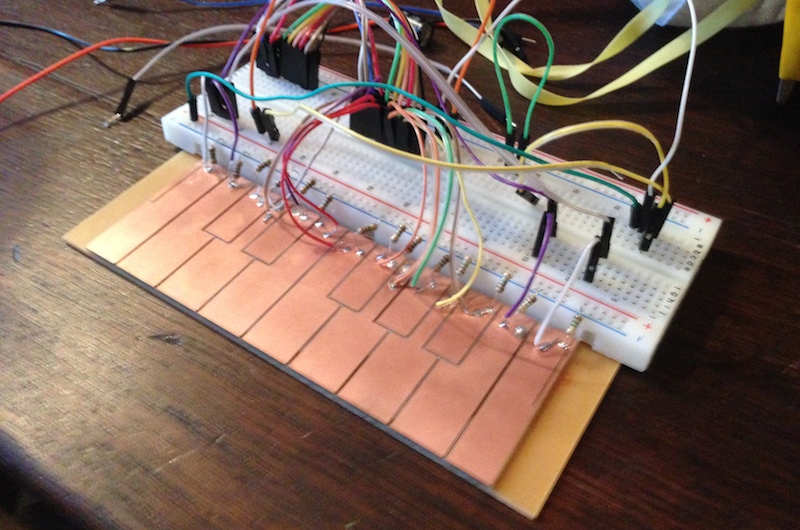

Capsense Piano

This week I designed a capacitive sensing piano with an ATMega328p programmed as a MIDI device.

Composites

POV spinner

This week I made a POV spinner by forming a composite bar with burlap and epoxy and mounting it on a stepper motor with an LED.

Project Ideas and CAD

This week I sketched some possible project ideas.