Week Seven: Molding and Casting

This week I molded and casted an MIT logo. I milled a positive mold with machining wax, cast a silocone negative in it with Oomoo, and then cast the logo out of Hydrostone.

Molding

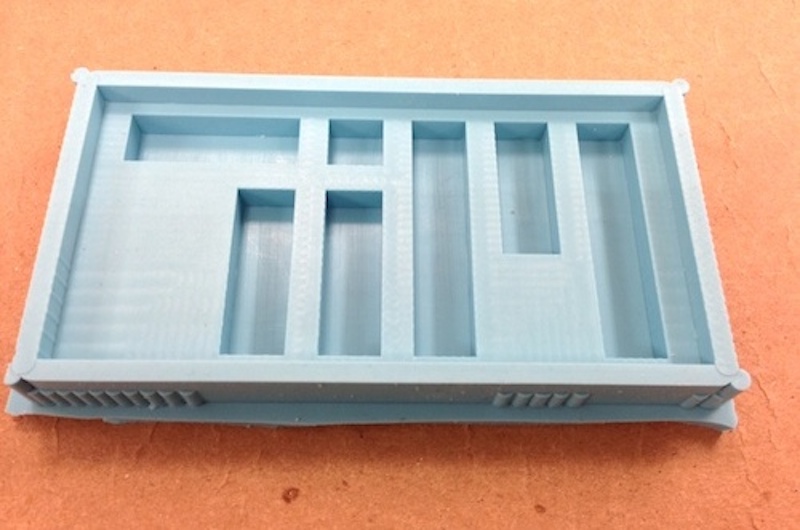

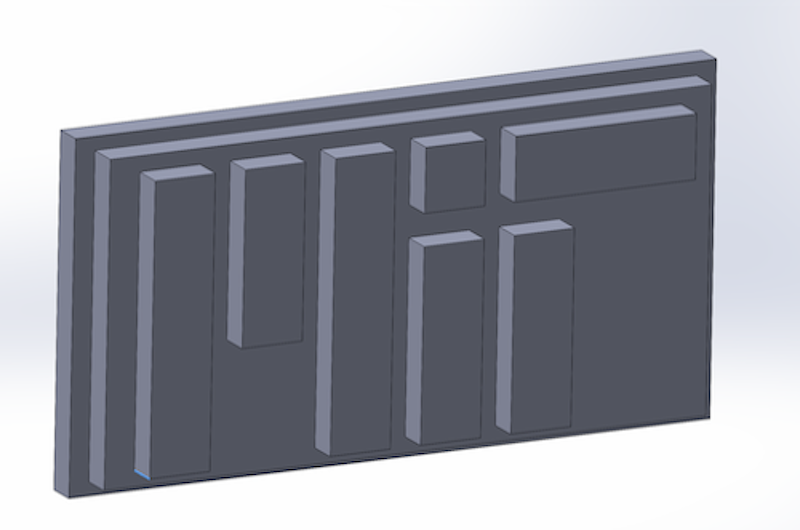

This past weekend I went to a seminar on parametric design in Solidworks so I also decided to make my model completely parametric. This was also a good idea because I didn't remember the dimensions of the wax ahead of time, so I would be able to scale the model easily by changing parameters. Here's a screenshot of the Solidworks model. There are two platforms in the design because the fab module removes one when it detects a model.

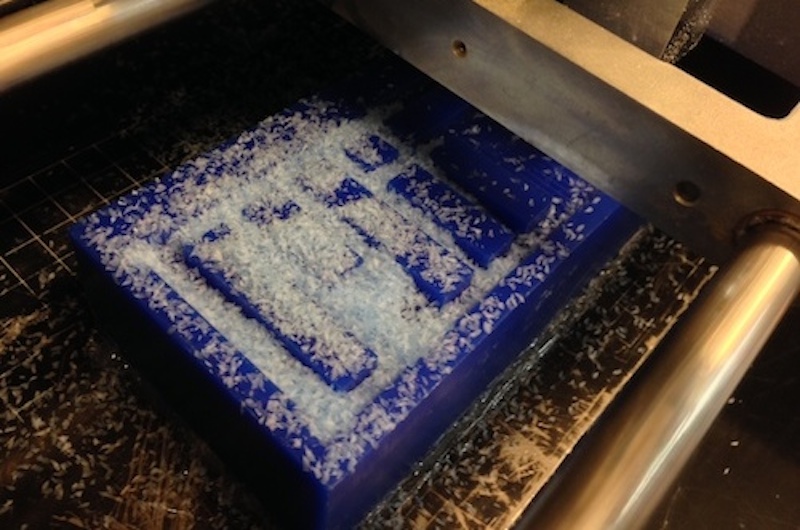

Casting

I brought an STL exported from Solidworks into the fab module make_stl_rml and went through two cuts, a rough cut and a finish cut. I used all default settings and they worked great. Next I mixed equal parts of Oomoo parts A and B and poured them into the wax. I put the mold into a pot with a vacuum pump to help remove bubbles from the Oomoo. After six hours of waiting, I pulled out a bubble-free silicone mold. Finally I mixed 100:22 hydrostone to water, poured it into the mold, and a few hours later had a finished cast.