Week Nine: Composites

This week I made a POV spinner by forming a composite bar with burlap and epoxy and mounting it on a stepper motor with an LED.

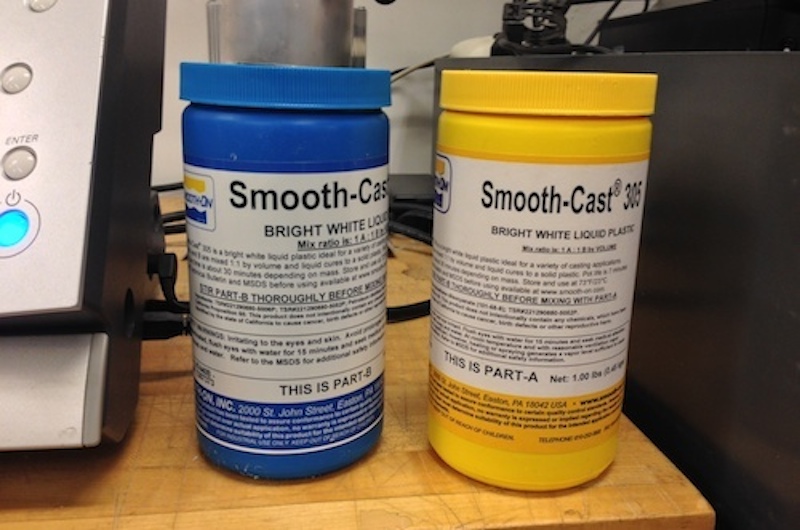

Rather than milling a mold for the bar I decided to laser cut a sheet of burlap. I drew a series of 10 inch by 2 inch rectangles in AutoCAD on the machines in the Architecture lab. The default power settings on the laser cutter worked perfectly. I was really pleased with how I could draw and cut simple shapes in just a few minutes. It was much faster than milling a similarly simple shape. Next I donned two pairs of glass, safety glasses, and a respirator to lay up the sheets with epoxy. I used a 2:1 ratio of the resin and hardener in a plastic cup and stirred it with a wooden spoon. I poured a healthy portion on the first layer and it was sufficient to wet the next four layers. I placed the piece between two sheets of plastic wrap and put it under the fume hood to dry. When I returned the next day however, the fume hood had been cleaned out and my part was missing. After a long search through the lab and even the trash, it seemed as though my part had been mistakenly thrown away. At the suggestion of James, one of the TA's, I decided last minute to try using the Smooth-Cast 305 which dries in only 30 minutes. I then mounted the bar with an LED and 9 volt battery on a stepper motor and I was done.