28 Sep 2016 · 2 min read

This week, I made a

FabISP,

an in-system programmer for AVR microcontrollers.

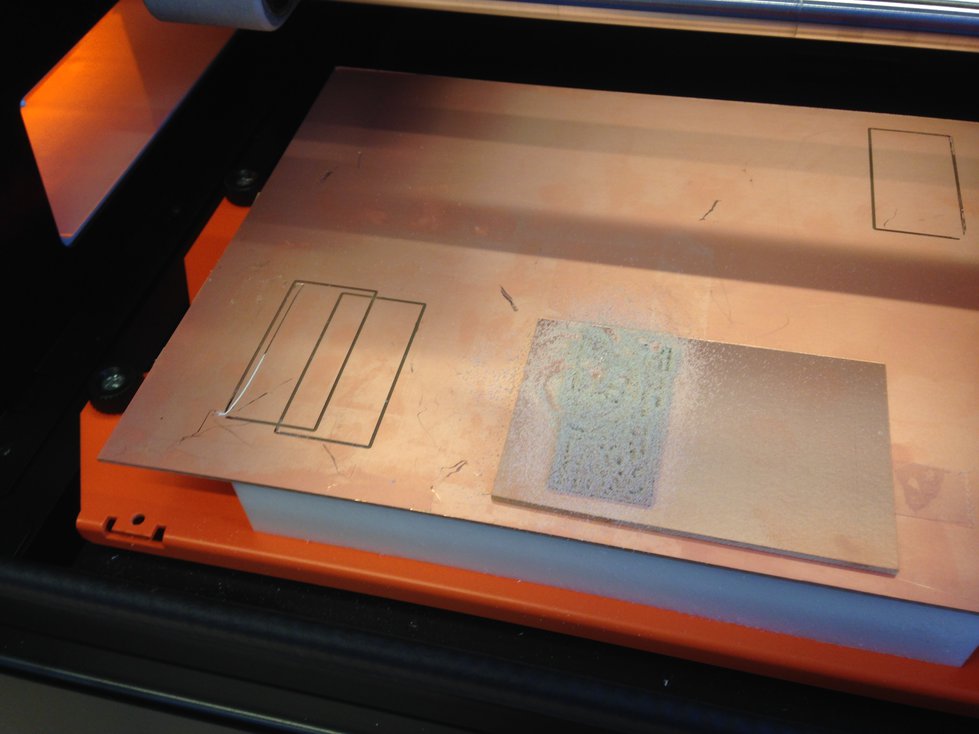

Milling the PCB

I milled a PCB (using these

traces

and

outline).

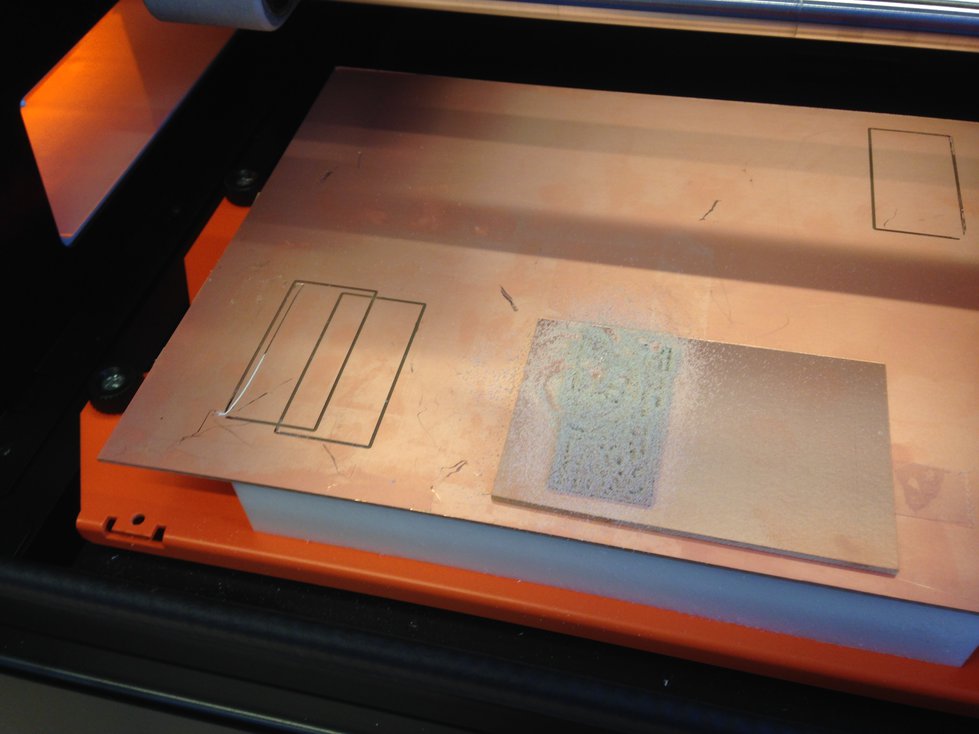

I used fab modules to calculate toolpaths for the

Roland SRM-20 milling machine, using all the default settings. I used a 1/64

end mill for cutting PCB traces and a 1/32 end mill for cutting the outline:

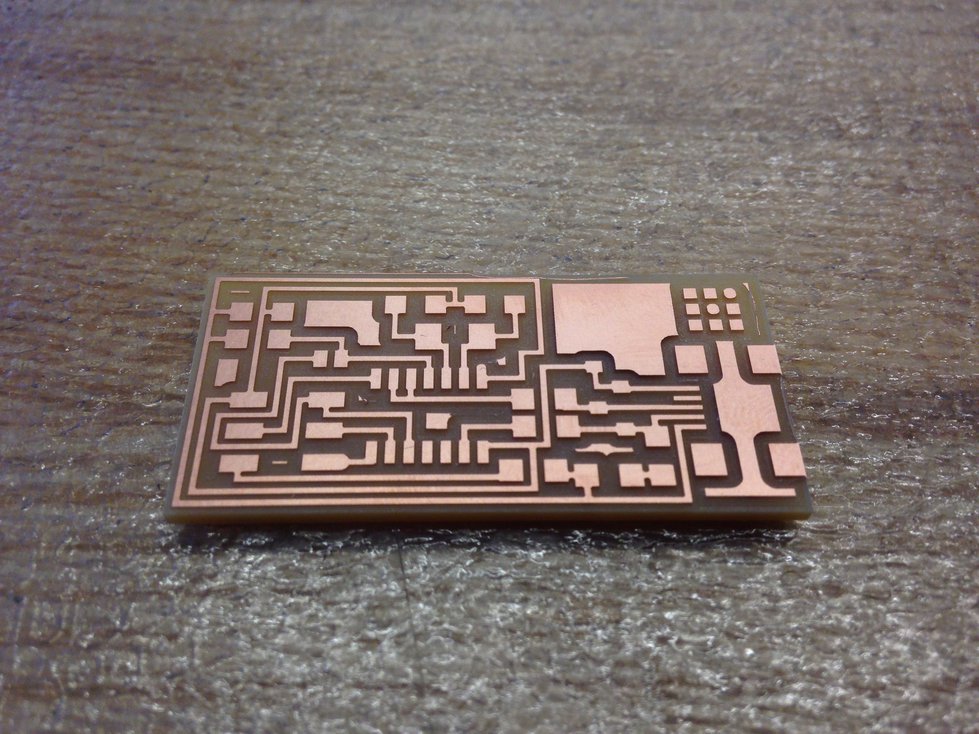

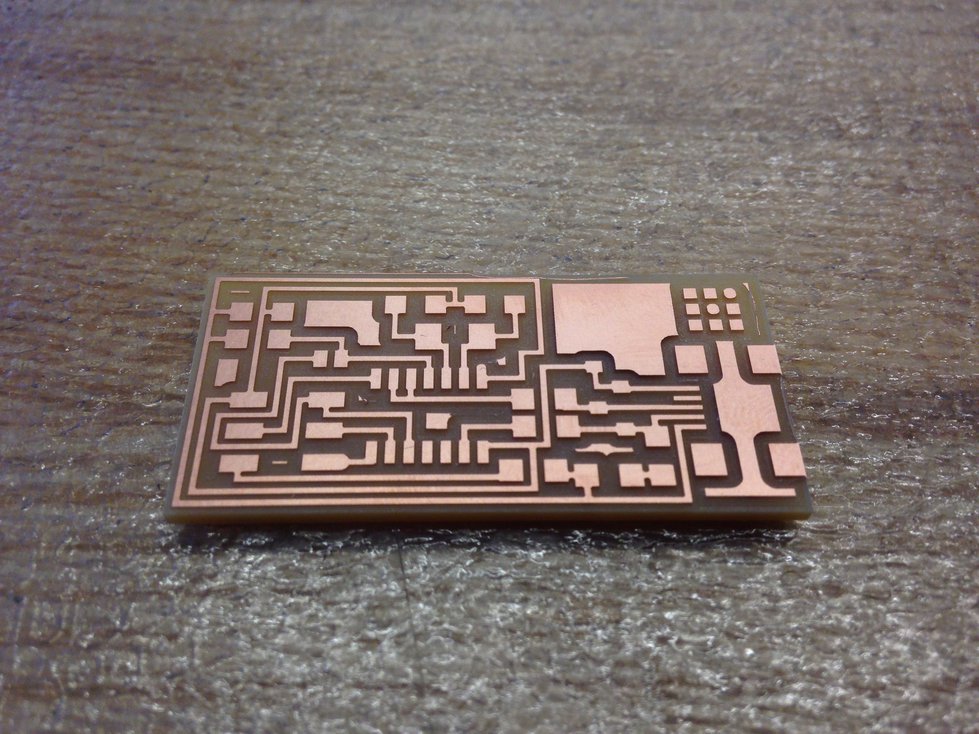

After working through it carefully, everything worked on the first try, and I

ended up with a nice finished PCB with pretty clean traces:

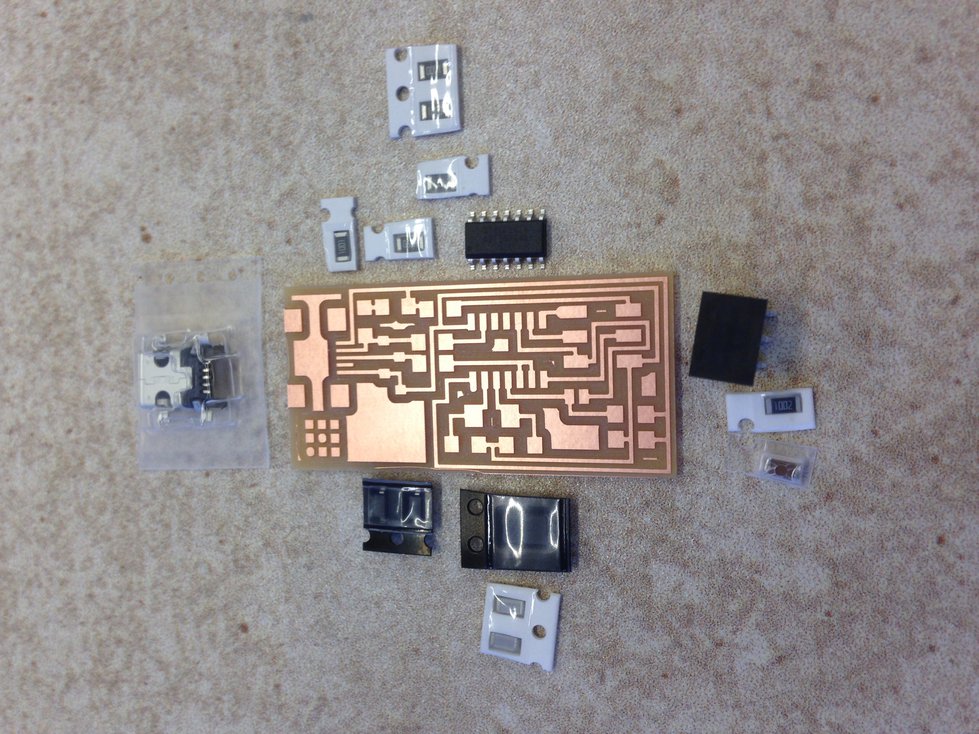

Soldering Components

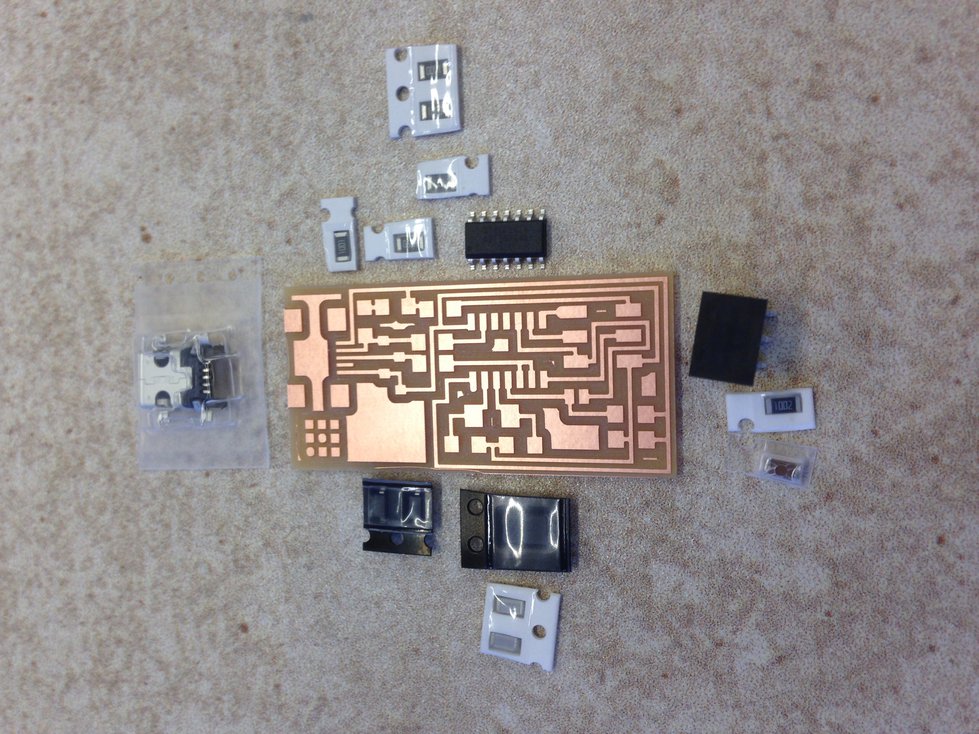

Next, I soldered the

components. Before starting, I picked out all the parts and made sure I knew what was going where:

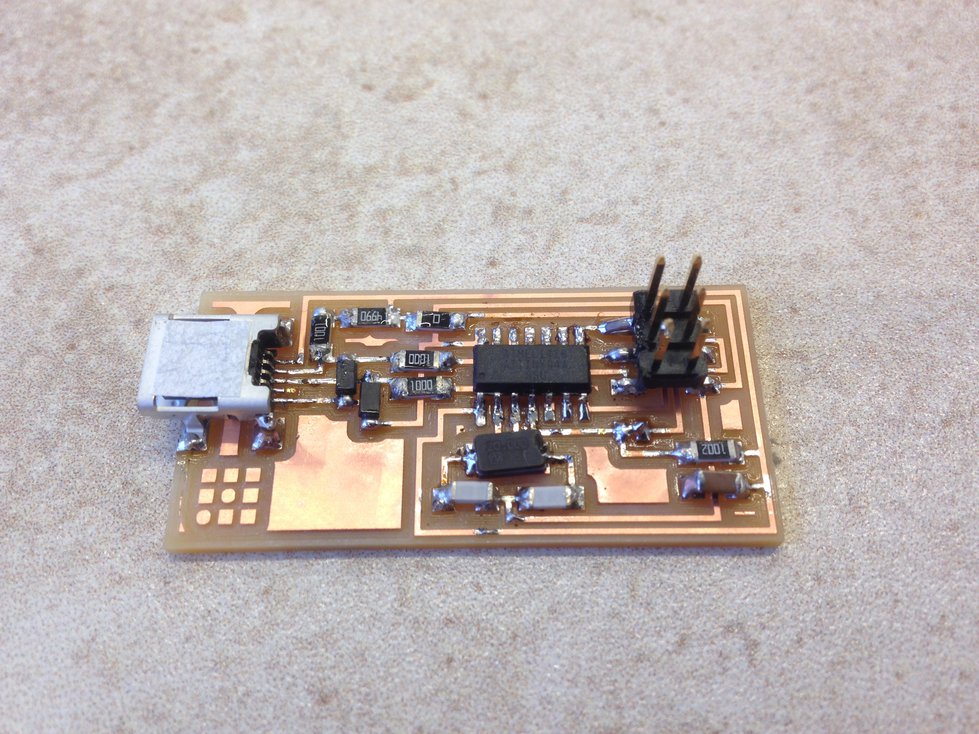

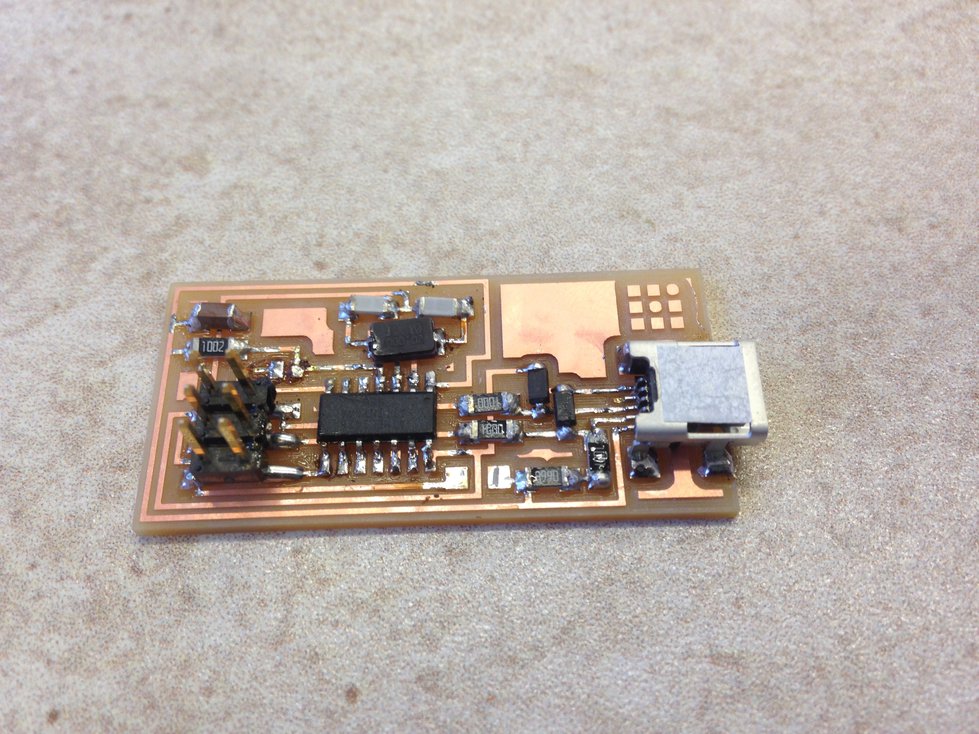

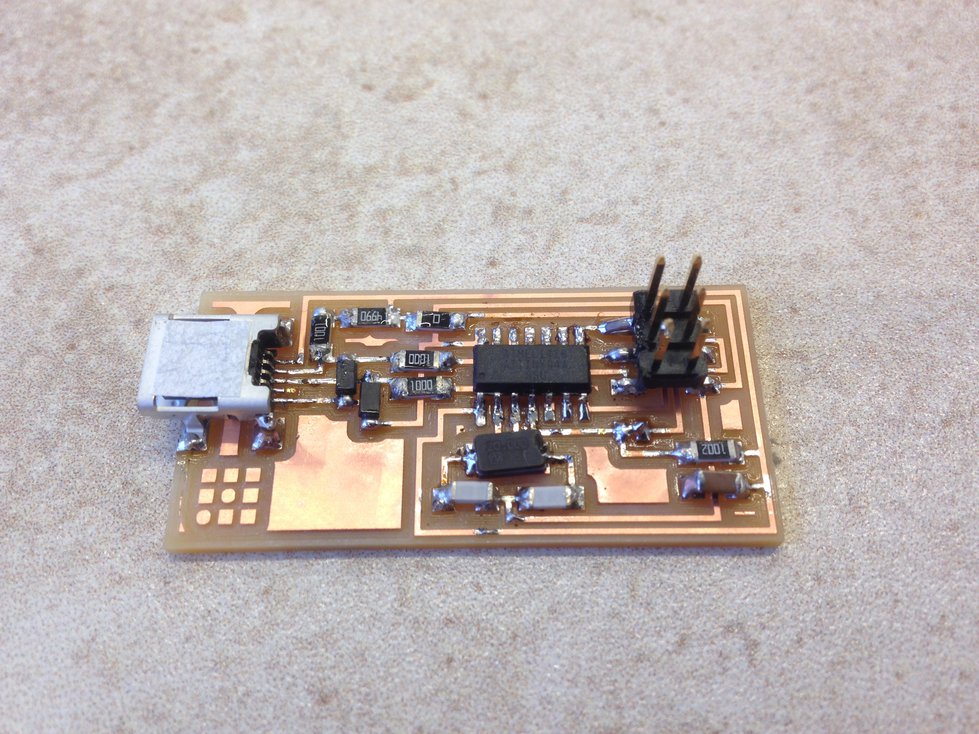

As I soldered components, I tested for continuity to reduce the amount of time

I would have to spend debugging later. After about half an hour of soldering, I

had a board that was ready to be programmed:

Programming

I used Debian 8 (Jessie) and followed the

instructions

for using Ubuntu (Ubuntu is based on Debian). I needed to use sudo when

running some of the commands that talked to USB devices, but besides that, the

instructions worked perfectly.

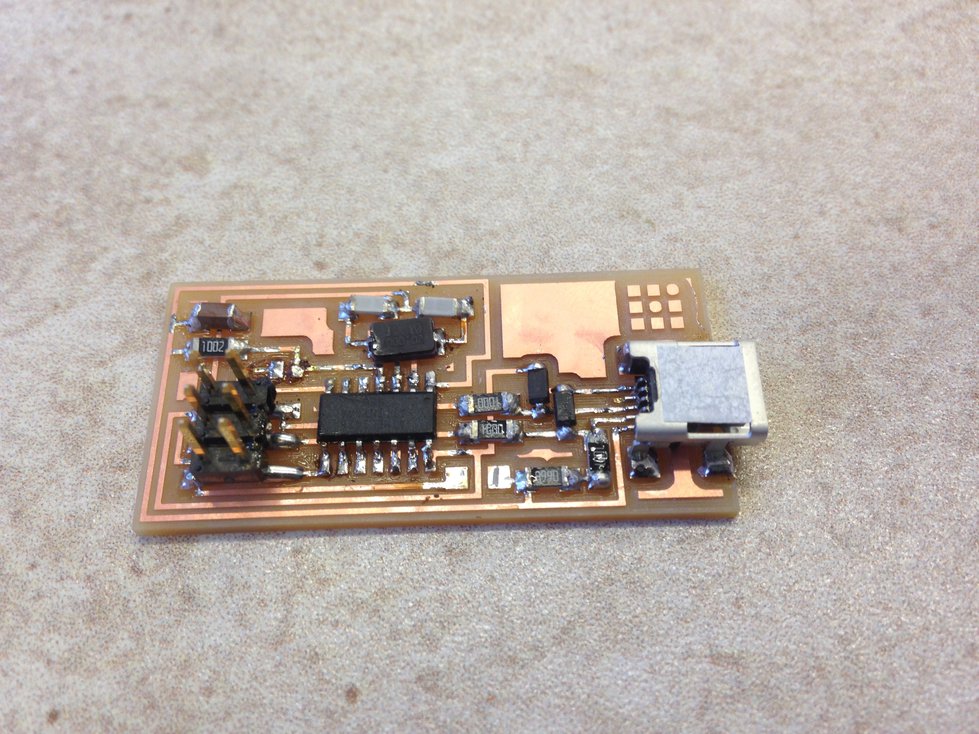

After programming, I removed the zero-ohm resistor and solder joint to finish

my programmer:

21 Sep 2016 · 3 min read

I used the laser cutter to build a press fit construction kit.

I’ve only used a laser cutter once before, and I didn’t really know what I was

doing back then, so in my design, I ended up with loose joints because I didn’t

understand what a laser kerf was. Back then, I compensated with epoxy glue, so

I didn’t end up with a nice friction fit design. This time, I wanted to make

sure I got it right, using a parametric modeling tool and making sure it was

really easy to tune the parameters until everything fit perfectly.

Design

I took the “press fit construction kit” part literally — I designed a part

that was designed to fit together with other copies of the same part, forming a

construction kit that could be used to make all sorts of (mostly very boxy)

shapes.

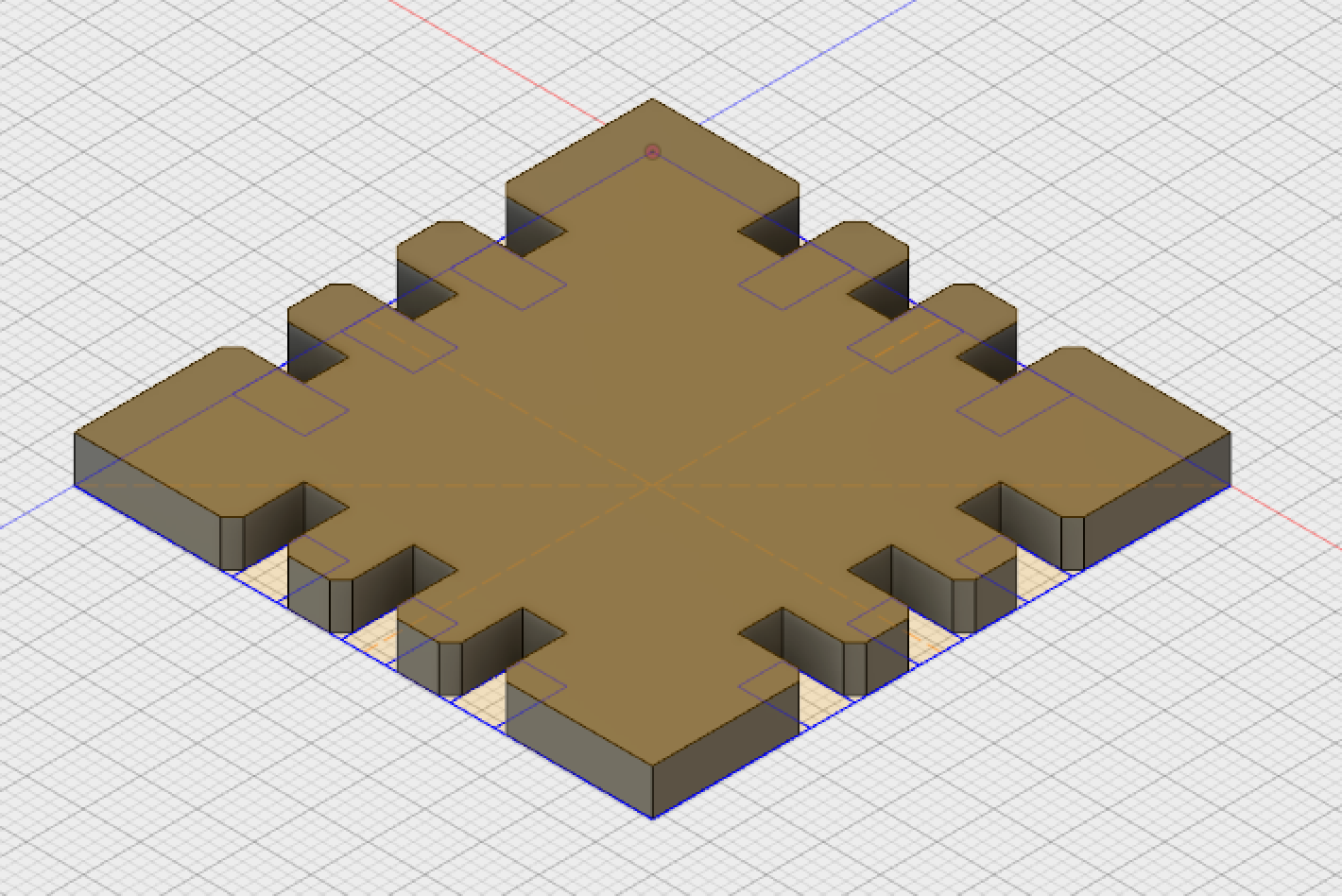

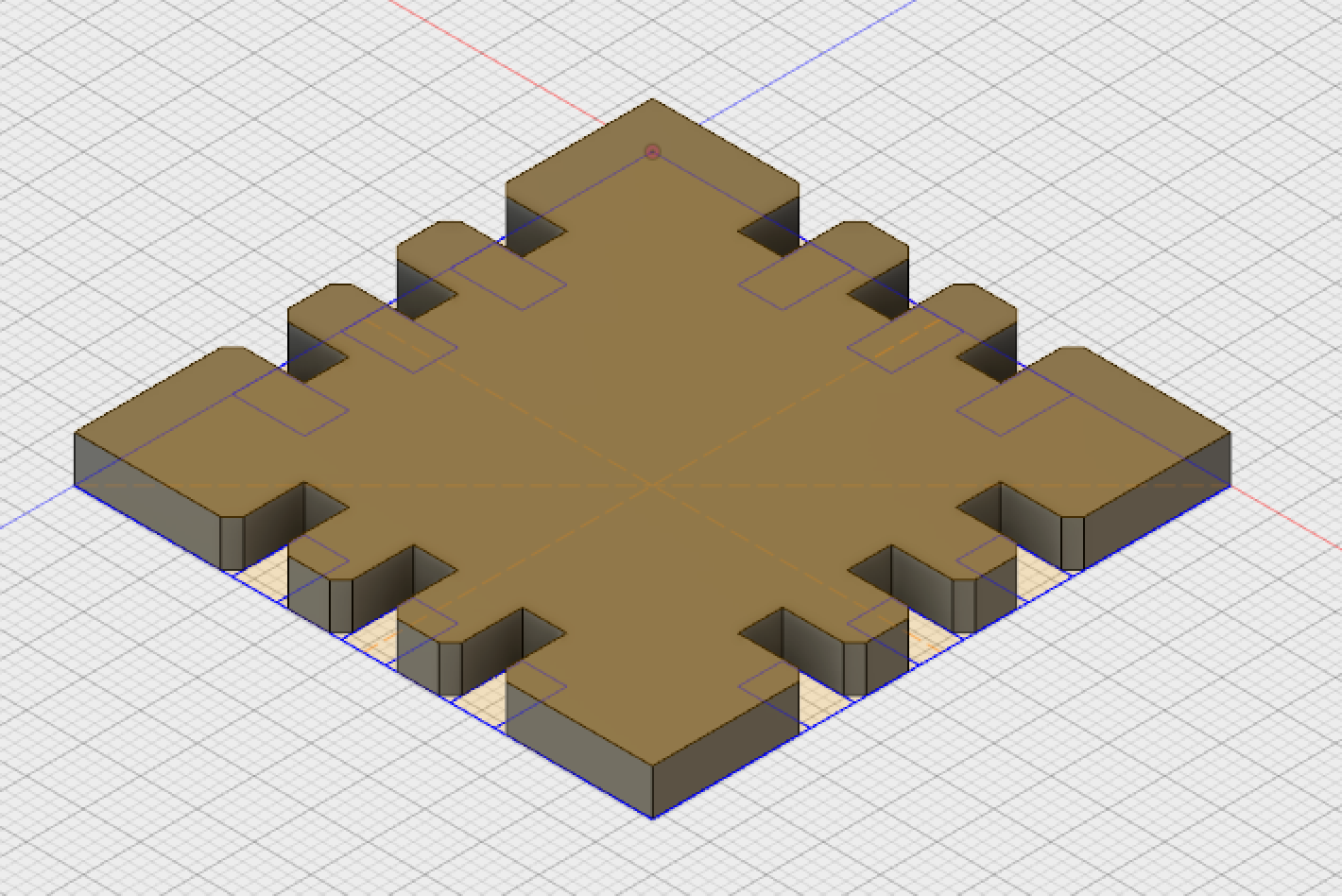

I used Fusion 360 to parametrically model a square shape with 3 cutouts on each

side for slotting into other copies of the same shape. Parameters included

things like piece size, slot spacing, and most importantly, material thickness

and laser kerf width.

Cutting

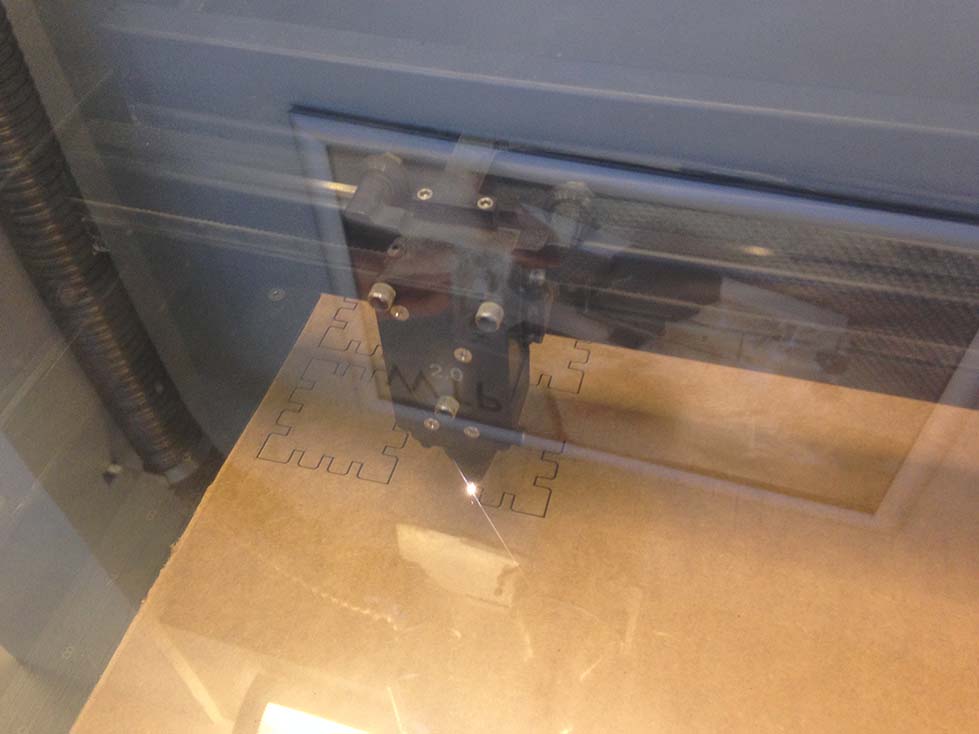

I was cutting this on a Universal PLS 6.75. When cutting, I had to experiment

with laser settings to get good results. Initially, I was using the materials

database, setting the material to balsa wood (it was actually cardboard),

0.160” thickness, with a +50% modifier for vector cutting.

That didn’t make clean cuts through the material, so I switched over to manual

control. I tried using 70% power, 8% speed, 300 ppi, and setting the thickness

to 0.160”. That worked a little bit better, but it wasn’t quite perfect — I

still didn’t get clean edges on some of the pieces I was printing. I tried

boosting the power to 75%, and I consistently started getting nice pieces.

Experimentation

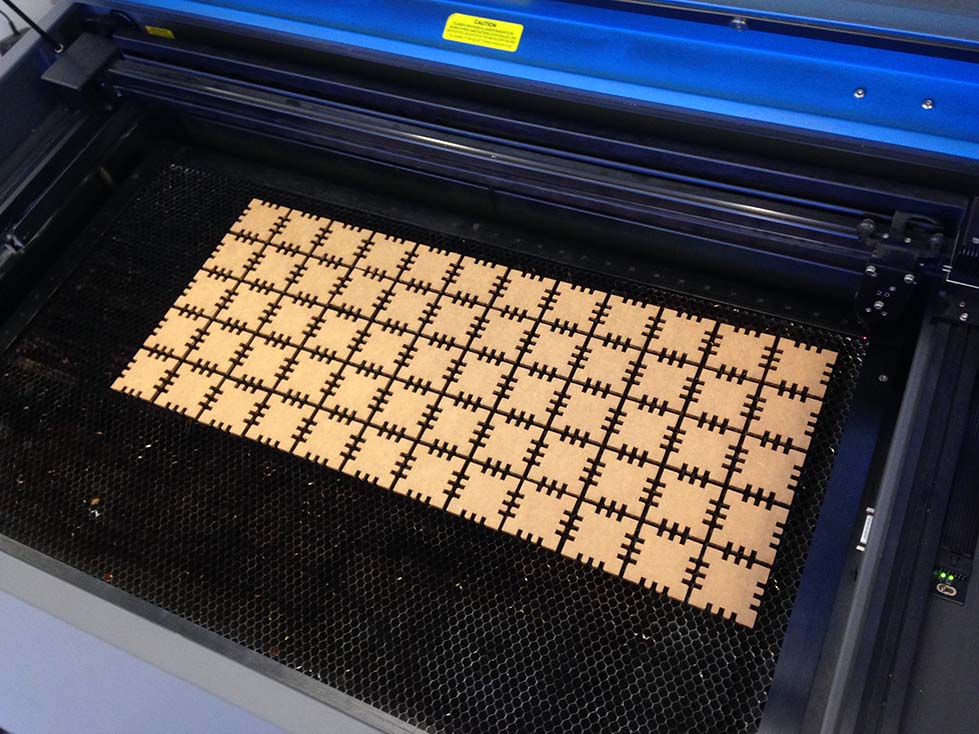

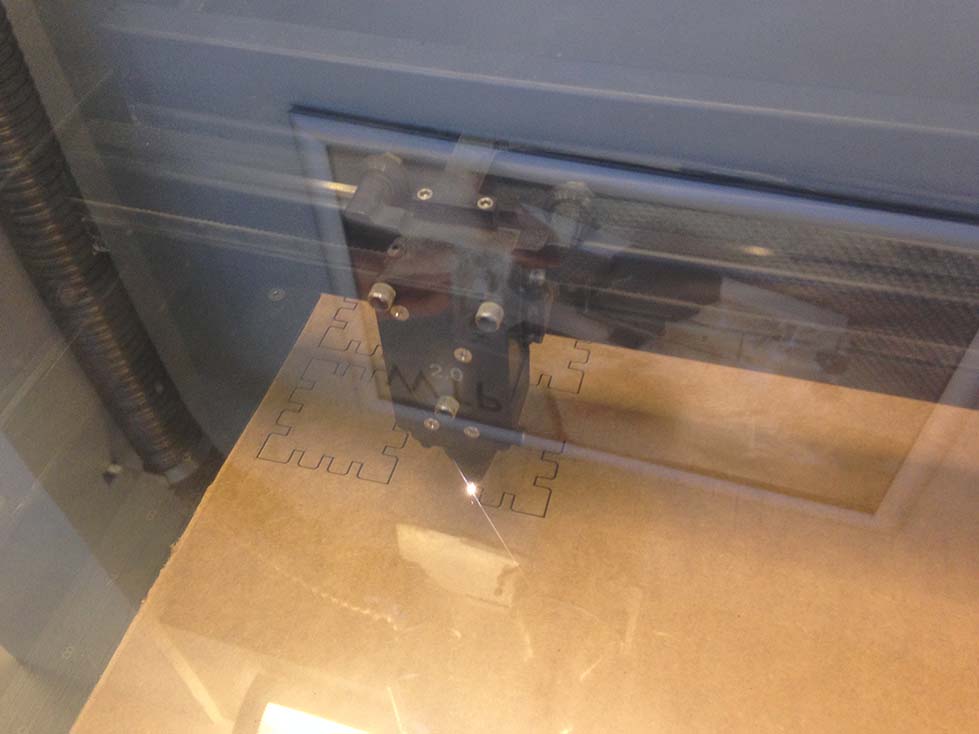

After getting the laser cutter parameters tuned, I did my first real cut:

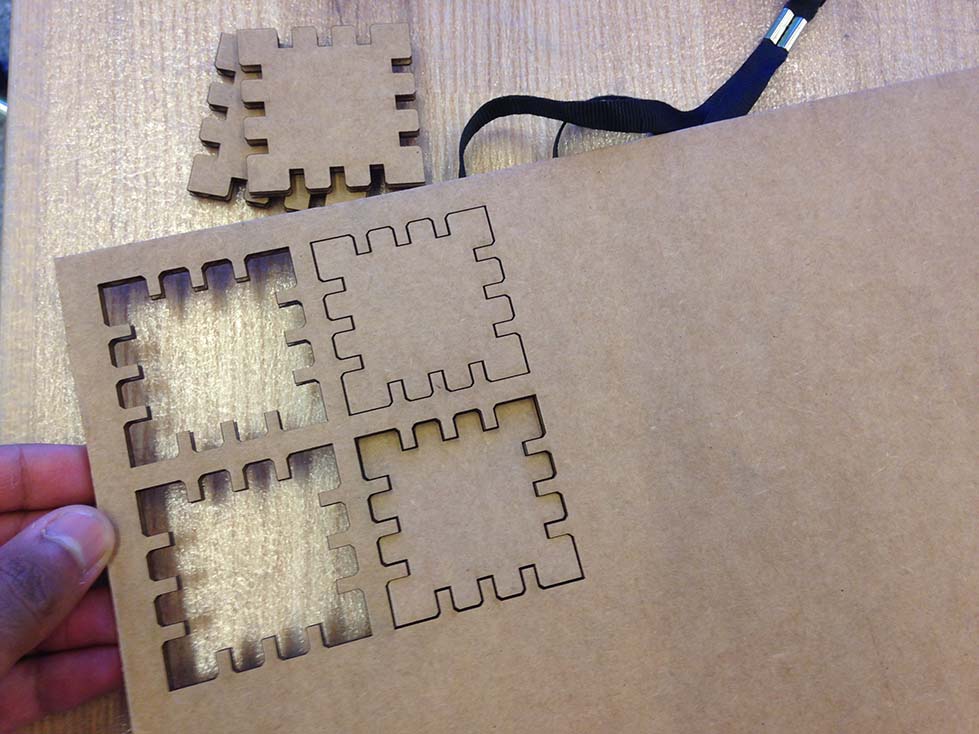

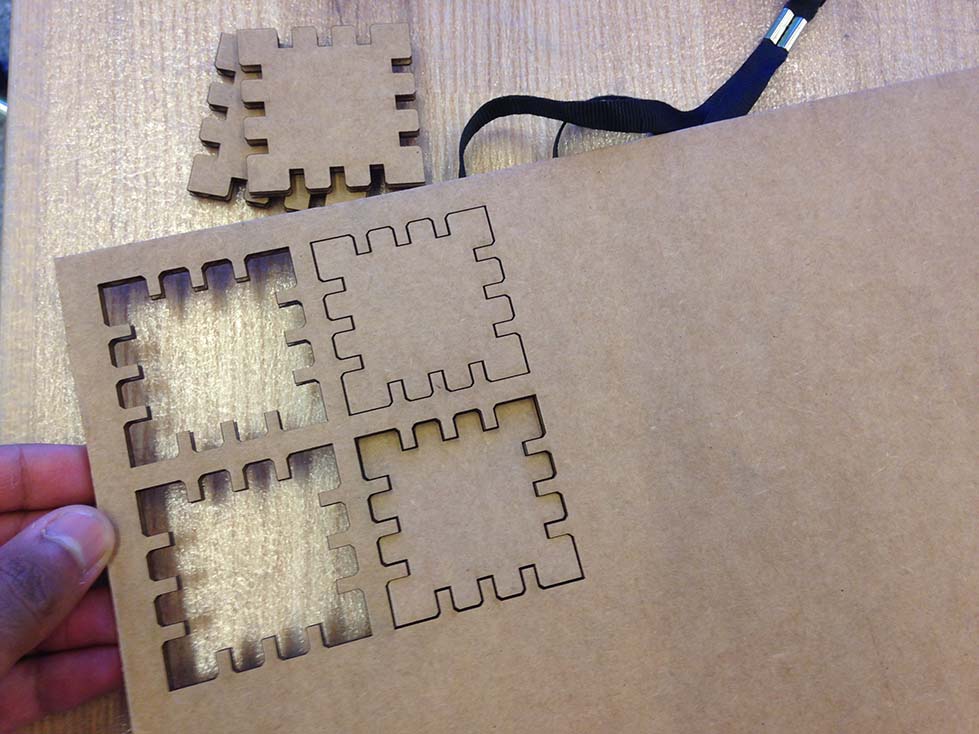

After playing around with the physical pieces, I felt that the notches were too

close together, so I tweaked the design and cut some new pieces. I was happy

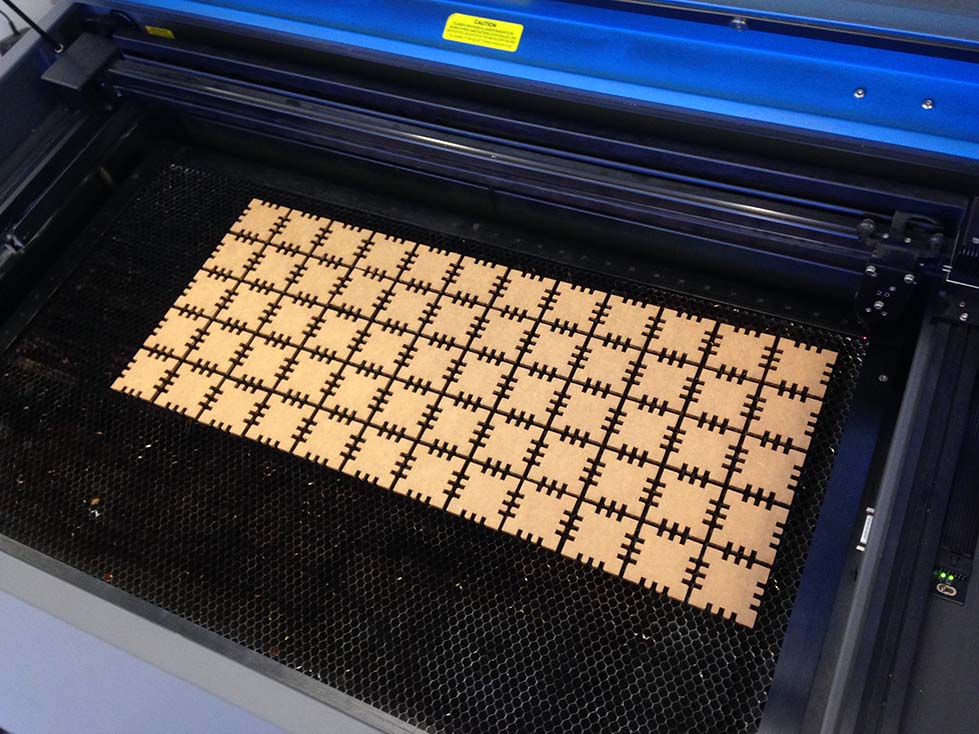

with the new results, so I cut 60 copies:

The pieces looked quite nice when neatly laid out on the laser cutter bed:

Final Result

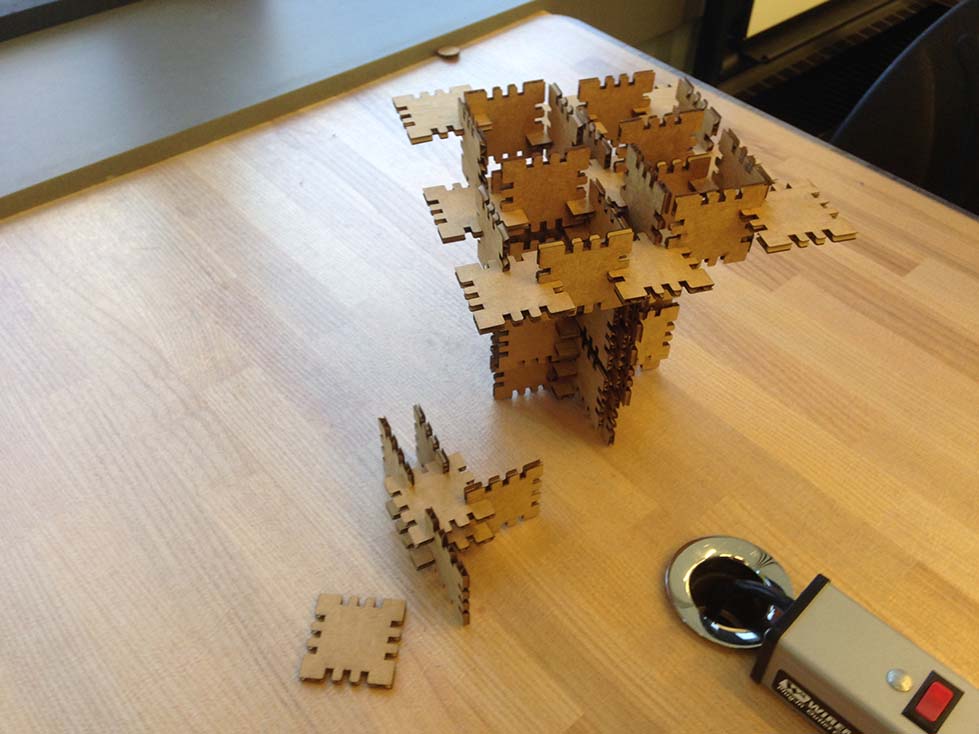

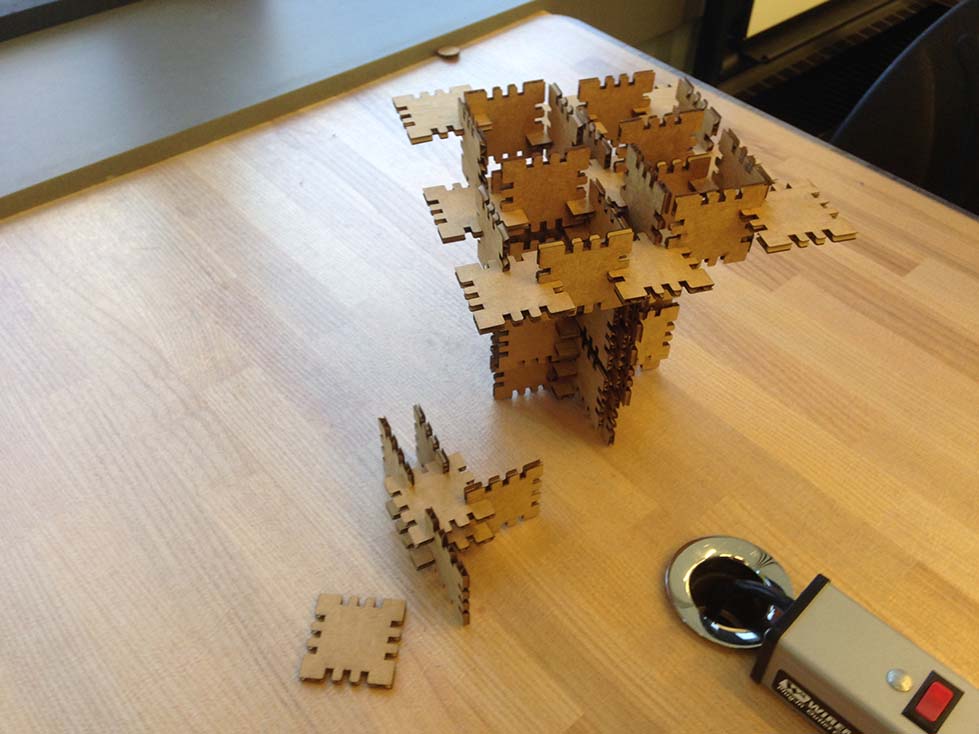

After printing, I ended up playing with the pieces for some time, and I ended

up with this art:

Bonus: Laser Cut Laptop Stand

After getting some experience with the laser cutter, I was interested in making

something useful for myself using the tool. I decided to make myself a laptop

stand, designed parametrically in Fusion 360:

14 Sep 2016 · 1 min read

For my final project, I plan to make a large (~2 meter wingspan) RC glider

capable of serving as an FPV / aerial video platform.

I’ve made a quadcopter before, so I have some experience with building RC

vehicles:

Even though I built the quadcopter myself from parts, it wasn’t from scratch. I

used an off-the-shelf injection-molded frame, and I used an off-the-shelf

flight controller that runs open source software.

For the glider, I plan to do much more from scratch. I plan on buying a motor,

servos, a video camera, a radio receiver, and a radio transmitter. I want to

construct the airframe by hand, and I want to design and build my own flight

controller and program it myself. I’m also going to look into designing and

fabricating my own propeller, which I would like to do if possible.