19 Oct 2016 · 4 min read

This week’s assignment was to make something big using a CNC. We had a single

piece of 4’ x 8’ x 7/16” oriented strand board (OSB) for us to use.

I decided to make something useful for my room. I do lots of outdoor

activities, each requiring different types of shoes. My shoes were taking up

too much floor space, so I decided to design a shoe rack. The first step was to

measure the shoes I had so I could figure out appropriate dimensions for the

shoe rack. I found that the largest shoes were around 12 inches long, 8 inches

wide for the pair, and under 10 inches tall.

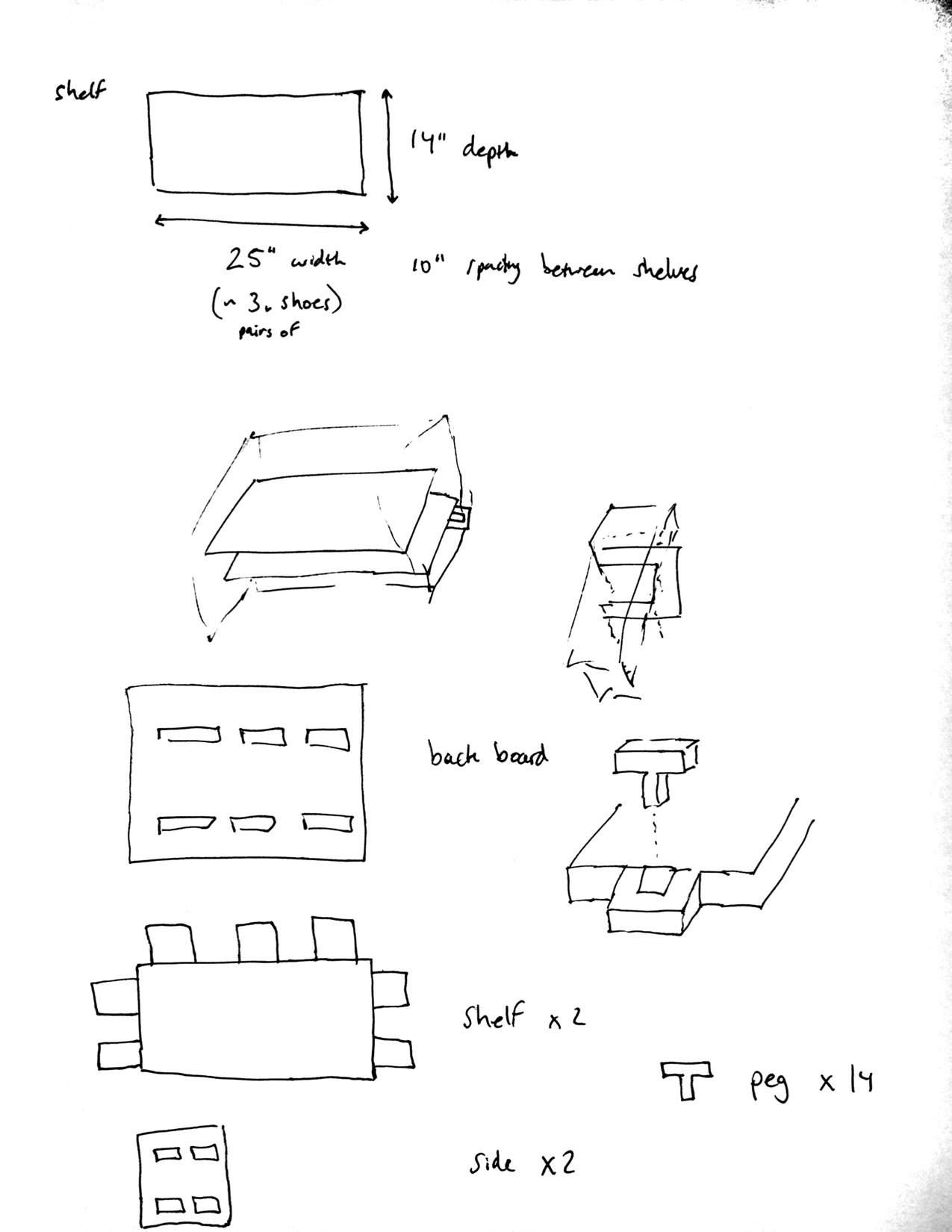

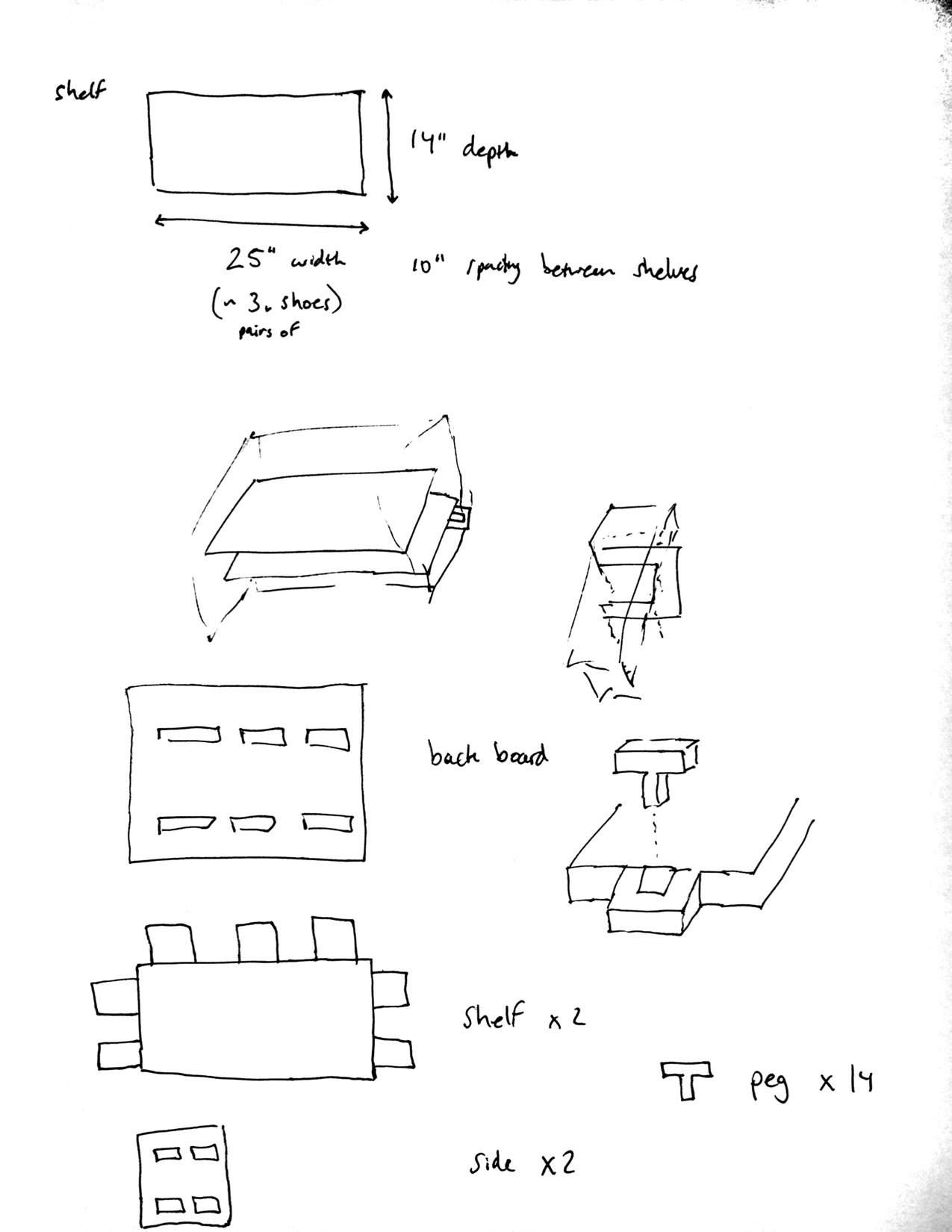

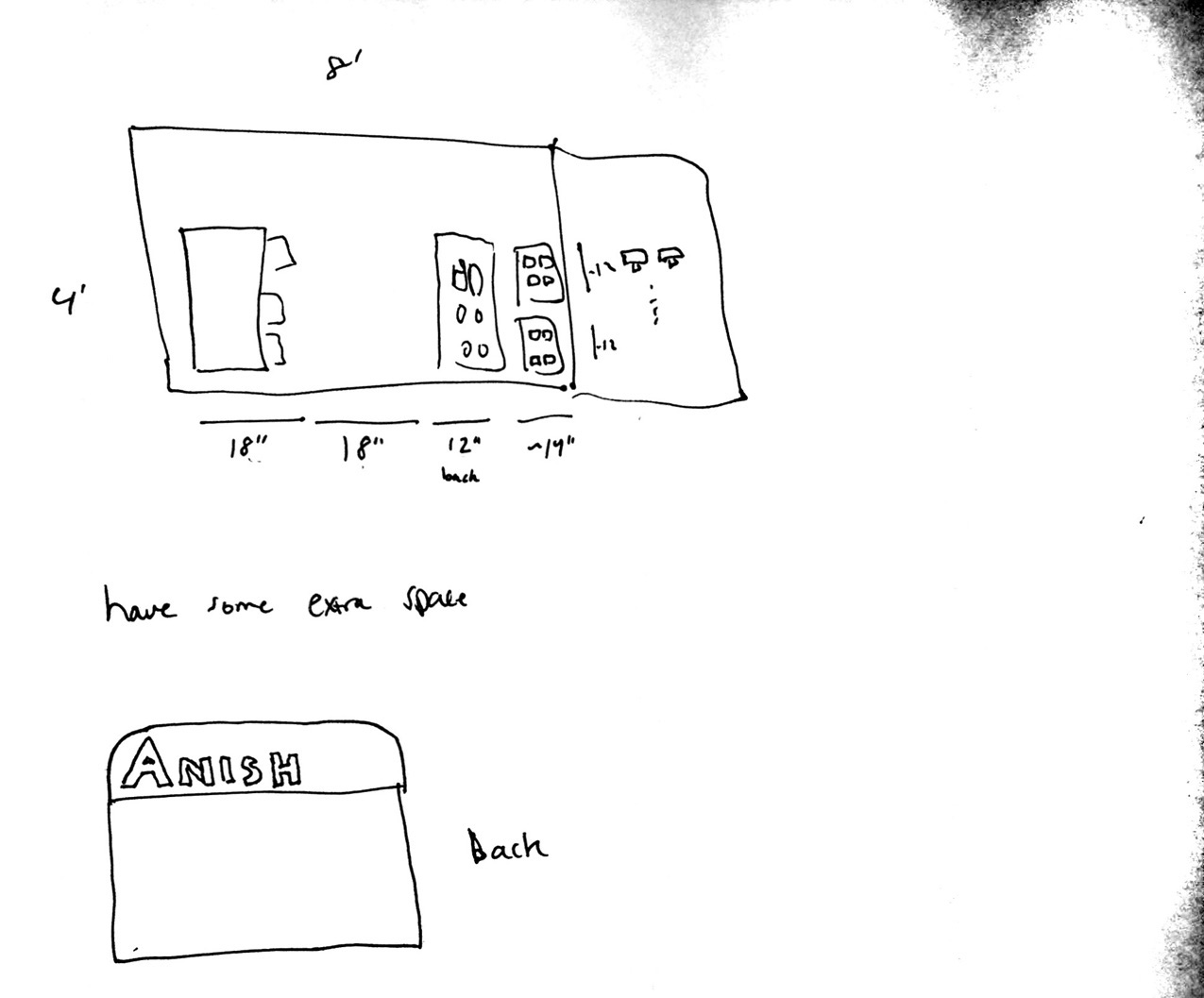

Sketches

After getting this information, I started making sketches on a piece of paper.

I didn’t want to use wood glue or nails or screws, so I initially thought about

making a simple press-fit design. I wasn’t sure how well press-fit would work

with OSB without very high-precision cuts, so I decided to go with a different

design that uses a peg, held in place by gravity, at a 90-degree angle to the

joint:

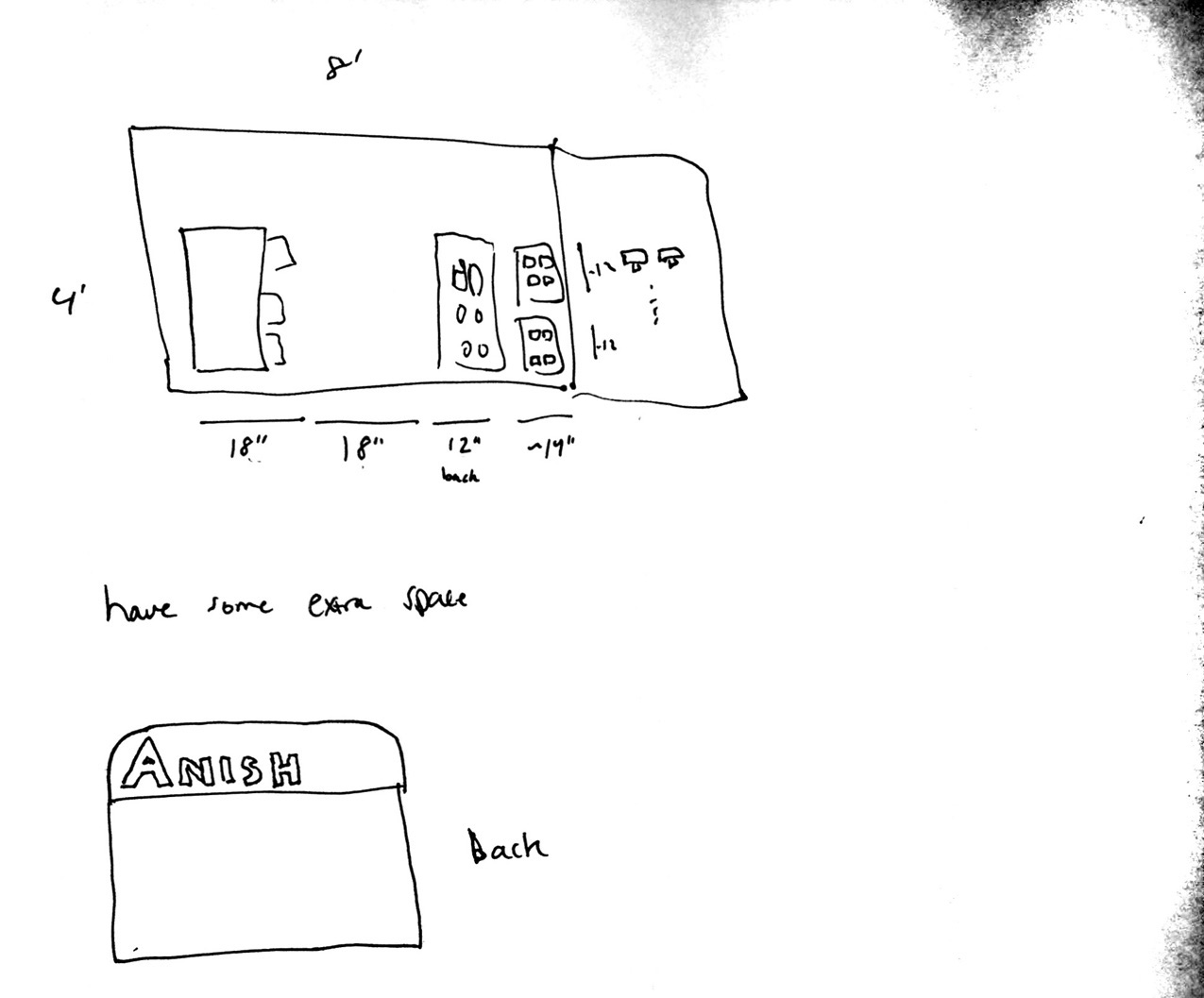

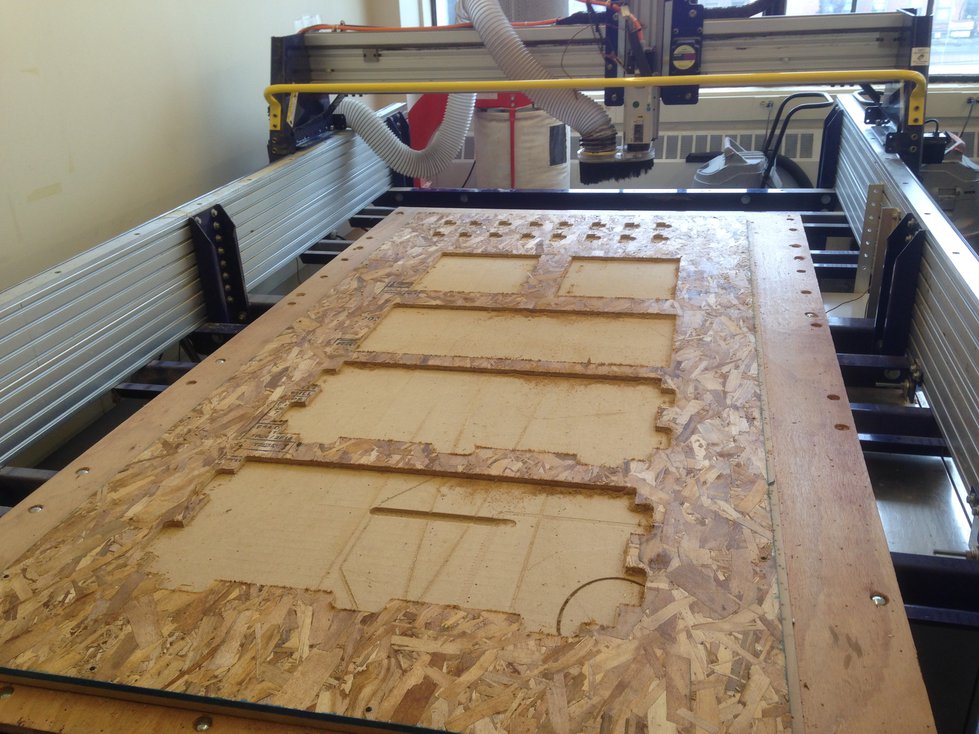

I made sure that everything would fit on my 4’ x 8’ OSB:

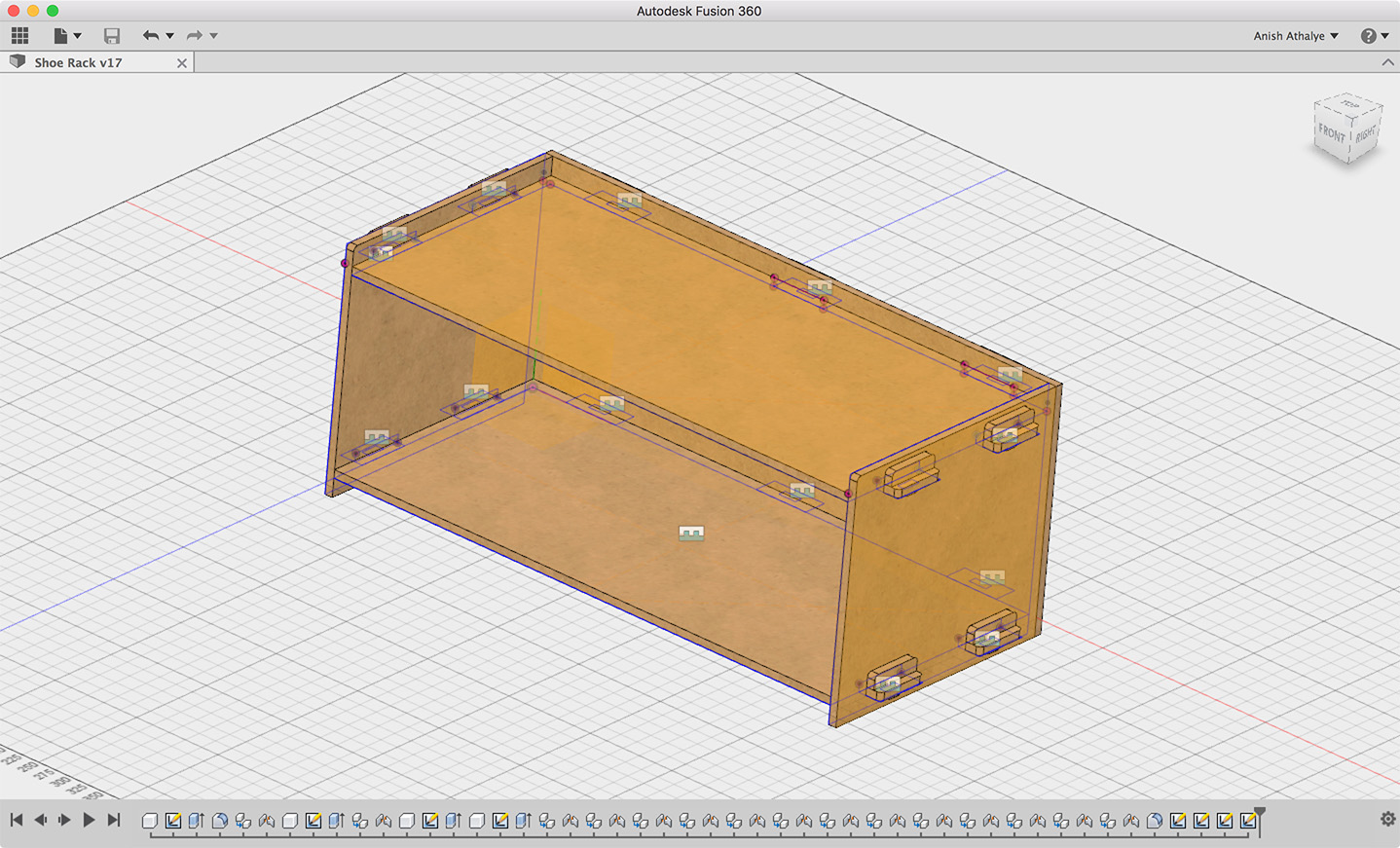

CAD

I decided to use Fusion 360 to design my shoe rack. I had used this software

only once before while designing my press-fit kit, so I was looking

forward to getting some more practice using the tool.

It took me about an hour and a half to complete a parametric design of the

part:

During the process of making the part, I made several mistakes that I had to go

back and fix. One of the bigger mistakes was caught when checking for

interference (overlapping volumes) — I found that my back panel was missing

some cutouts because I had not selected all the holes when extruding the part.

I fixed this using Fusion 360’s parametric timeline, which made the fix really

easy; going through this process also helped me better understand how the

parametric timeline works.

I decided to avoid engraving my name in the piece, because the inexpensive OSB

didn’t seem to work very well for engraving in tests done earlier.

After completing my design, I noticed that I had a little extra space available

on my piece of OSB, so I decided to change what I had in my sketches and change

the width of the shoe rack from 25” to 30”. Thanks to the fully parametric

design, this step took about 10 seconds.

Here’s a render of the final version of the shoe rack:

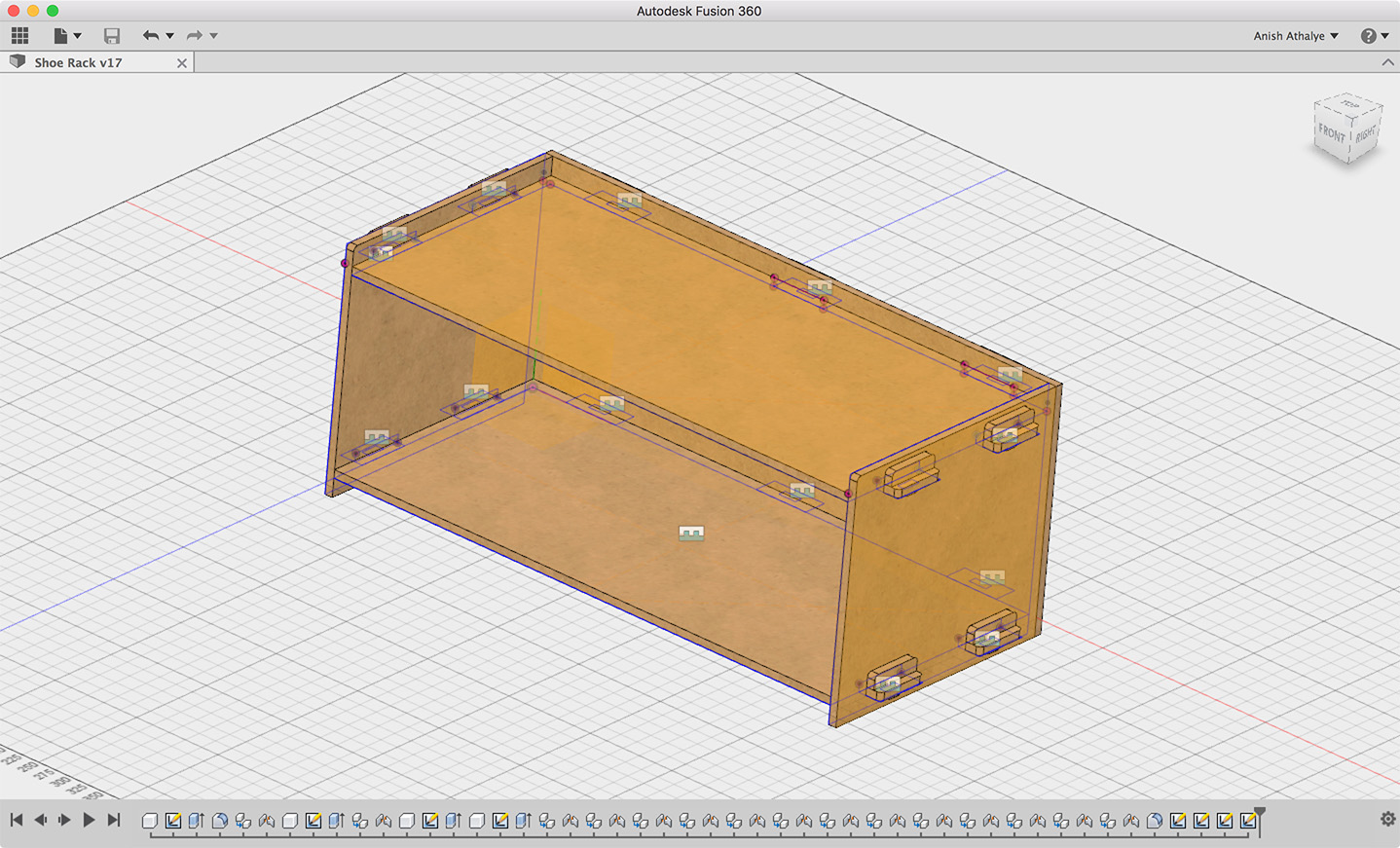

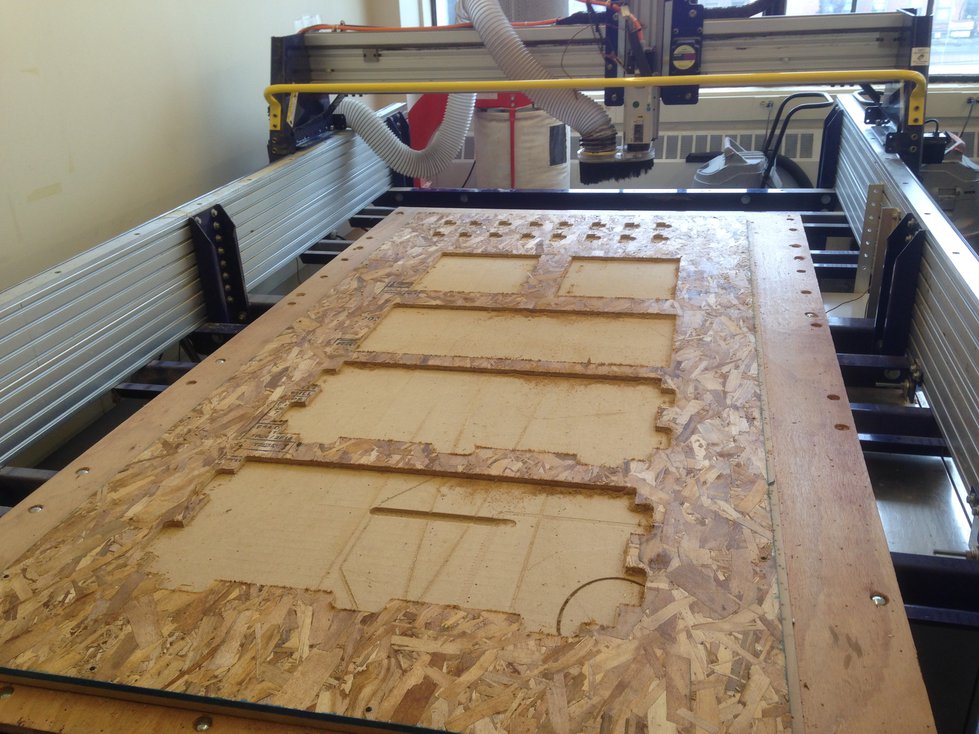

Machining

I used the ShopBot CNC router in the IDC to cut my piece. Here’s a picture of

me and Kevin

Kwok

loading the 4’ x 8’ piece into the machine:

Creating the toolpaths was very straightforward — I cut out the holes first,

and then I cut out the outlines. After creating the toolpaths, I zeroed the

machine and started my job. Here’s a picture of the job in progress:

The entire job took about 21 minutes.

When cutting the small pegs, one of the pieces got sucked up by the vacuum

attached to the end effector! I realized that this was because there was only a

single tab connecting the piece to the rest of the board:

Luckily, this only happened to one piece. I recreated a toolpath for the lost

piece, making sure to include a couple more tabs, and I machined a replacement.

Here’s a picture of the board with all my pieces removed:

And here are all my parts:

I realized that my parts didn’t fit together quite right. Making everything fit

required some manual dogboning using a wood rasp and some hammering together

with a mallet:

Here’s a shot of assembly in progress:

And here’s a close-up of a joint:

Result

Here’s the final result — a shoe rack, fully assembled:

It turned out really well — everything fit very snugly — it didn’t wobble

or anything. The whole project came together without using any wood screws,

nails, or glue!

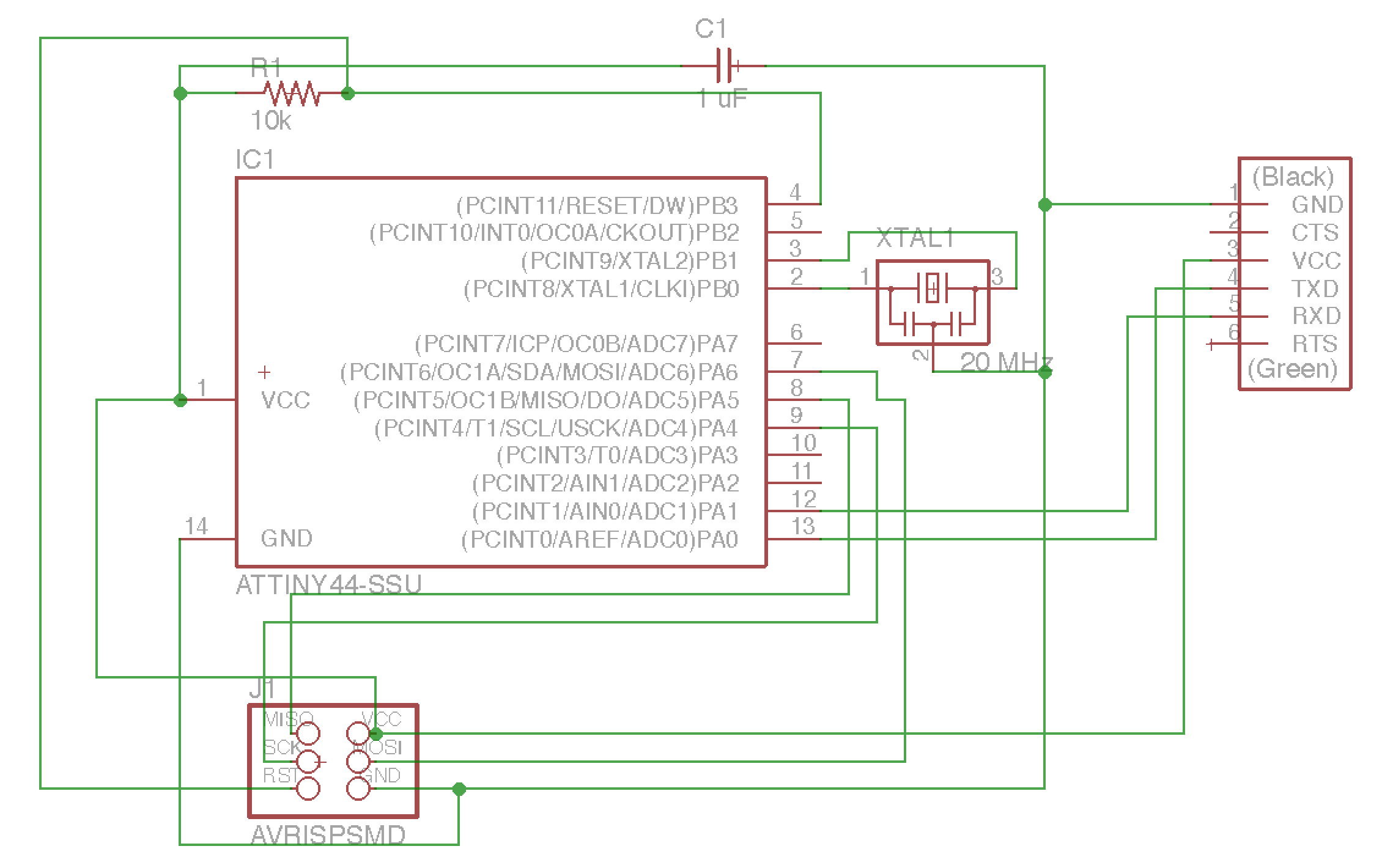

12 Oct 2016 · 4 min read

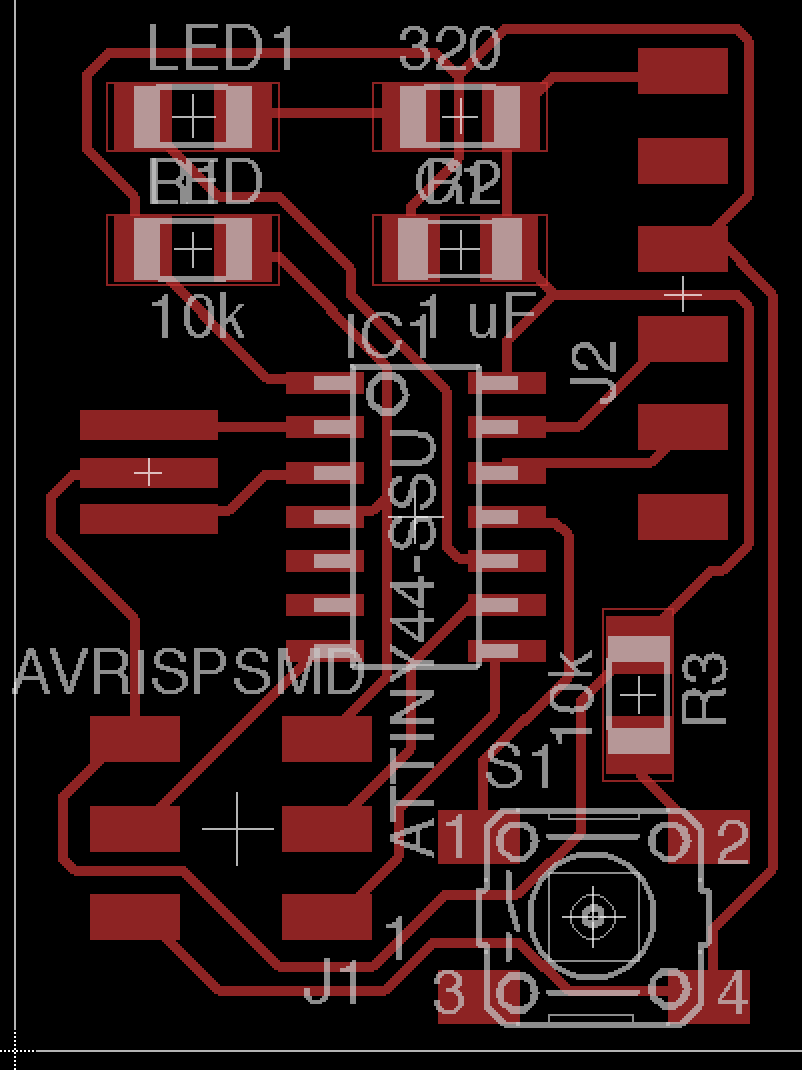

This week’s assignment was to redesign the echo hello-world

board

and fabricate the modified version.

I decided to use the EAGLE PCB Design software, because

it seemed like an industrial-strength tool for PCB design. Also, I had used it

once before (just for making schematics, though), so I was more familiar with

it than I was with other tools!

Schematic

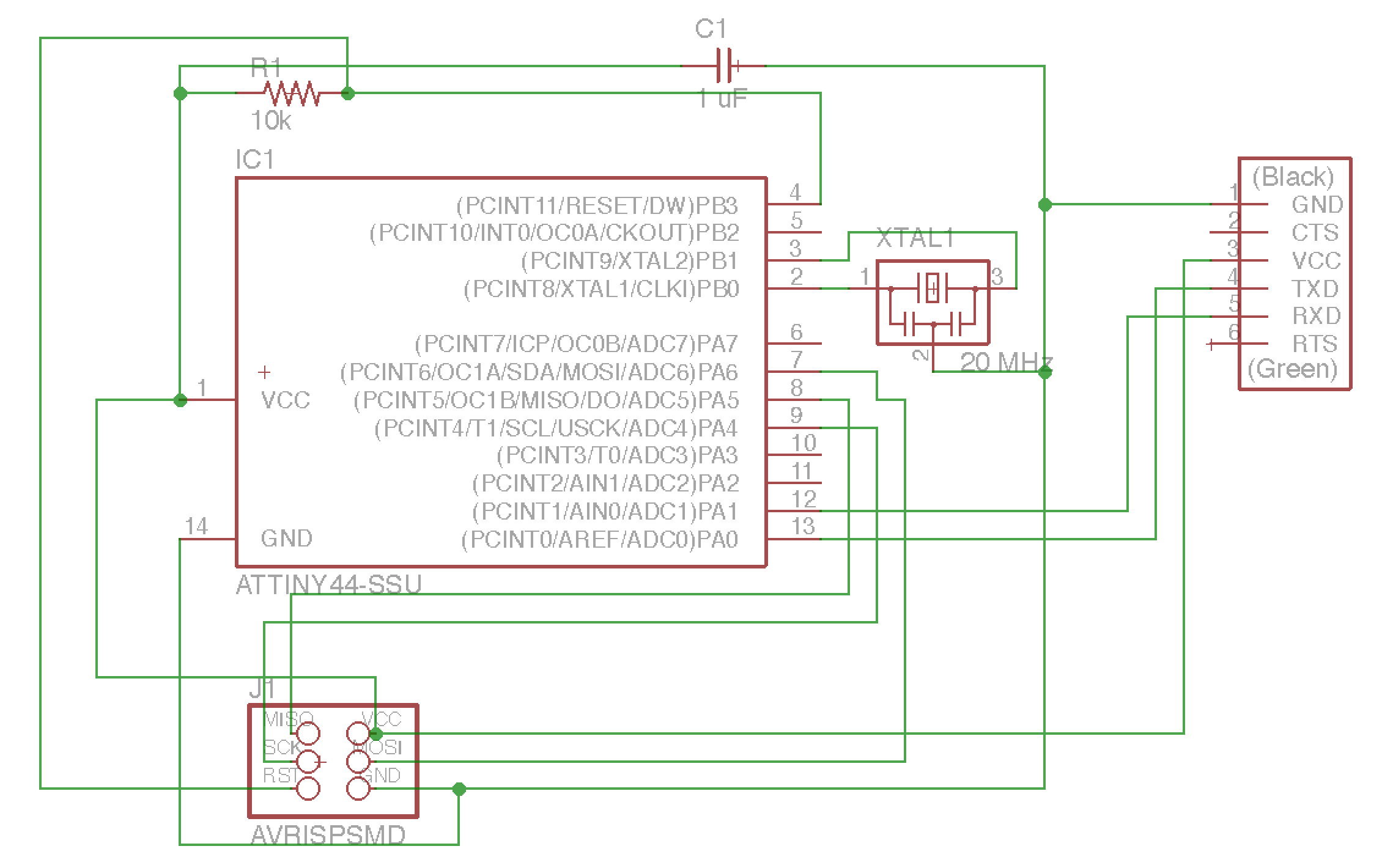

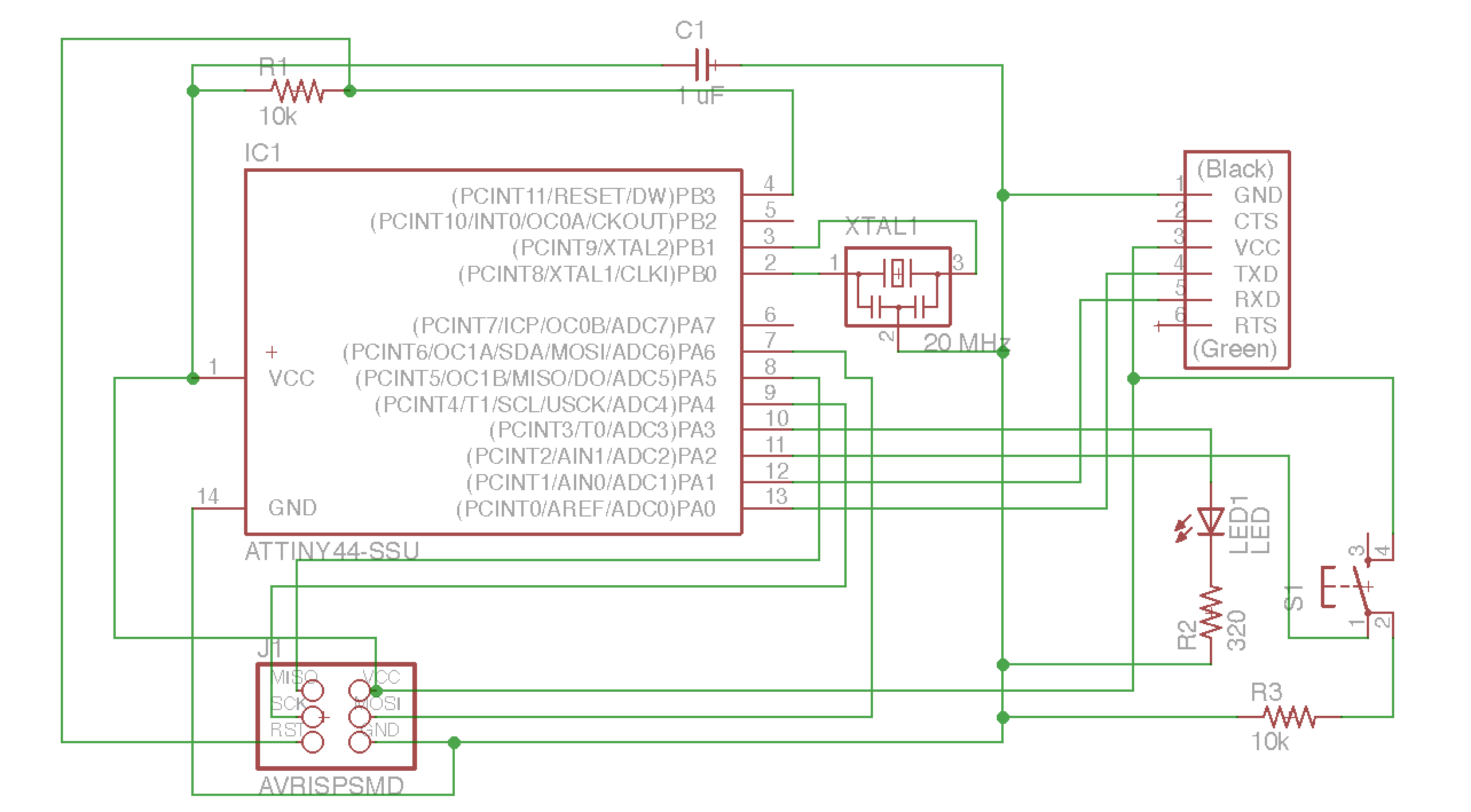

I started out replicating the schematics of the echo hello-world board:

I added a button and an LED to the design.

When adding the LED, I made sure to put it in series with a current-limiting

resistor. To estimate the resistance required, I considered using a blue LED,

which has a voltage drop of about 3.4 volts. With a desired current of 5 mA

through the LED, a (5 V - 3.4 V)/(5 mA) = 320 Ohm resistor is required.

When adding the button, I decided to use a pull-down resistor configuration.

Essentially, the microcontroller’s input should always be driven high or low,

and using a pull-up or pull-down resistor with the button is a way to achieve

that. I chose to use a 10k Ohm resistor.

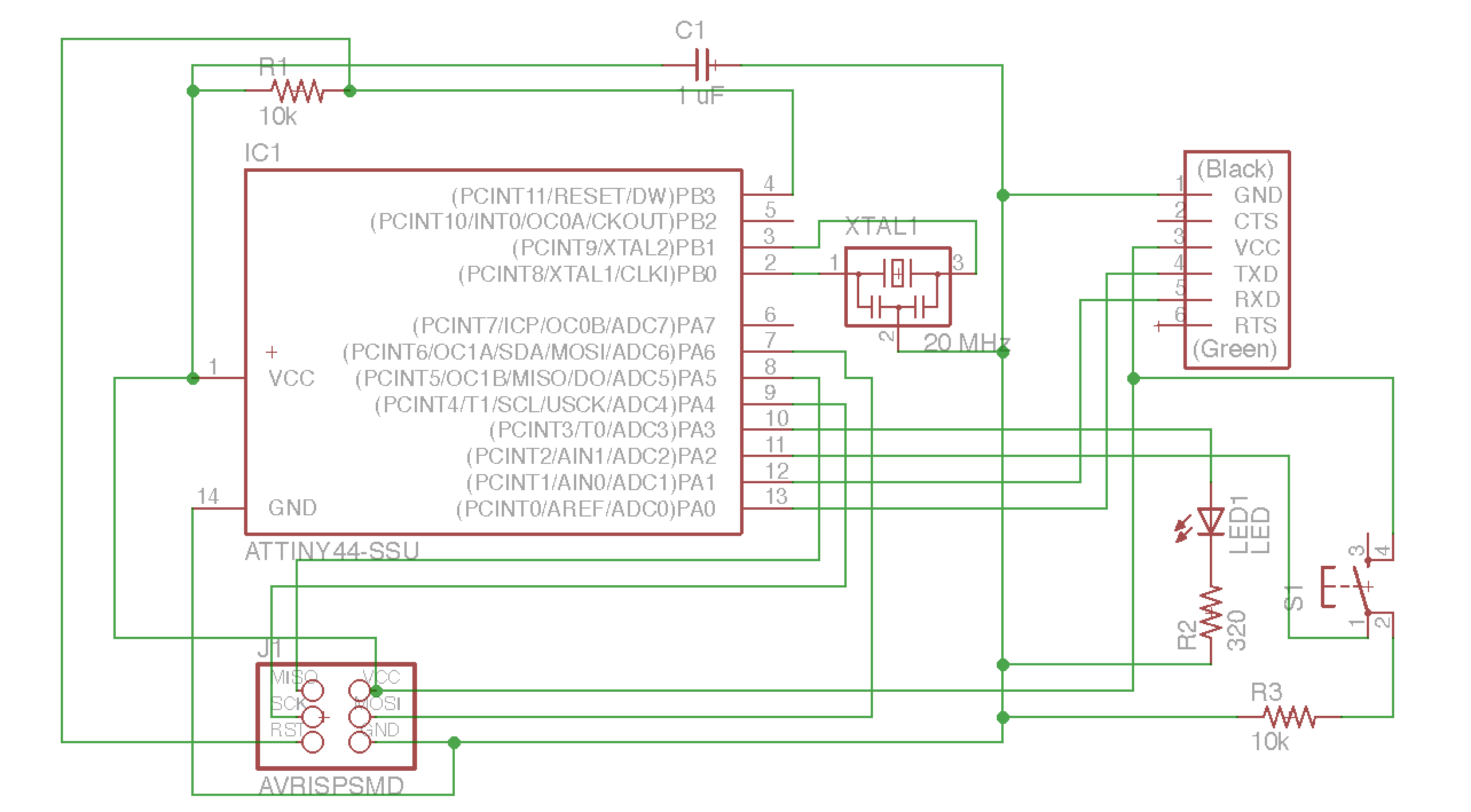

Here is the final schematic with the button and LED added:

Board Layout

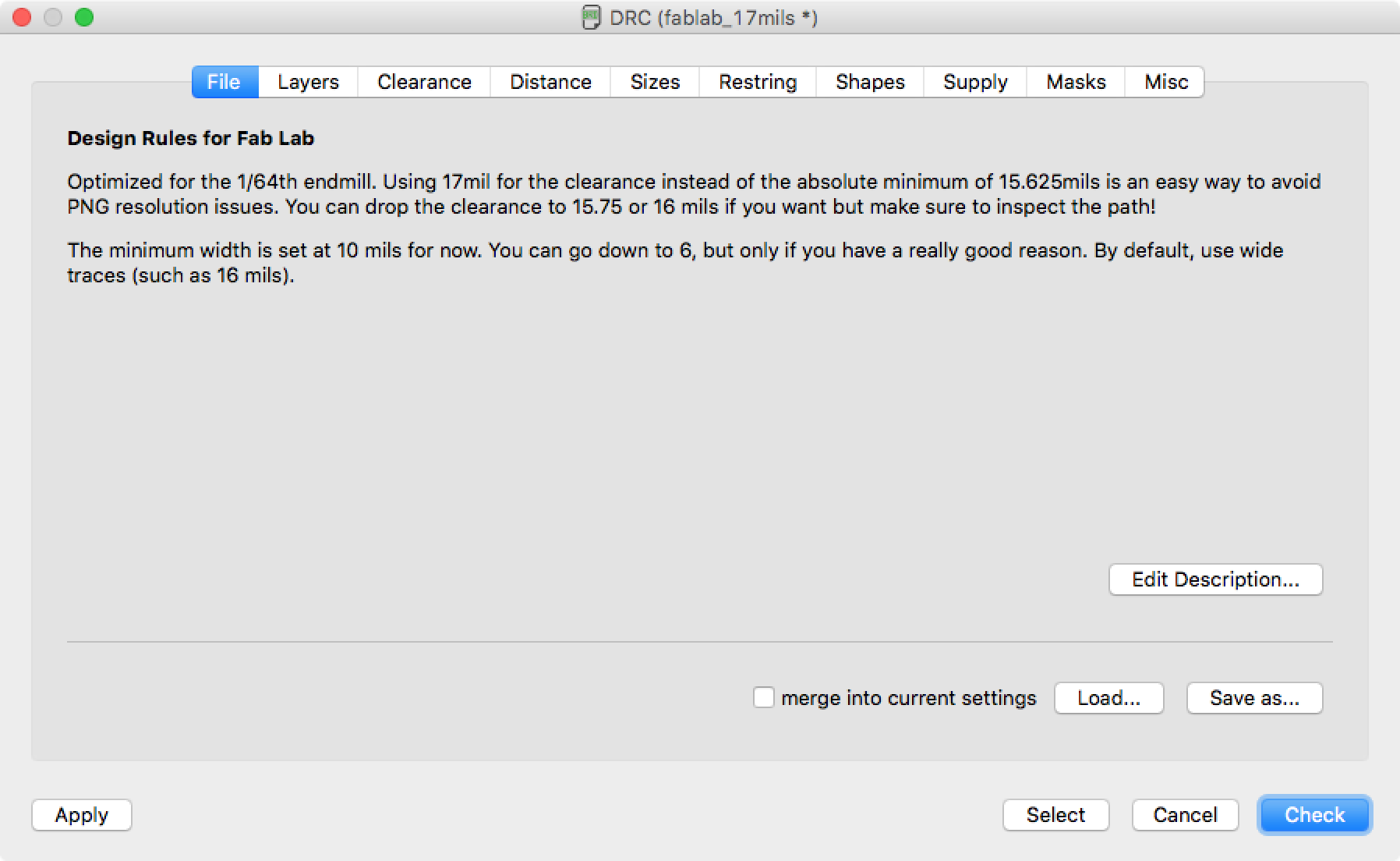

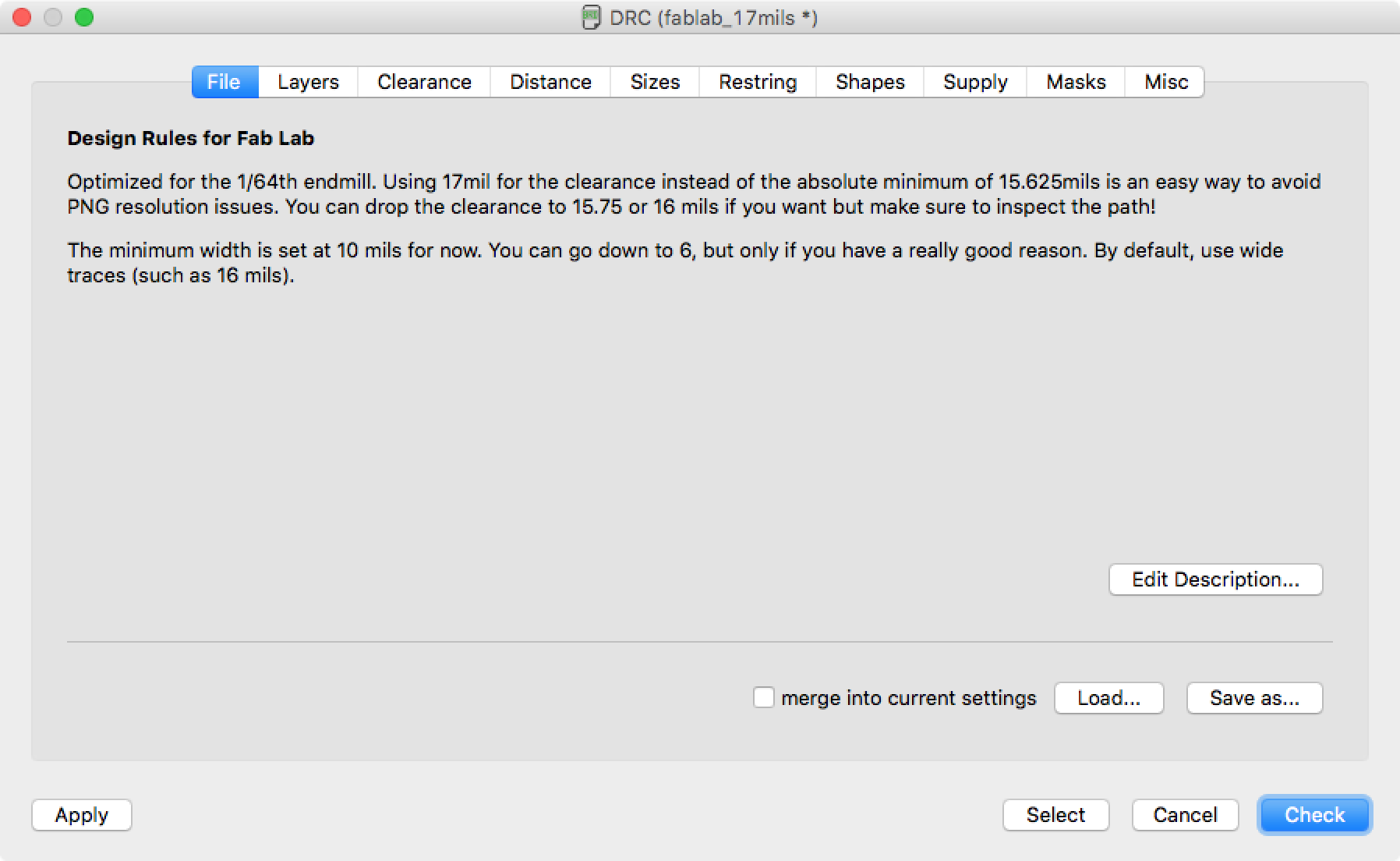

After designing the schematic, I did the PCB layout and routing. The first step

was to import the Fab Lab PCB design

rules

into EAGLE so that the design would be optimized for the 1/64” endmill used on

the SRM-20 (which would be used later for production):

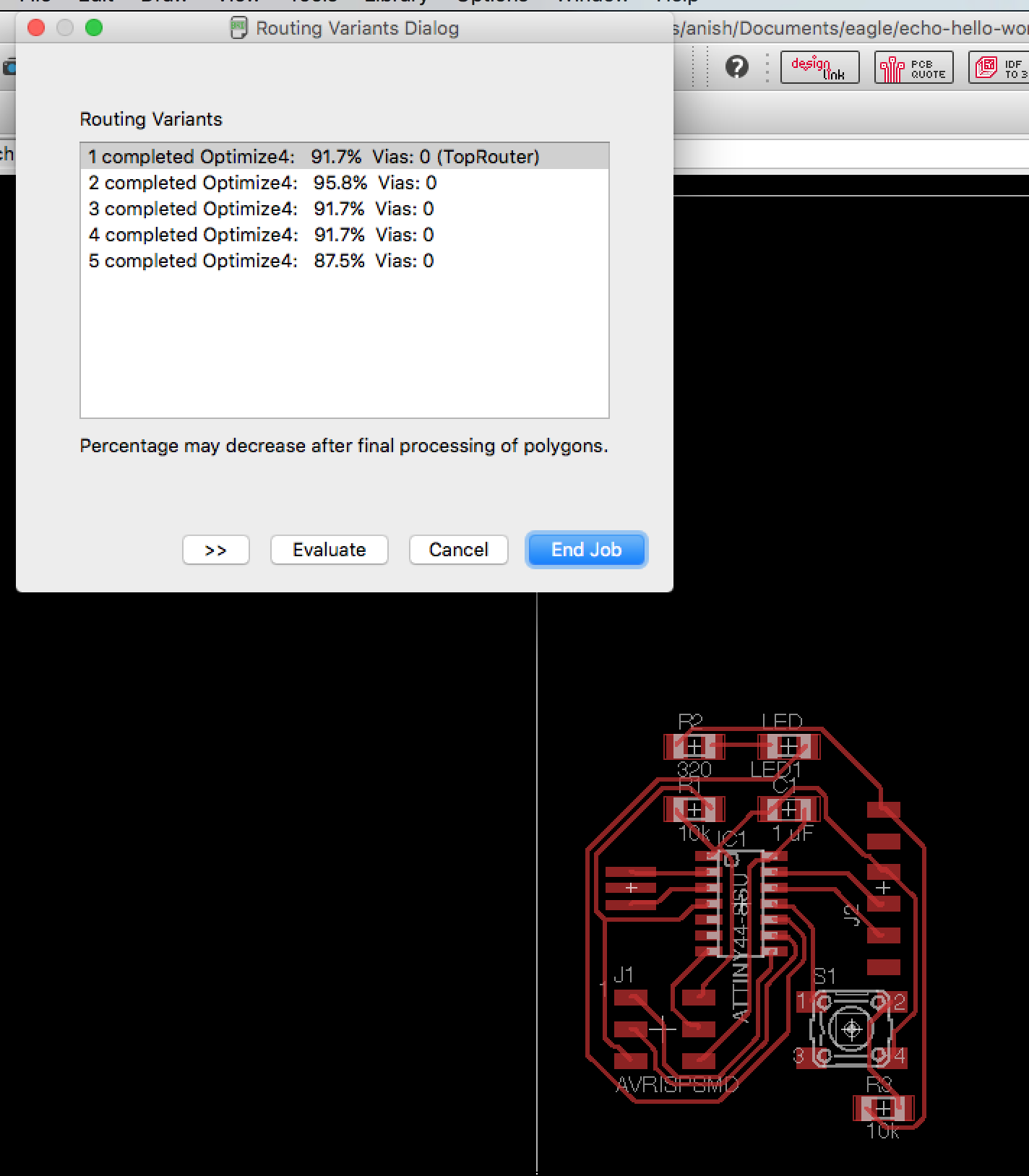

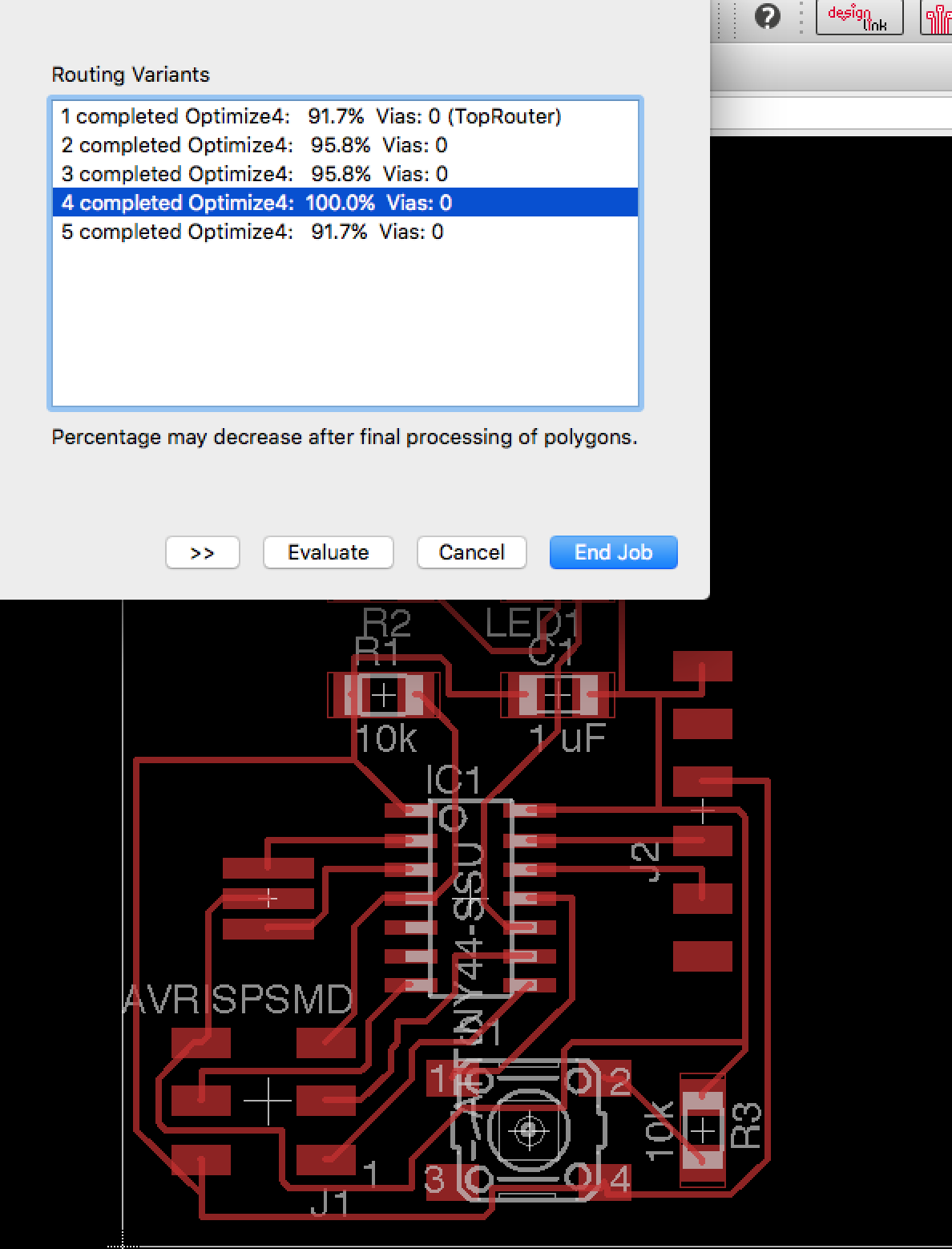

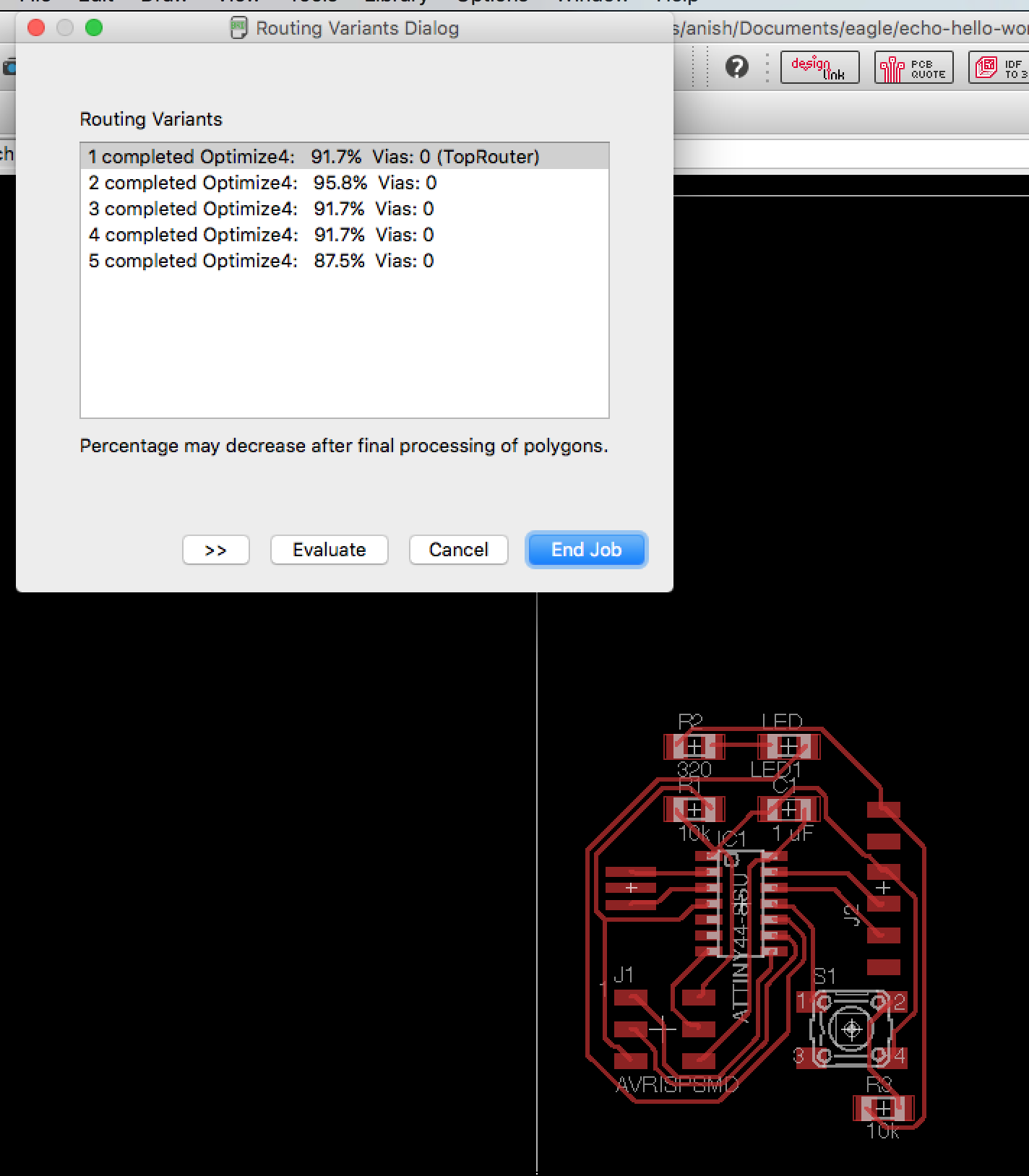

Next, I laid out the components on the PCB and tried to use EAGLE’s autorouter,

which attempts to automatically figure out how to wire everything together

while respecting the design rules and avoiding things like crossing wires. By

default, the autorouter uses 2 layers, but I disabled the 2nd layer, which

forced the autorouter to route for a single layer PCB. In my first try, the

autorouter couldn’t route all the wires (none of the routing variants are at

100%):

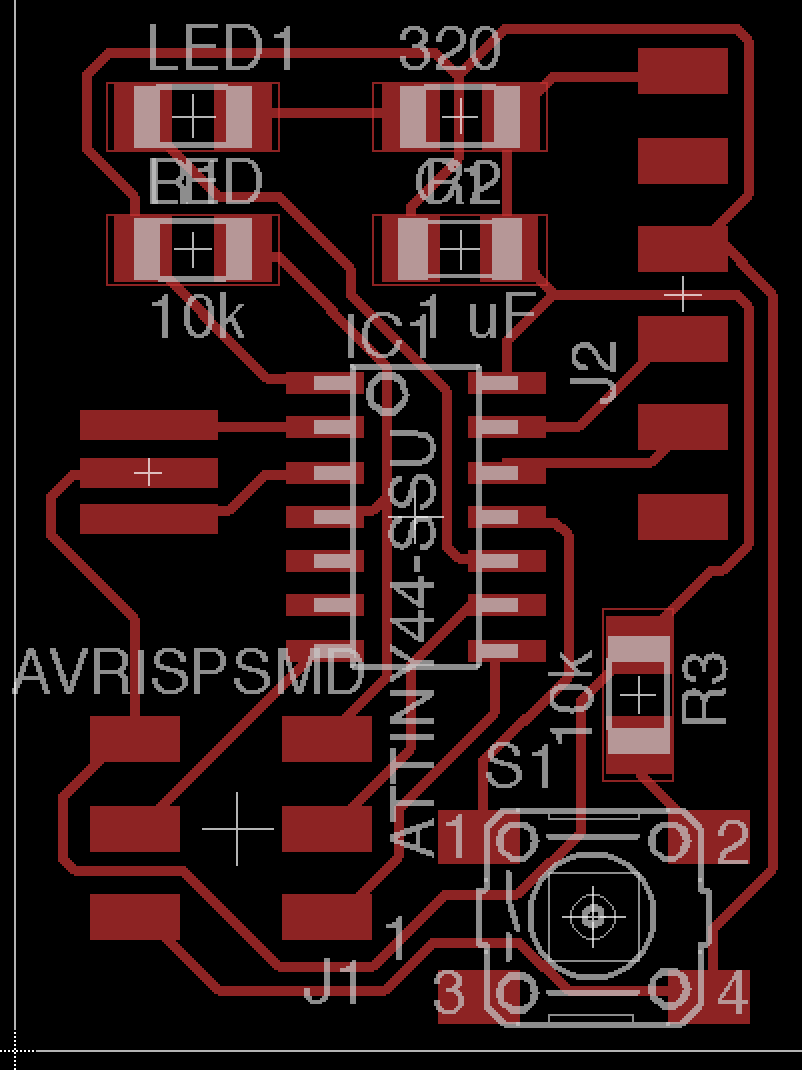

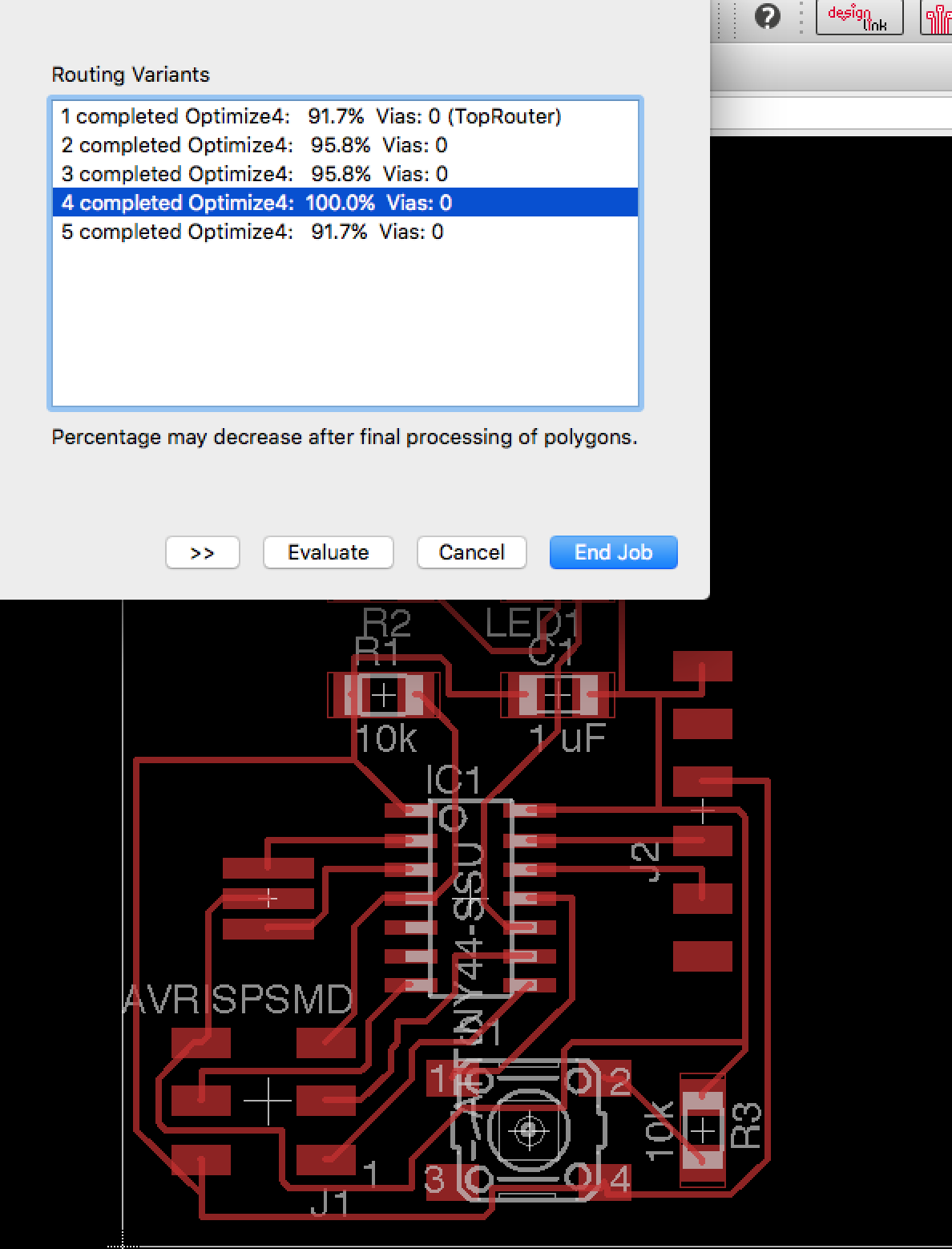

After moving and rotating parts to try to improve the design, I tried the

autorouter again, and it managed to route all the traces:

Now that I knew that routing was possible and that the autorouter could find a

valid routing, I played around with the design to try to get it to be a little

more compact. Here are the final results:

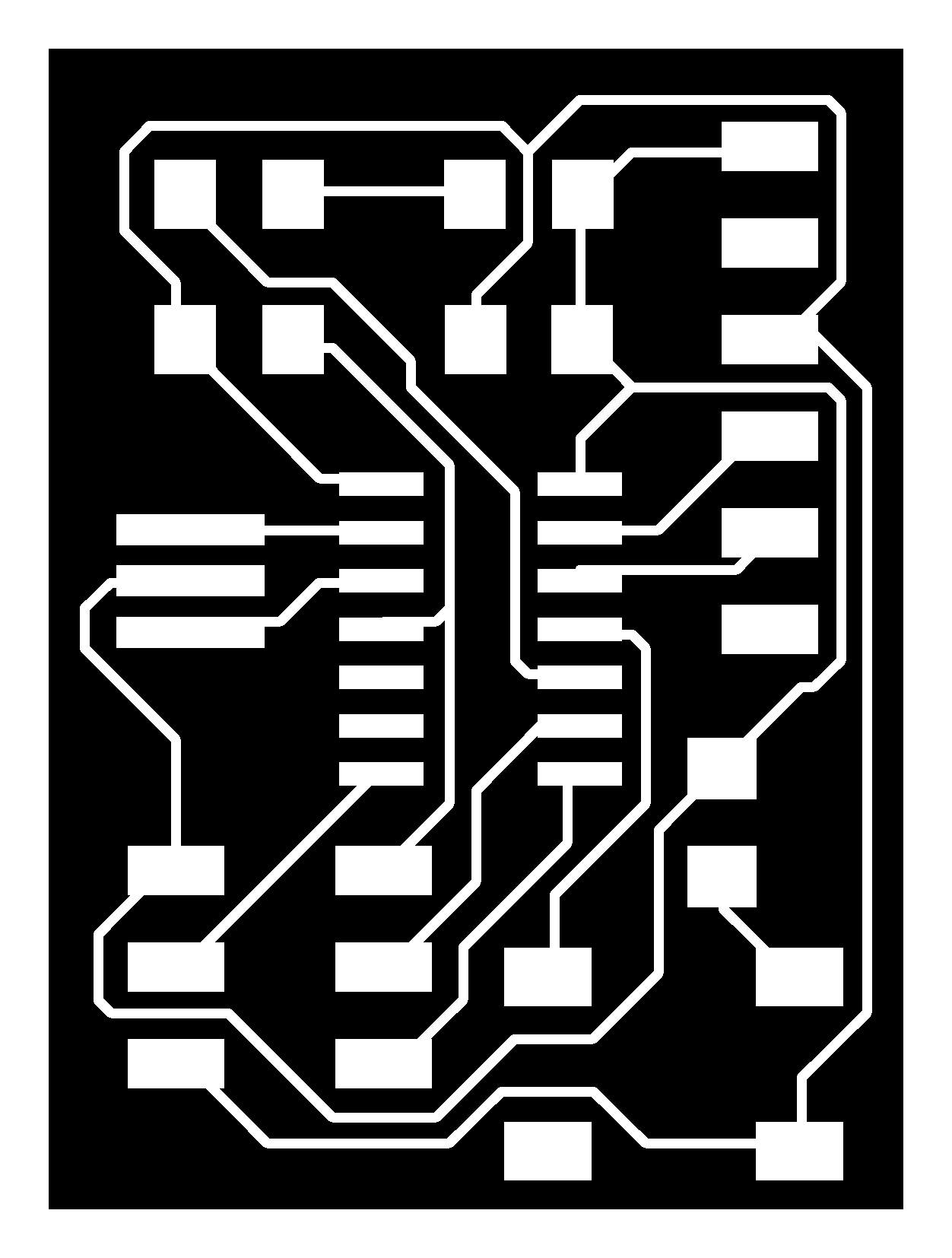

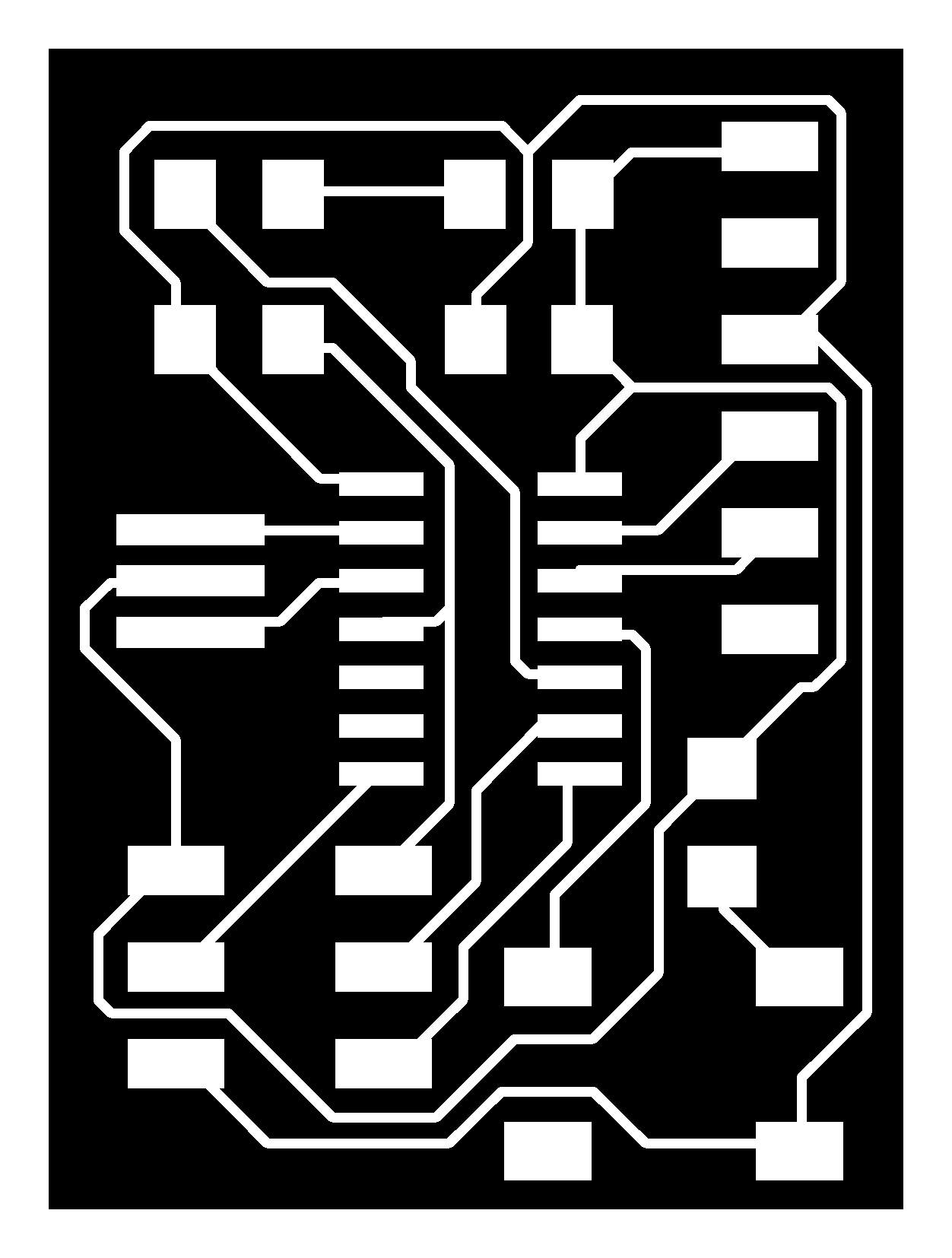

Exporting

Now that I had a PCB layout I was happy with, I needed to figure out how to

export it so that I could mill a PCB. Eagle can export PNG images of PCBs — I

just needed to disable all the other layers in “View > Layer Settings” so that

I could get a clean image.

I exported an image at 1270 ppi, imported it into Photoshop, cropped it

slightly, and made a 64 pixel border for the PCB outline. Here is the final

result:

The traces can be found here, and the outline can be found here.

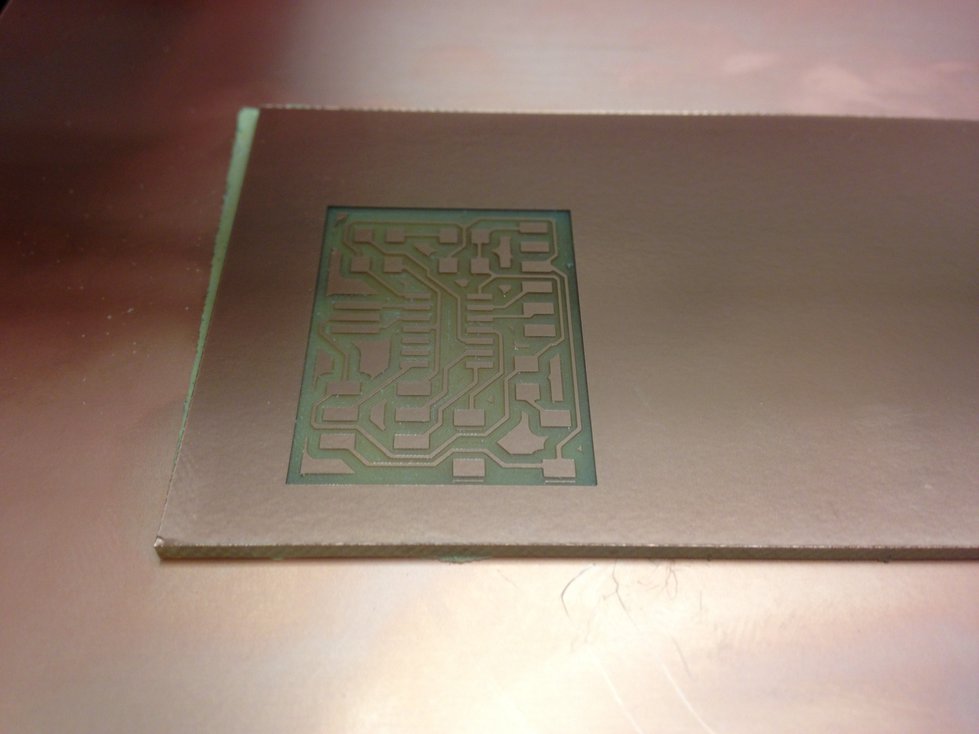

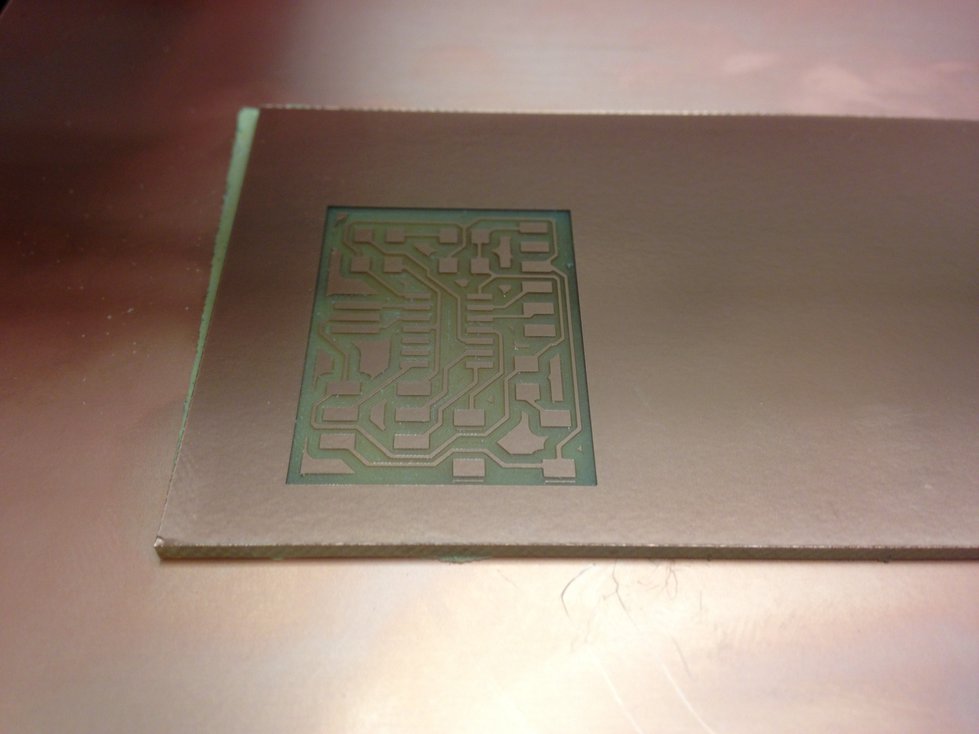

Fabrication

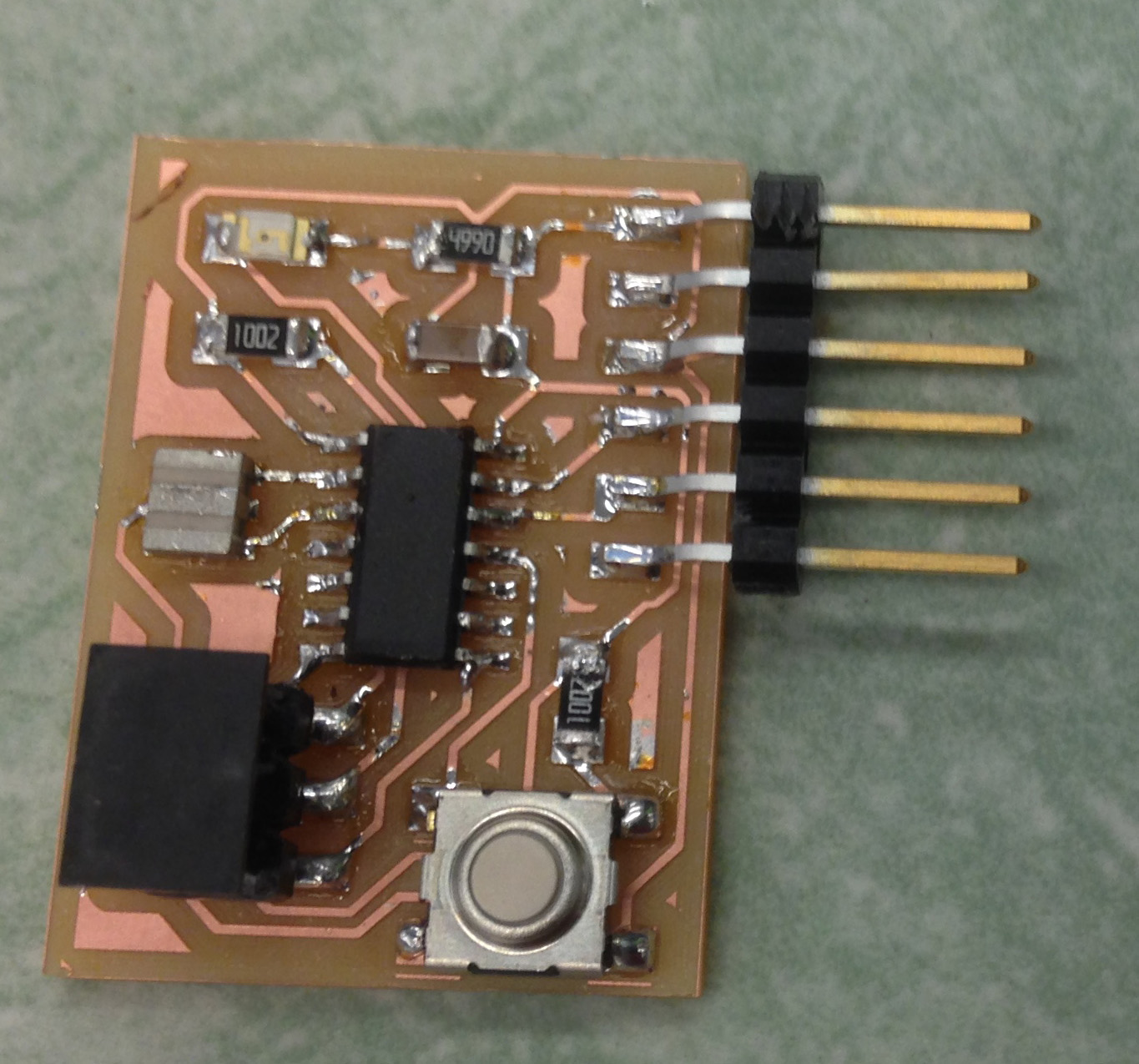

Using the same methods used in week 3, I fabricated a PCB. Here’s the

freshly milled board, about to be removed from the SRM-20:

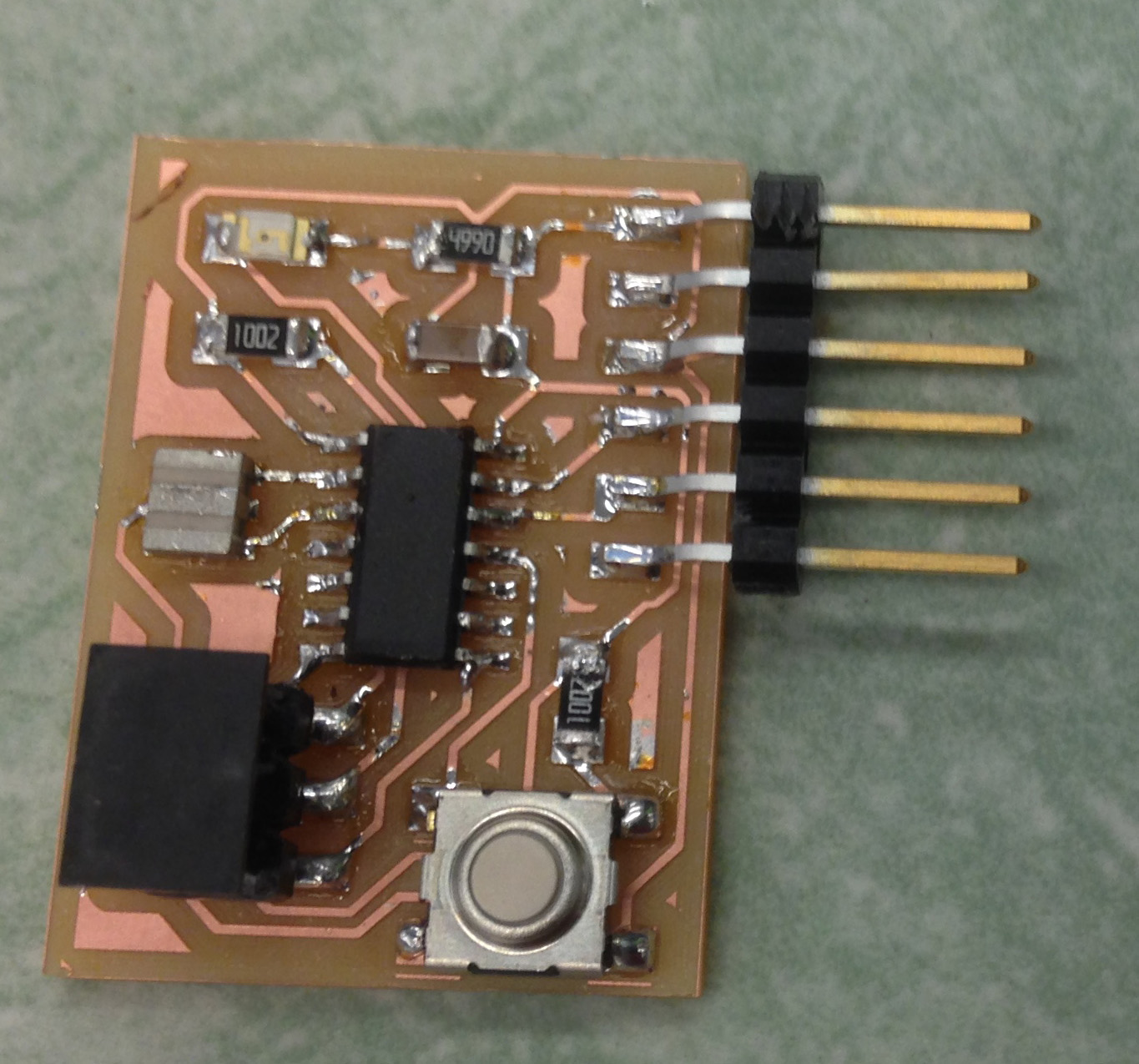

Choosing components for the board, I made some slight modifications to the

design:

- Chose to use an orange LED, which has a voltage drop of about 2.1

volts

- Chose to use a 499 Ohm resistor with the orange LED for a current of (5 V -

2.1 V)/(499 Ohm) = 5.8 mA through the LED

Here is the PCB and components, ready to be soldered:

Here’s the final result:

05 Oct 2016 · 3 min read

3D Printing

The assignment for this week was to 3D print something that could not be

manufactured subtractively.

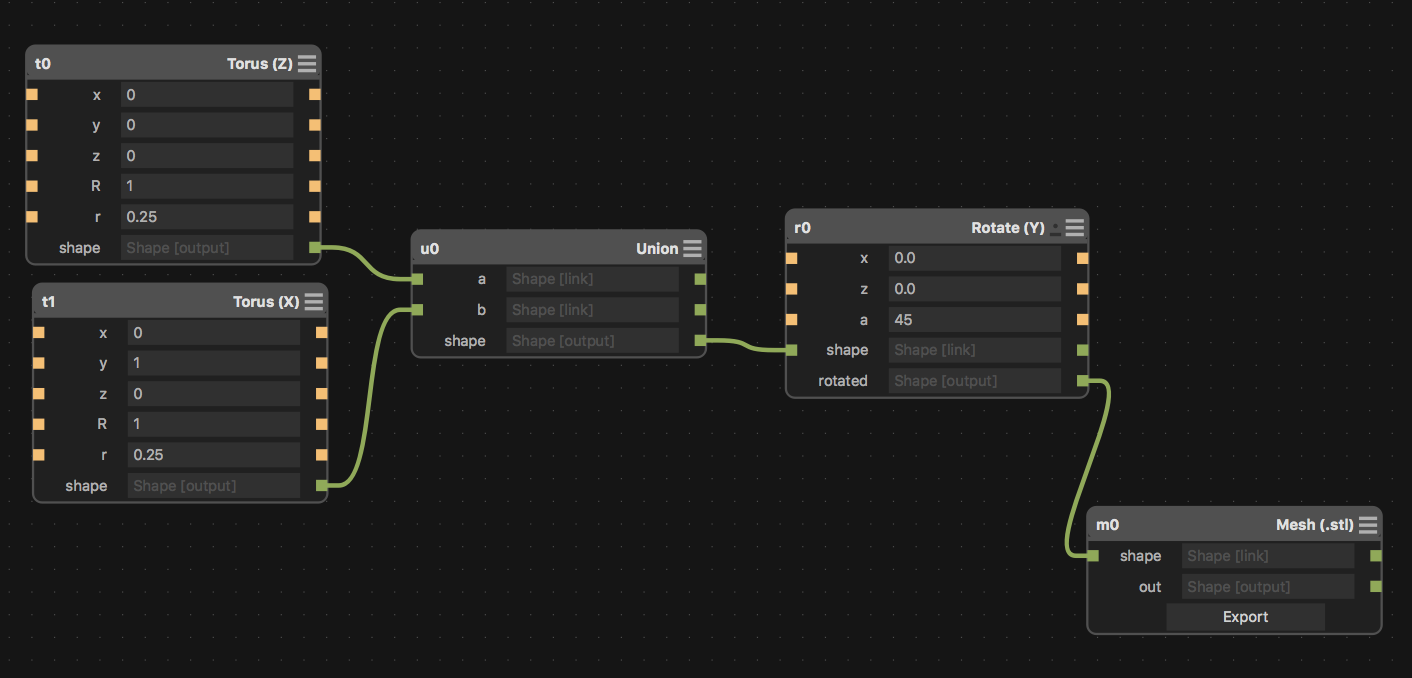

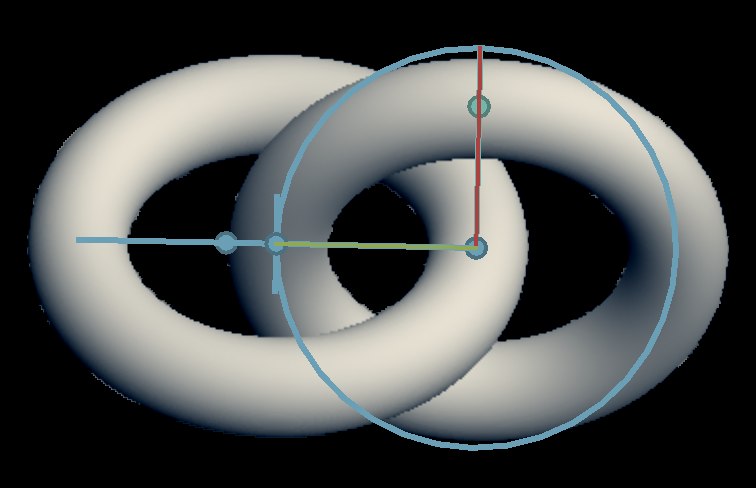

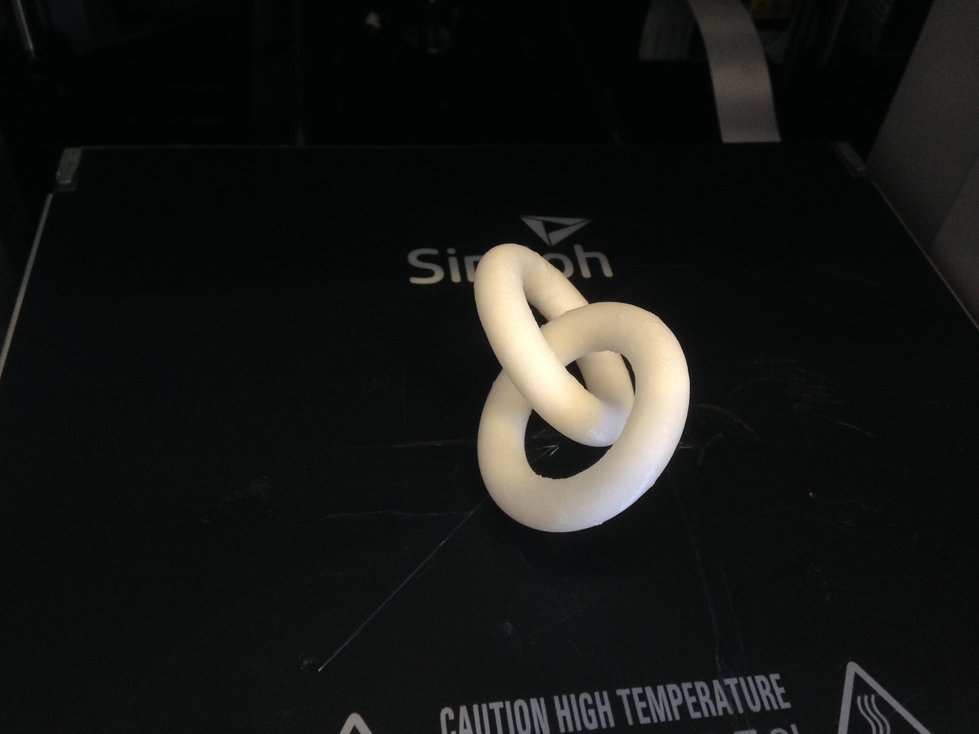

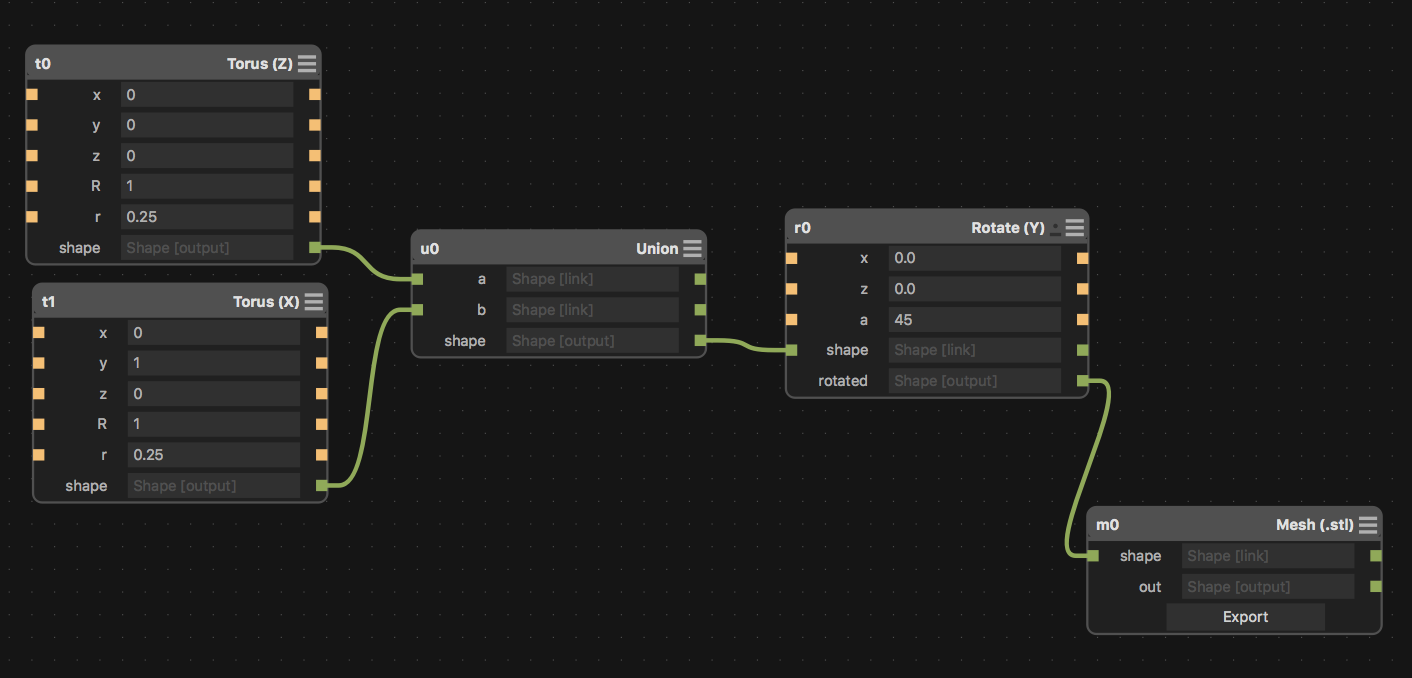

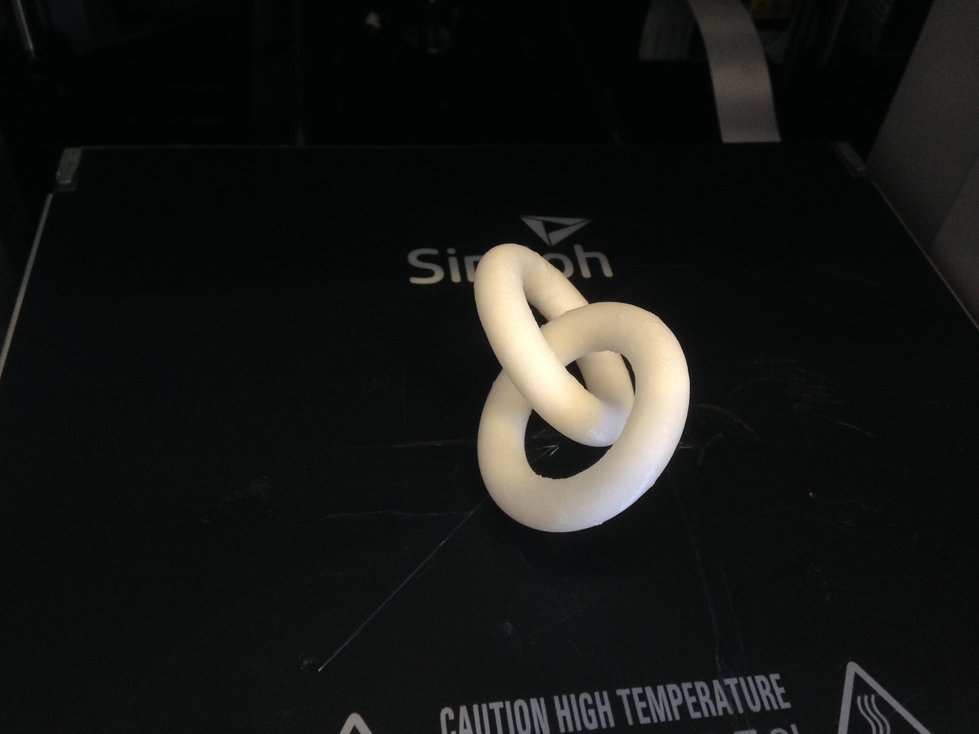

I chose to make a pair of interlocking rings. It was very simple to model using

Antimony as two identical toruses

positioned appropriately with respect to each other:

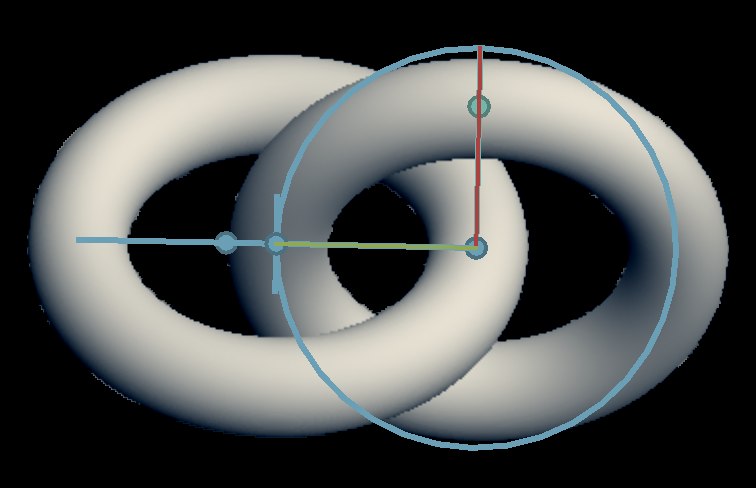

This is something that couldn’t be done subtractively. It also couldn’t be

produced as two parts and joined together later, unless one of the rings was

cut, the parts were put together, and then the ring was glued back together.

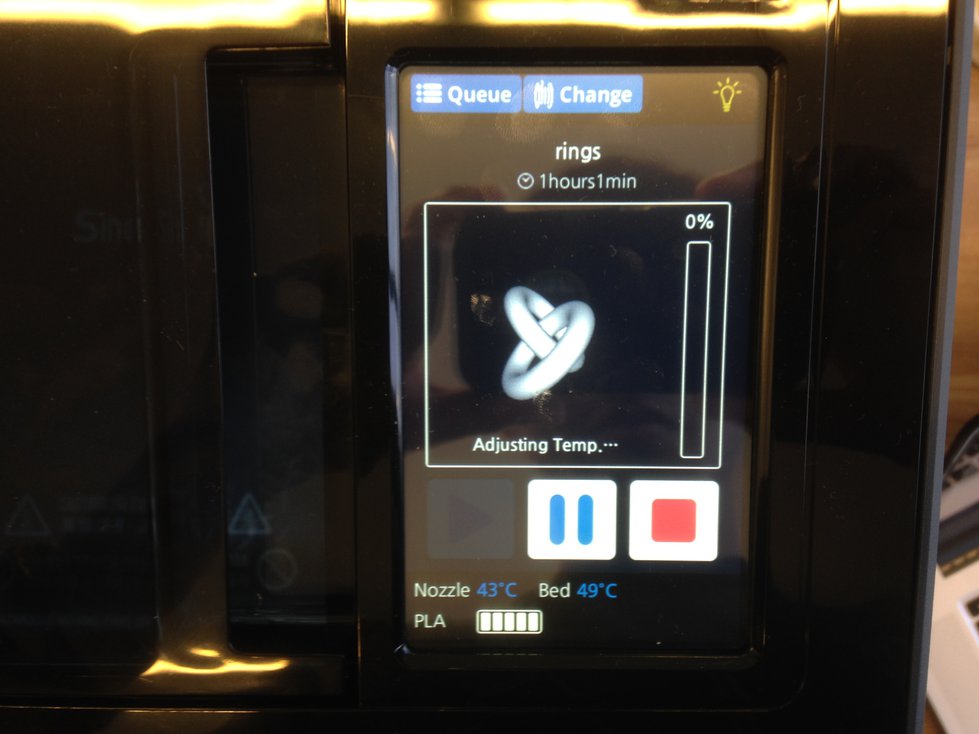

Printing Process

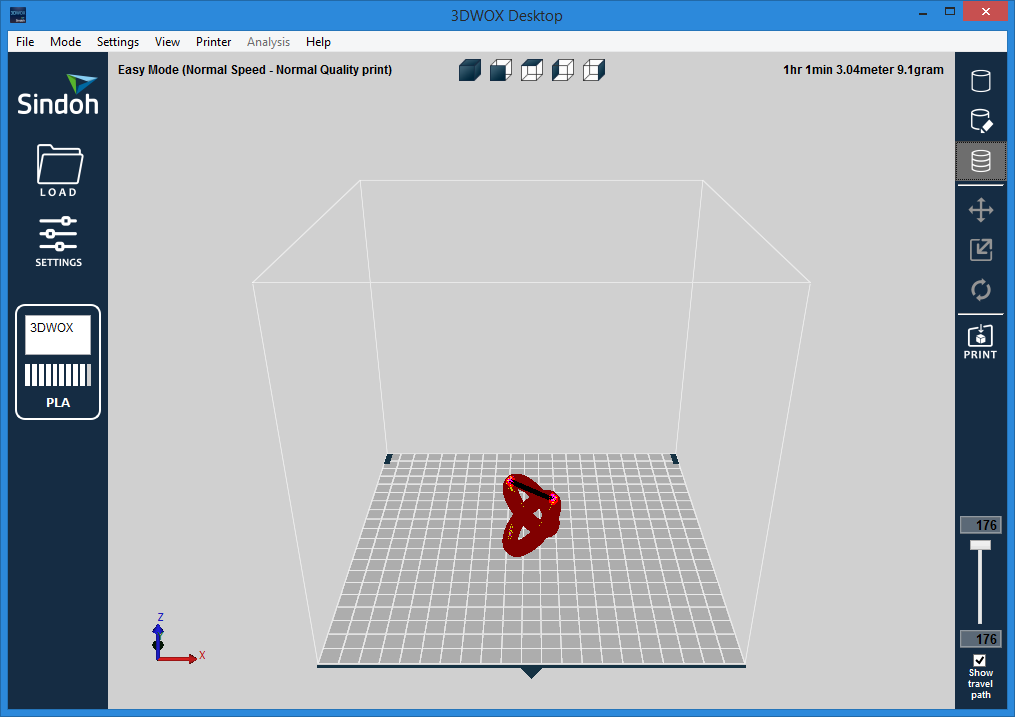

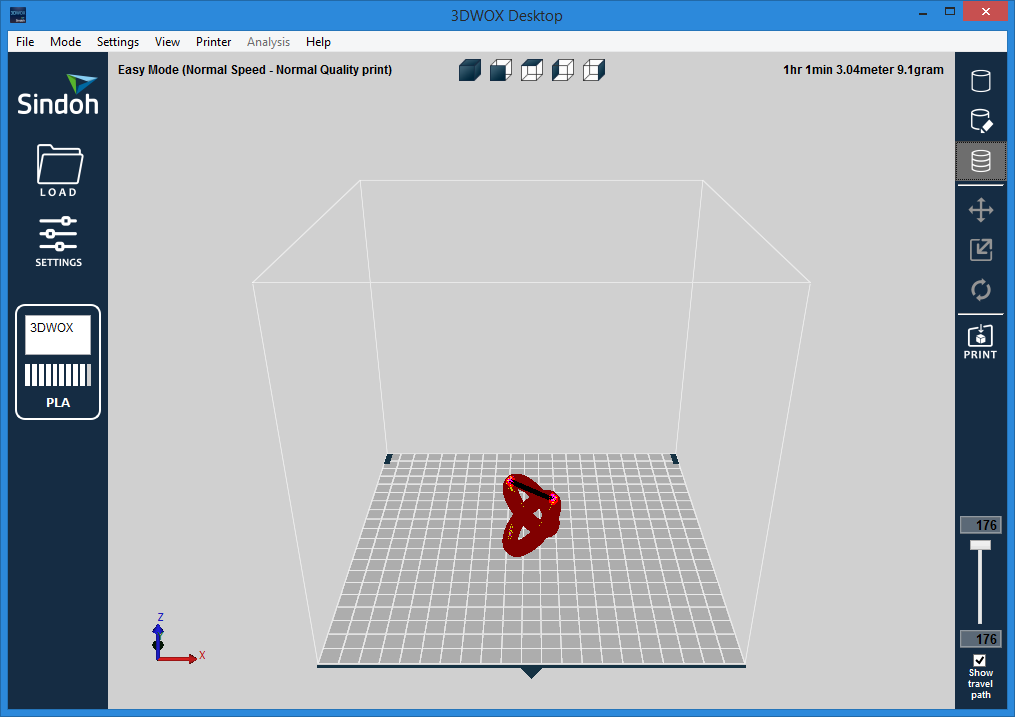

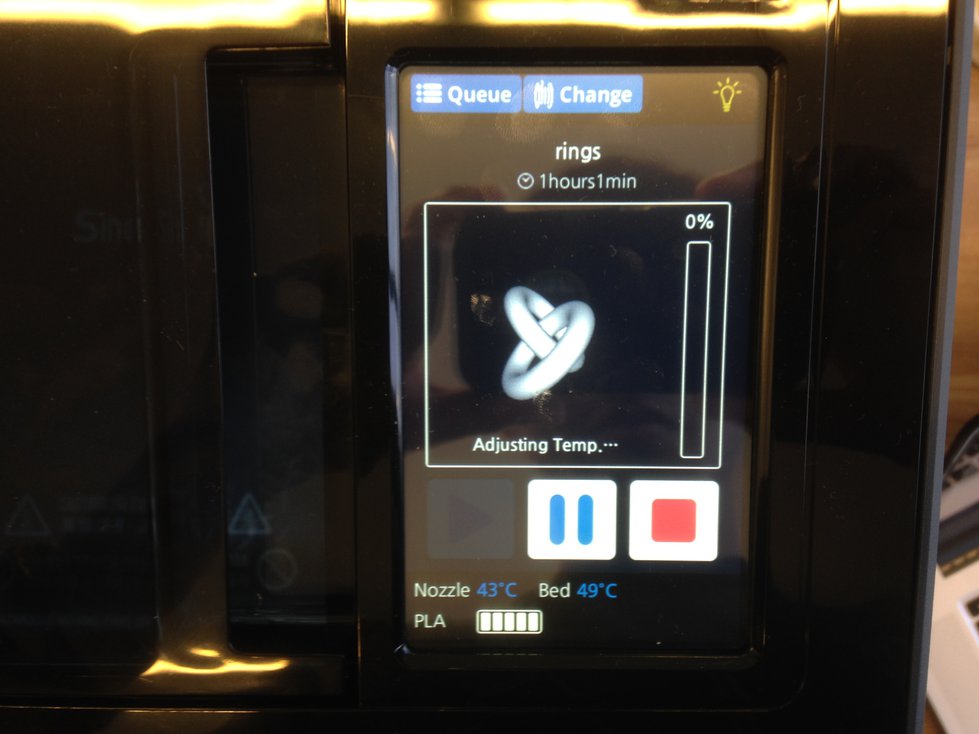

I printed my piece using white PLA. I used the Sindoh 3DWOX printer, which only

supports using a single material, so the same PLA was used to create support

material too. I used the 3DWOX Desktop software to import my STL file, rescale

it to a reasonable size, and print it. The software was very straightforward to

use.

I knew that printing this piece was going to be somewhat tricky, because it’s

pretty thin and narrow, and there would be a lot of freestanding mass. Before

printing, I oriented the toruses so that height was minimized:

The piece only took an hour to print:

Finishing Touches

The piece came out really well, even though it used almost no support material:

It only took a moment to remove the two small pieces of support material:

Result

I was quite happy with the result. It’s simple, but it’s still an interesting

piece that’s gotten a “how did you make that?” when I’ve showed it to people.

3D Scanning

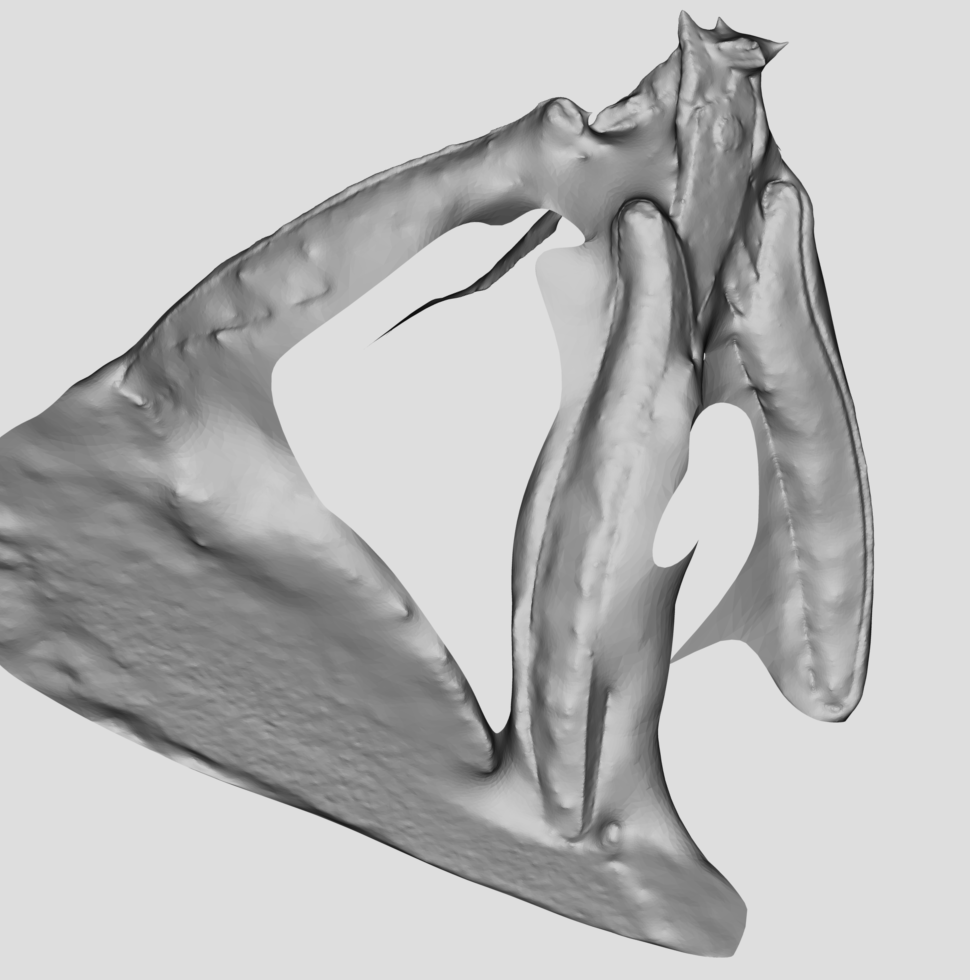

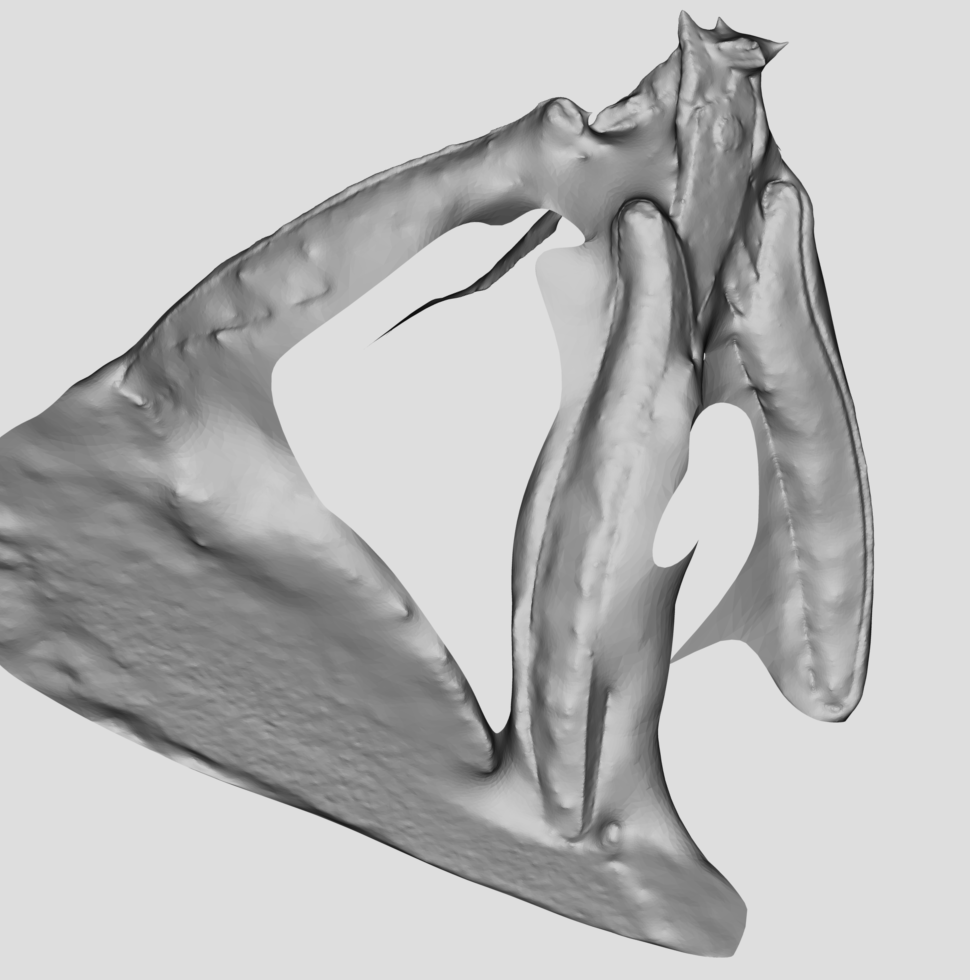

I did photogrammetry using Autodesk 123D Catch.

I scanned two wire cutters propped up against each other:

After taking about 30 photos from various angles, I let the software process

the photos, which took quite a while (it took an hour, but that might have been

an anomaly). Here’s the result:

In hindsight, this scan was probably too complicated for iPhone-based

photogrammetry. It’s far from perfect, but it does capture the basic geometry

of the object. And the top of the wire cutters actually came out quite well.