<<

[ Han - Will ]

Machine: MACRO PICK-AND-PLACE SYSTEM - preliminary thoughts

by: Han Hoang and Will Lark

05.17.2004

MACRO-PICK AND PLACE SYSTEM [MPPS]

ABSTRACT

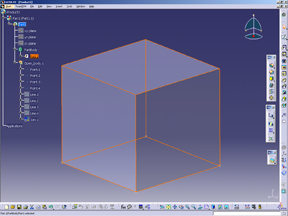

The current technology of any rapid prototyping machines can be

summarized in one, simple statement--The machine is always bigger

than the object it creates. From the current model of 3D printers

to any typical milling machines, these machines are generally the

size of cars, but they can only generate parts that are measured

in inches [Please see Figure A and B]. Our ultimate goal is to develop

a prototyping machine that can rapidly create parts and place

these parts to form a structure that is larger than the

envelope of the machine. We intend to answer questions of

practicality, methodology, effectiveness, economics and application

software that can be applied towards developing a machine suitable

for enhancing the technology and performance of architectural and

engineering practice.

KEY WORDS

Fabrication, Construction, Rapid-Prototype, Manipulation,

Customization, Modular, Precision, Efficient.

INTRODUCTION

This Macro-Pick and Place System [MPPS] was motivated

by the desire to have a machine rapidly and efficiently construct a

macro-scale structure using various pre-manufactured joints and

members. On a conceptual level, MPPS seeks to enhance the

conventional methodologies of design and construction with the

traditional technology of snap connections - [ppt] and modular

components mimicking the idea of building with Lego

blocks or any similar toy connector building systems.

PROCESS

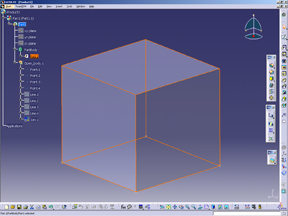

Design - The process starts with a three-dimensional CAD model

created with any 3D application such as AutoCAD or CATIA.

Output - Once the model is complete, the output procedure is

similar to that of any 3D printing exporting process. An "STL" type

data is then sent remotely to the on-board computer of the MPPS.

Output - Once the model is complete, the output procedure is

similar to that of any 3D printing exporting process. An "STL" type

data is then sent remotely to the on-board computer of the MPPS.

Analyzation - The MPPS then convert the given data into

recognizable parts and members and stategically calculate the precise

locations of each component.

Analyzation - The MPPS then convert the given data into

recognizable parts and members and stategically calculate the precise

locations of each component.

Construction - Once each part is located on a three-dimensional

grid, the MPPS then uses a local GPS locator system such as TOPCON's

integrated GPS recievers, to establish the exact location of any given

part on any give site.

Construction - Once each part is located on a three-dimensional

grid, the MPPS then uses a local GPS locator system such as TOPCON's

integrated GPS recievers, to establish the exact location of any given

part on any give site.

Machine Analysis and Features:

PARTS

a] analyzation of unique joint

b] snap connection

c] stacks placed in a hopper becomes part of the horizontal arm

d] tentatively, parts are design to satisfy limited construction condition

MACHINE [process]

a] xyz track motion arm with supporting tower [machine studies]

b] stategically locate first joint

c] location of hopper(s)

d] details of movement

e] limit numbers of actuators and motors

Output - Once the model is complete, the output procedure is

similar to that of any 3D printing exporting process. An "STL" type

data is then sent remotely to the on-board computer of the MPPS.

Output - Once the model is complete, the output procedure is

similar to that of any 3D printing exporting process. An "STL" type

data is then sent remotely to the on-board computer of the MPPS.

Analyzation - The MPPS then convert the given data into

recognizable parts and members and stategically calculate the precise

locations of each component.

Analyzation - The MPPS then convert the given data into

recognizable parts and members and stategically calculate the precise

locations of each component.

Construction - Once each part is located on a three-dimensional

grid, the MPPS then uses a local GPS locator system such as TOPCON's

integrated GPS recievers, to establish the exact location of any given

part on any give site.

Construction - Once each part is located on a three-dimensional

grid, the MPPS then uses a local GPS locator system such as TOPCON's

integrated GPS recievers, to establish the exact location of any given

part on any give site.