Matt Groh

3d Scanning and Printing

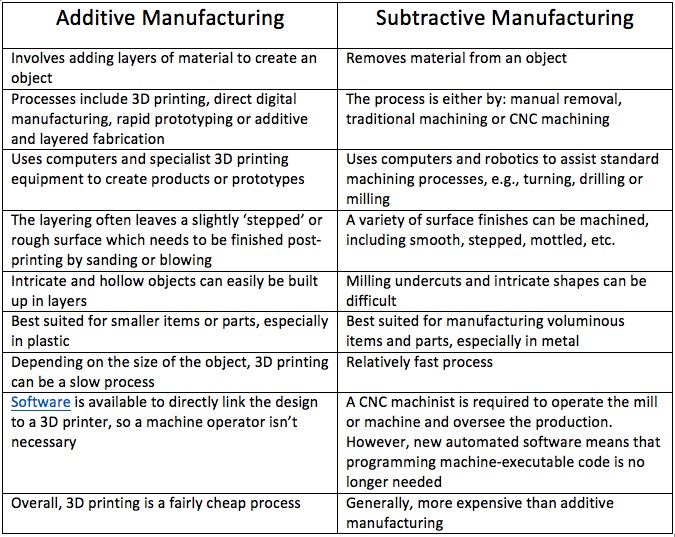

We're going 3d! This week, I experimented with 3d scanning and printing. 3d scanning is a technique for digitally capturing a real-world object and reconstructing it as a 3d model. 3d printing brings 3d models in a computer to the physical world. 3d printing is an additive manufacturing process as opposed to laser cutting and milling, which are subtractive manufacturing techniques. Here's a brief comparison of additive vs. subtractive manufacturing from manufacturinglounge.com.

You can 3d scan almost anything! Here's a photo of one of the instructors 3d scanning a students head.

Since we can scan and print almost anything, I thought it'd be fun to scan and print a ceramic shot glass inspired by ancient phallic Mochica pottery. A couple of my silliest friends travelled to Peru and brought me back this shot glass,

Here's a short clip of what the 3d model looks like

Initially, I tried to lay the shot glass on its "back" and print without supports. What I learned is that you need an absolutely flat surface for additive manufacturing. You can't print on a cylindrical base because you're essentially printing in mid-air and nothing gets connected together. I realized this 45 minutes into my initial printing. My print looked like plastic spaghetti. So, I tried again. This time, I set the object on its base and I added supports. Supports ensure the 3d printing doesn't print in mid-air to nothingness. The photo on the right shows an image of the print and the printing temperature. 200 degrees celcius is 392 degrees farenheit. Basically, the nozzle is as hot as the oven.

On the left below, you can see what the 3d print looks as it comes out of the printer with the supports still on it. The supports are easy to break off, and voila, you've got a near copy of the commercialized replica of ancient Mochican pottery. It's missing a couple spots, and it's plastic. But, there's a decent resemblance!

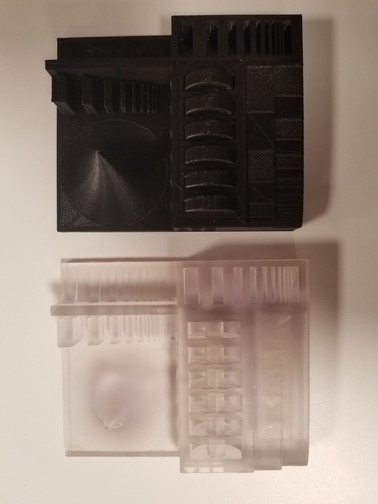

Here's a 3d print of an object, which gives us a sense of how thin raised pieces can be, how much space is required between raised blocks, and how different printers perform across these parameters. The Eden 260 VS beat out the Sindoh, which makes sense because they're sold at very different price points and the Eden 260 VS is designed to do much more detailed prototyping.

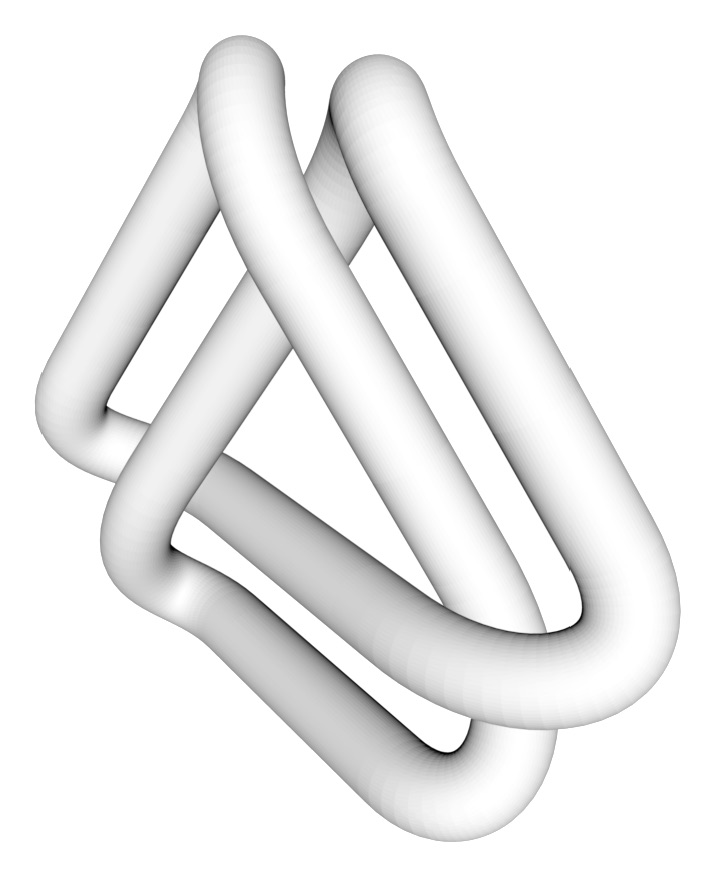

And last but not least, I printed an object that can only be manufactured additively. It's an escher triangle. You can see below, it's all one piece. At first glance, it looks like two inter-connected triangles. As you look closer, you'll notice it's one single material. Here's three photos displaying the 3d model, the print with the soluble coating intact, and the print in its final form.