3.1 3D Printing

3.2 3D Scanning

GROUP WORK

03

TRIALS & TRIBULATIONS

LESSONS LEARNED

Softwares: Fusion360, Rhino, Bamboo Slicer

Devices: Bamboo - PS2

Materials: PLA Matte Black, PLA Matte White

Files: NativeMini.f3d Cowrie_Shell.stl , CowryBangle.f3d

Devices: Bamboo - PS2

Materials: PLA Matte Black, PLA Matte White

Files: NativeMini.f3d Cowrie_Shell.stl , CowryBangle.f3d

Softwares: RevoScan, Revopoint Pop 2 Scanner

Devices: Phone, Revopoint Scanner

Files:NativeMini.mov, ShangtaoScan.mov

Devices: Phone, Revopoint Scanner

Files:NativeMini.mov, ShangtaoScan.mov

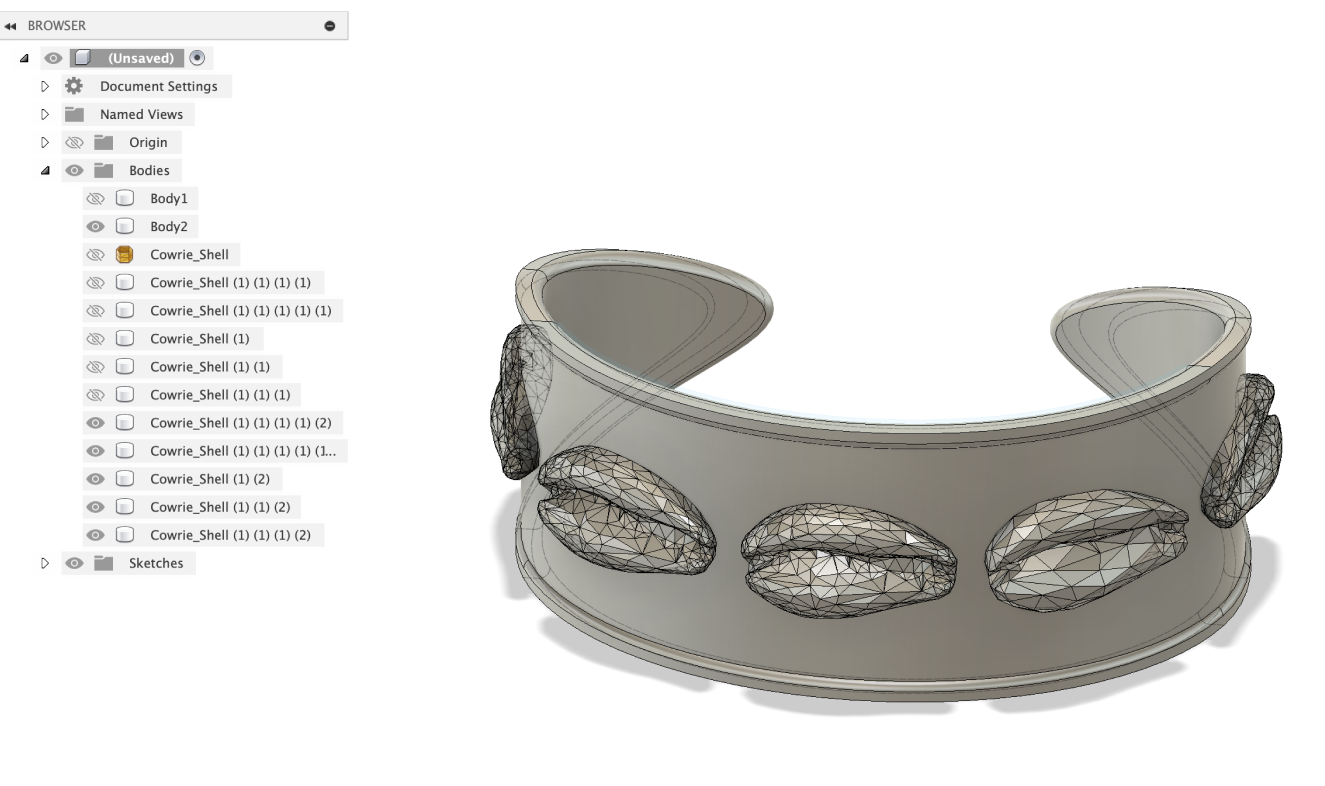

- Mesh Modeling and Holes - while importing STLs I had issues working with the meshes... a lot of them were extremely high resolution which blew up my file size and made editing extremely difficult. I found that lowering the poly-resolution and converting the mesh to an object was the easiest way to incorporate outside models into my design!

- Sketching your ideas out really helps with the CAD process

- Try to use .OBJ files for online imports and ALWAYS check file size

- Use other softwares to accomplish what you can’t on Fusion

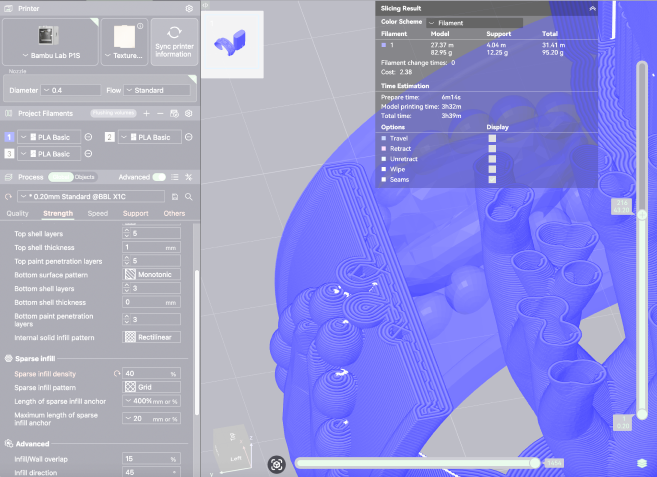

- Always check if the infill makes sense, especially if the piece is small!

Architecture Assignment 3 Group Work

First thing I scanned was my bag deodorant! I was told that the RevoScan app

was not great at scanning small objects, but my scan turned out pretty good!

I was not able to export any files (I only have the free version ;-;), but

recorded videos of the scans.

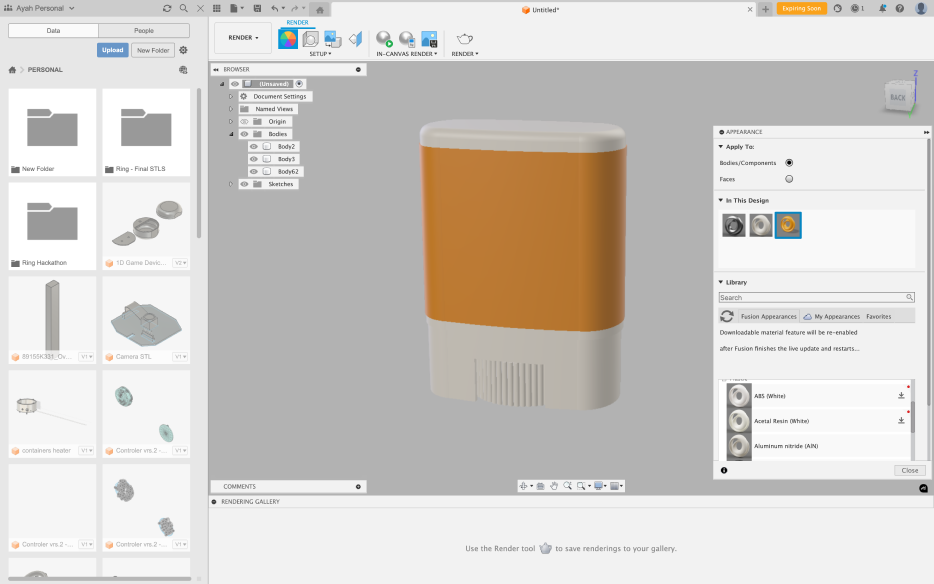

The first thing I CADed was my mini deoderant that I scanned! I used

Fusion360, and just eyeballed all the sizes.

We also tried scanning Shengtao’s head. I was very surprised that the scan

also picked up the rest of the room and as well as other people. I think in

the future, it’s important to have a more simple background if I were to do

larger scans.

NATIVE MINI DEODERANT

COWRY SHELL BANGLE BRACELET

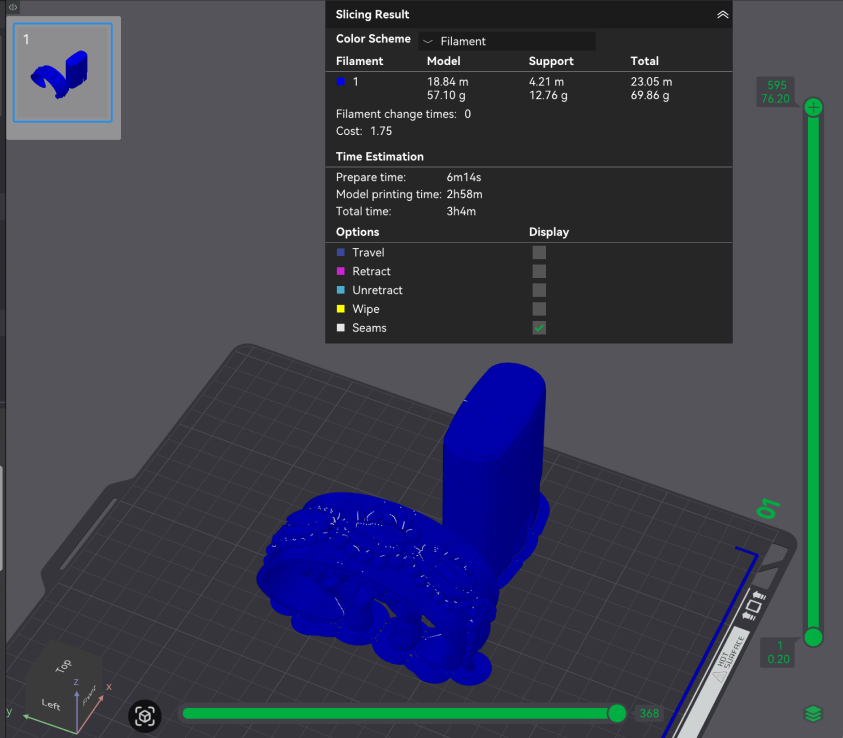

PRINTING: ROUND 1 (FAILURE ;-;)

PRINTING: ROUND 2 (SUCESS)

I started a CAD file in Fusion, approximating my wrist size, and

downloading a basic

cowrie shell mesh

from LennyFace on Thingiverse.

Then I fit some sphere embellishments around each shell, making the center

ones larger. I debated adding cut outs or spherical embossing along the

background of the cuff, but ultimately decided to go for the more simple

look.

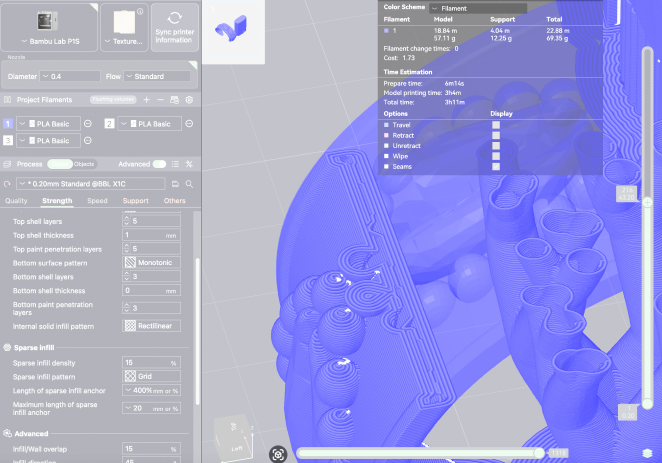

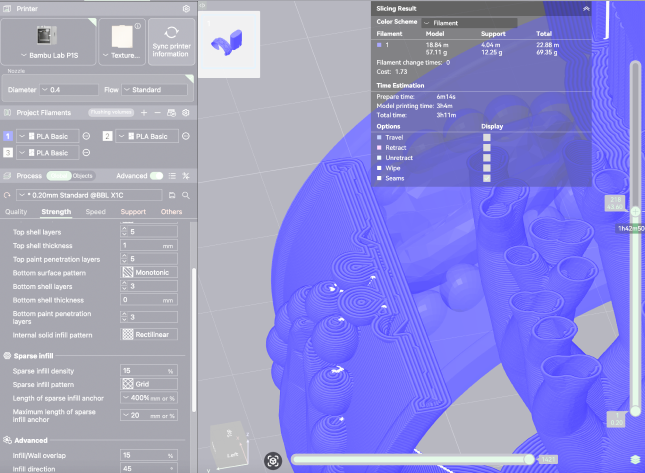

Print Time: 50m38s | Material: PLA Basic Matte Black | Support: Tree

(default) | Infill: 15% | Brim: 5mm outer | Nozzle: 4mm

I printed both of them on the same plate on Bamboo Slicer and made

adjustments to the settings that I thought were appropriate for this type of

print, such as a 5mm Brim for better bed adhesion, and added tree supports.

Tree supports were the best option because they are the easiest to remove

and leave less rough markings on the print. I also oriented the bangle to be

printed facing upright so that the visible part of the piece would be most

smooth.

Print Time: 3h4m | Material: PLA Basic Matte White | Support: Tree (default) | Infill: 15% | Brim: 5mm outer | Nozzle: 4mm

Print Time: 3h4m | Material: PLA Basic Matte White | Support: Tree (default) | Infill: 15% | Brim: 5mm outer | Nozzle: 4mm

It failed!!!!! ;-;

So i took a look at the print to see where it stopped and then reopened

Bamboo Slicer.

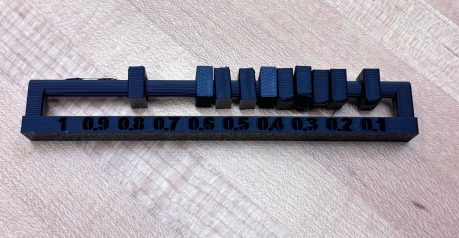

The print worked out!! I was very happy about the thickness and overall

look, and I think if this were a larger project I would’ve lived to sand it

and spray it silver. The cowrie shell meshes printed out well, but a little

grainy (nothing some sanding can’t smooth out!), and the tree supports were

extremely easy to remove with a pair of wire-cutters! I also reaaaaally over

estimated how large my wrists are... the bangle does not sit well at all and

is almost x2 longer in width...

The deodorant ended up well too! Since the infill was increased, it did feel noticeably denser my usual prints!

The deodorant ended up well too! Since the infill was increased, it did feel noticeably denser my usual prints!