Week 14: Wildcard Week

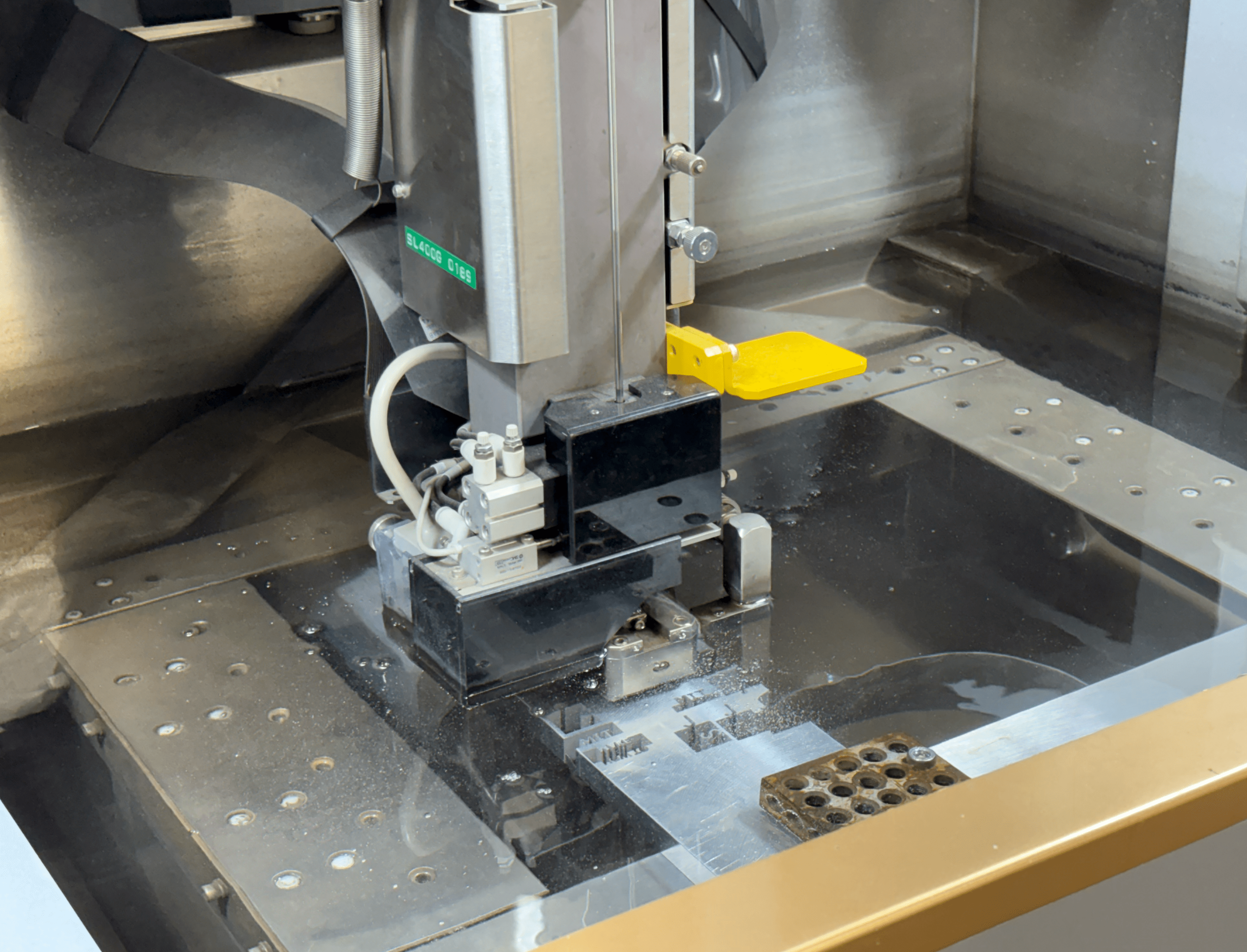

This week I worked with the Wire EDM (Electrical Discharge Machining) machine in the CBA makerspace. It works by using electrical sparks from a thin, continuously fed wire to eroe and cut electrically conductive materials, and is able to create intricate shapes with extreme accuracy and detail.

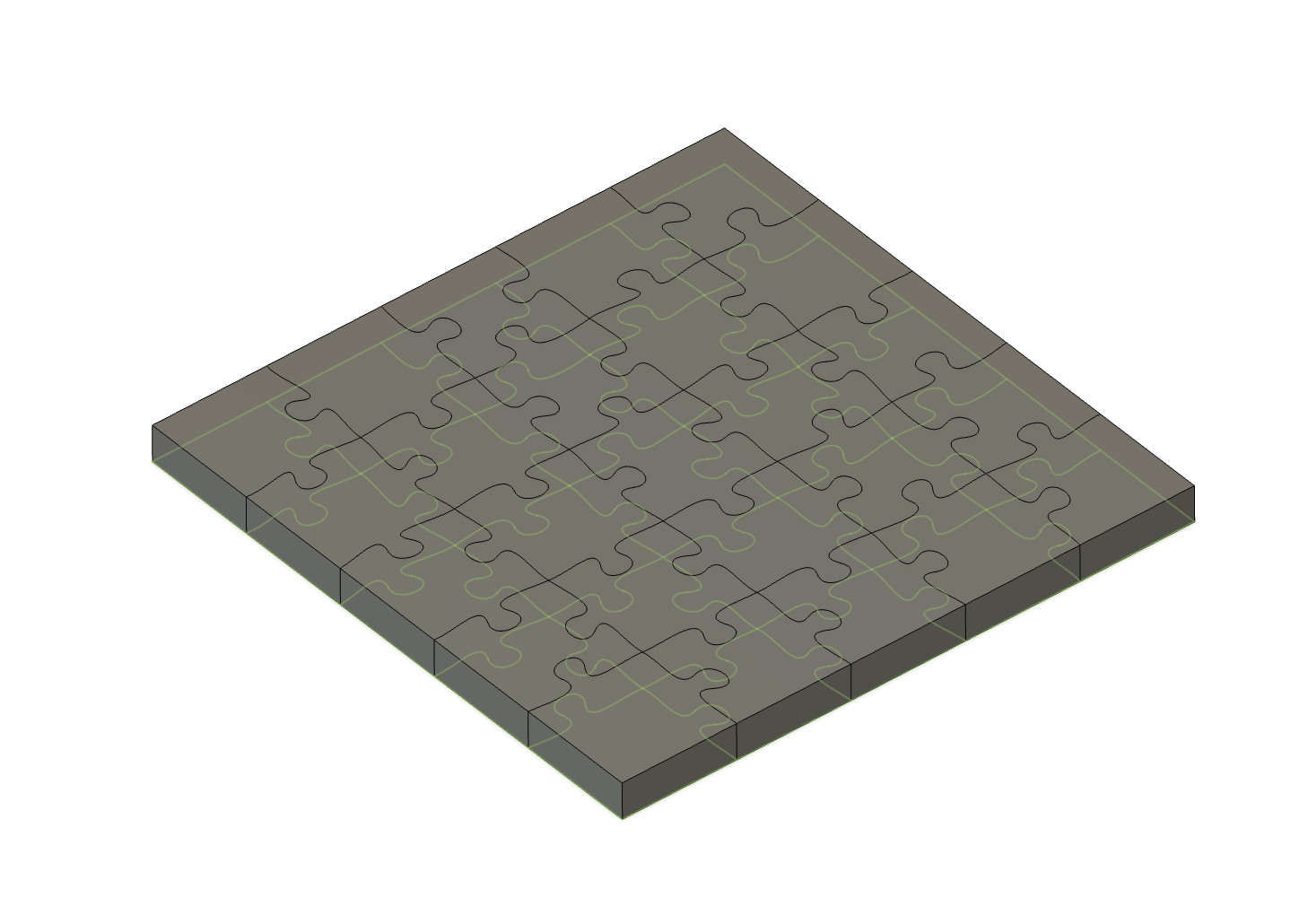

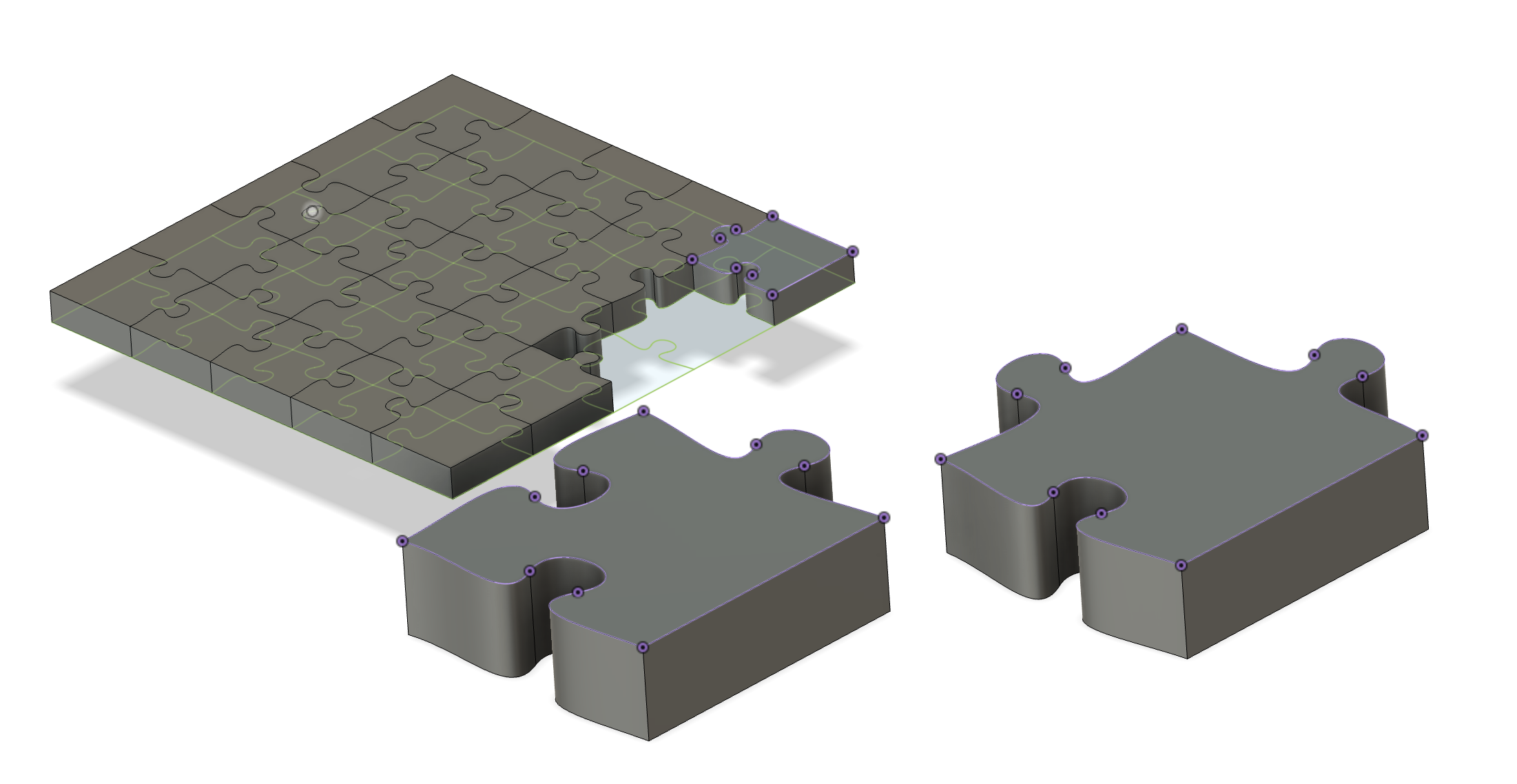

I started with using an online tool to generate a svg to fusion component of a map of puzzle pieces. I then exported the svg as a dxf file.

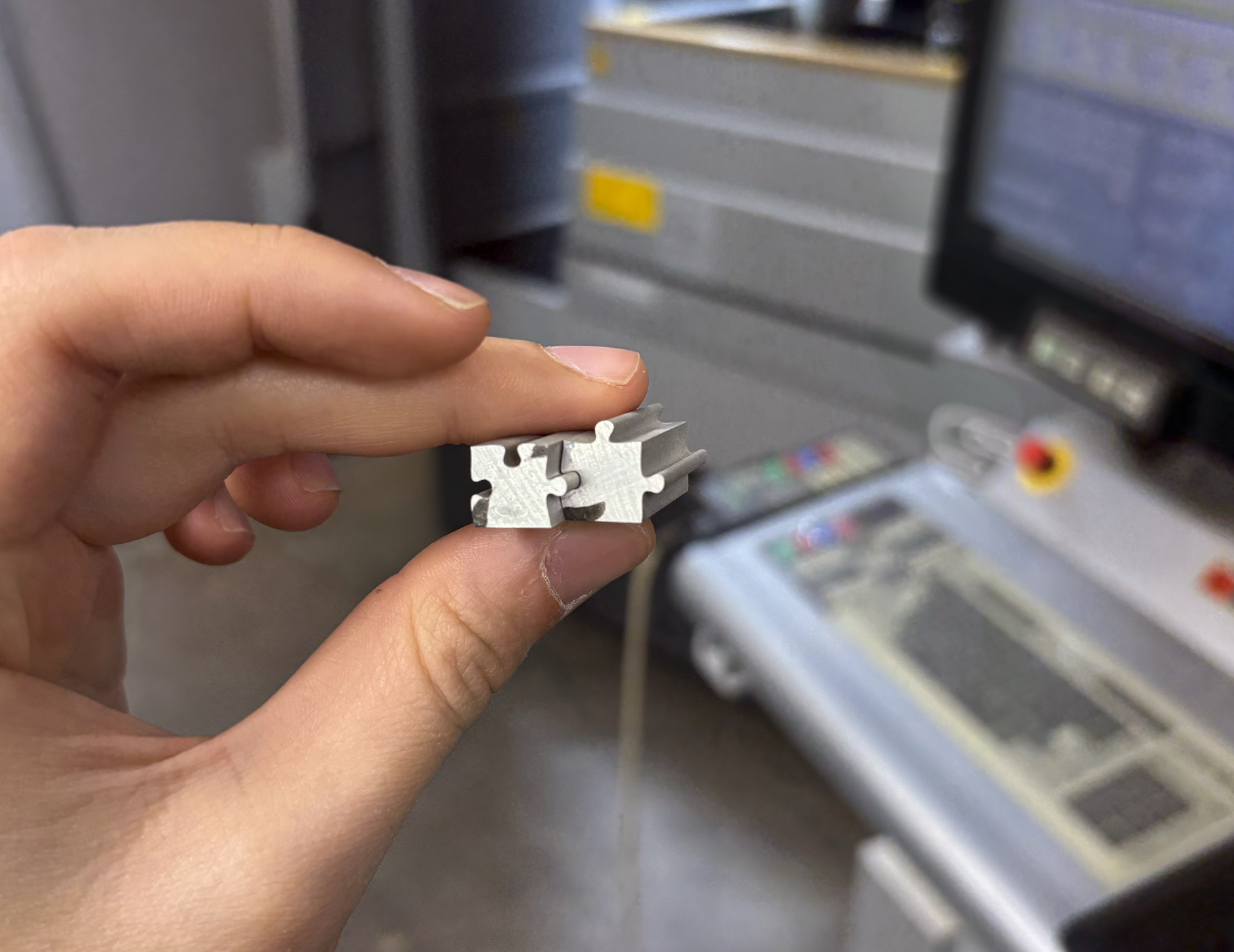

Since the wire EDM machine is able to cut ~0.12-0.18 inches per minute, a lot of the larger pieces would have taken too long to cut. For example, the two pieces I cut were 0.375 by 0.375 inches, or 2 inch circumference, which took 20-ish minutes each.

I scaled these pieces, projected them to get the dxf sketch, and exported! On the Wire EDM machine, you convert it from dxf into a gcode file and determine where the machine should start cutting, what position relative to the start point it should be cutting, and so on. The machine geneates 300+ volt sparks in the wire, and for it to work you must use conductive material. I ended up using a piece of scrap aluminum that had a nice finish. The machine also uses dielectric flushing, which flusehes away the eroded particles and cooling the area.