Week 2: Making parametric design and vinyl cutting

Vinyl Cutting

I learned to do vinyl cutting using the open source tool developed by Neil and the Media Lab on the Roland Vinyl Cutter.

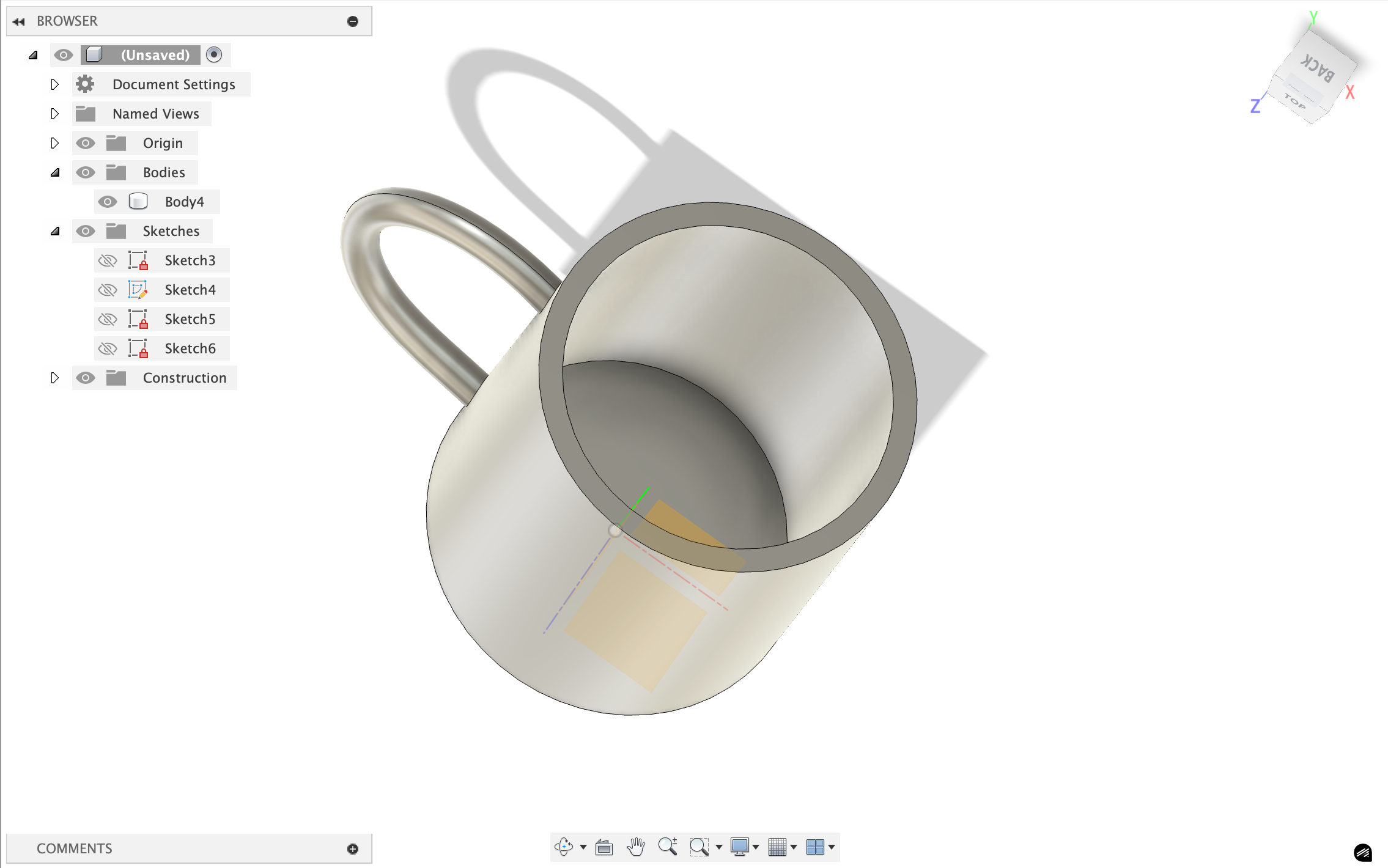

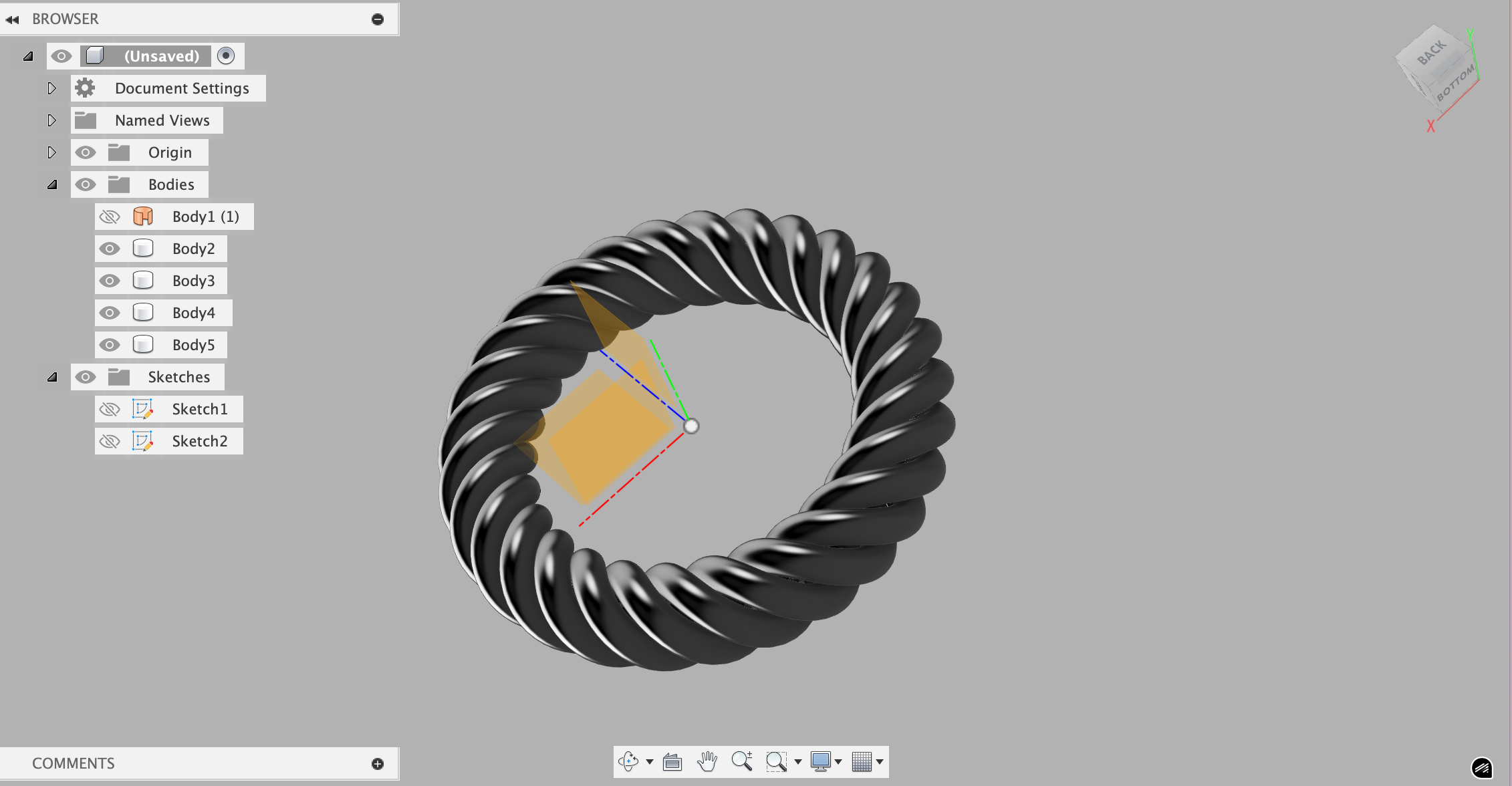

I've also been playing around a lot on Fusion360. I initially tried using FreeCAD but after struggling around with it for ~3+ hours, I decided to stick with Fusion, since I've used it before and I find the sketch to 3d workflow much more intuitive.

I'm going to try to make this design I made in Figma (for my favorite band) on the Vinyl cutter:

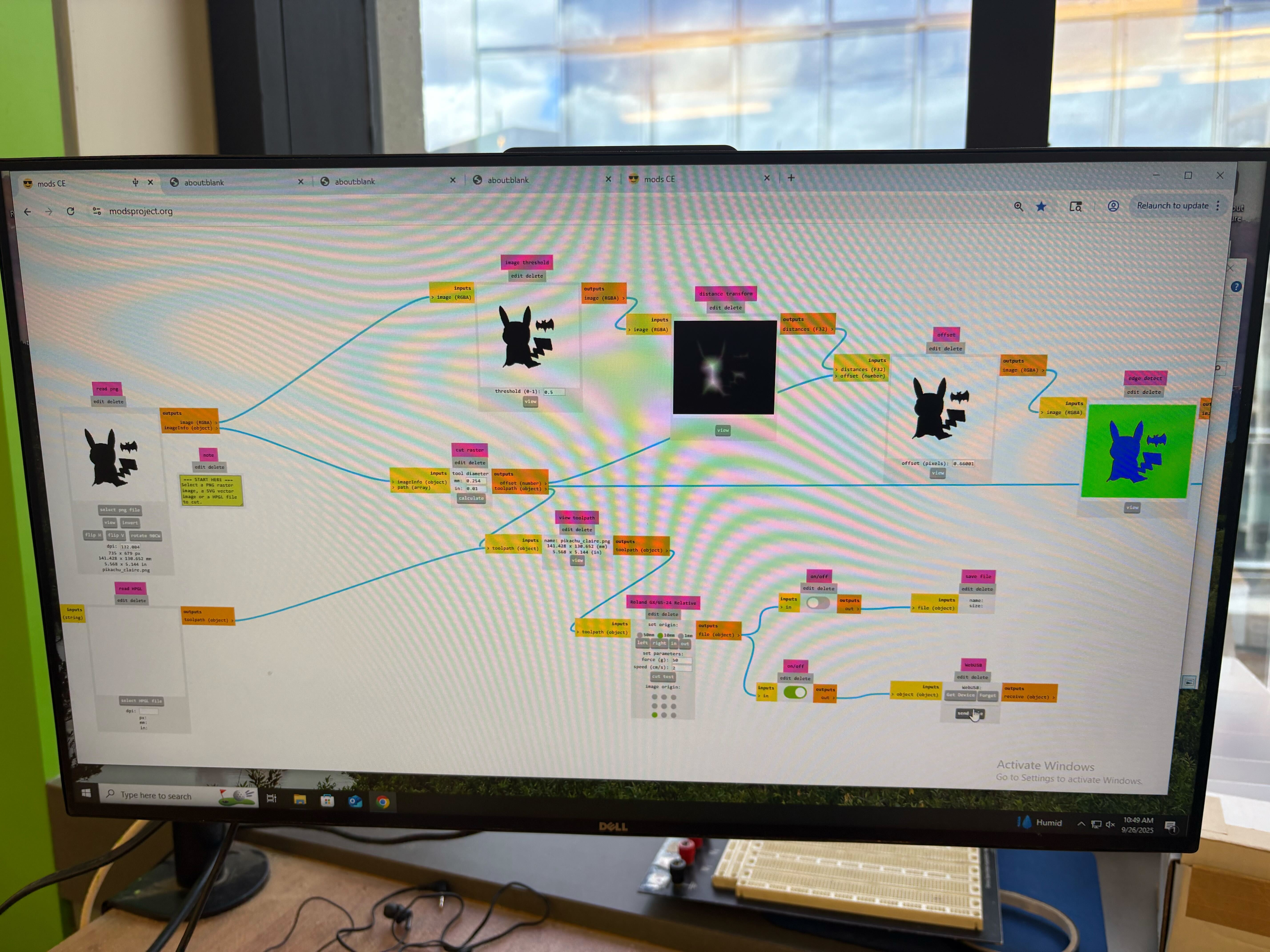

Here's a photo of the modproject interface when I put in a doodle of a pikachu batman:

This is inspired by my consistent profile photo:

Final product (ignore the background, I stuck it on my notebook that had a photo of snoopy in a batsuit):

Laser Cutting

Things that we figured out about the Laser Cutter in the EECS makerspace is that the kerf is about 0.0049 inches, and the clearance is about -0.0045 inches, meaning that we should design for an interference fit.

Hardware setup:

- 75w co2 laser (large machine)

- generates infrared light that gets focused to a tiny point. when this concentrated energy hits material, it instantly heads and vaporizes it along the programmed path.

- what "kerf" means (which is 0.0049'' average) is the width of material that gets completely removed by the beam

- 60w co2 laser (small machine)

- universal laser systems hardware

- universal control software for parameter control

- inkscape for vector design and job sending

Design process

- design vectors → red lines w/ 0.001'' weight is full cuts and blue lines (0.001'' weight) is engraving/scoring

- focus the bean using the focusing stick until it just touches material surface

- set parameters: 100% power, 30% speed baseline, 500 ppi

- ctrl+p to send job to universal control software

- turn on air compressor, hit green button

Things to remember!

- focus accuracy determines cut quality—we use the white part of focusing stick

- kerf compensation is needed in design (if very precise)

- material thickness affects join clearance (-0.0045'' interference fit on cardboard)

- the bed moves during focusing, laser tracks the material plane

Here's the final produce of the various building blocks I made:

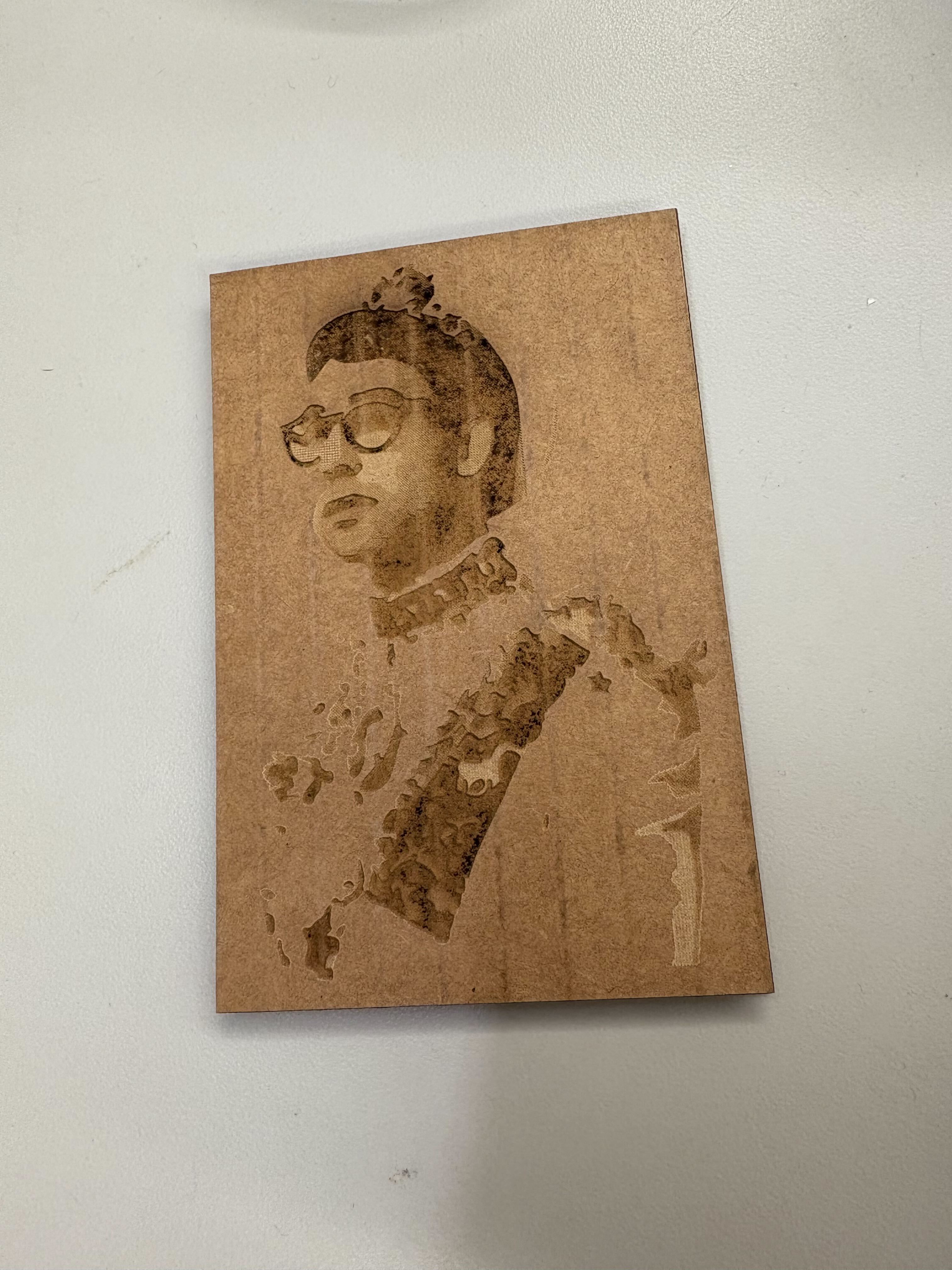

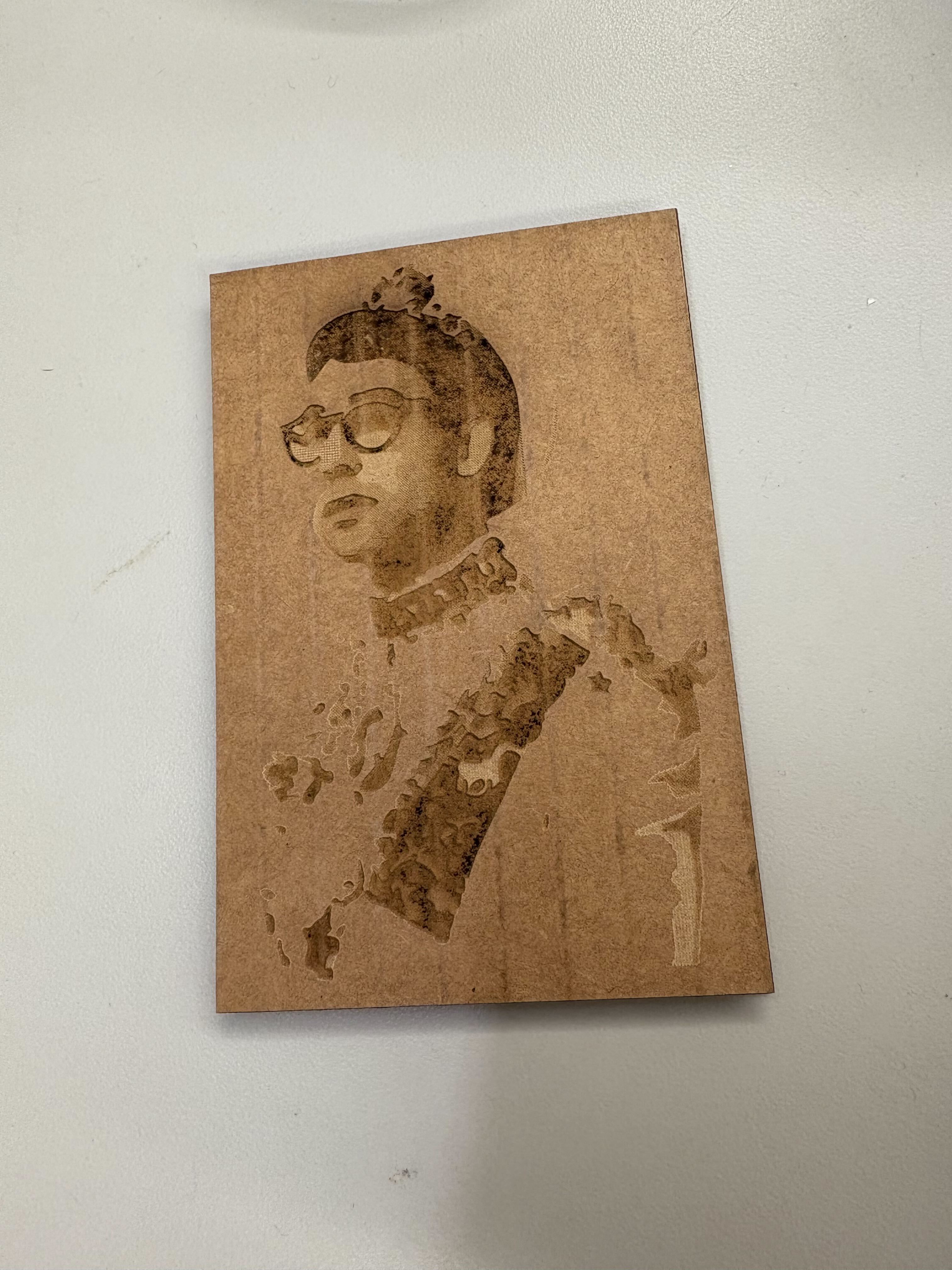

I also made an engraving cut of an album I love, called Gone Now by Bleachers. It came out relatively okay on cardboard, even though some teaching with the strength of hte cuts and using a different material will probably make it come out better:

CAD

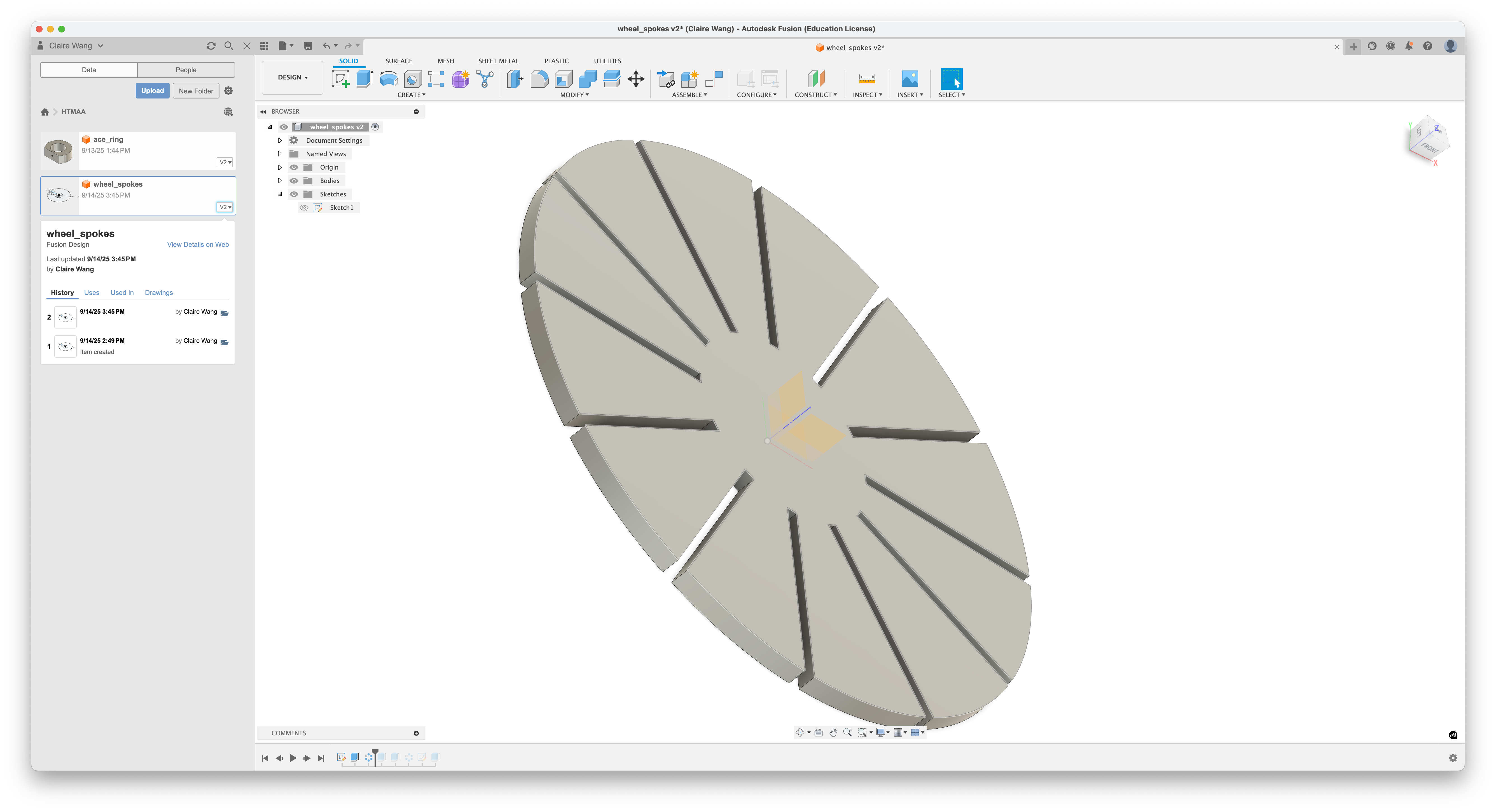

I watched this video on making a wheel and made this:

I also tried to make a CAD of my ring, but it is not very perfect, so maybe I'll try to learn how to do this more professionally:

Todos:

- ✅ Vinyl cutting

- ⏳ Builder kit w/ Laser Cutting!