Week 8: Input Devices

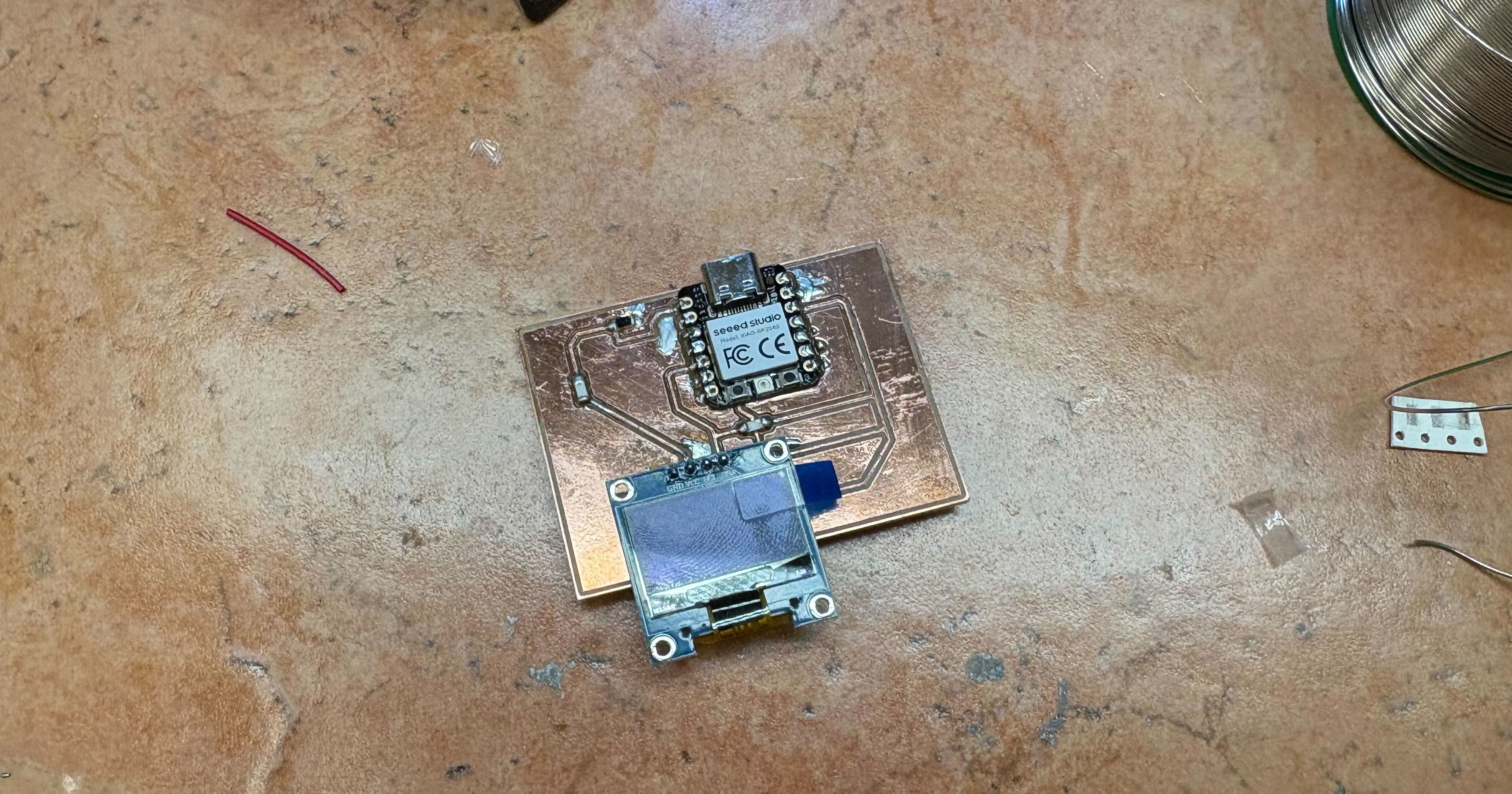

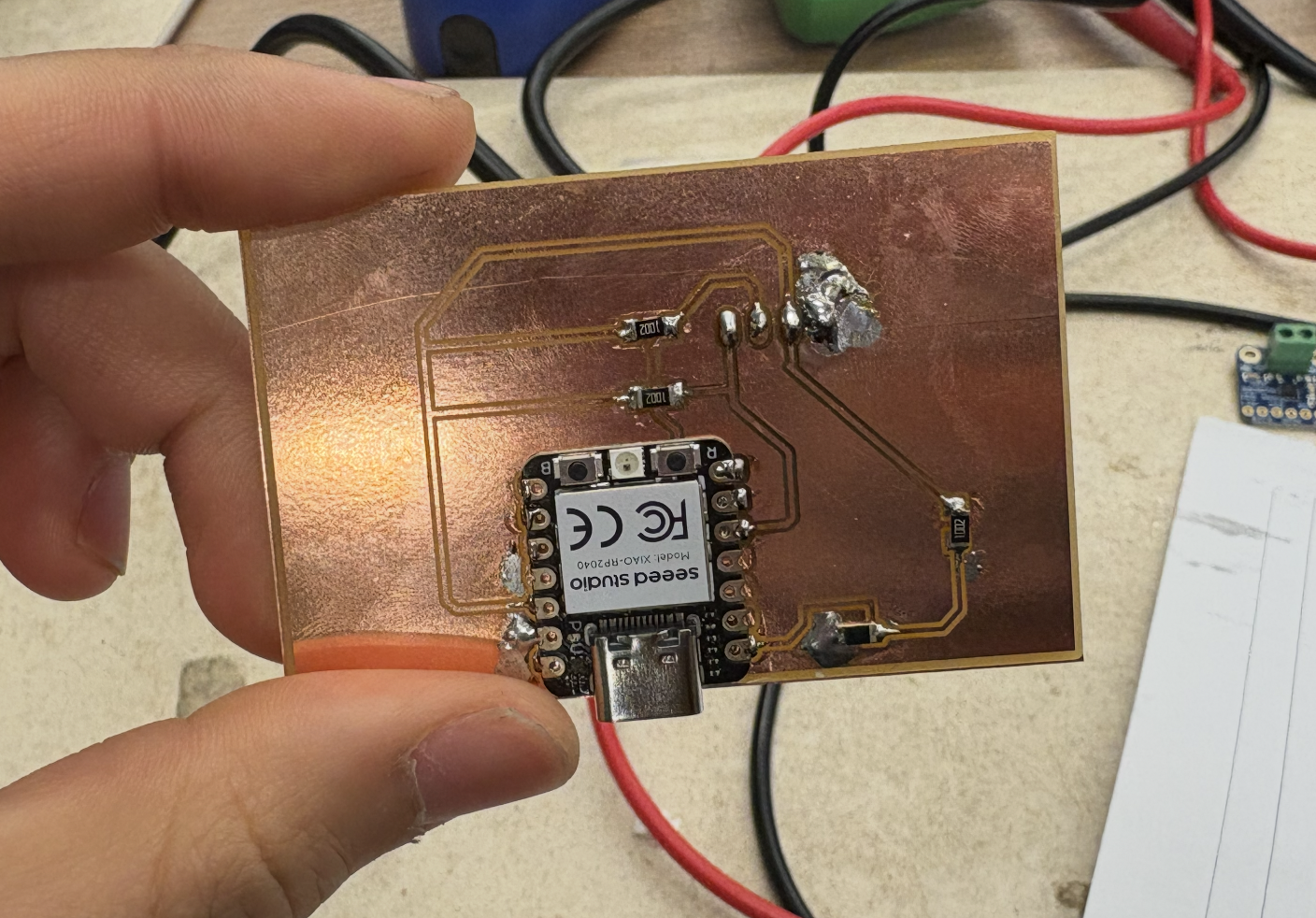

This week is a combination of some of the previous weeks' topics, so not too much that is new. Last week, the board that I had soldered and made didn't work — never turned out, and I realize it was because of a mix of not testing if my solder didn't cause a short and not having a good enough connection to the board. You can look at the original design in Week 6.

IR Phototransistor

This week, I stuck with the same pads design but did some more research on the phototransistor and fixed the soldering.

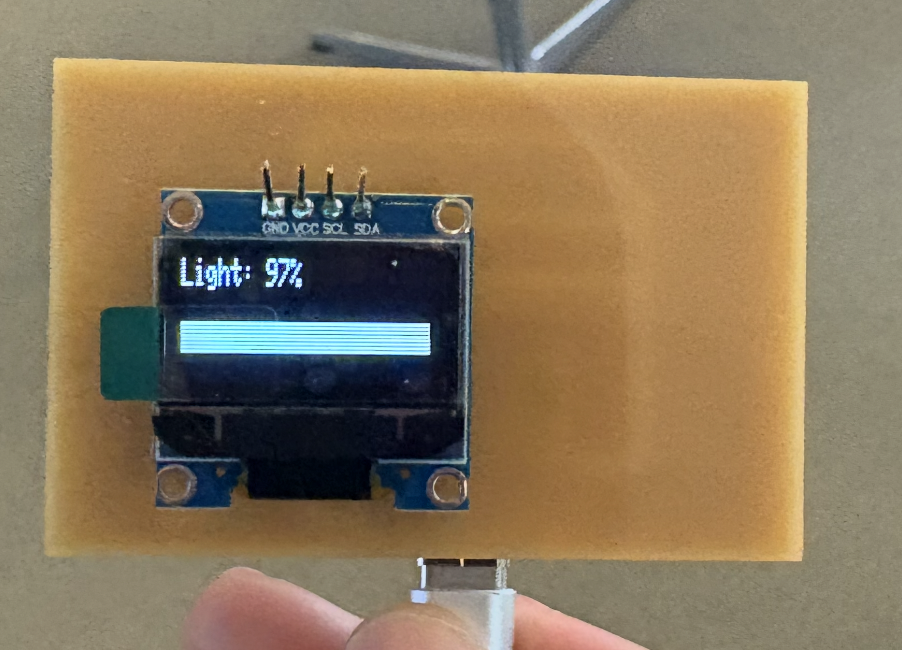

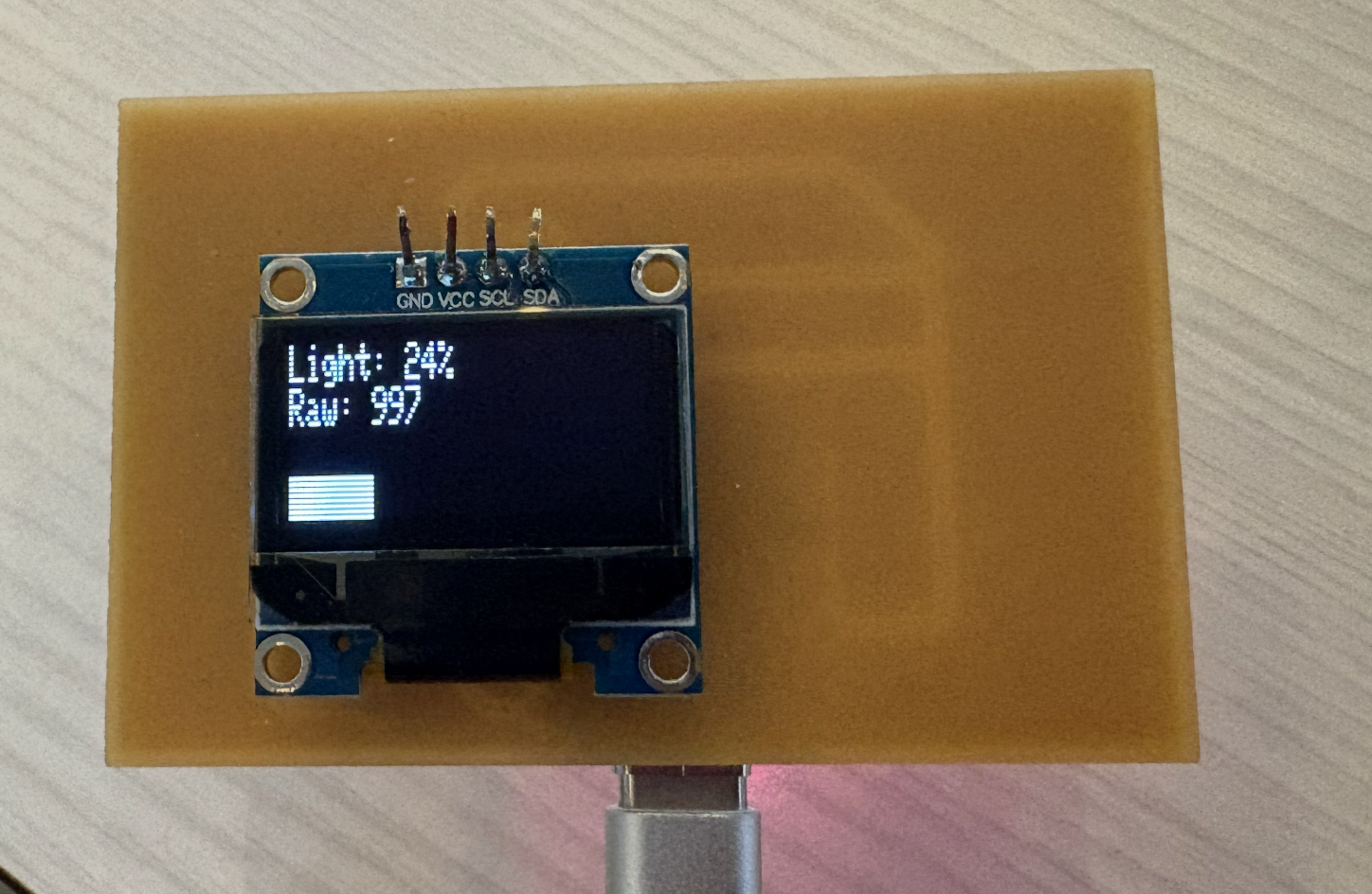

Then, I flashed a simple program to take in the data from the phototransistor and display it on the OLED display.

#include

#include

#include

#define SCREEN_WIDTH 128

#define SCREEN_HEIGHT 32

#define OLED_RESET -1

Adafruit_SSD1306 display(SCREEN_WIDTH, SCREEN_HEIGHT, &Wire, OLED_RESET);

const int PHOTO_PIN = A0; // P26_A0_D0

void setup() {

pinMode(PHOTO_PIN, INPUT);

Wire.setSDA(6); // P6_D4_SDA

Wire.setSCL(7); // P7_D5_SCL

Wire.begin();

if(!display.begin(SSD1306_SWITCHCAPVCC, 0x3C)) {

while(1);

}

display.clearDisplay();

display.setTextSize(1);

display.setTextColor(SSD1306_WHITE);

display.display();

}

void loop() {

int raw = analogRead(PHOTO_PIN);

int light = map(raw, 0, 4095, 0, 100); // 12-bit range

display.clearDisplay();

display.setCursor(0, 0);

display.print("Light: ");

display.print(light);

display.print("%");

// debug - add raw value

display.setCursor(0, 8);

display.print("Raw: ");

display.print(raw);

int barWidth = map(light, 0, 100, 0, SCREEN_WIDTH);

display.fillRect(0, 24, barWidth, 8, SSD1306_WHITE);

display.display();

delay(100);

}

It turns out I had a slight misunderstanding of the Q phototransistor NPN I was working with. It's an IR sensor (not visible light), so the ambient light doesn't really affect it (and covering it doesn't change too much). Using a 10k resistor as a scaling resistor is good, but if I want it to be a bit more sensitive to small changes I can use a higher-value resistor.