Week 06 :: Molding and Casting

How do we design a production process for reproducible elements?

1. Group Training

We started the week by reviewing safety data sheets for the casting compounds we'll be trying this week, followed by a demo in the shop using some prior years' molds.

SDS Review Notes:

SDS for OOMOO SILICONE RUBBER

Section 1: Indicates that this SDS is relevant for both the "OOMOO" series which we'll be starting with, but also with others such as the "SORTA-CLEAR" series.

Section 2: Not a hazardous substance or mixture according to OSHA.

Section 4: First Aid Measures: fresh air in case of inhalation, water in case of eye contact, water+soap in case of skin contact.

Section 7: Handling and Storage

Handling Precautions: Wash hands after use.

Storage Requirements: Keep container(s) tightly closed and propery labeled. Store in cool, dry, well ventilated place away from heat, direct sunlight, strong oxidizers, and any incompatibles.

Although this is slightly generic text, it seems to be highlighting something important which is that as long as the material is properly labeled, and stored without contamination, it's fairly non-hazardous.

Section 8: PPE

Safety glasses and appropriate ventilation are recommended.

Section 10: Stability and Reactivity

Chemical Incompatibilities: Strong bases, and acids.

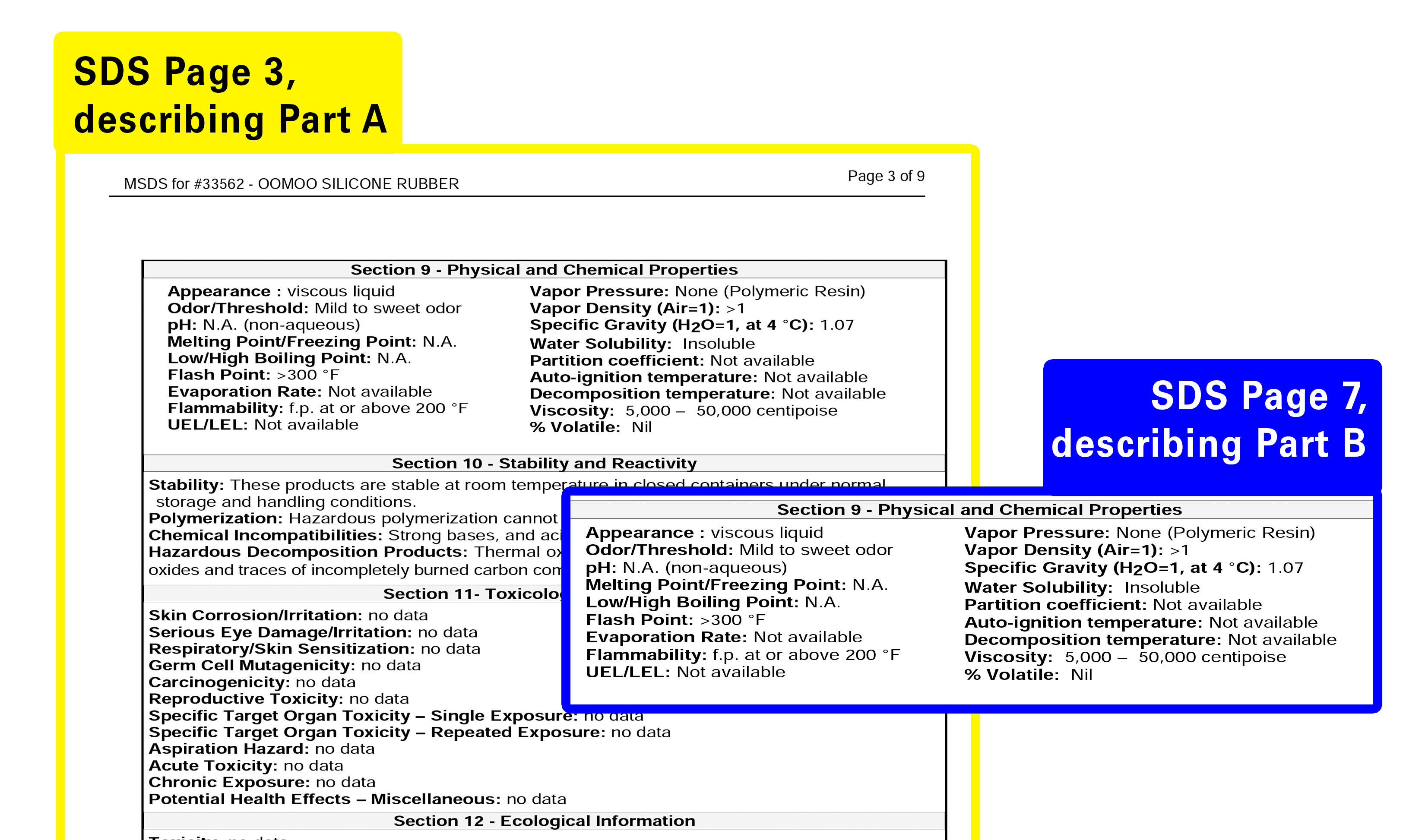

I didn't realize that Part A and Part B had different sections initially. Both are labelled for general use as "Silicone Elastomer," and comparing "Section 9 - Physical and Chemical Properties," there are no differences listed.

I didn't realize that Part A and Part B had different sections initially. Both are labelled for general use as "Silicone Elastomer," and comparing "Section 9 - Physical and Chemical Properties," there are no differences listed.

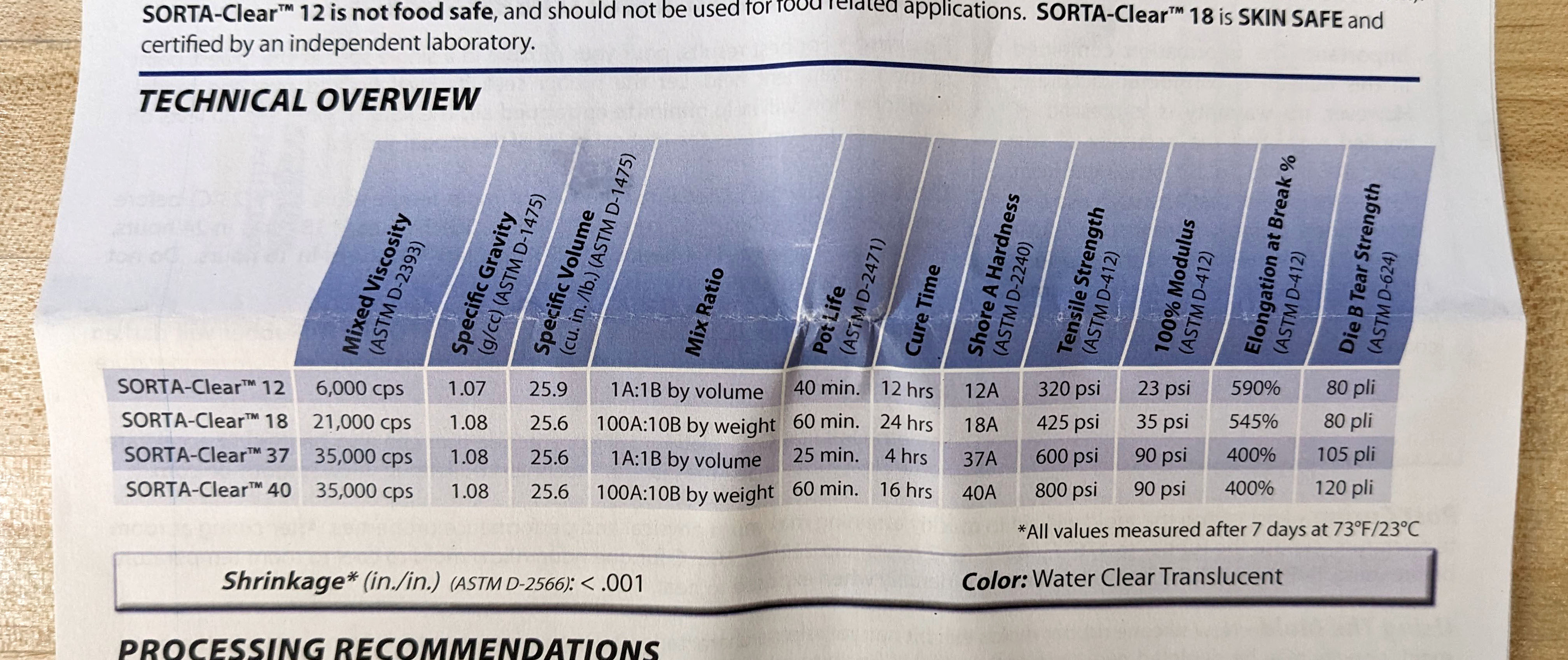

Reading the technical overviews for different products, I decided to try the sortaclear mixtures, which have higher shore hardness than the OOMOO products.

Reading the technical overviews for different products, I decided to try the sortaclear mixtures, which have higher shore hardness than the OOMOO products.

2. Design a Mold

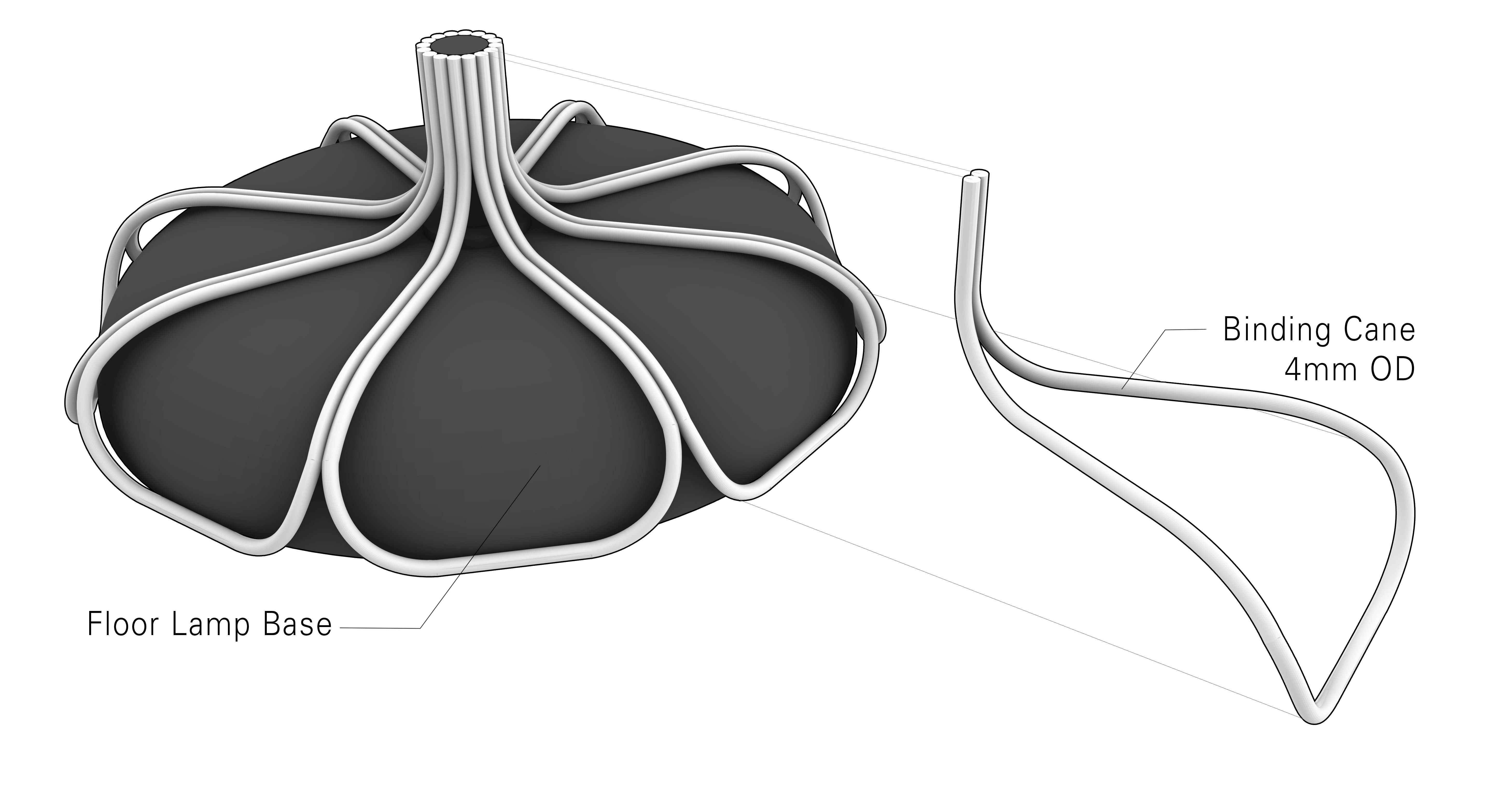

This week, I wanted to explore an idea I've been curious about for a while - how do I get binding cane (AKA rattan) to take on a highly specific geometry?

CAD Mockup in Rhino.

CAD Mockup in Rhino.

I had a very specific dimension in mind, because I want to design around the base of a floor lamp. I modeled the lamp in Rhino, then started to model an array of rattan petals to cover the geometry.

Design process steps in Rhino 7.

Design process steps in Rhino 7.

This specific dimension I was working around immediately presented a challenge when Jen showed me the wax block we'd be using for milling. The volume is more than sufficient for my intended shape, but the aspect ratio of the wax required me to design a 2 part mold.

Once the two parts are cast, one is rotated 180 degrees to meet the other. I decided to build a housing for the two parts using lasercut masonite, rather than try to fuse the two parts together.

Excerpt from toolpathing setup with Jen O'Brien, showing specific paths imported to cut as close as possible to the positive of the cane. There were no overhangs in the geometry, but there were sharp corners. We decided to do a specific path using a 1/8" ball to incorporate a fillet into the surface at these locations.

Not pictured in these steps, I picked up some 1/8" masonite from the scrap pile at the shop, and lasercut a housing for the two parts. (see below)

3. Steambending Test

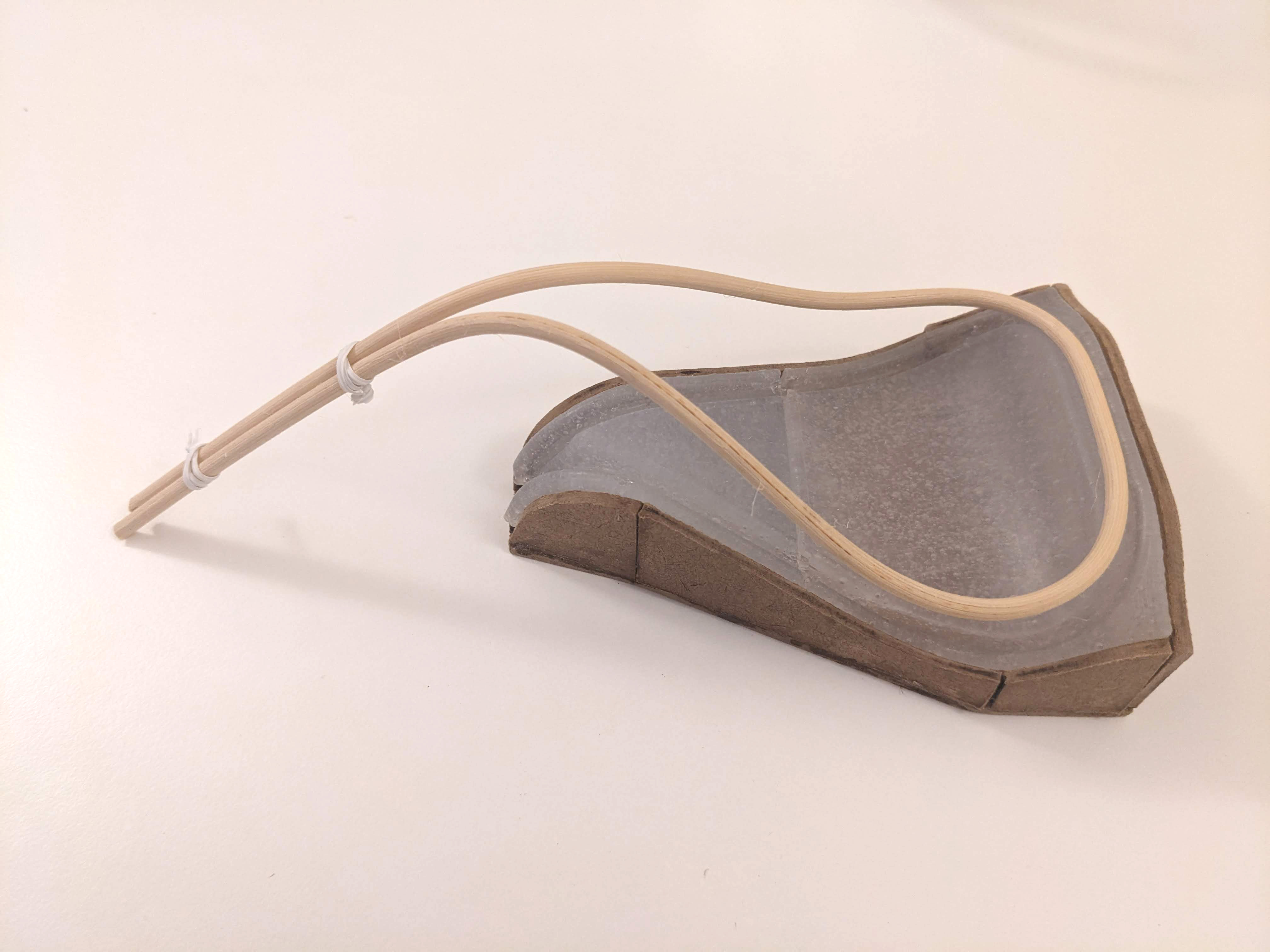

The reason for choosing Sorta-clear 37 and masonite for the materials was that they're both hard and hold up well to wear. Rattan springs back when compressed, so I was expecting this jig needed to be resilient.

Steambent rattan, and cast steambending jig.

Steambent rattan, and cast steambending jig.

The process for using the cast mold was to soak the rattan in boiling water until it was saturated and pliable. Then, I would manually press the rattan into the channels of the mold.

At the start of this week, I was skeptical about the relevance of casting now that 3D printers are so prevalent. However, I really enjoyed the degree of customization in this process, especially in the mix design, or fine-tuning the material performance of your mold and cast.

The repeatability of the process feels quite rewarding, where it takes a fair bit of setup to create the first object, but each subsequent one you produce gets incrementally simpler.

Casting was not part of my plan for the final project, but now I'm quite curious to try more.