Week 07 :: Computer-Controlled Machining

How do we prototype quickly at scale?

1. Group Test run

I started this week by heading to N51 to measure the OSB stock, then sitting down with Chris Dewart to discuss file setup.

Joined by Diana Mykhaylychenko, Mateo Fernandez, Nasibe Nur Dundar Arifoglu, and Niklas Hagemann, we found some scrap OSB to run a test file.

Joined by Diana Mykhaylychenko, Mateo Fernandez, Nasibe Nur Dundar Arifoglu, and Niklas Hagemann, we found some scrap OSB to run a test file.

2. Design Something Big

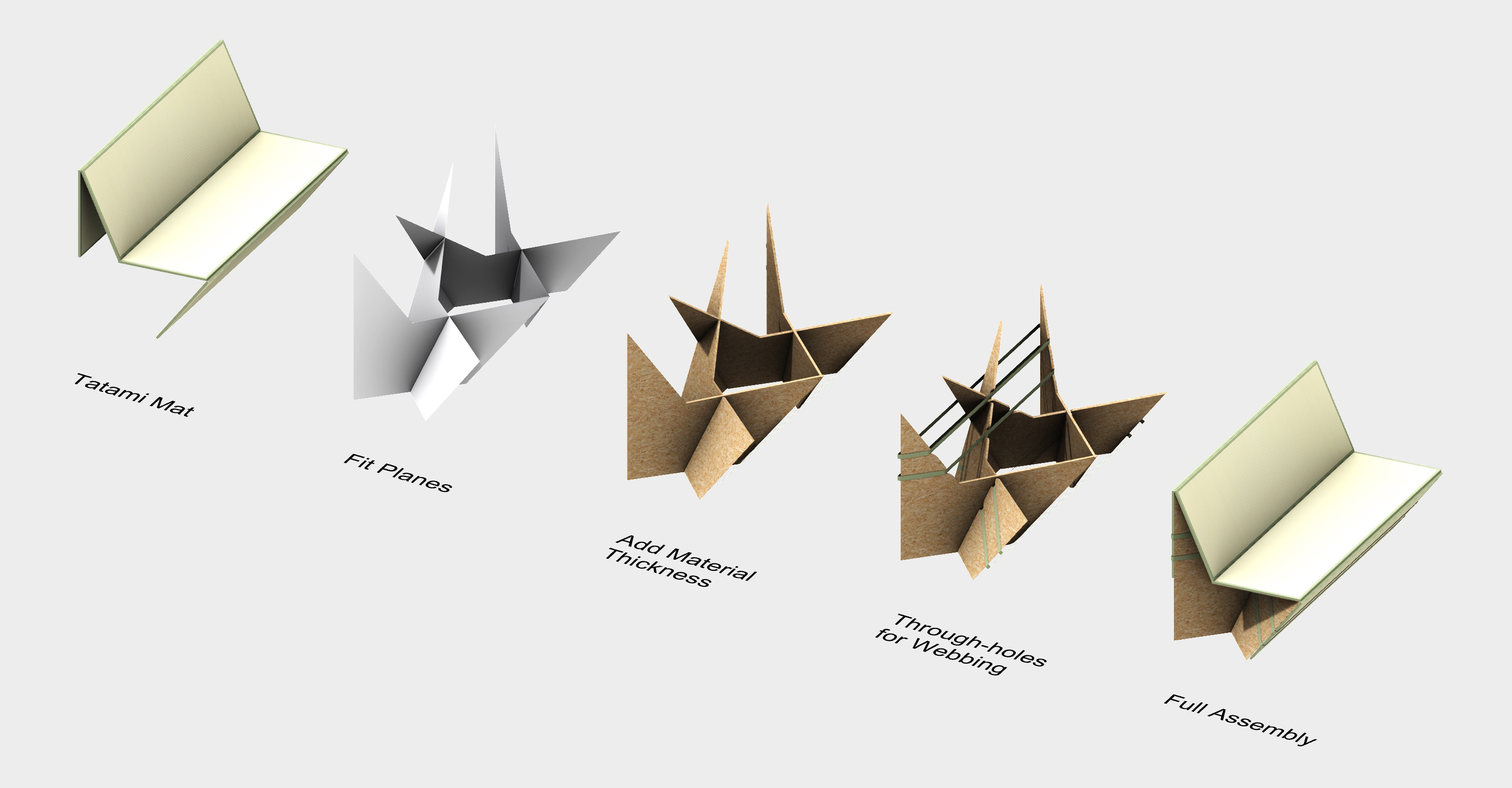

I'd like to use this week to upcycle a tatami mat. My apartment doesn't have a great place to store the mat, so I'd like to incorporate it into a piece of furniture.

The plan here is to design a series of intersection profiles using friction fit joinery to act as the substructure for the chair. Polyester webbing will be used to strap the tatami mat in place.

The plan here is to design a series of intersection profiles using friction fit joinery to act as the substructure for the chair. Polyester webbing will be used to strap the tatami mat in place.

3. Make Something Big

After design and CAM preparation, the job is ready to bring to the Onsrud.

Full scale assembly of substructure. As I designed in Rhino, I thought of it as a chair, but in real life, it feels more like a couch.

Full scale assembly of substructure. As I designed in Rhino, I thought of it as a chair, but in real life, it feels more like a couch.

After sanding the edges by hand to remove splinters, I brought the pieces from N51 to RPL to finish.

After sanding the edges by hand to remove splinters, I brought the pieces from N51 to RPL to finish.