.. ,

. . . ,,

week six

casting (almost) anything

. . , .

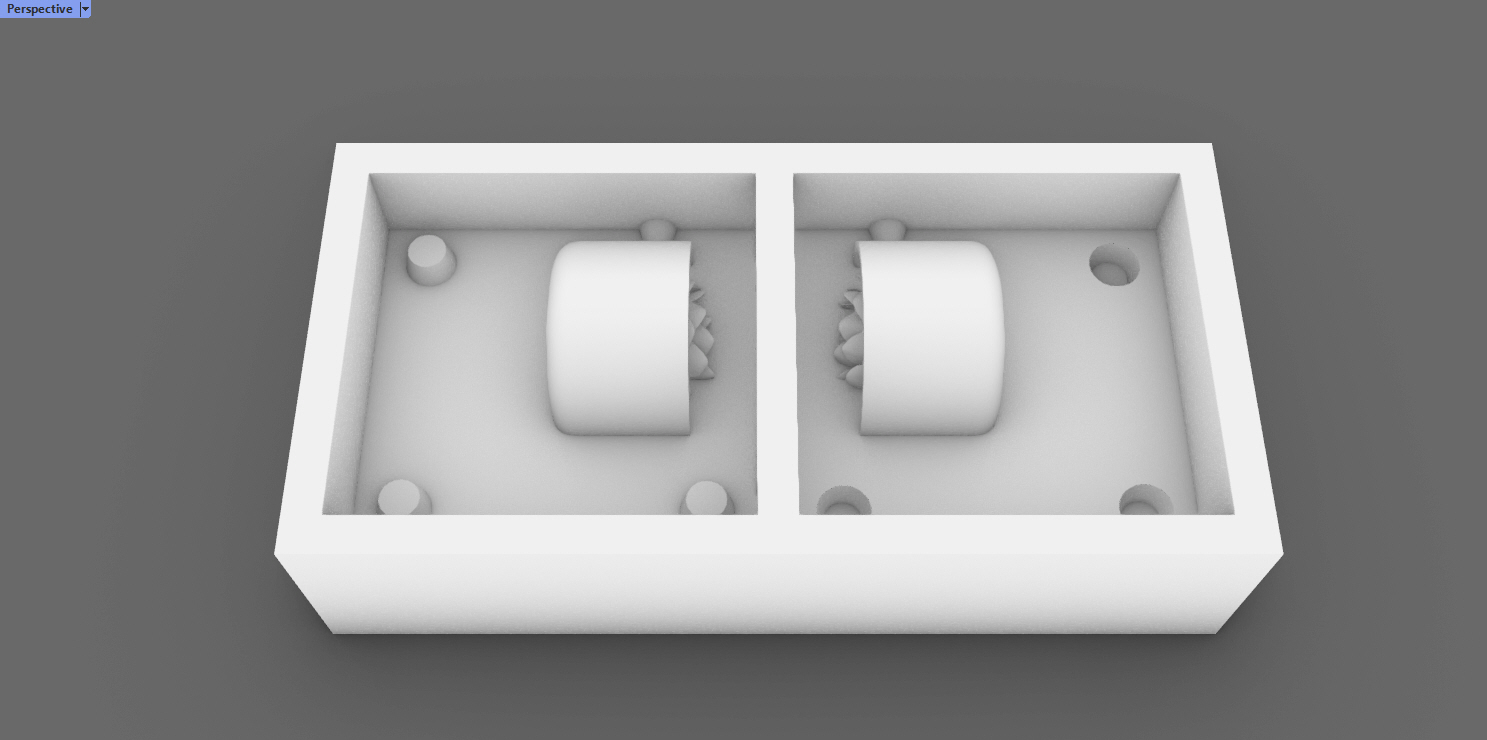

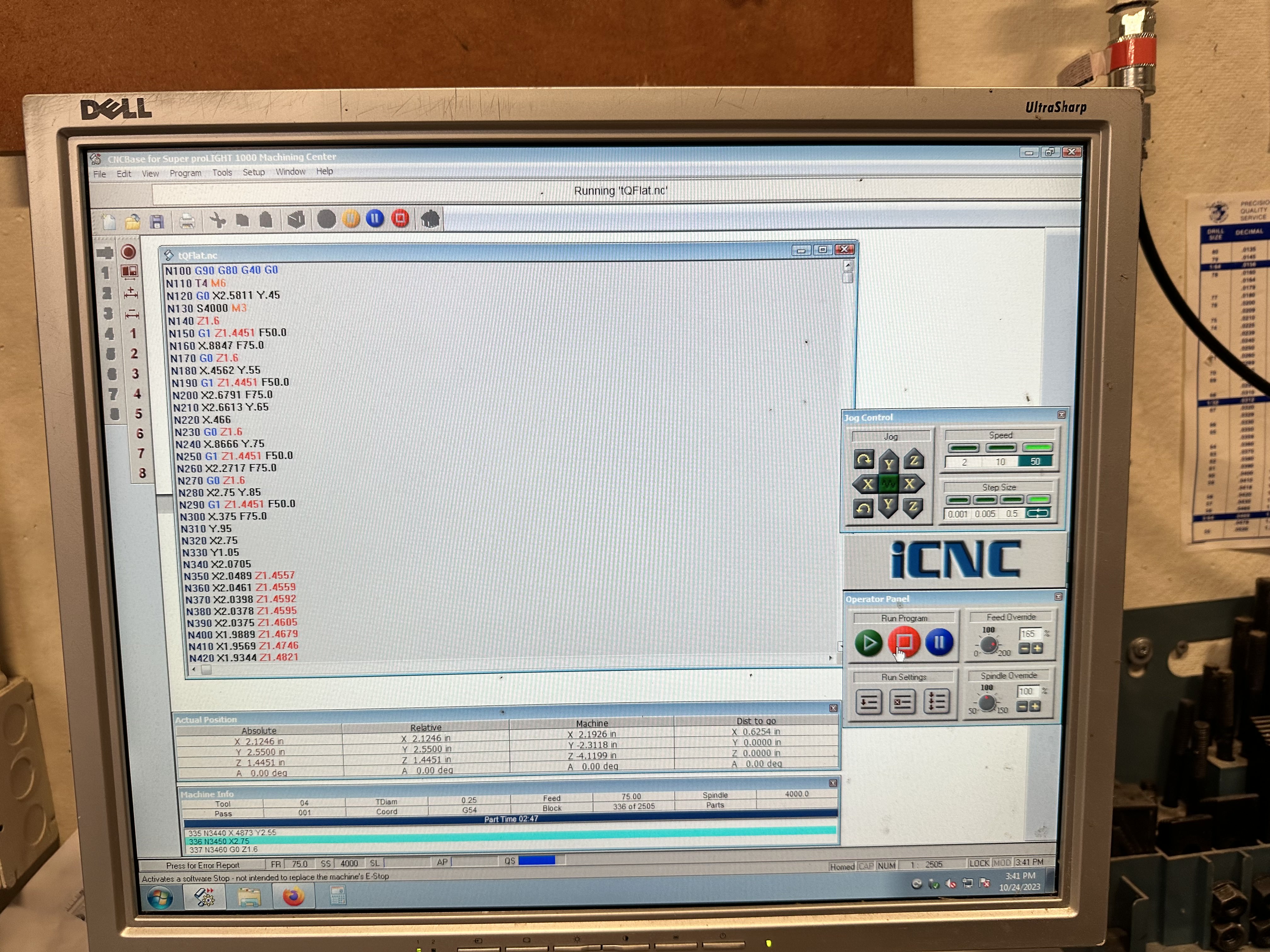

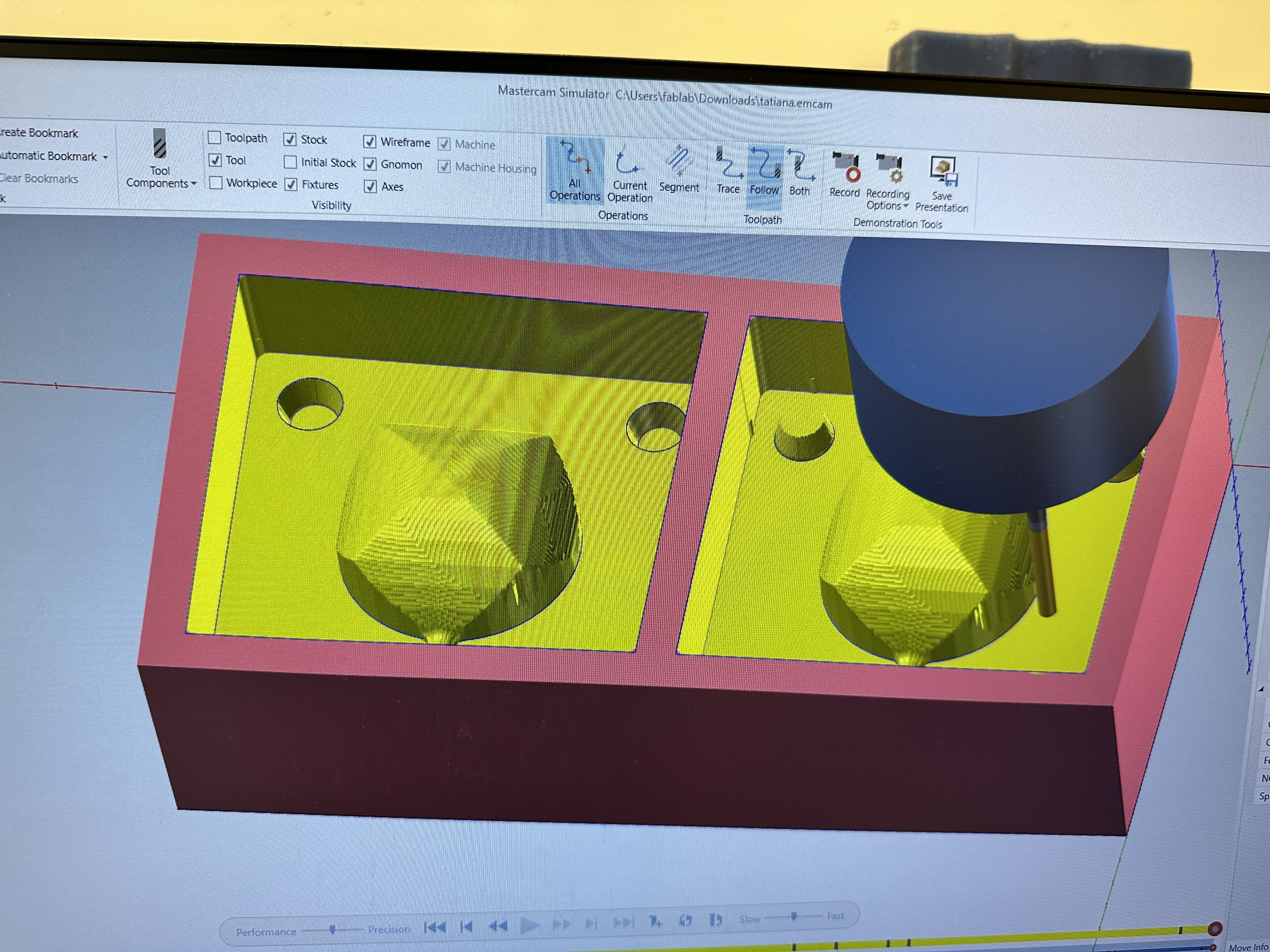

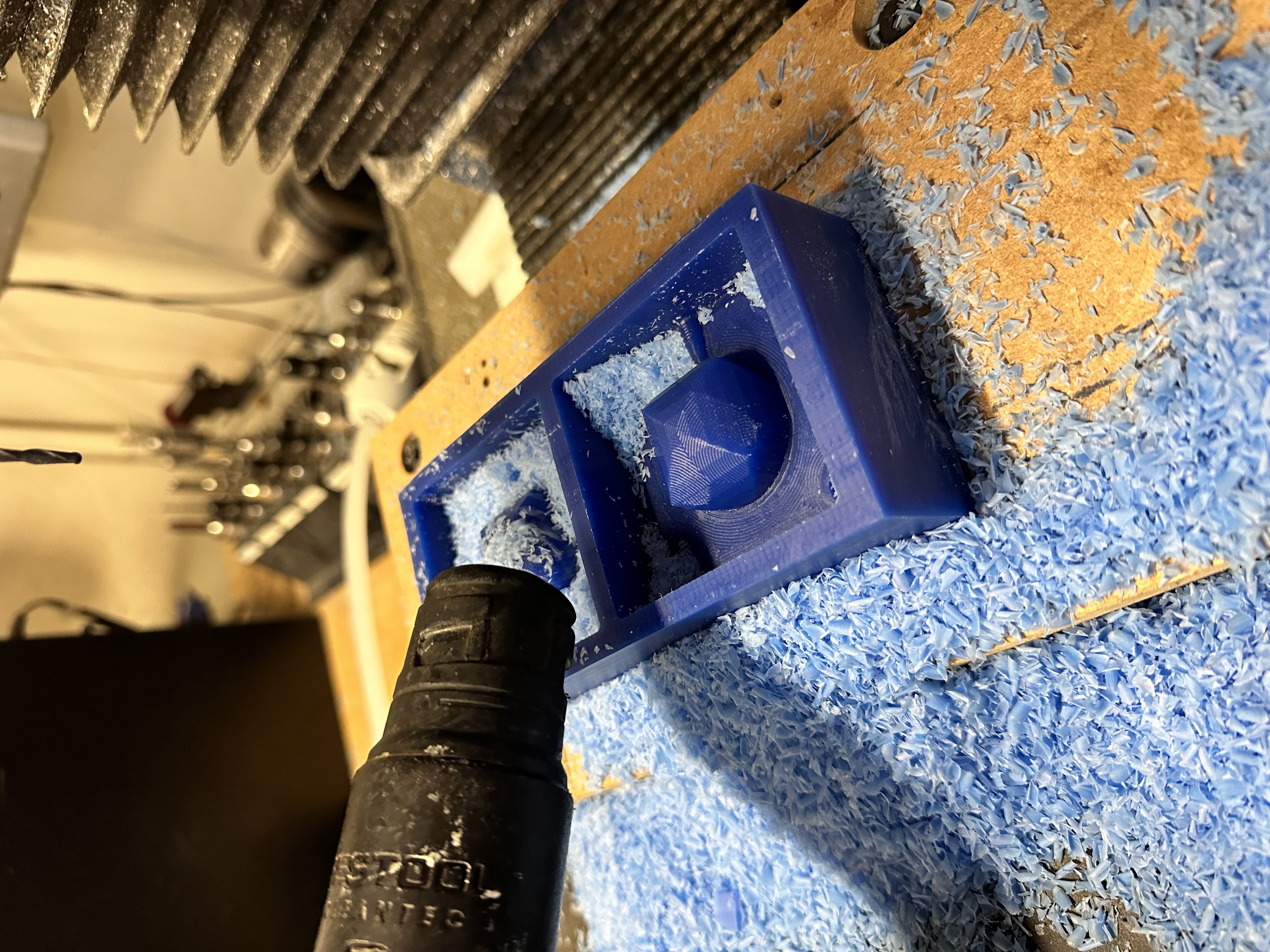

Cutting a Wax Mold

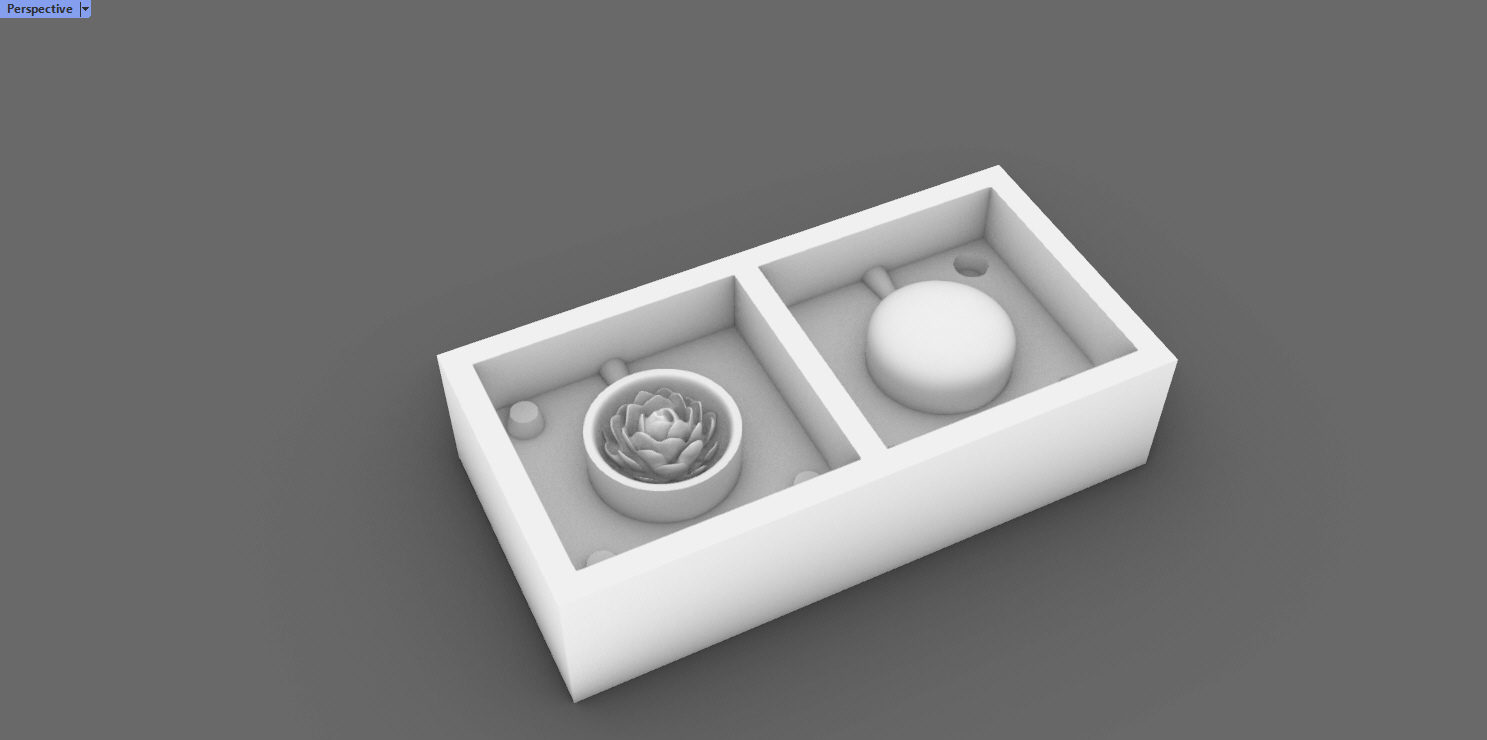

As I have several tiny succlents on my desk, I thought adding a plaster succulent would be very fun so I decided to model that.

. . , .

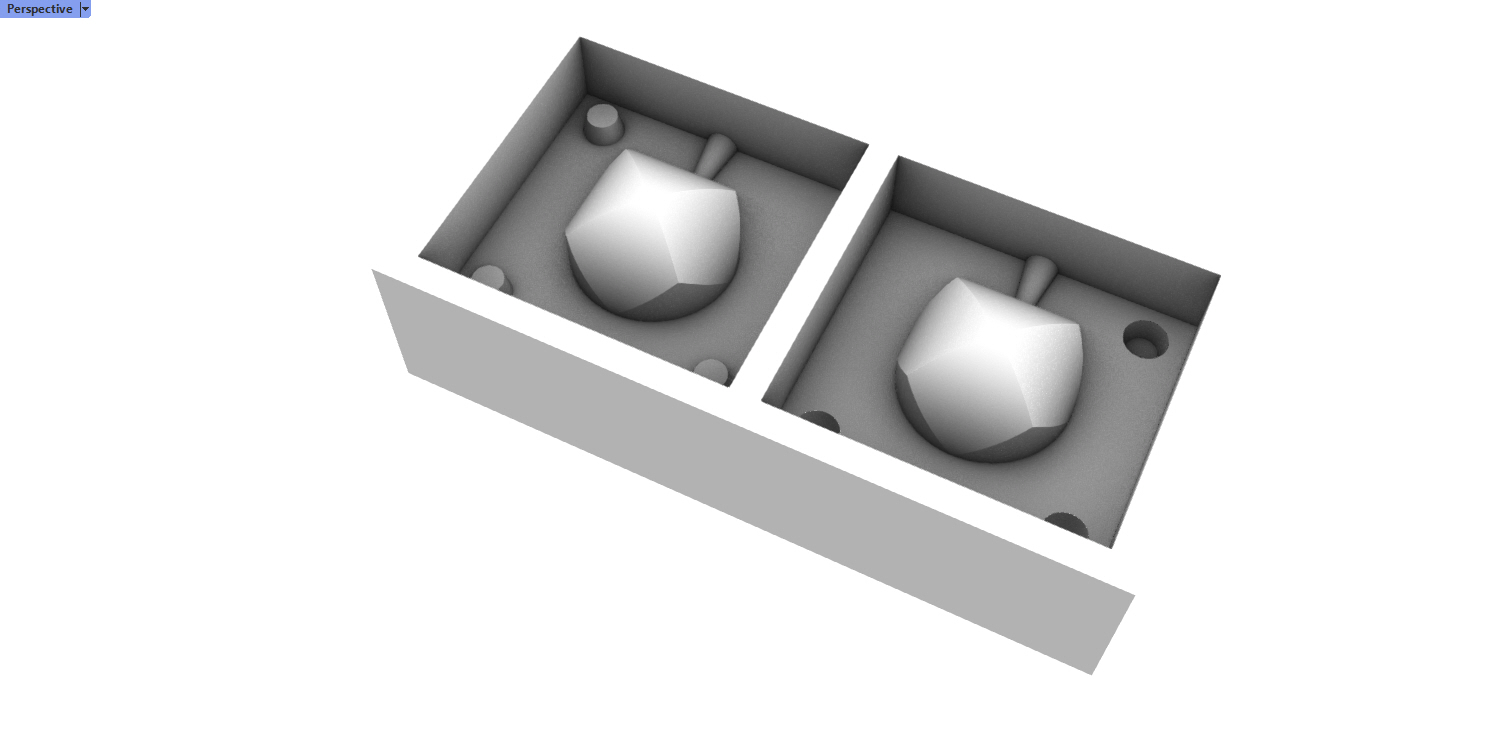

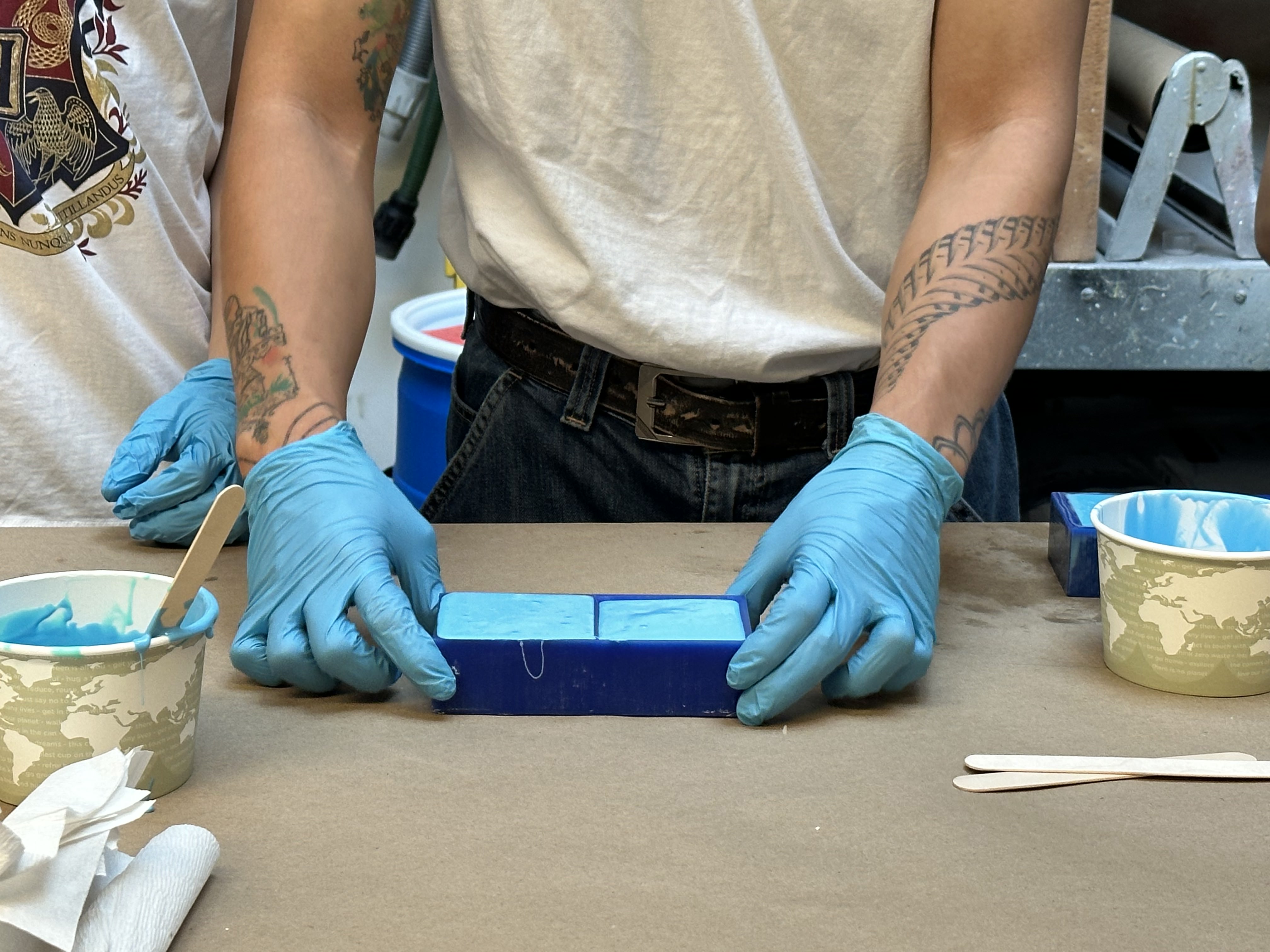

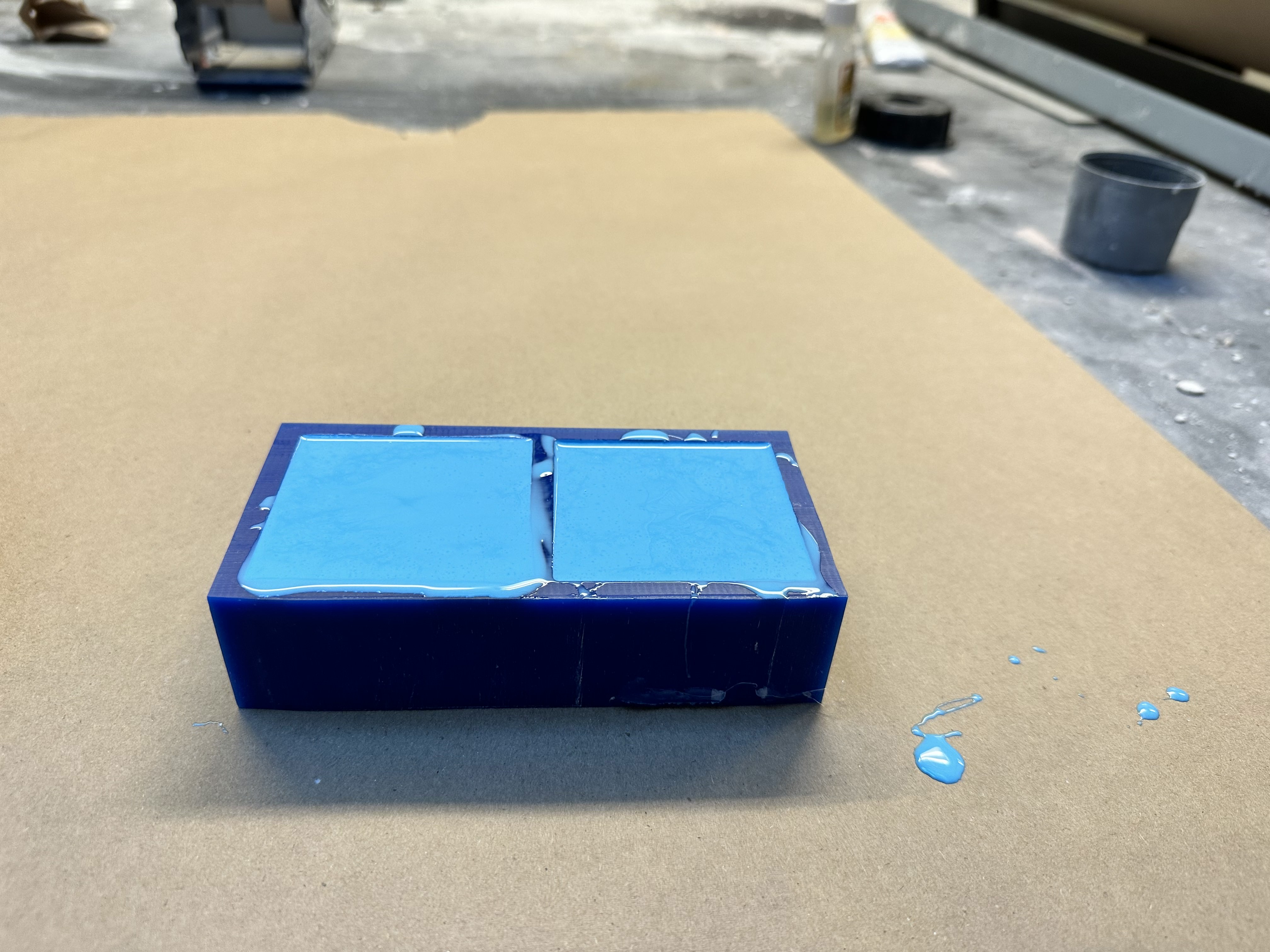

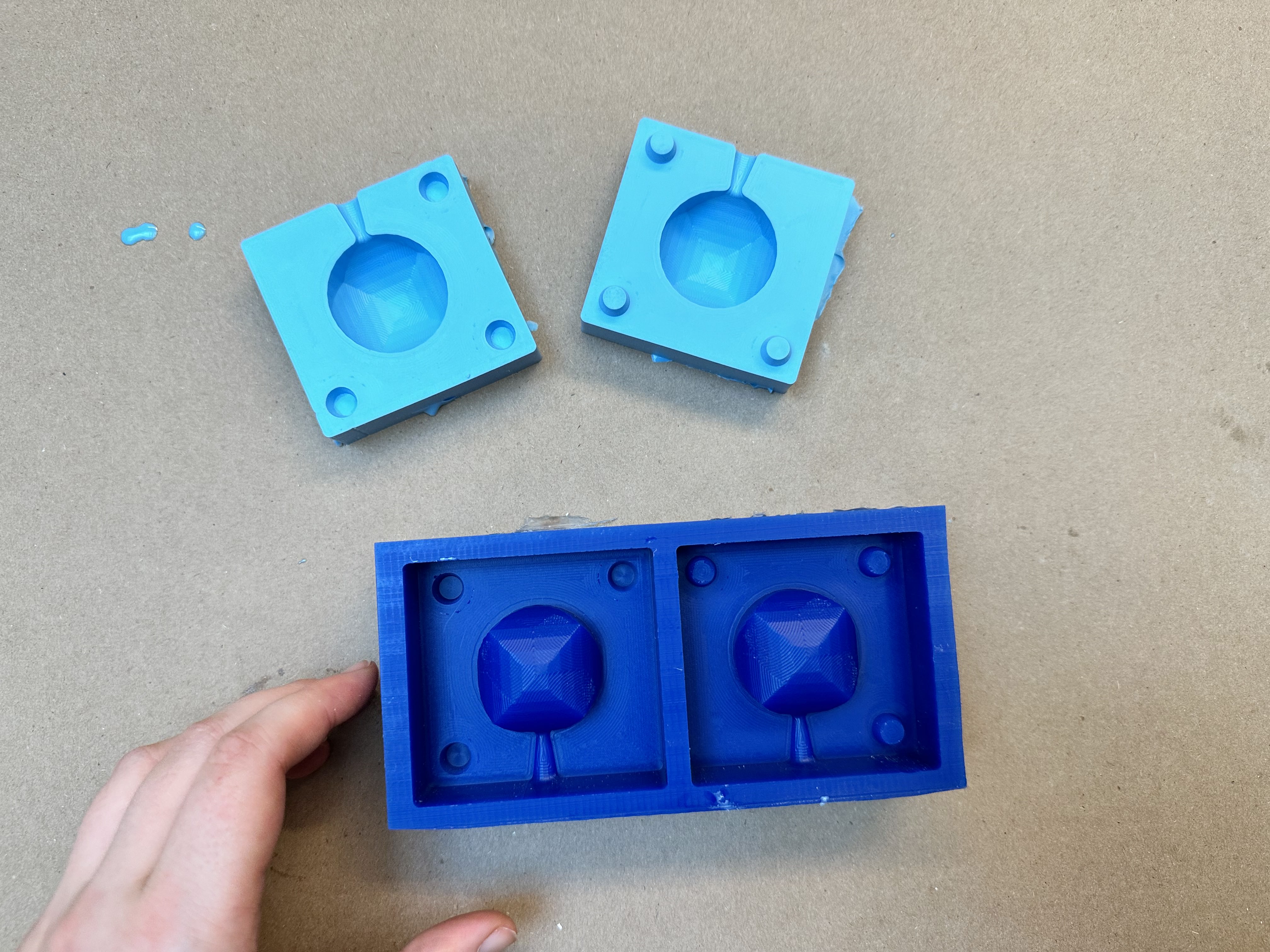

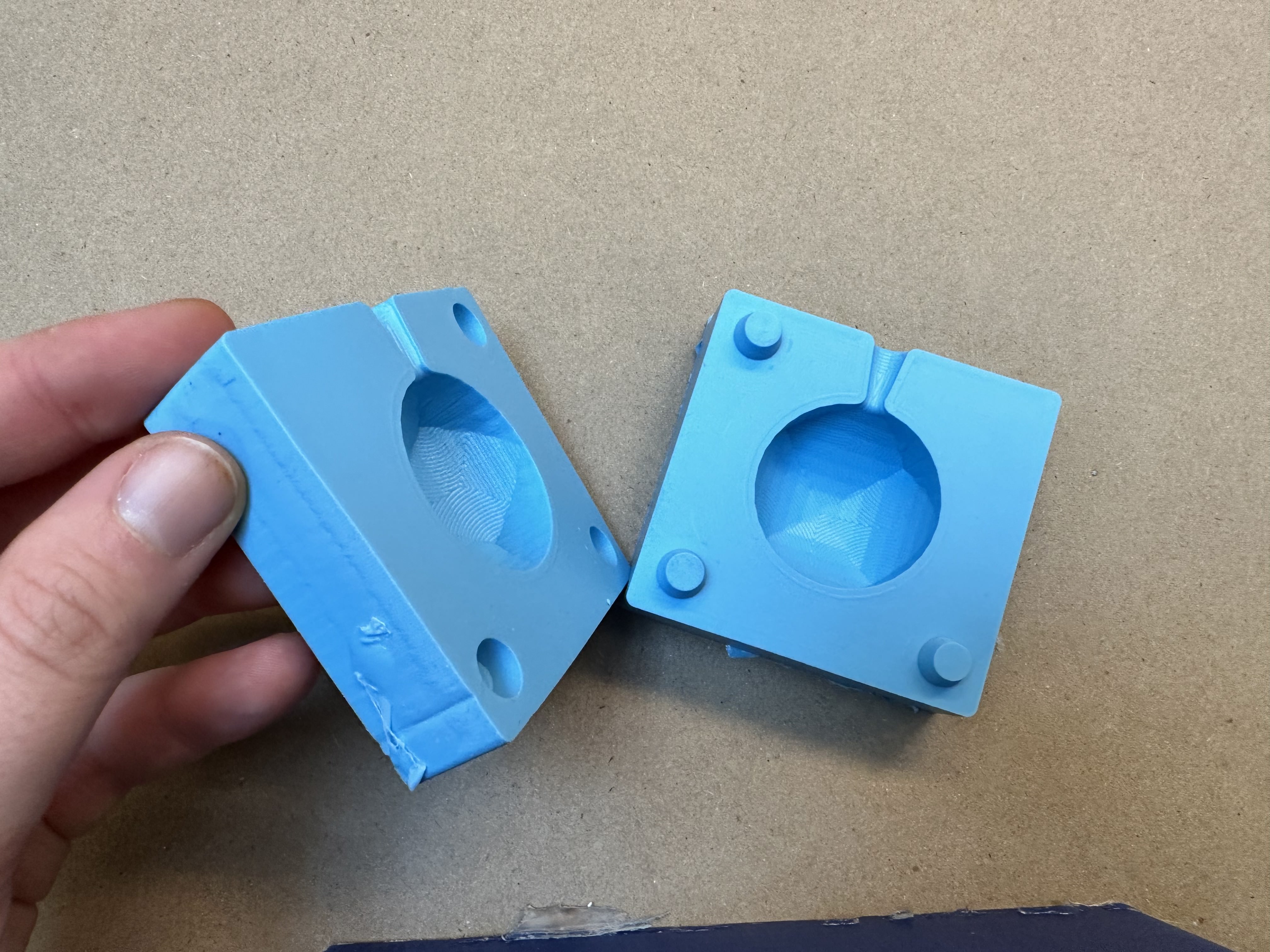

Casting a Silicone Mold

. . , .

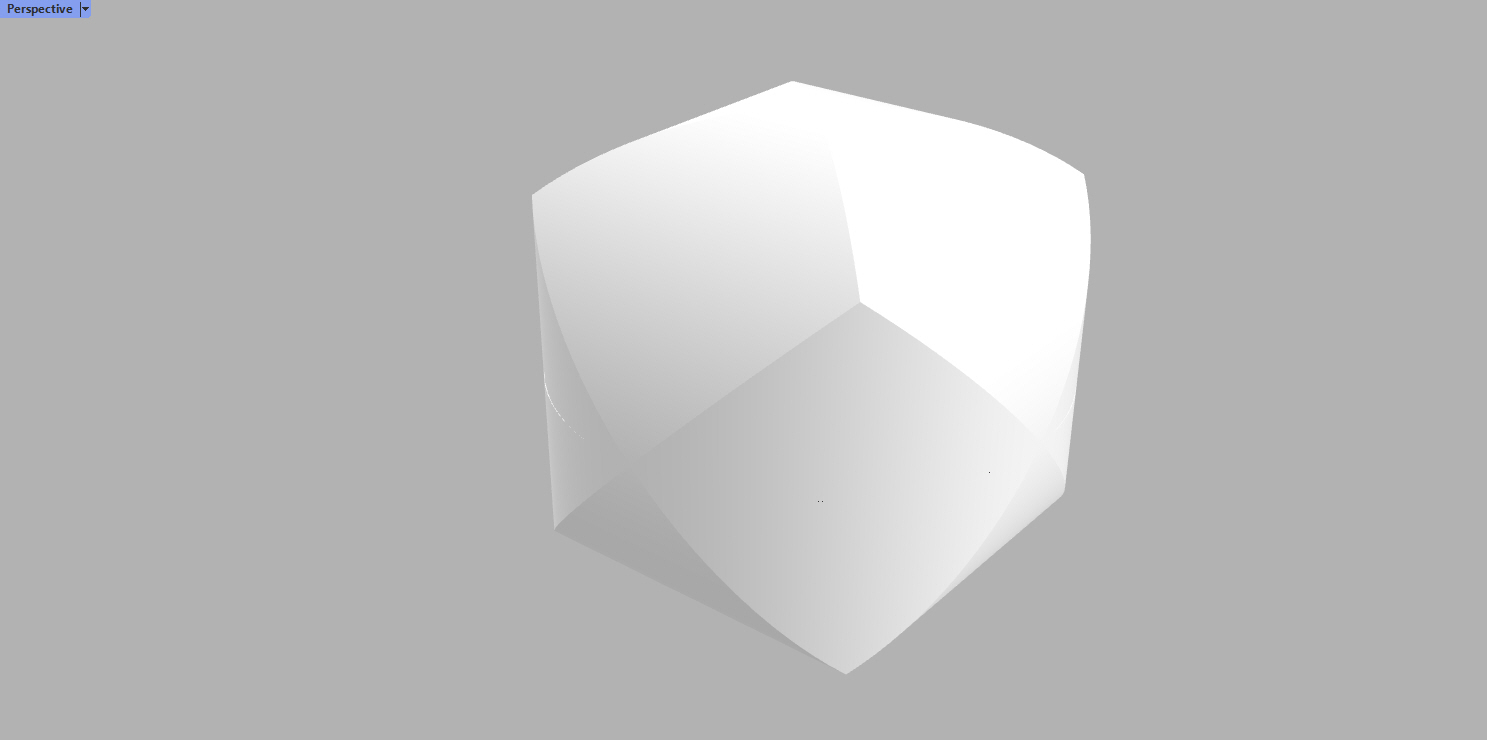

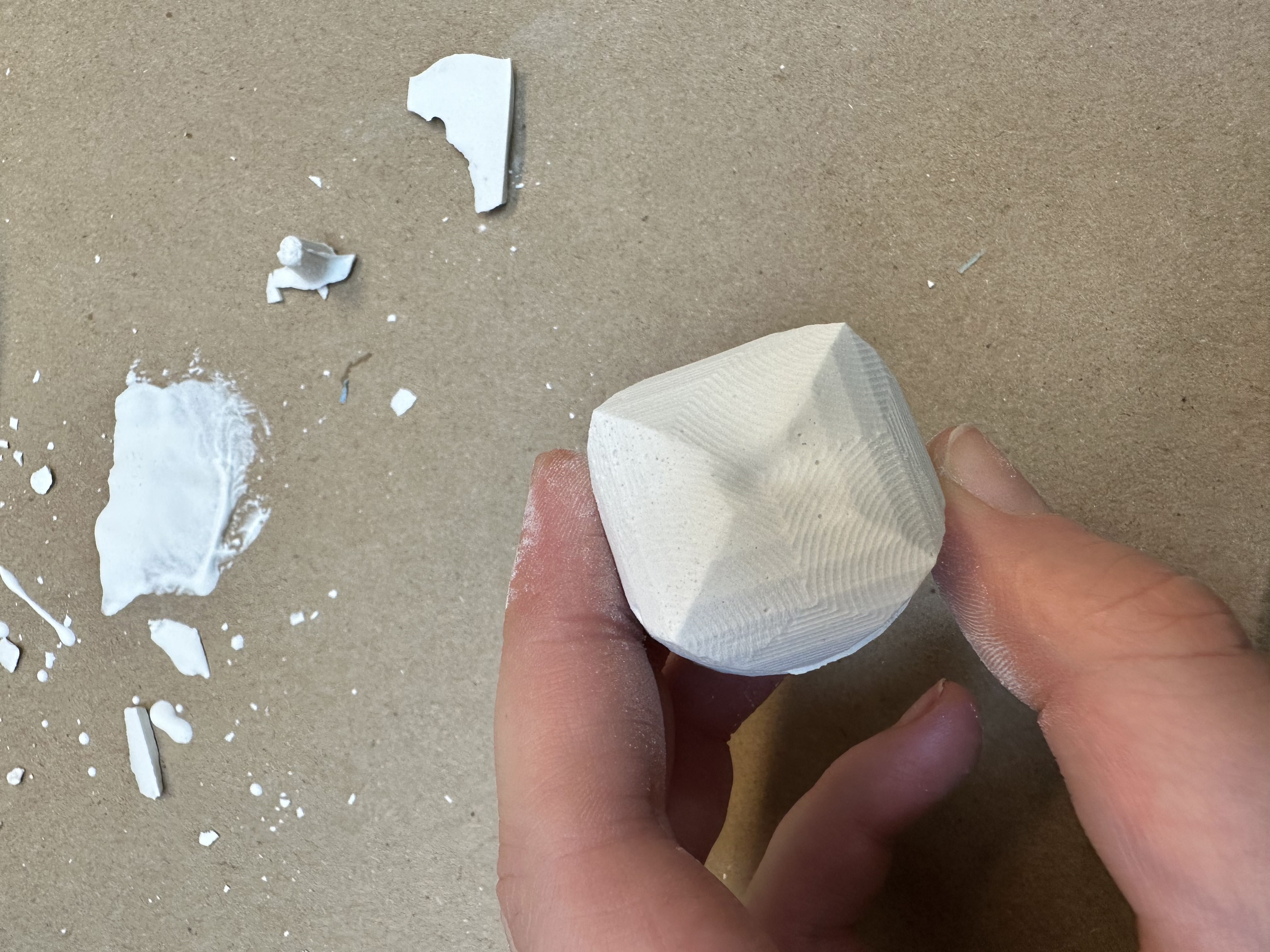

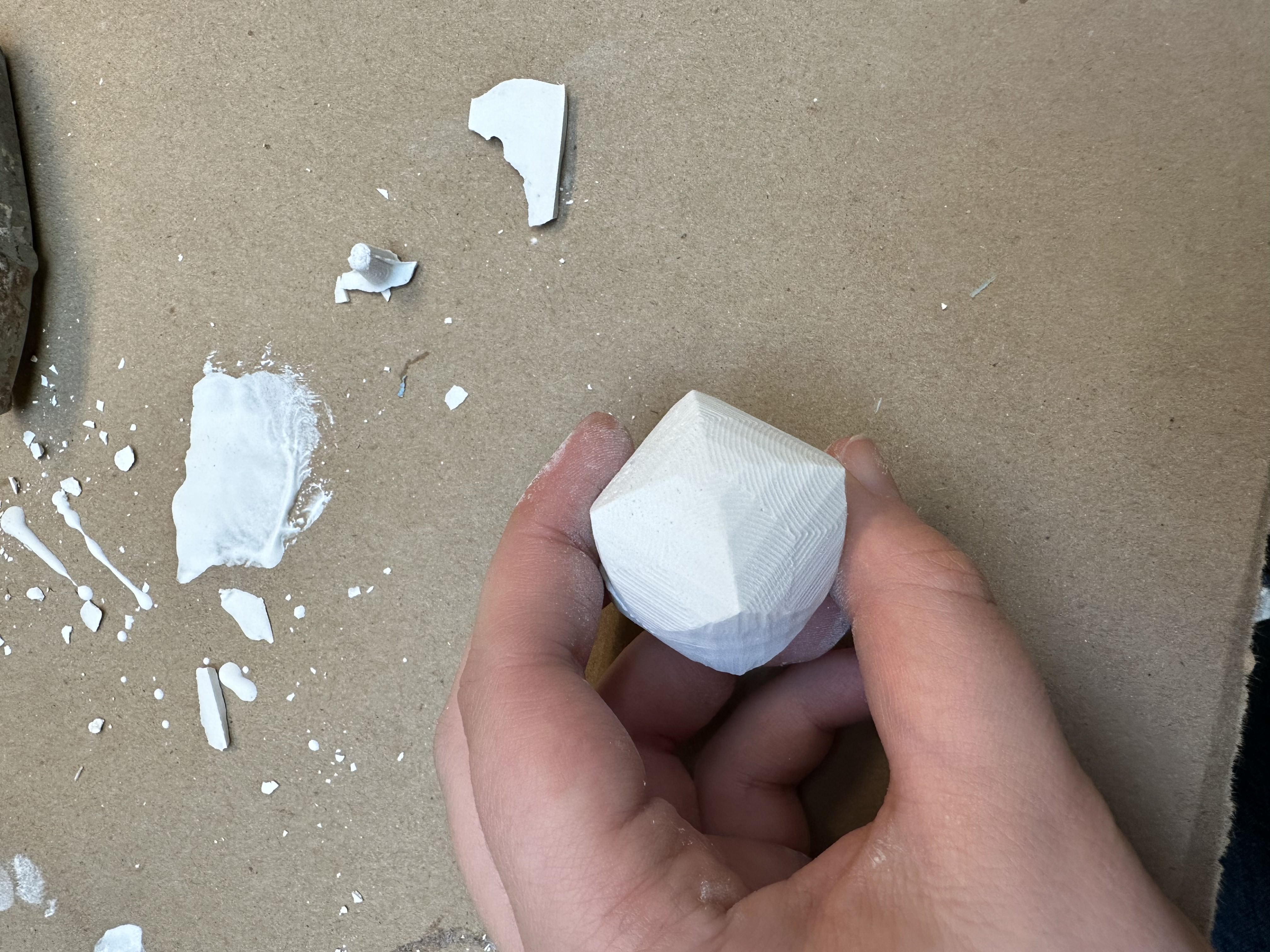

Casting the Plaster Geometry

. . , .

!! 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 ??