I wanted to build a kit for a reconfigurable marble run.

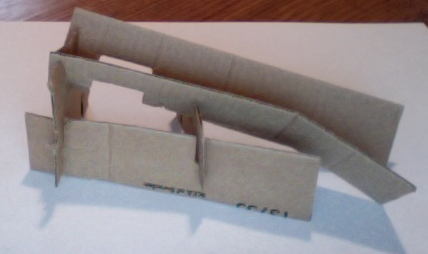

First I built a cardboard prototype to try to figure out what components I needed. My logic was backwards and the first one angled the wrong way! But I was able to understand that I needed at least three basic pieces: the run pieces, pieces with angled slots to hold the run in the right place, and pieces to go between those and hold them together while creating anchor points for the next run to begin.

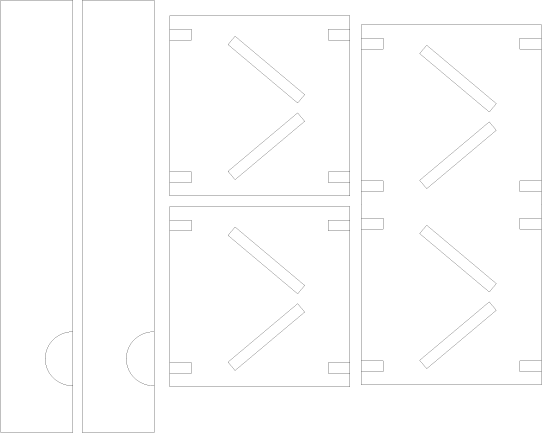

Then I made the shapes in Adobe Illustrator:

I cut these out with an Xacto to test.

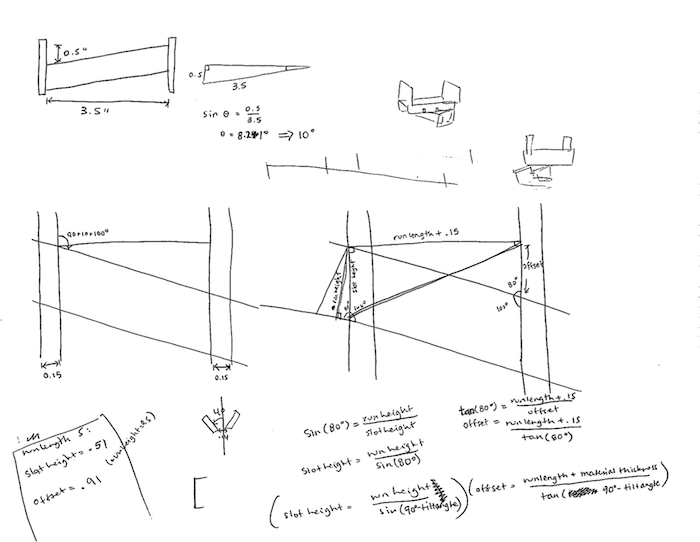

The initial idea was that the angle would be created by having two columns of pieces at different heights. I realized that I could instead have two slots on each end piece and the angle between them could be created by putting the top of the run in the higher slots and the bottom in the lower slots. To do that I needed to figure out the height of the slots (to allow the run pieces to enter at the right angle) and the distance between . I used some basic trig and found a formula that took as parameters the thickness of the material, the slope of the run, the width of the run pieces, and the length of the run.

I also used this prototype to figure out how steep the slope of the run needed to be to allow a marble to roll down, by rolling a marble down and measuring. It was about 8 degrees (math below) which I rounded to 10.

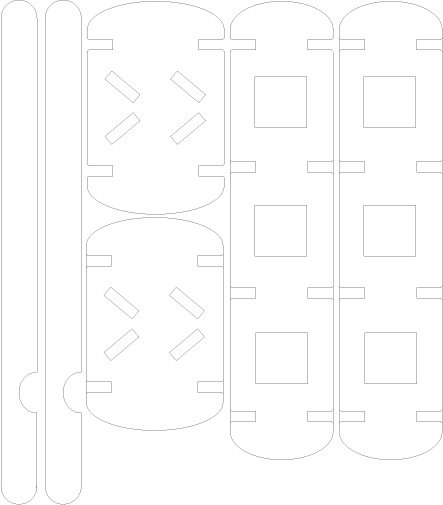

Based on this, I made a new version, choosing a run length of 5 inches.

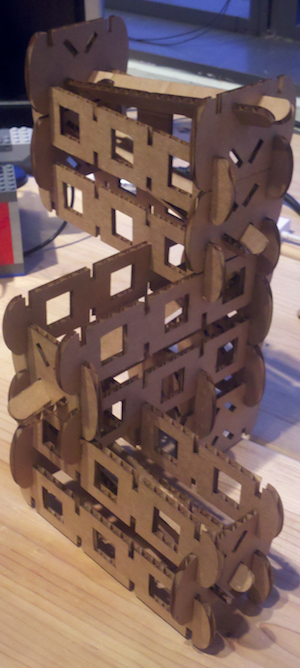

I cut these on the lasercutter and got this:

The way it all fit together worked perfectly…BUT I had estimated rather than measuring exactly the size of the hole the marble needed to fall through, and it didn't fit! I cut the holes a little bigger by hand just to show how it worked, version 2 is now in progress (which will also incorporate more places to actually see the runs, because right now they are blocked a little too much by the lengthwise pieces).