Computer-Controlled Machining

Machine: ShopBot

Material: Oriented Strand Board (OSB)

Design Software: Inkscape, Partworks 2D

Share: Stork_Scissors.dxf

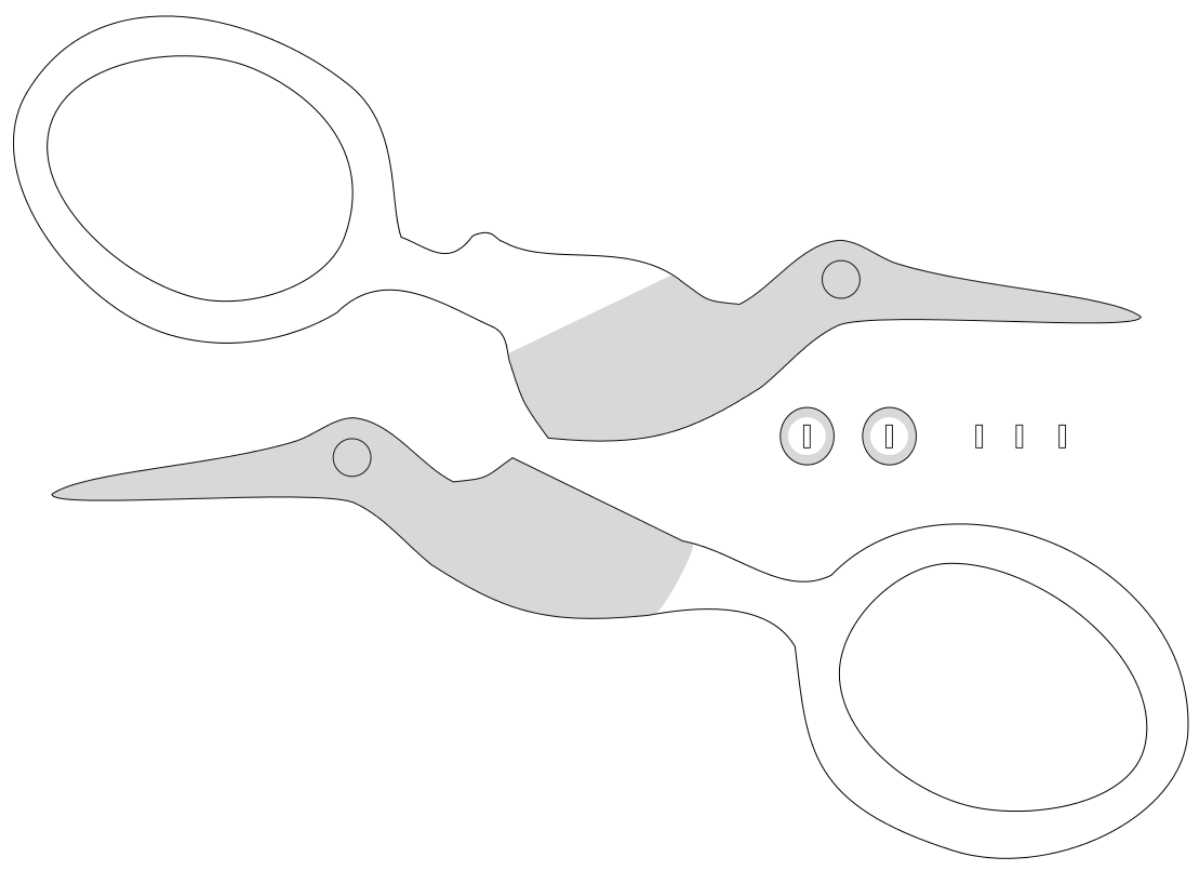

Our OSB was 4' x 8' x 7/16" and I decided to make the largest pair scissors I could with this constraint. Since several of my previous weekly projects were inspired by animals or animal parts, I decided I would model my big scissors after the stork-shaped scissors above. I used similar scissors when I first learned safe cutting technique.

I designed my scissors using Inkscape. That choice was largely driven by a broken Windows VM on my Ubuntu machine and by the comfort I developed for drawing curves within Inkscape during Week 2. In my design above - includes two blades and five parts for a hinge - grey regions represent pocket toolpaths and black curves represent profile toolpaths. I saved this work as an AutoCAD DXF and then opened that file from Partworks. I first noticed several of my curves were broken into segments. Tom introduced me to the "Edit > Join Vectors" function, which solved my problem by applying it to all vectors at once. Finally, I added T-bone fillets inside the hinge's circlular parts and both normal fillets and tabs on the rectangular pieces for press-fit. After choosing the settings for both toolpaths (Note, I set the pocket to 1/5 inch) I saved my work as CRV and exported to a SBP that I ran on the Shopbot.

It's big! Unfortunately my press-fit parts did not suffiently fasten the hinge, so if time permits I will redesign and try again. Meanwhile, the hinge is secured by 4 screws.

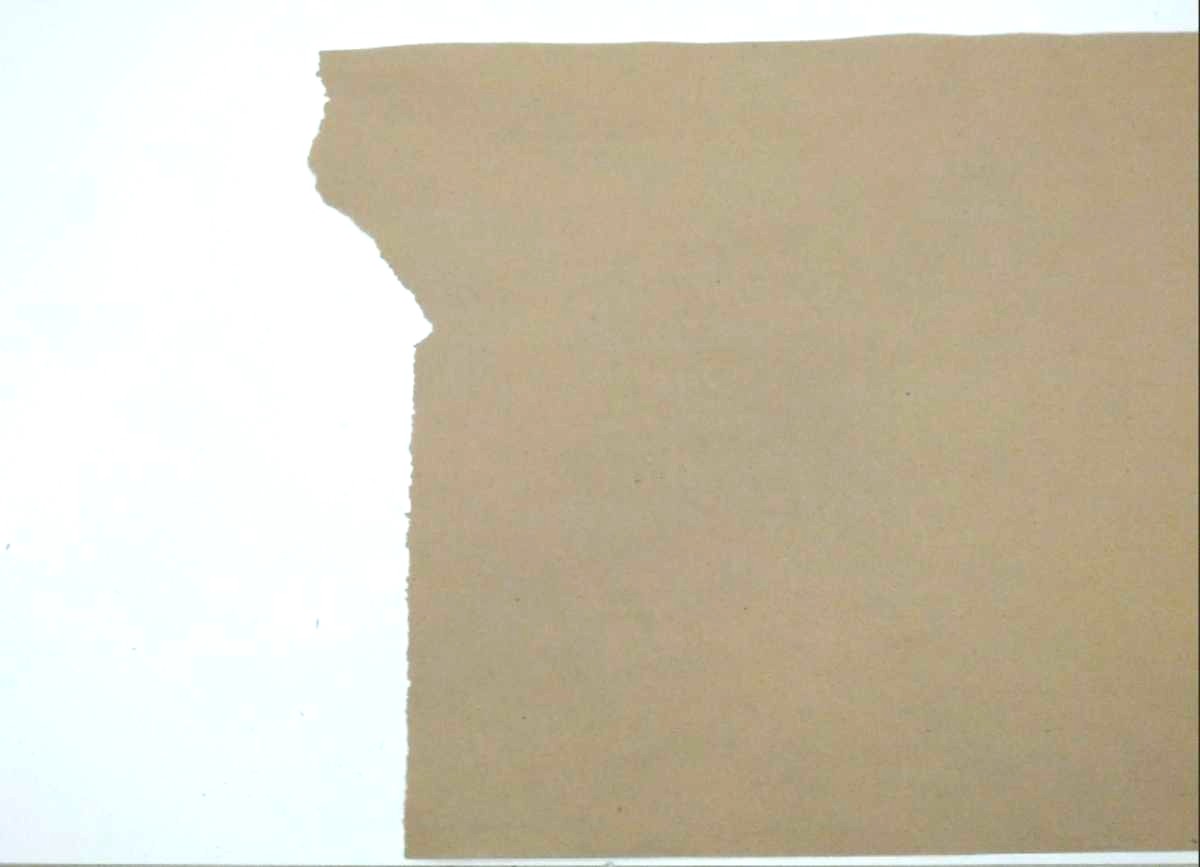

Kenny and I tore off a sheet of wide brown paper from the CBA shop for test cuts. This experiment is shown on top and the result can be found below. I was excited to see how straight of a shear they left.

The scissors even cut a few inches through cardboard until...