Week 13

Wildcard

Laser Micromachining

Laser Process

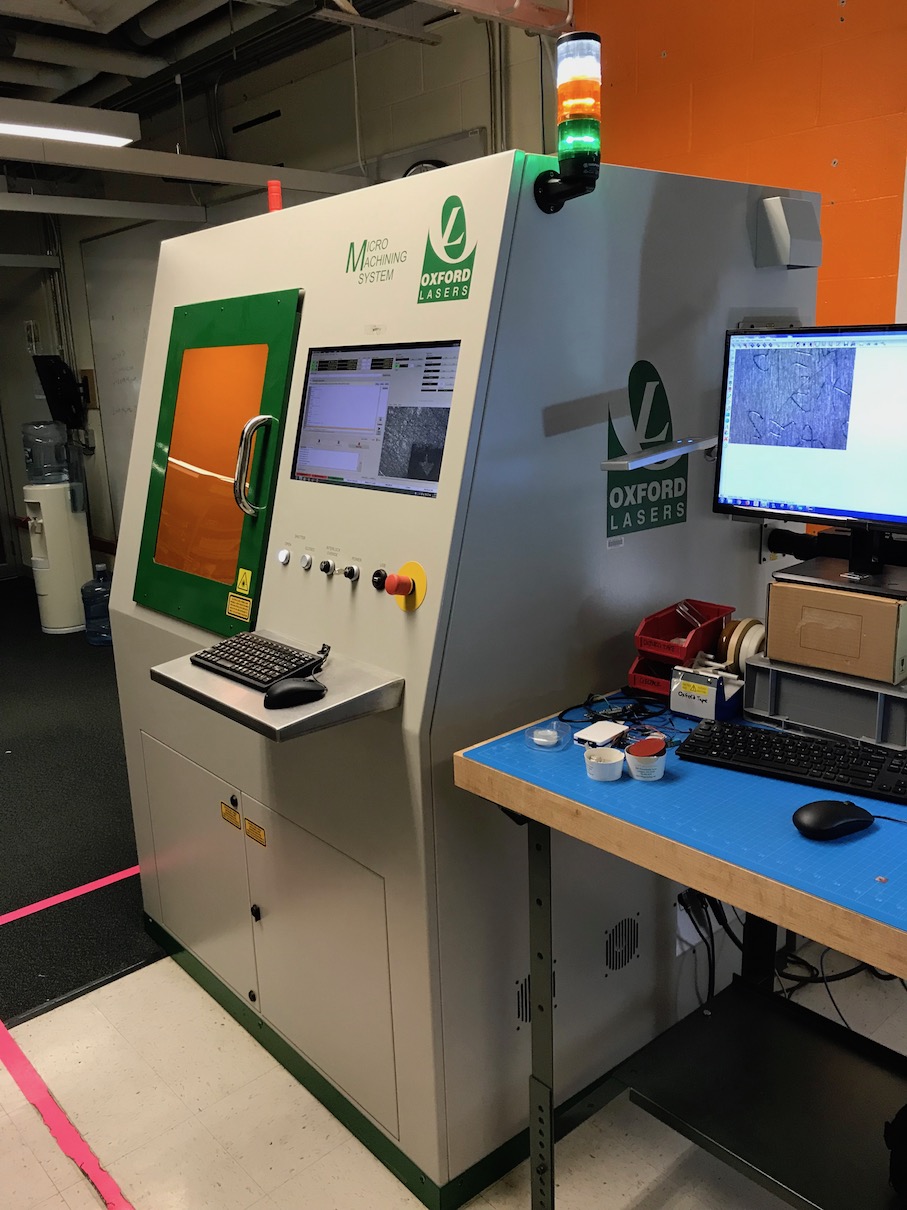

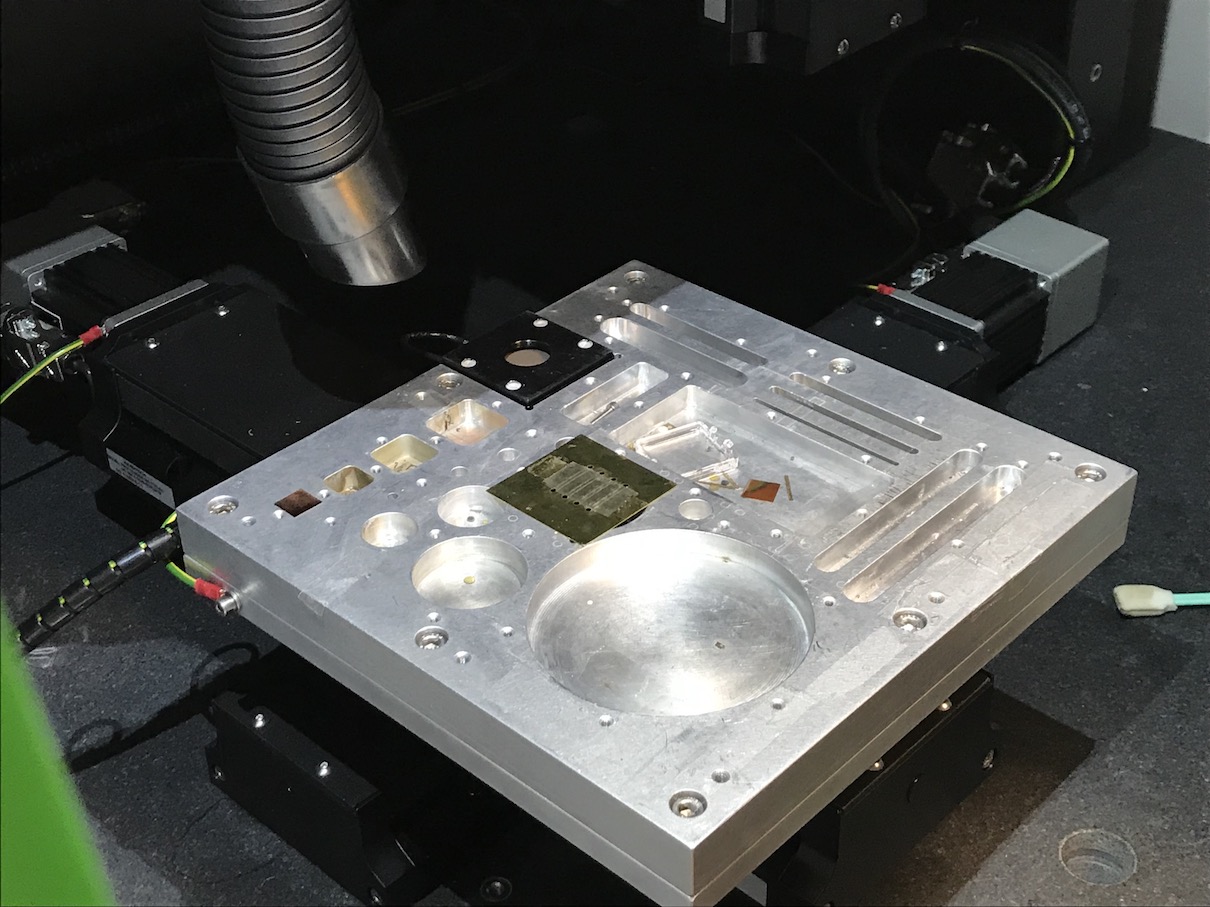

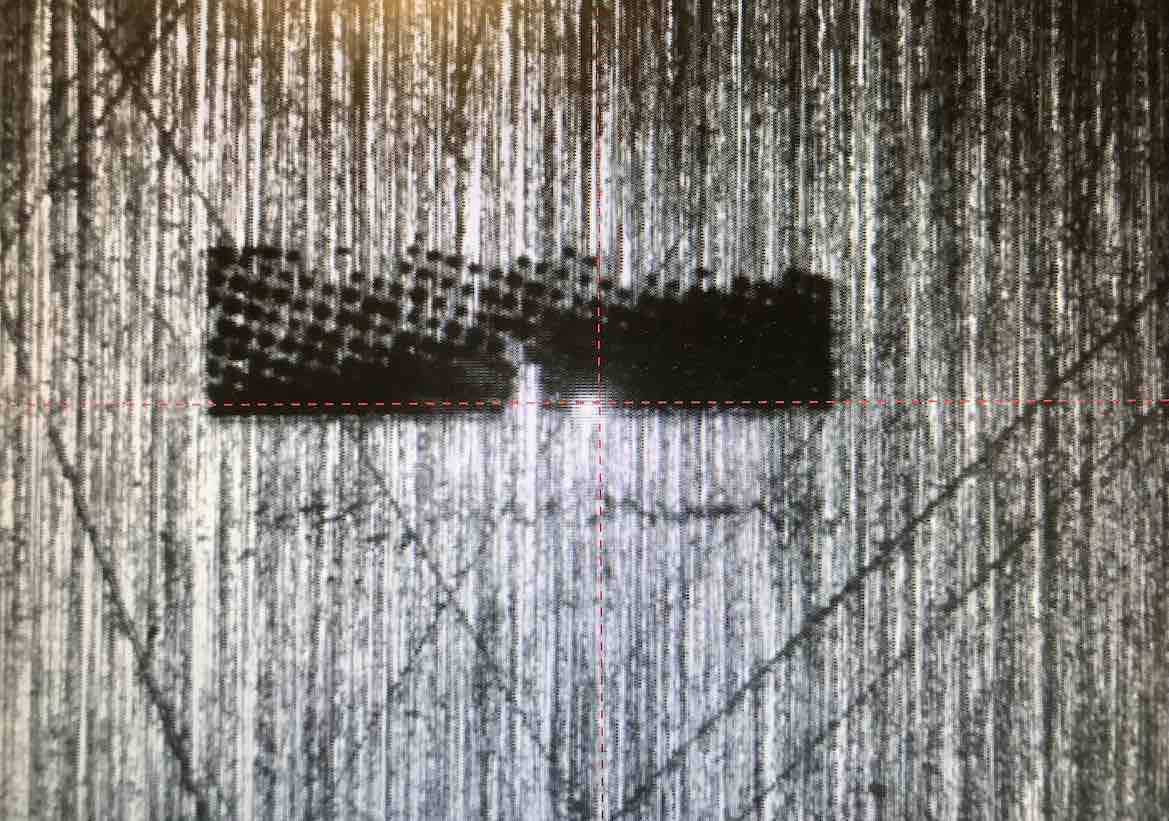

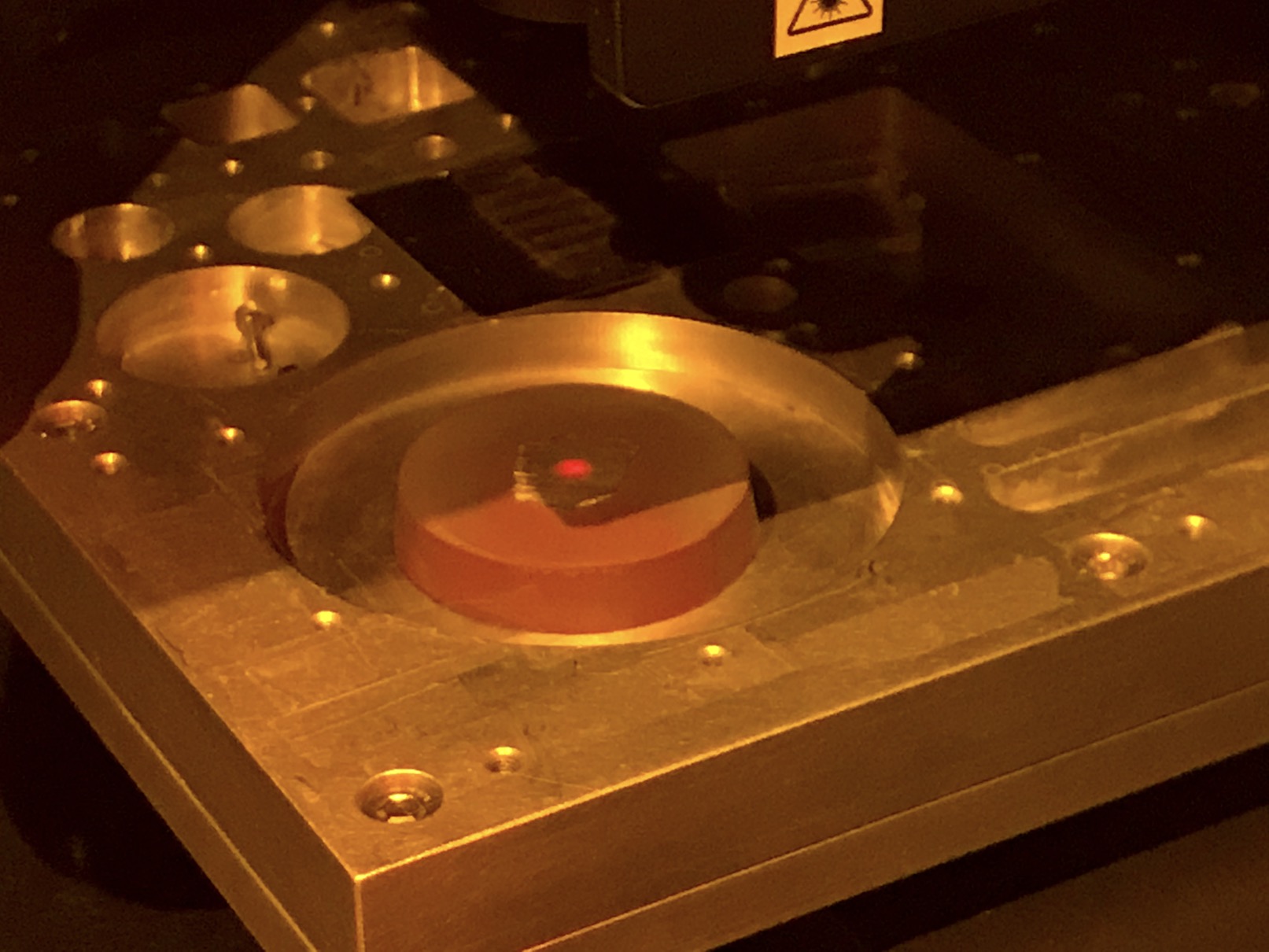

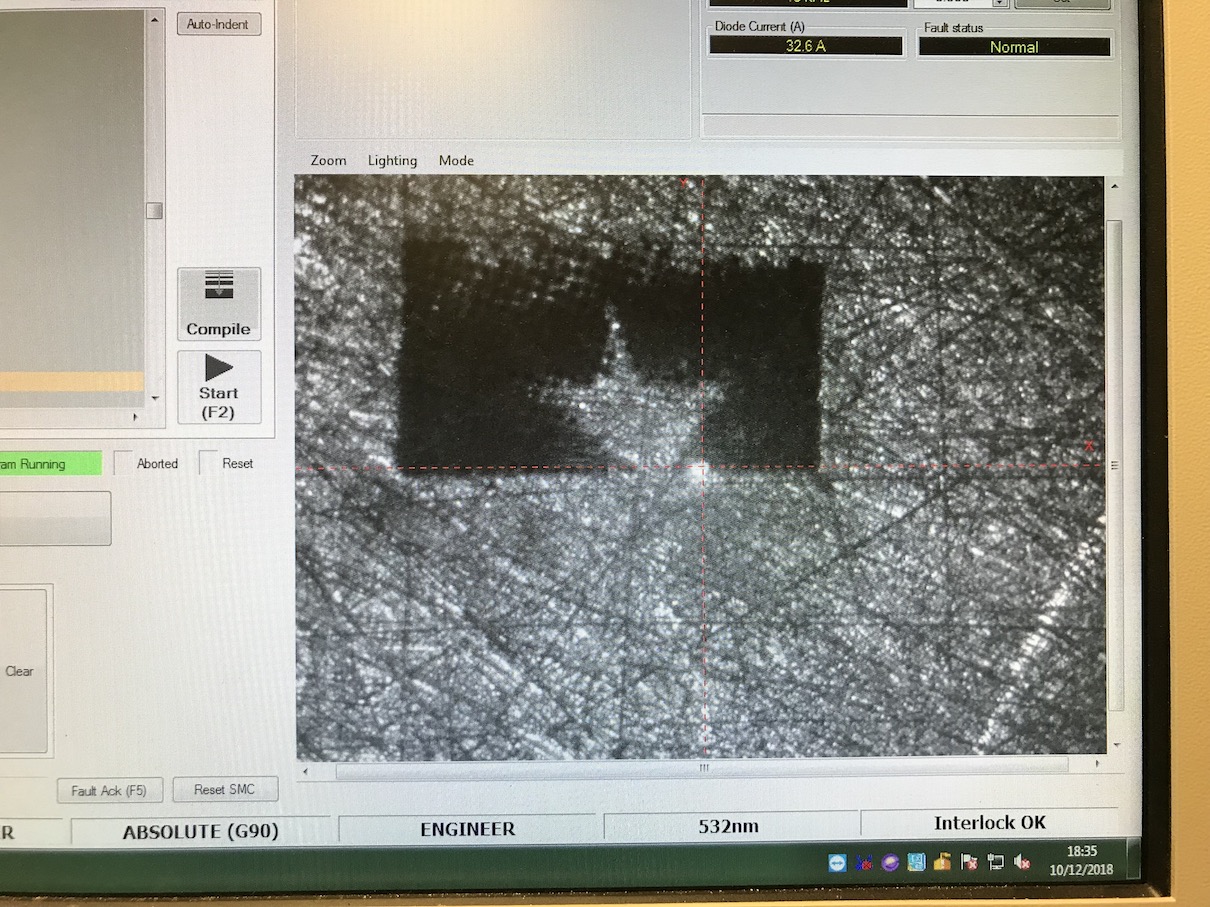

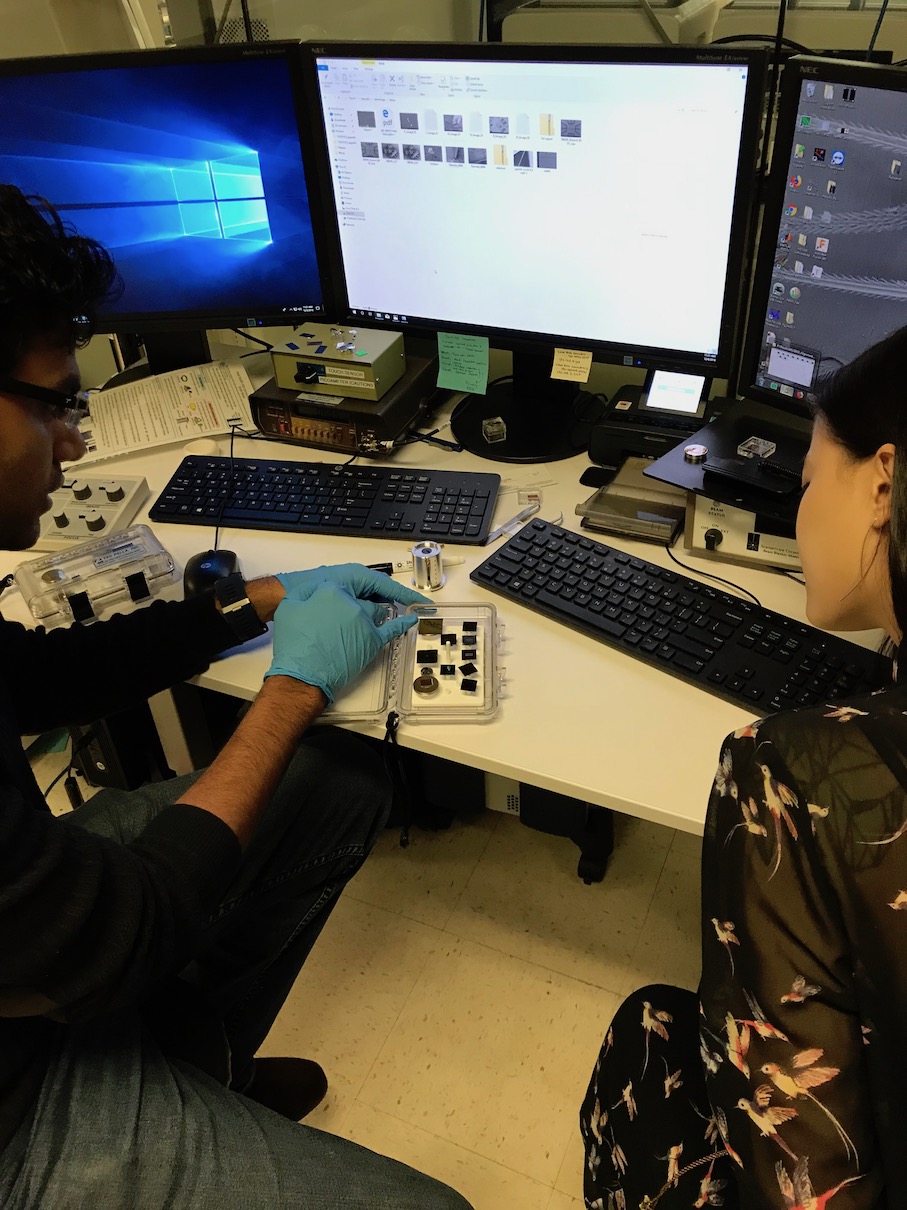

This week I decided to work primarily with Prashant on laser micro machining. This involves a specialized laser which can etch and cut at the scale of nanometers. After spending a first day exploring the basics of how it works and what was possible, we came back a few days later to attempt to etch an image. I decided to try and use this technology with another project I have been working on, and etch a photo from the MIT Institute archives into a small piece of tin and bismuth alloy which I produced.

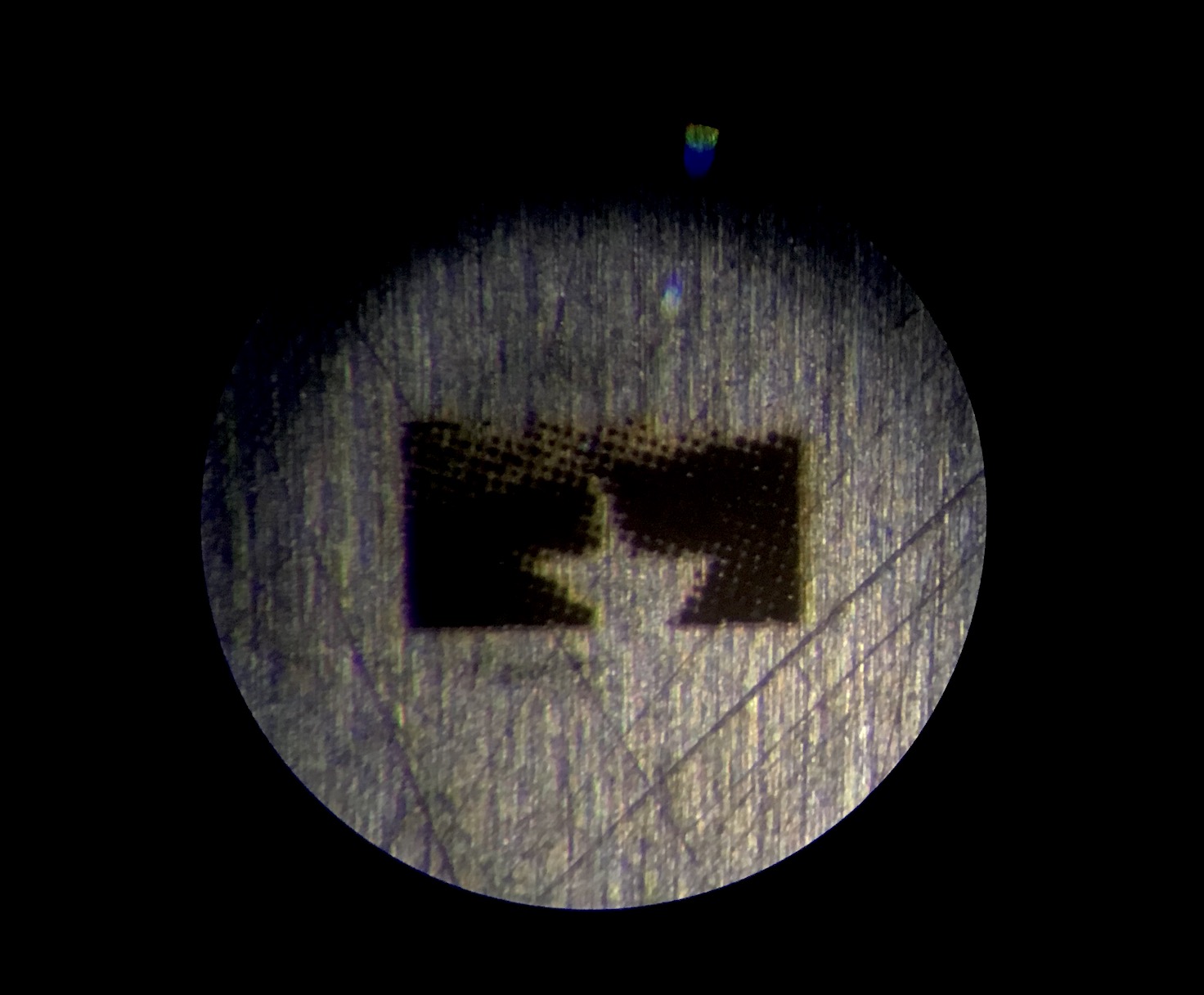

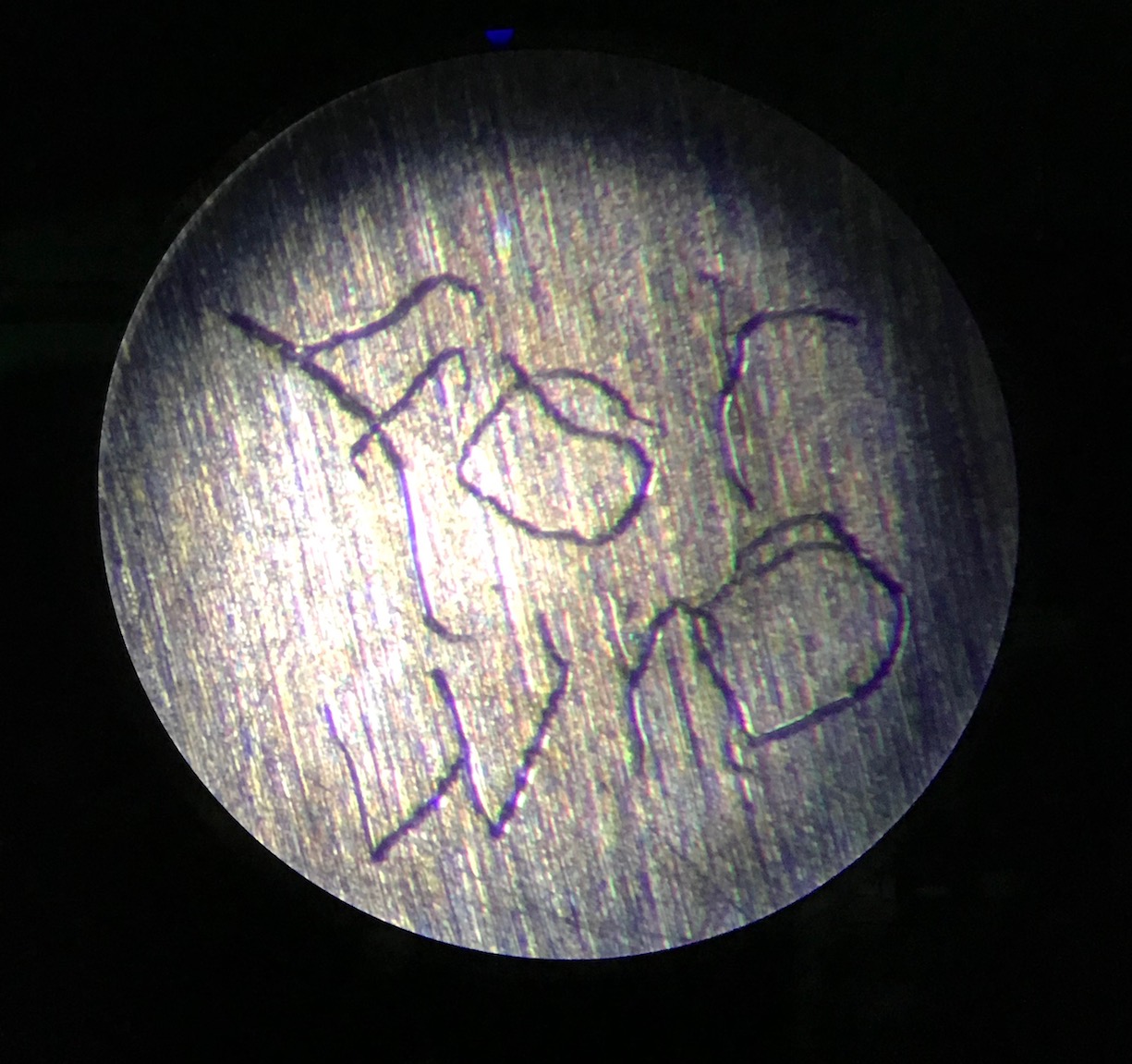

In order to get the laser to etch an image, I suggested that it might be possible to achieve using a halftone which is generated in order to closely match the 2 micron width of the laser beam. I resized the image to 200 pixels across, and generated the black and white halftone accordingly. This image I chose depicts an arrow painted on the street from the archive on the Perceptual Form of the City. Generally the machine seems quite user friendly. There were no significant issues with it. The image quality was greatly reduced by each step of the process, including some burning and what was likely small imperfections on the surface. In the resulting image, the halftone is certainly visible as is the arrow, though I think it would take some experimenting to get it fully functioning. In the meantime, while that was in production, I was experimenting with drawing made for viewing under this powerful optical microscope.

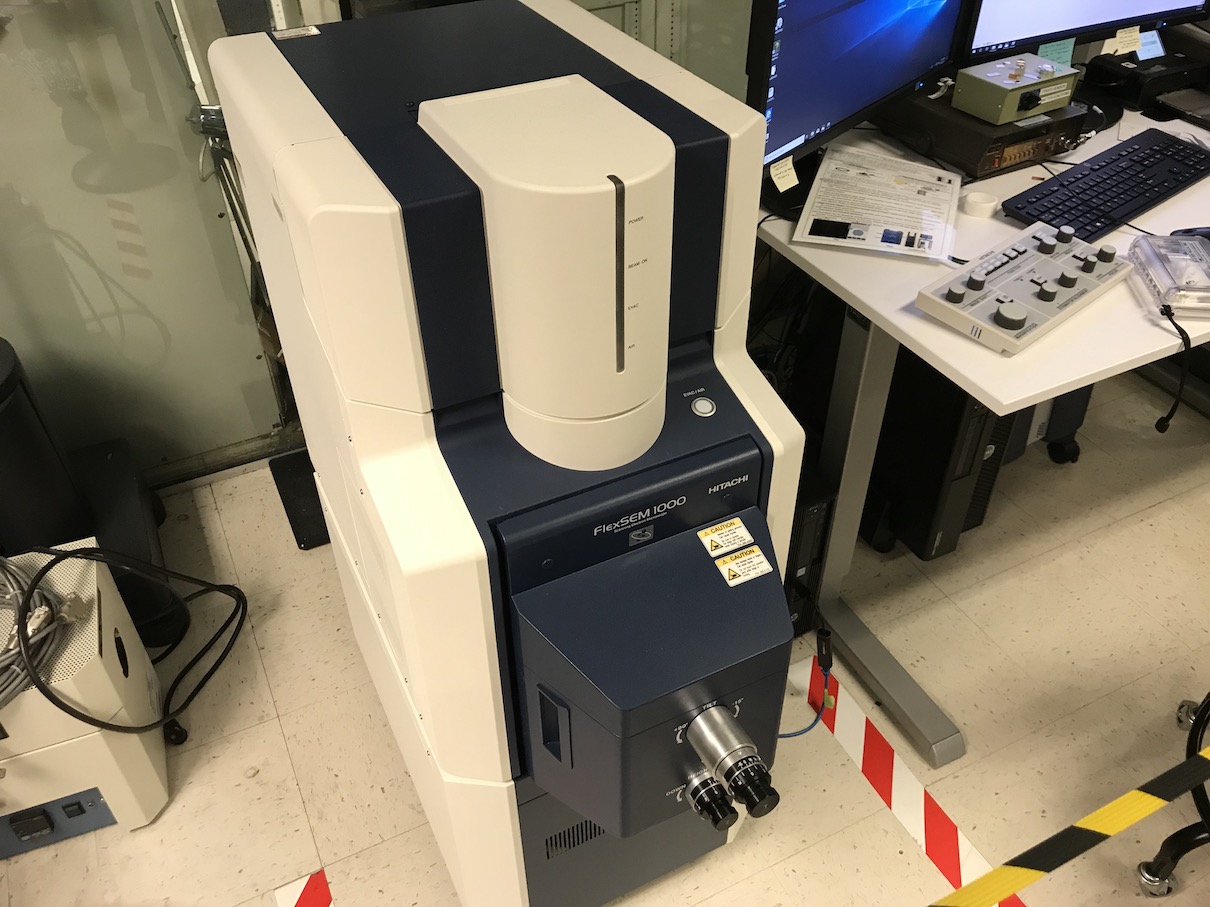

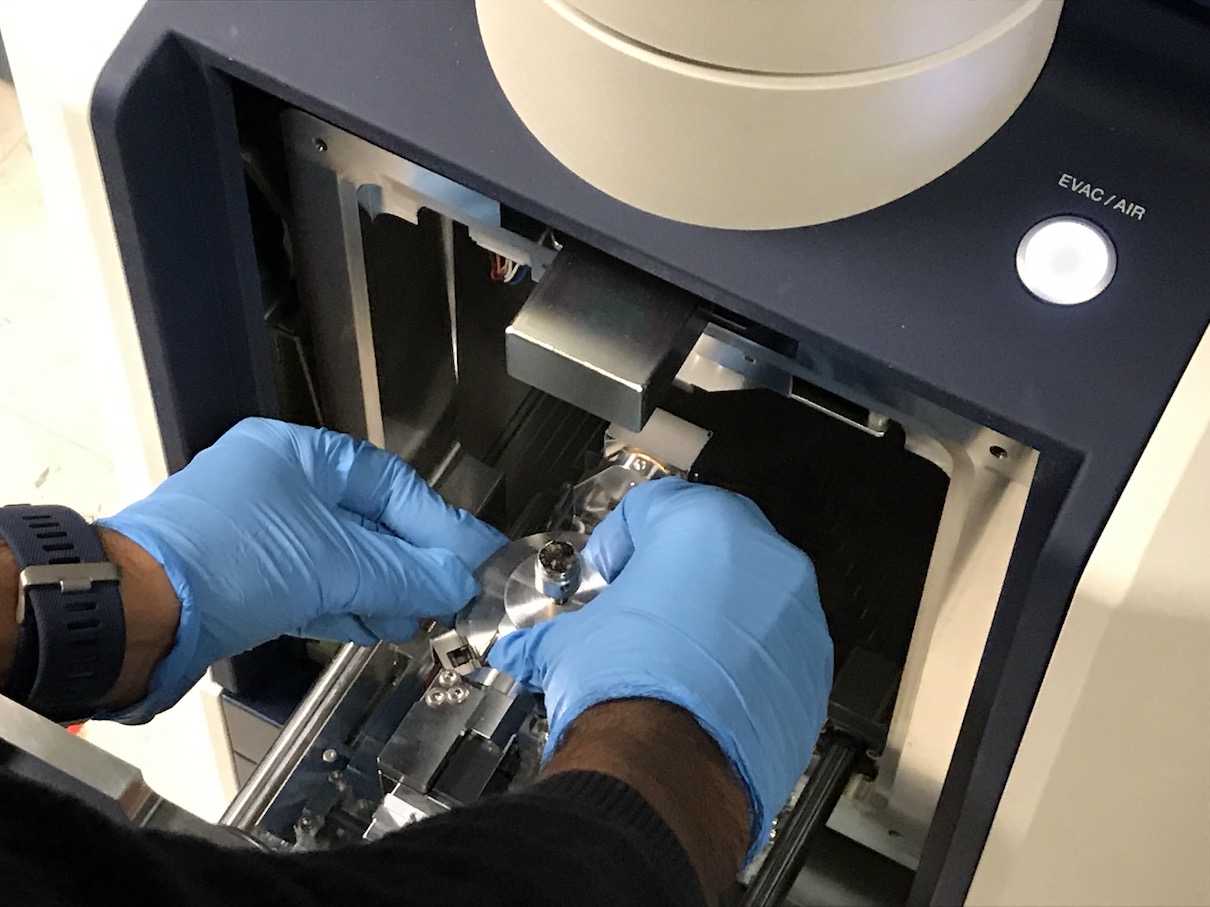

Scanning Electron Microscopy

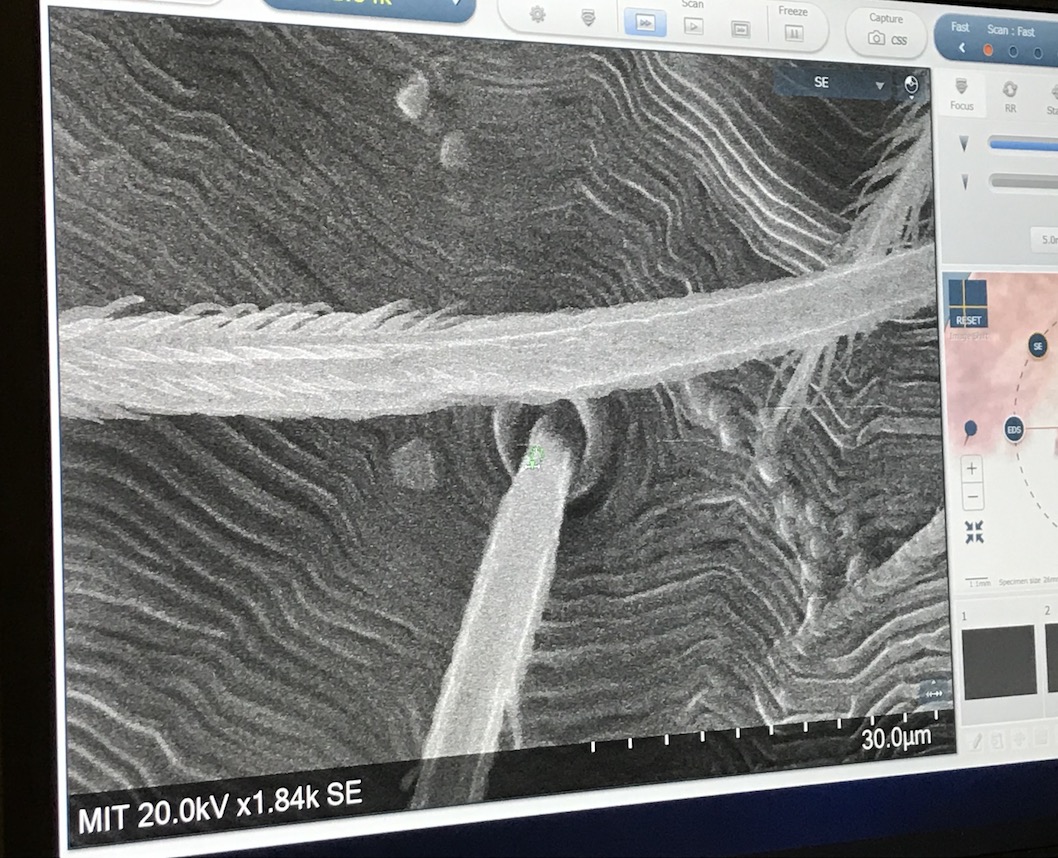

We also got a chance to look at the scanning electron microscope. We looked primarily at a sample of a spider. It was an amazing opportunity and something I would really like to explore in the future, the images it produces are unbelievable. The electron beams which produced the images on the screen also seemed to be moving some of the tiny hairs, prompting a meditation on electron wind and the nature of post optical image technologies.

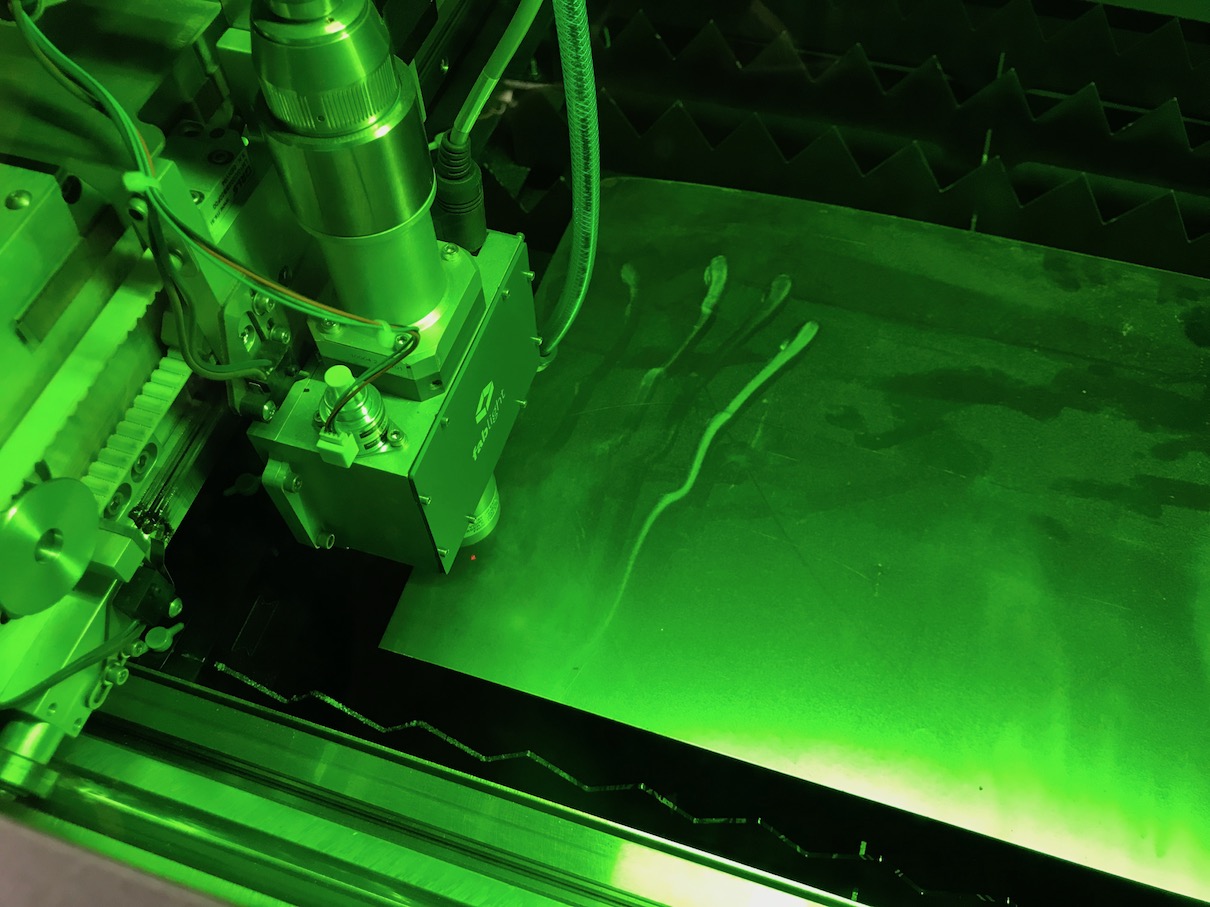

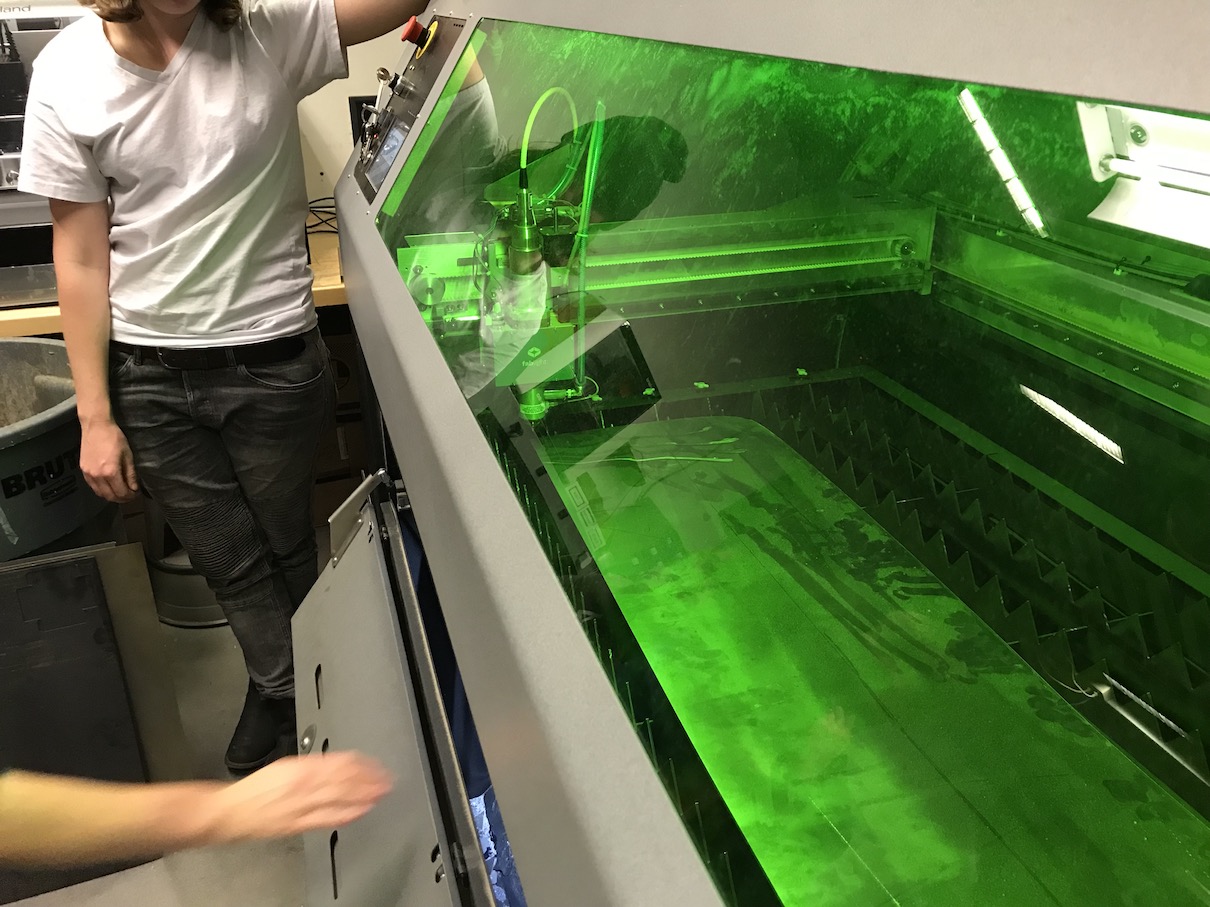

Fablight Sheet Metal Laser Cutting

Also sat in with Sara on the Fablight tutorial. This was amazing, and surprisingly quick. I didn’t get a chance to use it yet, but got a good sense of what it is capable of doing and hope to make use of it in the future.