Final project progress

Project Proposal

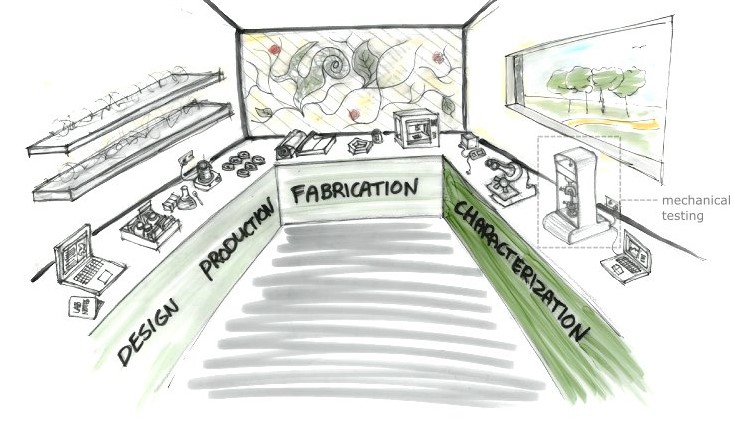

A low-cost mechanical testing machine for property characterization of bio-based materials in makerspaces.

Rationale

With the growing global movement to find substitutes for petroleum-based materials in consumer products and other markets, I foresee an emerging need for tools that can characterize nontraditional materials such as biopolymers, bioplastics, waste-based materials, upcycling solutions (e.g. Dave Hakkens) and molecules produced by (genetically modified) bacteria, fungi, plants, and other biological organisms. Currently, mechanical testing machines are expensive and therefore not yet part of the basic equipment in fablabs. A low-cost table model will enable designers and makers to get preliminary data on the mechanical performance of a newly developed material, that either can be published, used as a guideline in consultancy projects or for elevator pitches to investors.

Approach

There are two approaches: 1) absolute value, 2) values to compare samples to each other (less precise) --> suitable for iteration. There are two ways to go about designing the mechanical testing machine: 1) load cell 2) computer vision

Materials

USB microscope camera Instead, an ultrasound camera. This measures how cracks propagate through the materials. https://www.materialstoday.com/composite-applications/features/ultrasound-camera-makes-internal-composite-damage/ What does it do? Who's done what beforehand? What did you design? What materials and components were used? Where did they come from? How much did they cost? What parts and systems were made? What processes were used? What questions were answered? How was it evaluated? What are the implications? Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, microcontroller interfacing and programming, system integration and packaging Where possible, you should make rather than buy the parts of your project Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable Present your final project, weekly assignments, and documentation