Week 6: 10/10: computer-controlled machining

Assignments

- group assignment: test runout, alignment, speeds, feeds, and toolpaths for your machine

- individual assignment: make something big

Tools used: Fusion 360, AutoCAD, ShopBot 3 software, VectorPro, ShopBot, DeWalt orbital sander, GIMP

Week 6: 10/10: computer-controlled machining

Materials: A 4x8 foot piece of OSB wood

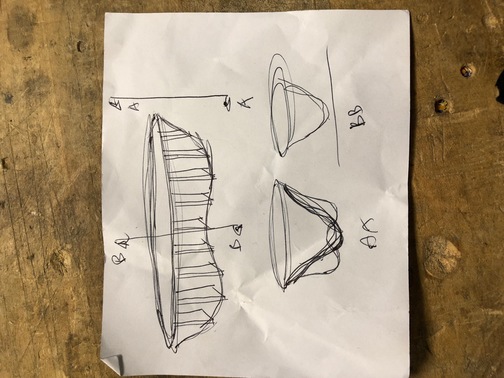

For this week's assignment, I made a coffee table for our apartment. This is an initial sketch.

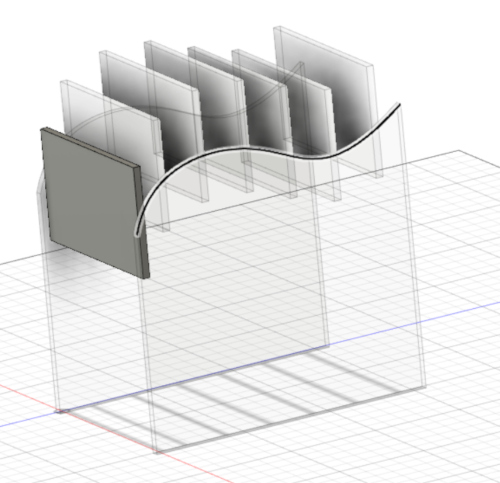

Initial experiment in Fusion 360.

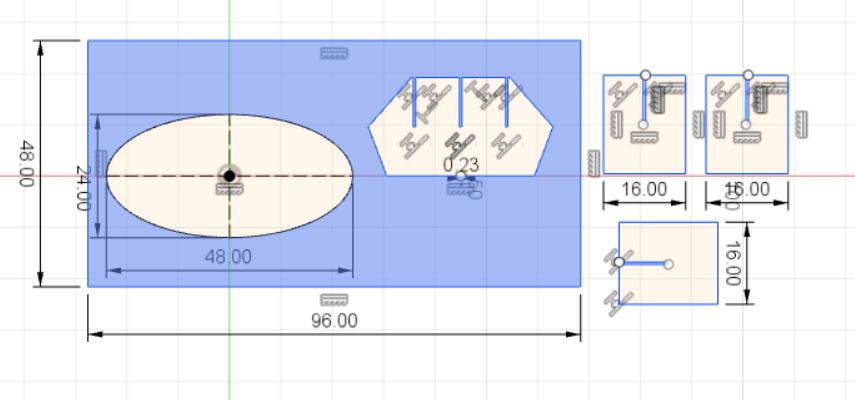

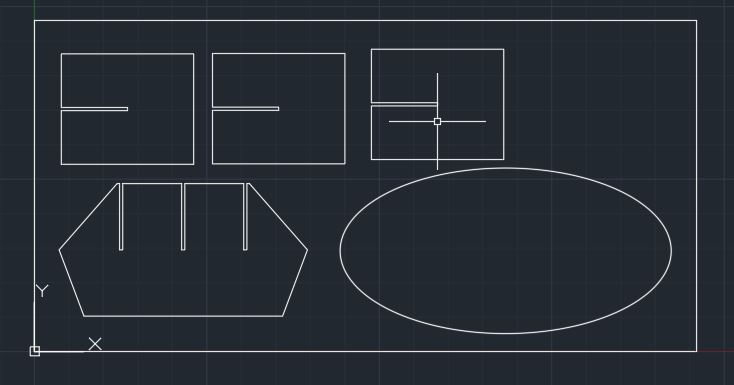

Final design in Fusion 360

Layout of the design within the dimensions of the OSB wood in Autocad.

Notes on setting up the ShopBot milling machine

- Sacrificial layer - scar this a bit to make sure

- Wood screws to fasten the part on the MDF sacrificial layer

- Open vcarve Pro (Fab & FabClass18)

- Job setup 4’ x 8’ X axis is the long axis Y the short

- Actual thickness 0.416 inch. Thickness is 0.52 to go deeper into the material with your toolpaths for a nice cut

- Always z on top of material (check) XY origin by default on bottom left corner Import DXF out of rhino 3 Selection tools: third is for moving, rotation 2 types of toolpaths: Select all lines — edit — join to make DXF files suitable for milling Pocket toolpath for hatch — create pocket toolpath — start dept is 0 cut depth 0.15 Tool database — verify the tool diameter — 1/4 inch tool Cutting parameters — pass depth should not exceed the diameter of the tool. We choose 0.26 to make the clean cut Step over 95% Spindle speed 10,000 Feed rate 120 inches/min Plundge rate 60 inches/min Feeds and speeds understand them well Program had a good help menu Raster - left to right Offset - smarter way - take a close look! Keep at conventional / climb is trying to walk a wild dog Calculate Profile toolpath for cutting out all the way through Machine vectors: select tool offside: outside, inside or on. Choose outside Two passes Gaps for slots (0.47 is a little wobbly, you want to be smaller - experiment with this) 0.46 for material thickness in sketch Create fillets for T-bone and Dog-Bone to create square corners - to account for the tools limitations (rounded corners) Machine executes in layers: pocket first, then profile Floppy disk: save toolpath twice: .sbp file in toolpath tab on right - floppy disk .crv file

- Open Shopbot3

- Turn on shopbot XY button

- Press reset (blue button) on desk

- Left/right with arrows

- Page up / page down keys to move tool up/down

- Attach collets into the tool - pay attention Make sure you have enough tool sticking out Needs to stick at least one inch out Wrench to hold collet holder other wrench to slide tool up Zero menu — zero 2 axes for x and y Cutting in the air - zero it up high to test Key pad — move manually to area where the cut approximate will be Cuts menu - C2 Make sure to exit out of the keypad Hit enter when above plate and ready to zero Lay down metal plate — machine touches it twice to calculate the z axis Remove metal plate Get power to the spindle by putting key in the control box next and turn it — should say 10 for us - this says the exact spindle speed Bring tool back close to XY for putting the magnetic dust collection tool on File — part file load — select toolpath Ignore the notepad message Click start to load file Press green button !!!! Turn dust collector on Hit OK on the prompt and it starts

- Tape (3-4 inches in between)

- Max 2x2 feet - limited by how far Hit scan New scan Press green button Move left to right until thing turns blue Decide where you want to cut (color code lines) Insert usb Decide where to place it Z-touch to know where z=0 How deep to cut: 8’’ Cut on outside of tool Cut - decide what tool you’re using Turn vacuum on Turn motor on on the machine You can move along the line Press green button to start cutting

Start milling

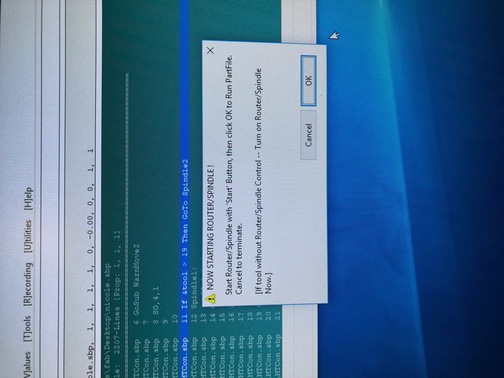

Tricky button..

This happens when you forget to press the green button..

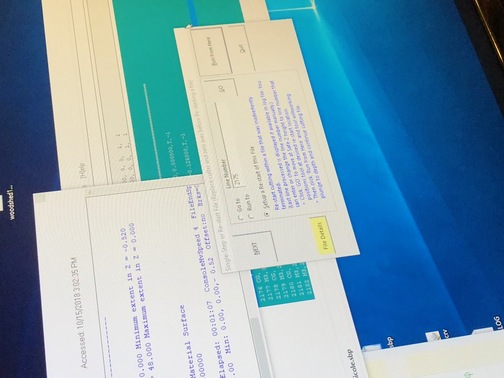

Recovery of the drill.

Successful machining of the file.

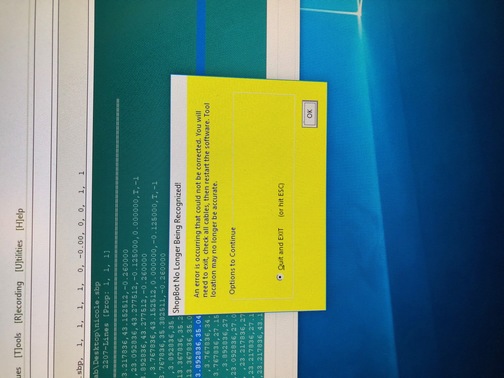

Weird error that showed up toward the end of the job..

The machine ran into an unknown problem.

Tom removed the code of the part that was already milled, then we could resume the job.

Removing the board from the sacrificial layer.

The final pieces!

Sanding away the text and smoothening out the surface.

Before and after sanding.

Sanding all edges by hand.

Assembly of the parts for the base.

The result!