Week 1: 09/05: introduction, computer-aided design

Assignment

- Plan and sketch a potential final project.

Tools used: sketching paper, AutoCAD, Fusion 360, Illustrator, Photoshop, Inkscape

Project Proposal

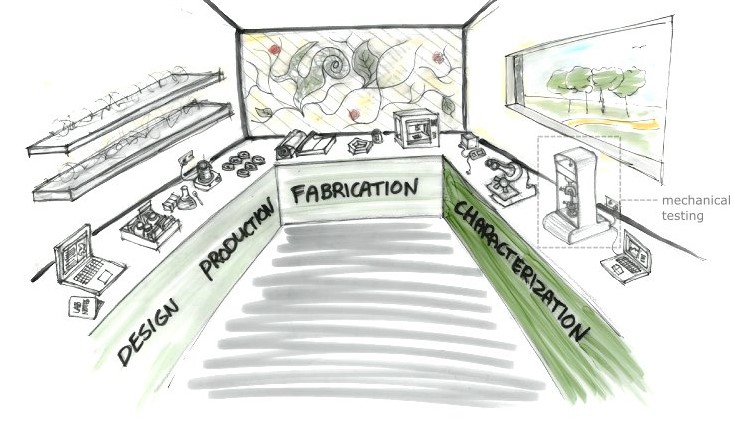

A low-cost mechanical testing machine for property characterization of bio-based materials in makerspaces.

Rationale

With the growing global movement to find substitutes for petroleum-based materials in consumer products and other markets, I foresee an emerging need for tools that can characterize nontraditional materials such as biopolymers, bioplastics, waste-based materials, upcycling solutions (e.g. Dave Hakkens) and molecules produced by (genetically modified) bacteria, fungi, plants, and other biological organisms. Currently, mechanical testing machines are expensive and therefore not yet part of the basic equipment in fablabs. A low-cost table model will enable designers and makers to get preliminary data on the mechanical performance of a newly developed material, that either can be published, used as a guideline in consultancy projects or for elevator pitches to investors.

The workflow for bio-based material production could include the following steps:

1. Design- Research into material properties, interactions with other materials

- Design of metabolic pathways, etc.

- CAD design for fabrication

- Bioplastics / polymer station

- Recycling of existing materials (e.g. Dave Hakkens)

- Genetic engineering of polymers

- Molding

- Sheets (roller)

- 3D printer ready

- Mechanical

- Tensile testing machine (5 kN)

- Optional: pressure, three-point bending, five-point bending

- Thermal

- U-value test for conductivity

- Durability

- Weathering test: does it biodegrade, and if so, how fast?

- Viscosity / Rheology

Scope

The scope of this project is limited to the mechanical testing machine.

Approach

I am planning to start with a tensile loading cell, because this provides data that can be used to determine some key properties in materials science, including Young's modulus, yield strength and Poisson's ratio. If time allows I'd like to try to expand this to compression, three-point bending, torsion, and/or five-point bending tests. Finally, I'm passionate about trying to let the machine run on a renewable energy source. Potential energy sources include solar panels, bioreactors, combined heat and power (CHP) and Microbial Fuel Cells. But as stated before, energy supply is out of the scope of the project because it is unfeasible in terms of scale, efficiency and time constraints.

Requirements

- Low-cost: <$100 for basic kit with optional add-ons

- Size: moving box-size or some standard for airport transportation

- Portable

- Loading capacity: at least 5 kN

- Optional: renewable electricity / fuel source

Related projects

Example of a rather dangerous $50 DIY version, by Youtuber The Idahoan Show

Instructables also has a version, uploaded by MechEngineerMike. This is a $300 model.