Margaret Tries to Make (almost) Anything | 2020

Margaret Sullivan | Undergraduate

Mechanical Engineering | MIT

Margaret Sullivan | Undergraduate

Mechanical Engineering | MIT

Assignment

design and 3D print an object that could not be made subtractively Box with Convoluted Hole

Scan (and print if you can) Basketball Sneakers

This week was all about 3D printing and Scanning. We started off the week with training on the 3D printers and Leo the 3D scanner (an amazing tool). I had worked with 3D scanning and photogrametry before but not recently and was blown away by how easy and fast the processing of the scannin data was!

As soon as I recieved the assignment I knew I wanted to scan my Basketball Sneakers. I thought that they were a good object to test a few questions that I had about both the scanning process and the 3D printer capabillities. Even more than regular sneakers, basketball sneakers have high ankle support, which presents an additional challenge for trying to scan the inside of the shoe. My biggest question for 3D printing was how it would hangle the inside hollow part of the shoe that was scanned. I was impressed with the 3D printer as it created an object that would be extremely difficult to create with other methods.

.

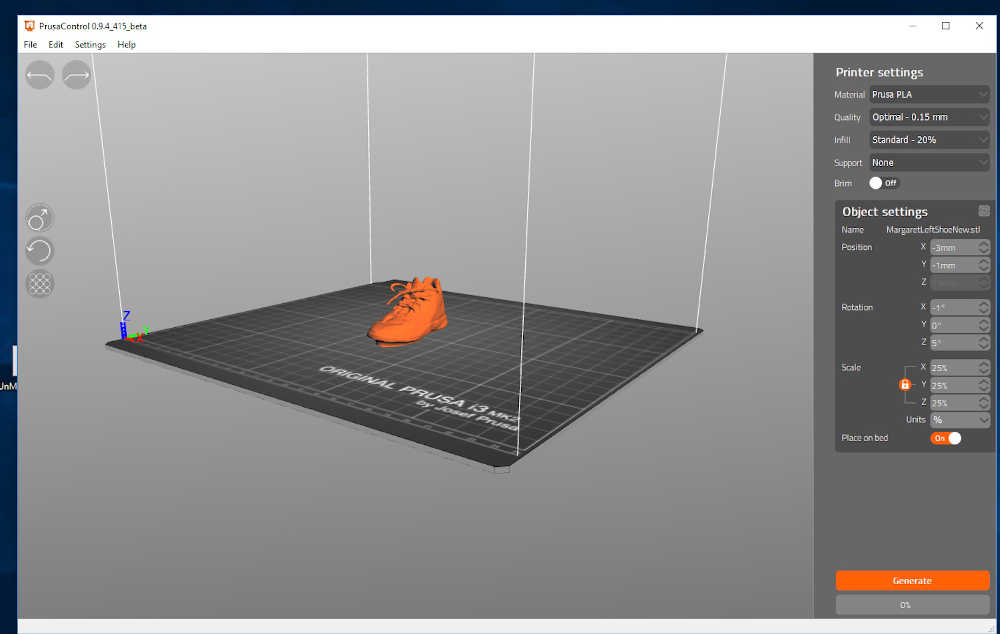

The 3D model in Prusa Control

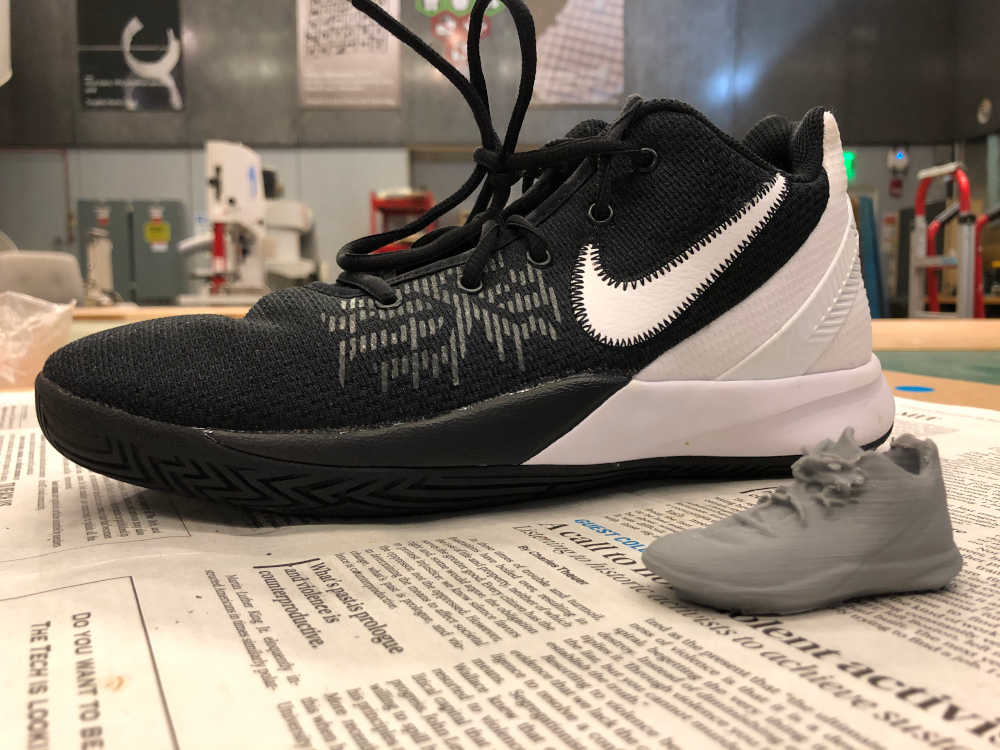

The 3D printed Shoe!

The 3D printed shoe showed an impressive level of detail. THe Kyrie logo is faint but visible and the subtle nike swoosh can be made out. If I had more time I would print a larger version and see if the limiting reactant for the detail is the scan or the 3D printer.

Next, I wanted to makes something that would be almost impossible to make without addative manufacturing. In Fusion i designed a box with a curvey track on the inside.

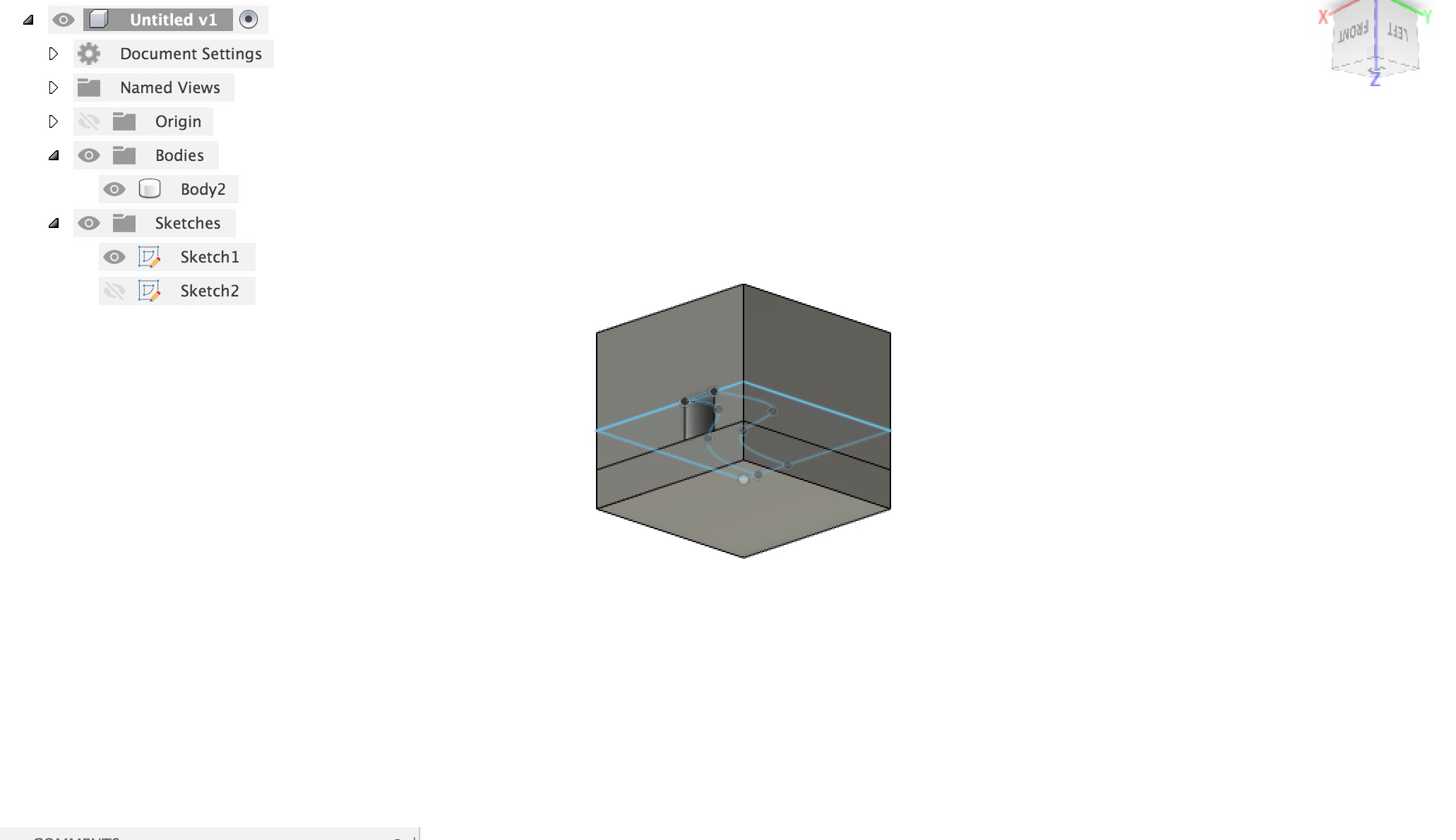

The design in fusion

The results!

Both images above do not really show the interior well, but using a felxible wire I was able to confirm that the track goes all the way through!