HYEMIN.BAE

How to Make Almost Anything 2021

How to Make Almost Anything 2021

Week_2: Electronics Production

The assignment for this week was to make an in-circuit programmer using the existing file provided here.

I chose hello.D11C.serial.5V.1.1 to begin with. And the machine I used was a Roland MonoFab SRM-20.

To mill a PCB board, I needed two png files with a resolution of 1000.

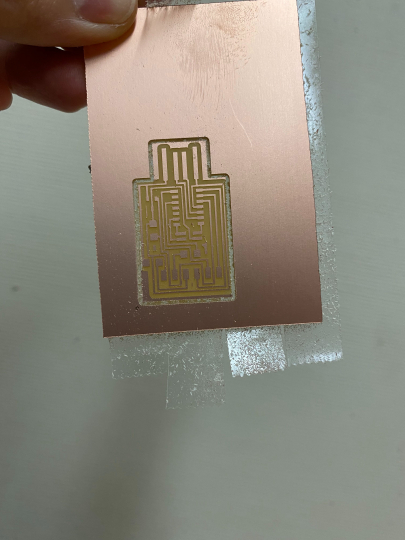

The first file is for traces and tells 1/64 bit to cut the surface of the copper board.

The second one is for the exterior, and it cuts all the way through. The file should be in black and white.

The white color parts are where the copper surface will remain.

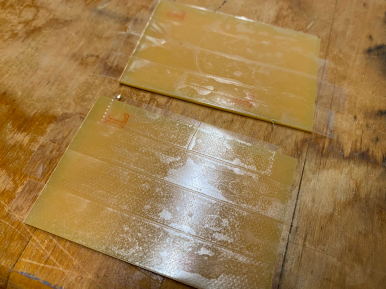

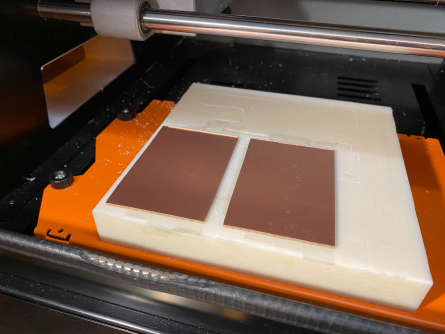

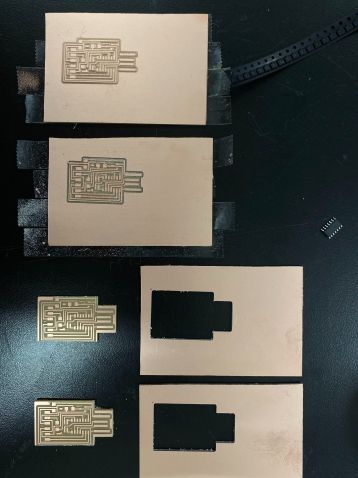

There are two types of plates, double-sided and single-sided.

I chose the single-sided copper plate since I don't have any vias.

Before milling the board, I had to put double-sided tapes in the back so it could be attached to

the sacrificial layer of the milling machine and doesn't move around during the milling process.

Having no overlapping tapes is essential to get a good result.

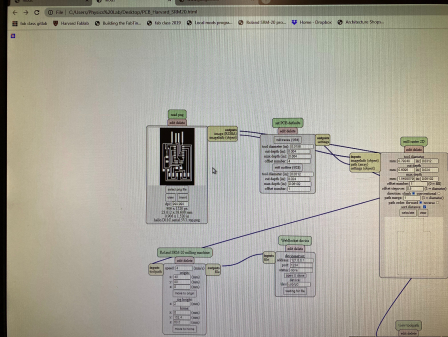

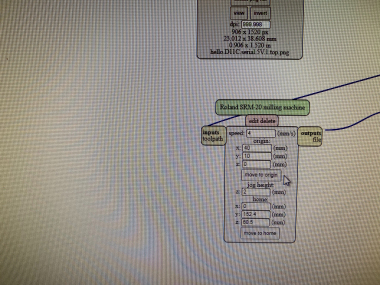

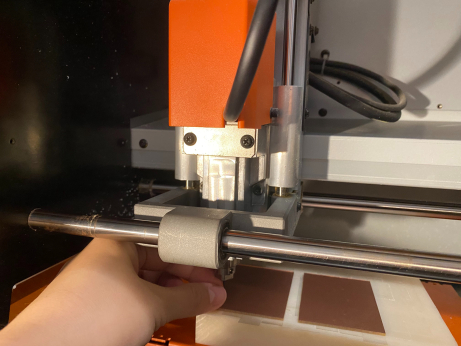

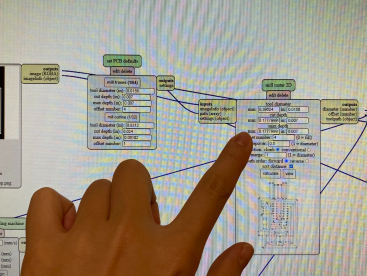

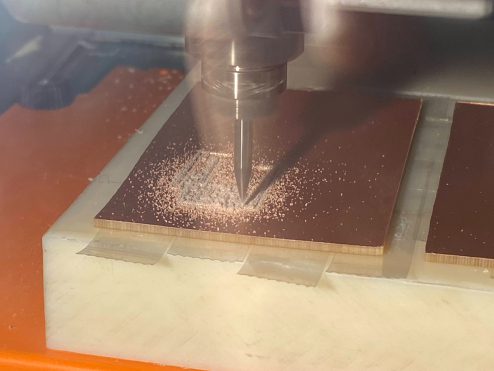

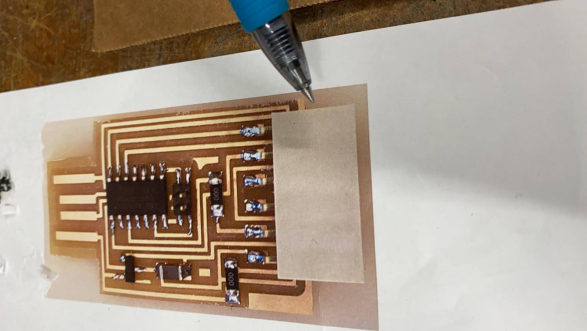

I placed the plate on the sacrificial layer of the machine and turned on the mod.

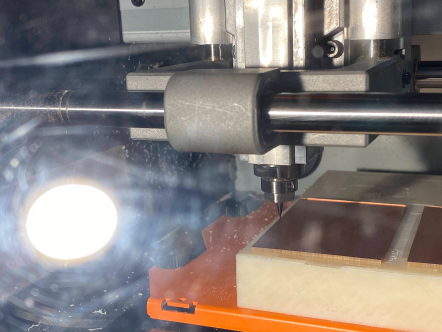

Uploaded the first file for milling traces. I checked and changed the milling bit to 1/64 thickness.

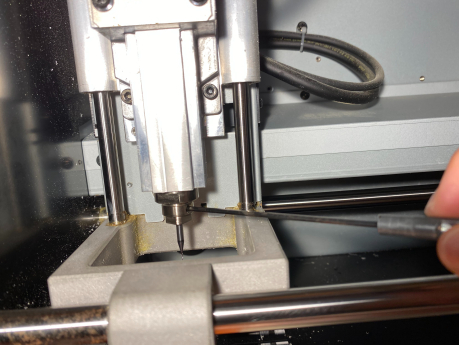

After adjusting the starting point, I put down the milling bit to touch the plate firmly,

then used the Allen key to fasten the bit to the machine.

Although I firmly pressed the milling bit, it didn't show happy-white dust.

I was scared to break the delicate milling bit if I pushed hard to the copper plate.

So I adjusted the mod's cut depth from 0.004 to 0.007.

Luckily it worked and changed to a bigger bit(1/32) to cut the outline of the PCB.

The changing the bit process was the same. I just needed to change the mod's mode to 'cut the outline.'

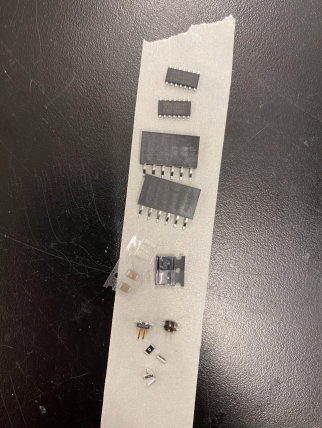

I found all the components needed and put them onto the tape to avoid losing them.

It is not in the picture, but I also label them, so I don't get confused.

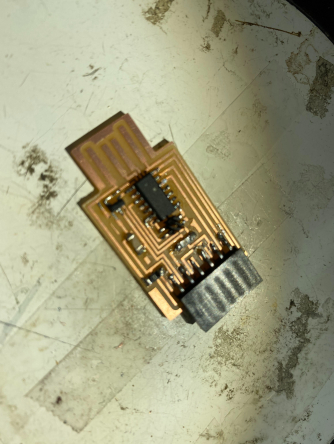

The soldering part wasn't as difficult as I expected.

It was almost therapeutic, except it gave me a little concern regarding the adverse health effect

of using lead material for soldering. I made sure the fan was on and close to the soldering station.

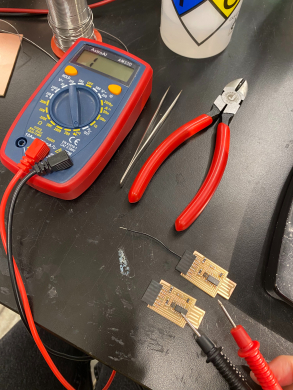

After soldering, I tested with a multimeter. It can detect if the traces are connected correctly.