HYEMIN.BAE

How to Make Almost Anything 2021

How to Make Almost Anything 2021

Week_3: 3D Scanning & 3D Printing

3D Printing

I decided to 3d print one of my final project ideas.

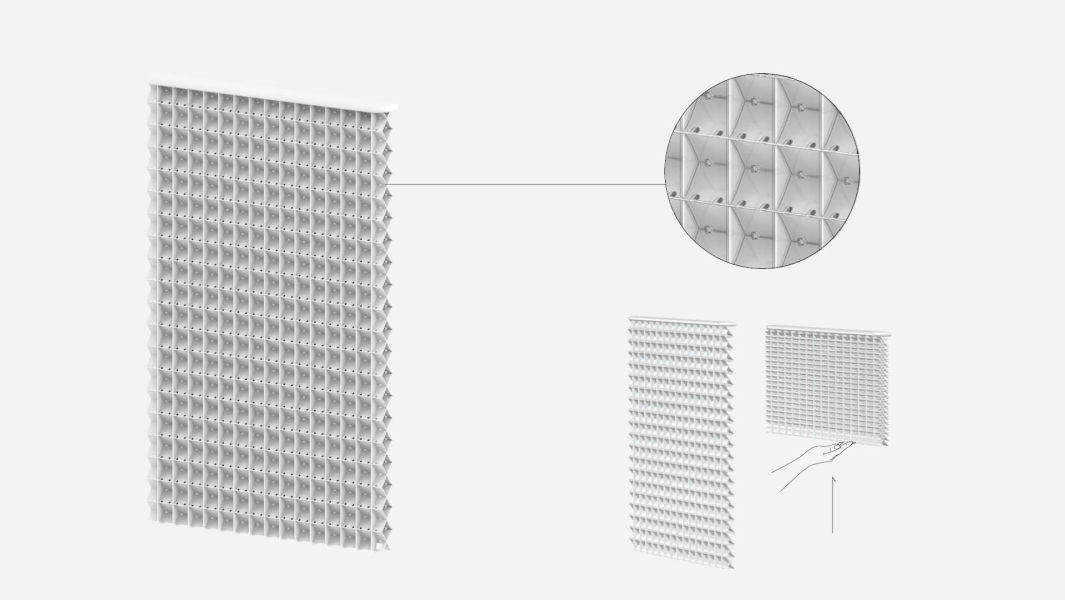

A product can sit or be attached to the window to reduce outside noises and convert the sound collected through

a microphone to rhythmic sounds through speakers. The structures to minimize the noises were designed based

on literature reviews on dampening the sound.

The software I used was NX to do complex parametric design.

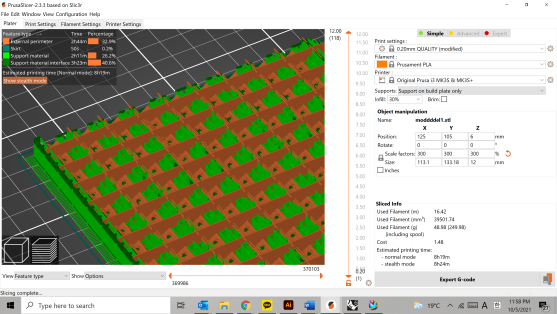

My Model was big, so I scaled it down to be printable. Also, I had to cut it to reduce printing time to 3 hours

because of its' complex shape. Since I will use the Original Prusa 3D printer, I used Prusa Slicer to communicate

with the machine(G-code). The steps I followed were importing the STL file, placing it in a printable area,

changing the object's rotation. Hence, it has maximum contact to the printing bed, then choosing the option

for having a support structure.

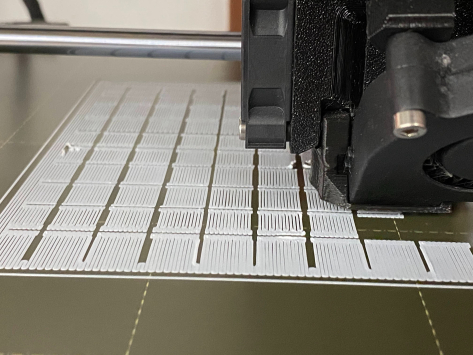

It was my first time to see the Prusa 3D printer.

I was surprised about the smoother surface quality compared to the Dremel 3D printer at GSD.

The extrusion seems more refined than the latter one.

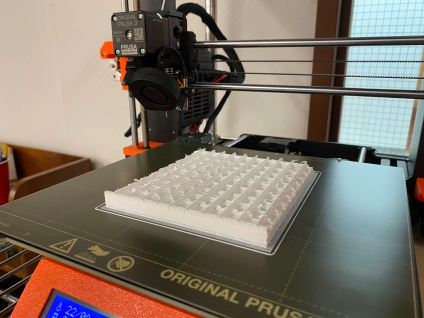

Finally, the printing was finished.

Because I chose to have support materials to prevent the print from going wobbly, it looked a lot different from my 3d design.

I reduced the size too much, so the wall thickness was too small to remove all the supporting structures safely.

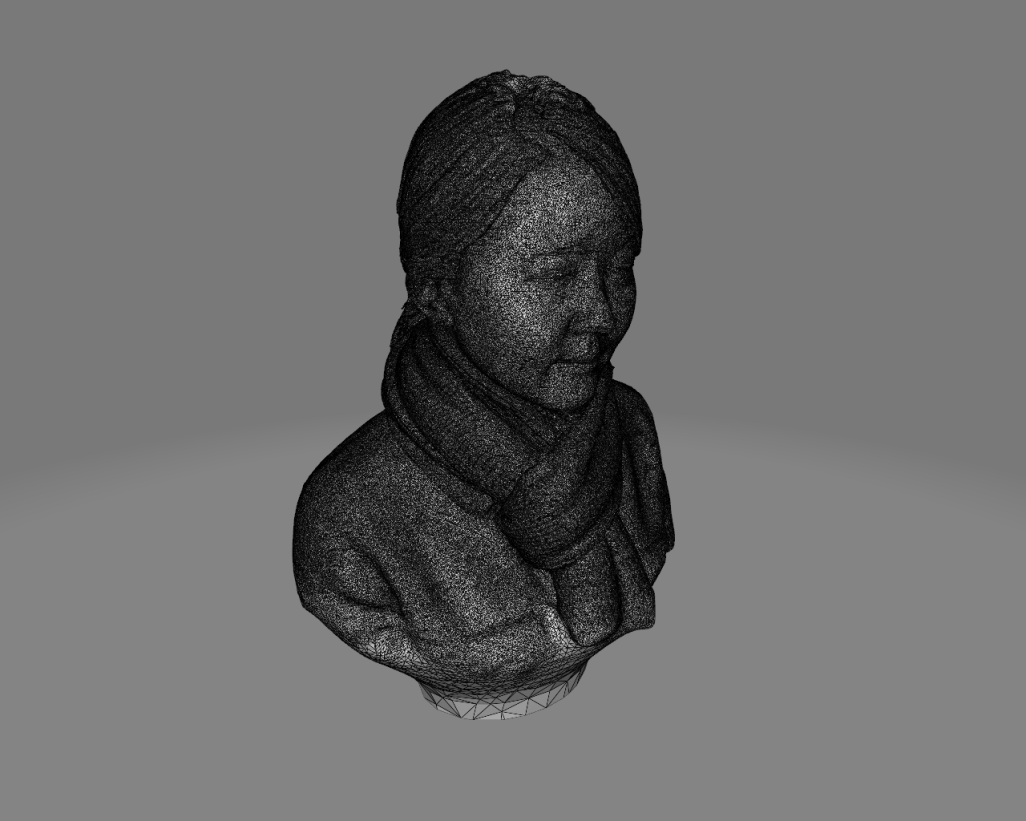

3D Scanning

I used Artec Eva Scanner available at GSD. It is a hand-held device costing more than $6000.

To get an excellent result, it needs to scan the desired object thoroughly and steadily from all directions.