HYEMIN.BAE

How to Make Almost Anything 2021

How to Make Almost Anything 2021

Week_7: Molding & Casting

Molding

I always dreamed of designing and making unique jewelry, so I decided to embrace this week's time to fulfill my dream.

There was a perfect material to cast the jewelry: silver clay, which contains 99% silver, and other materials to make it workable like clay.

Since the clay was expensive, I designed a small piece of jewelry, an ear cuff.

First, I started creating a mood board before sketching and 3d modeling.

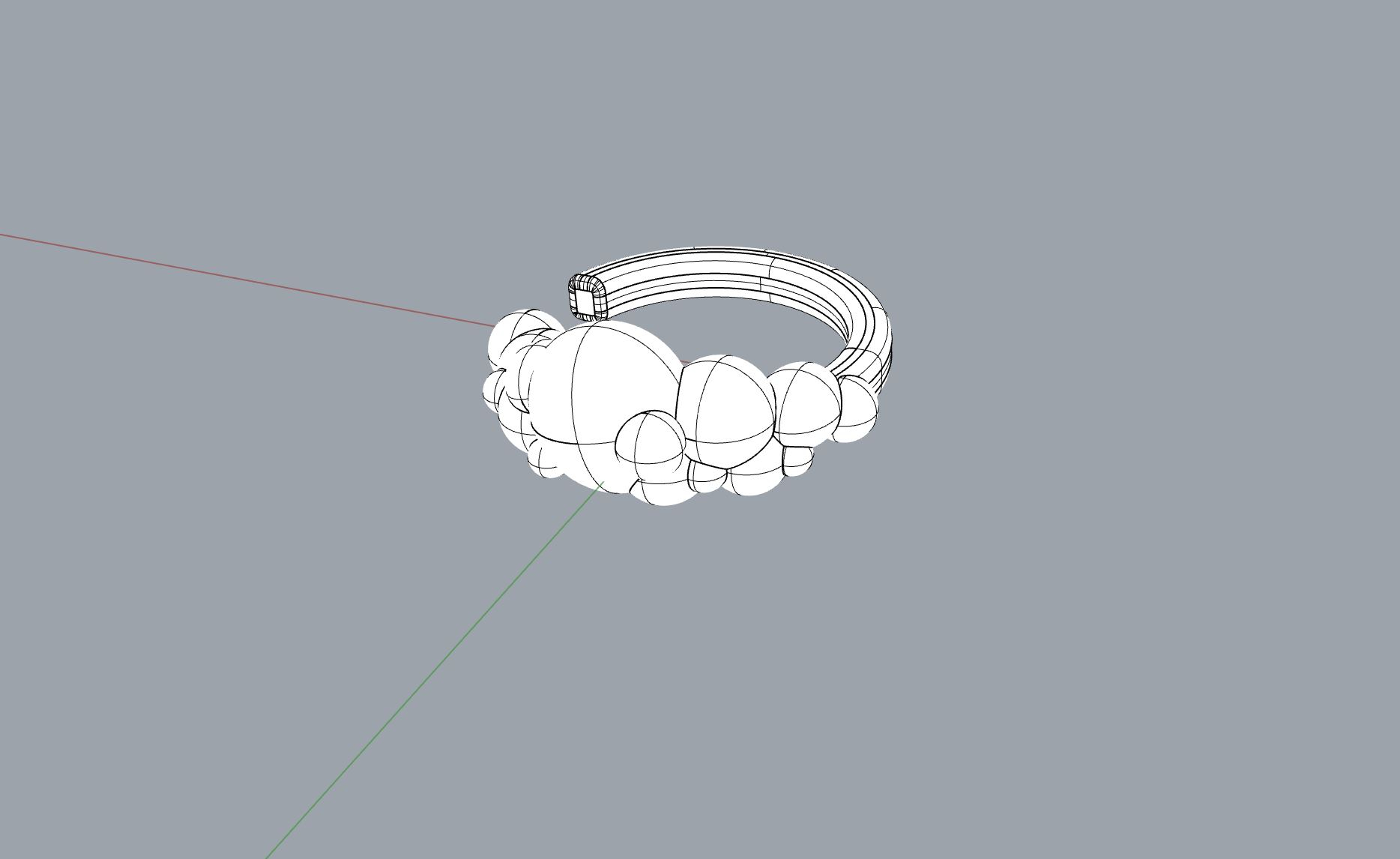

Sadly, I lost my sketches, but my 3D model in Rhino is here. I chose Rhino; although it is horrible at keeping histories and changing each component's dimensions,

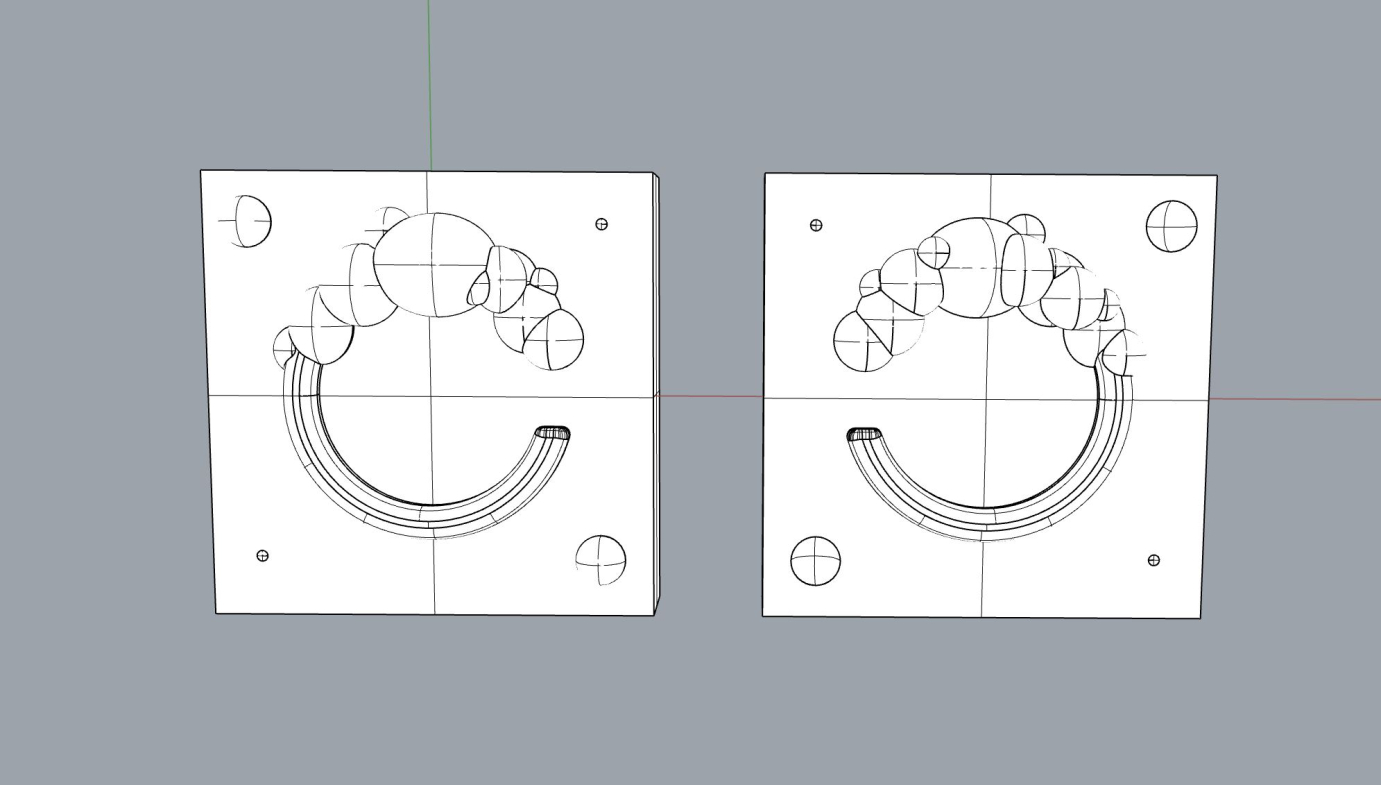

it is good at organic shapes. Then, I cut the model in half to create a base for a mold. Different than 3D printing, the body needed to have no undercut!

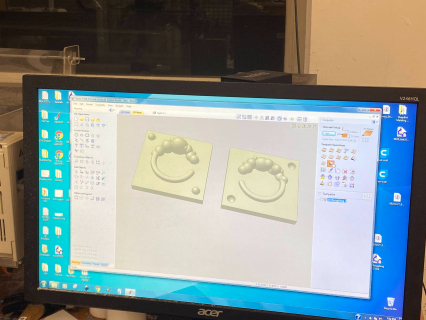

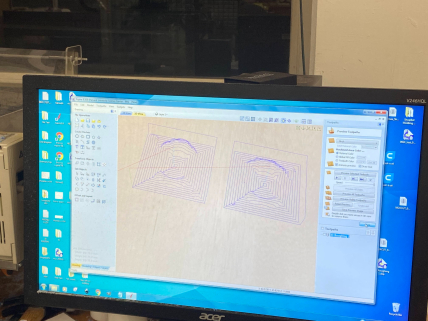

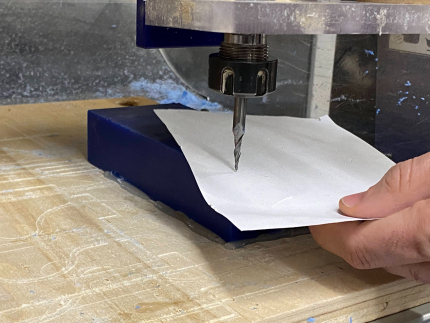

With Ibrahim's help, I set two Aspire files, one for rough cut and one for fine finishing.

The tool I used was 0.0625inch with a ball nose.

Setting the starting point and zero-ing.

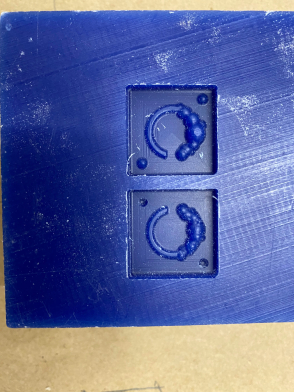

The details were fine enough to pick up the fine pieces of the cloud shape.

Casting

OOMOO™ 30 seemed easy enough and delicate enough to pick up the details.

It has a cure time of 6 hours, according to the datasheet. After mixing the A and B solution thoroughly,

I used a toothpick to fill the tiny edges of the ear cuff then poured the mixed solution into the wax. This step was necessary to prevent the tiny air bubbles.

I tested with clear resin before using the precious silver clay to confirm the shape.

It looked good enough, so I put the silver clay into the mold. After 24 hours of leaving the clay in the mold, it got dry enough to sand down excessive clay.

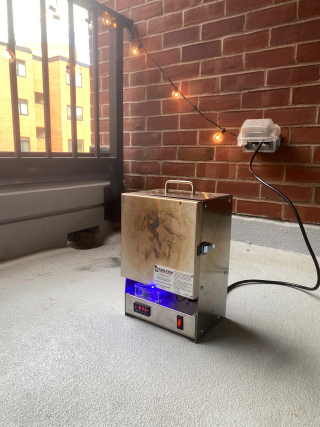

The final step was to fire it in 1200 Fahrenheit for 30 minutes. So I did!

And here is the result! It still needs to be polished using sanding paper; after done so, it will be as shiny as every other silver jewelry we know.