For Molding and Casting week I wanted to make a multi part mold that is modular. The eventual goal would be to cast in bio material that bacteria and other living organisms could grow on.

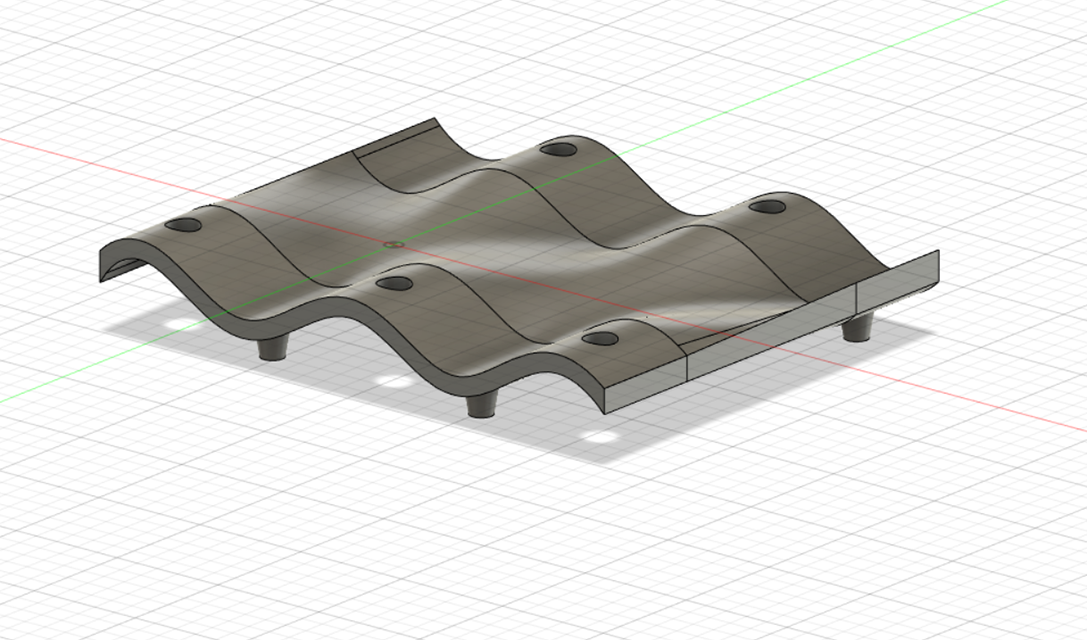

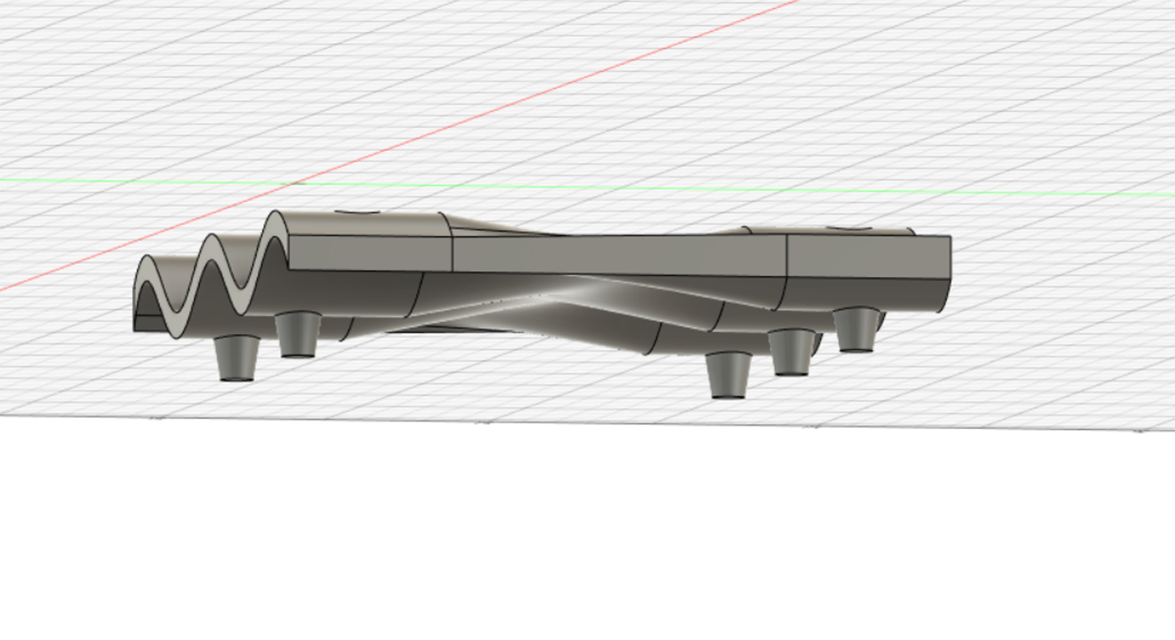

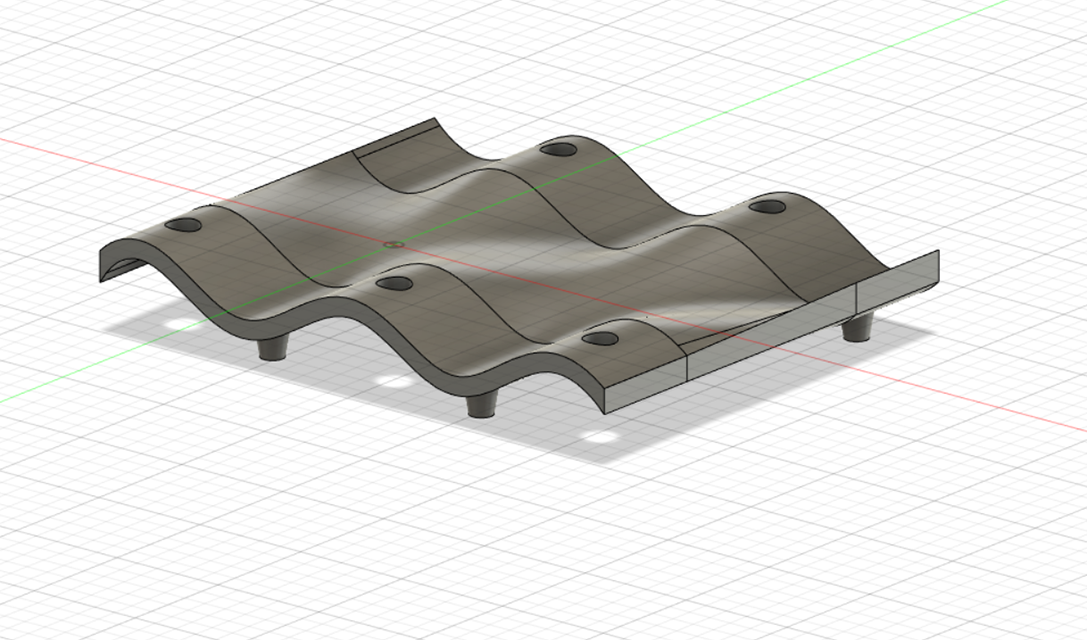

I used Ntopology to design these forms for my architectures. However given that these forms are way too complex for developing molds and casts out of. I tried to make a simpler version that would be modular

Trials and Tribulations

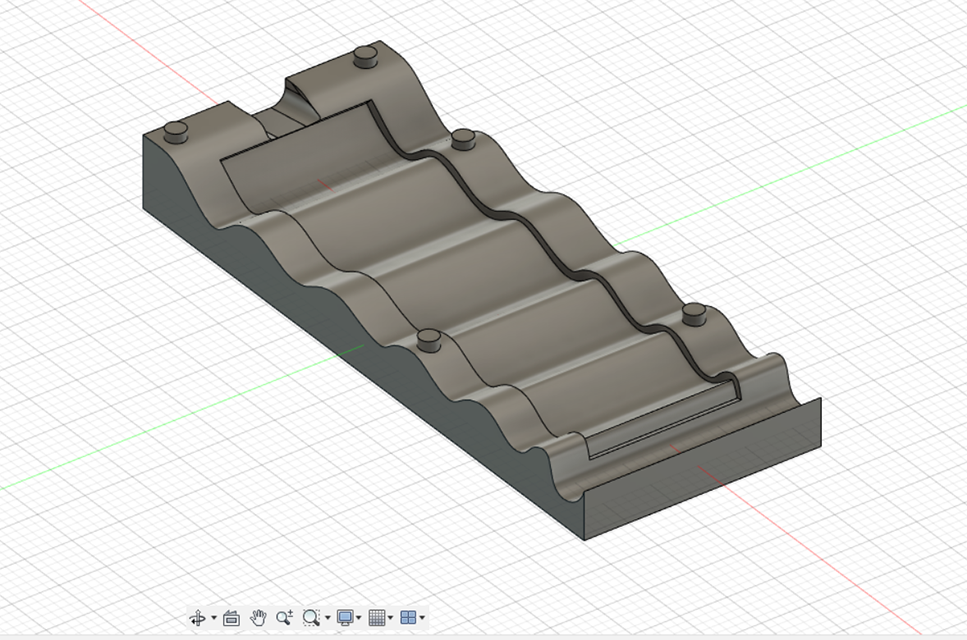

I couldnt quite figure out where to part the mold so that it could be a two part mold design, after a lot of discussion with tom and also due to time limitations. I ended up even further simplifying my design to this version from the first one. The complex curves on the first design made it hard to imagine how I would design the mold.

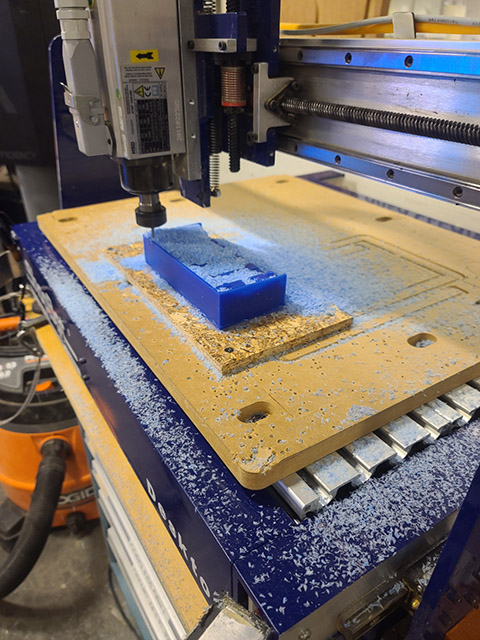

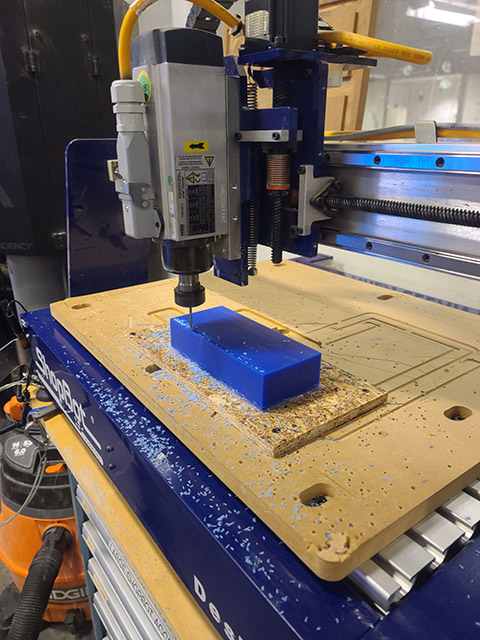

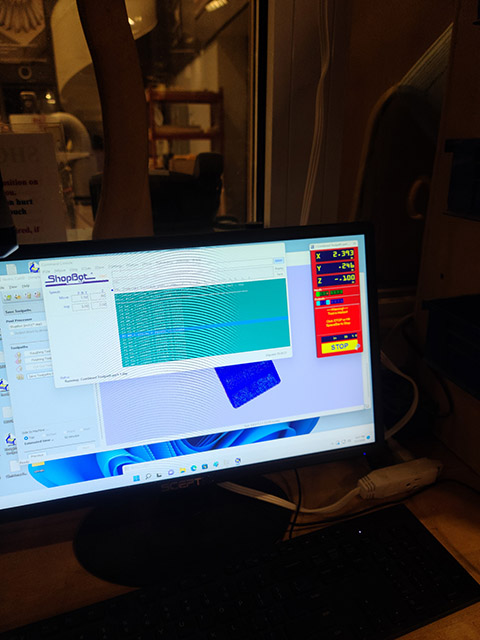

After the multiple redesigns, I went ahead and worked with the small 3 axis cnc machine to mill out my form out of machineable wax

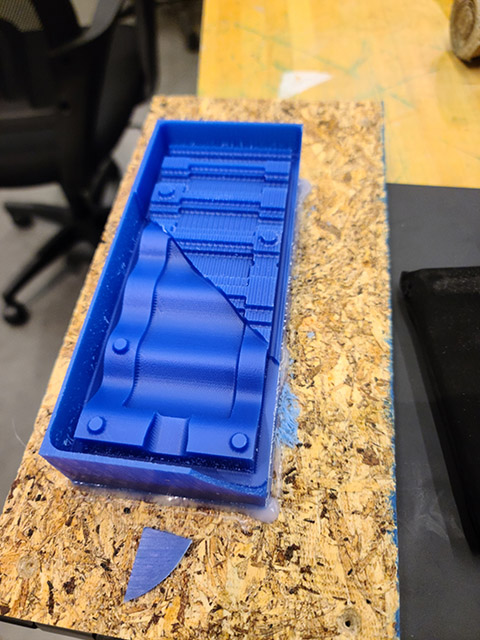

As you may have anticipated from my original design, the cast would have been inverse and thus not useful for me. The spout where I have put in a hole for pouring in casting material would be blocked by the initial silicone pour. So I decided to stop the print once I realized it was not going to work

As you may have anticipated from my original design, the cast would have been inverse and thus not useful for me. The spout where I have put in a hole for pouring in casting material would be blocked by the initial silicone pour. So I decided to stop the print once I realized it was not going to work

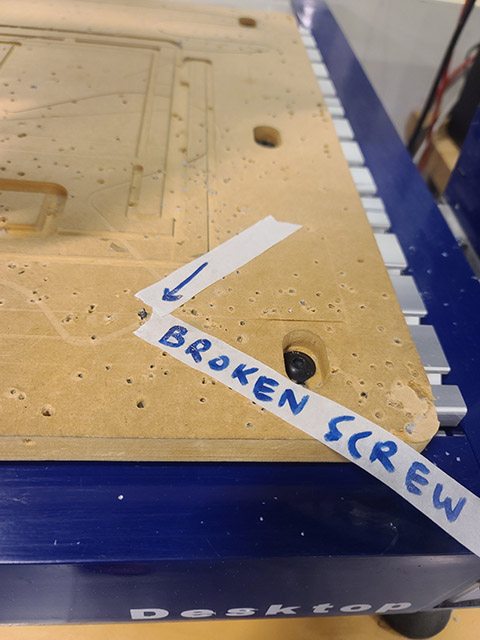

Also when I was finishing up and taking off the obs plywood from the cnc bed, One screw head came undone so I left a note saying there was a screw that I was unable to get off.

created with

Best Website Builder .