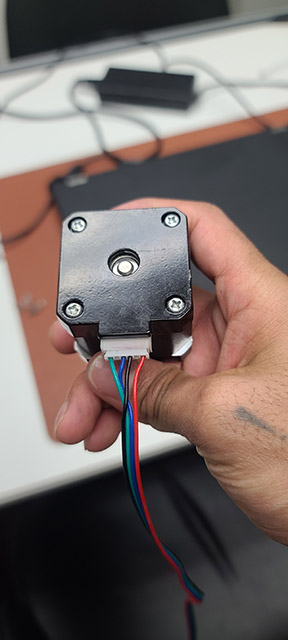

Since I knew that I wanted a rotational component to my final project. I decided to try working with some recycled stepper motors.

It was surely more challenging that I expected because my coding background is very limited and here I needed a lot of help from the TAs and my friends to get me acquainted with the basics of code.

Trials and Tribulations

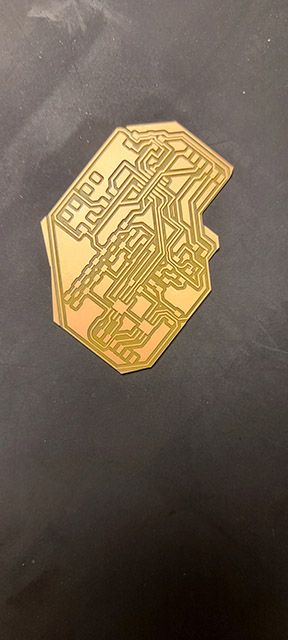

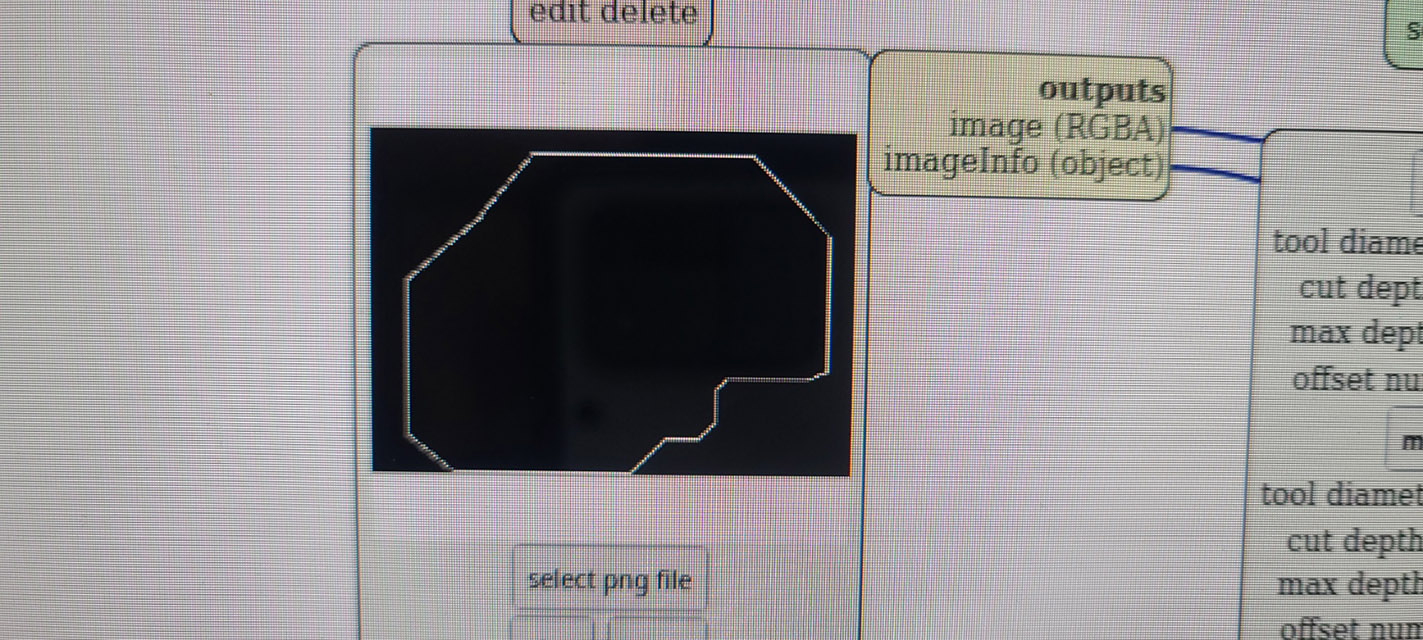

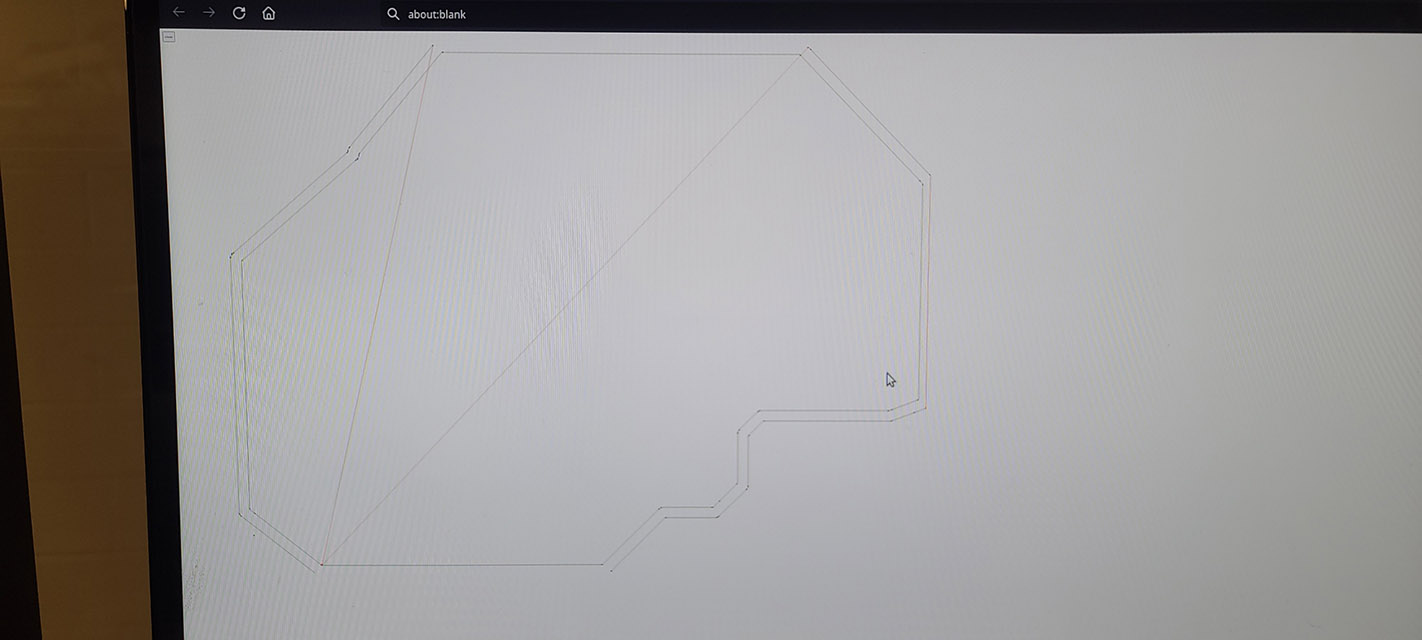

I used Eagle on Fusion 360 to design my circuit. I also decided to use the Attiny 1624 again because Eyal suggested that it is best to work with a chip that you understand and iterate and build on it each week. So for this week I tried to figure out how to interact with H-bridge. Which also helped try out reflow soldering technique. Overall the milling went better than last time but there were a few odd things that happened. For example my outline was cut into two lines because I did not clean up the file in photoshop first and also because in this board I did not export a copper pour. Instead I exported the outline only which led to mod thinking that were two lines insead of one clear edge

Here you can see how mods also didnt register the edge information because the export was right up to the edge and the machine had a tolerance built in to not cut at the very edge of the design. so I needed to go into photoshop to increase the black area beyond the edge of the design.

This time I used two buttons because I wanted one to turn on the stepper motor and the other to turn on the leds. The two components needed in my final project planning. It was supposed to be capacitive touch but due to time limitations, I had to settle for a button.

I did get the stepper motor to move after a lot of effort trying to interface with the board and also trying to figure out how to interact with the stepper code.But eventually I got it to make simple movement in response to the switch. However I do not have the documentation uploaded yet. To be Uploaded at a later time...

created with

Website Builder .