Molding and Casting

design a mold around the stock and tooling that you'll be using, mill it (rough cut + three-axis finish cut), and use it to cast parts.

3D modelling and stl file generation

This week, I would like to make a flower. I used Rhino to make the model and then export it as stl file.

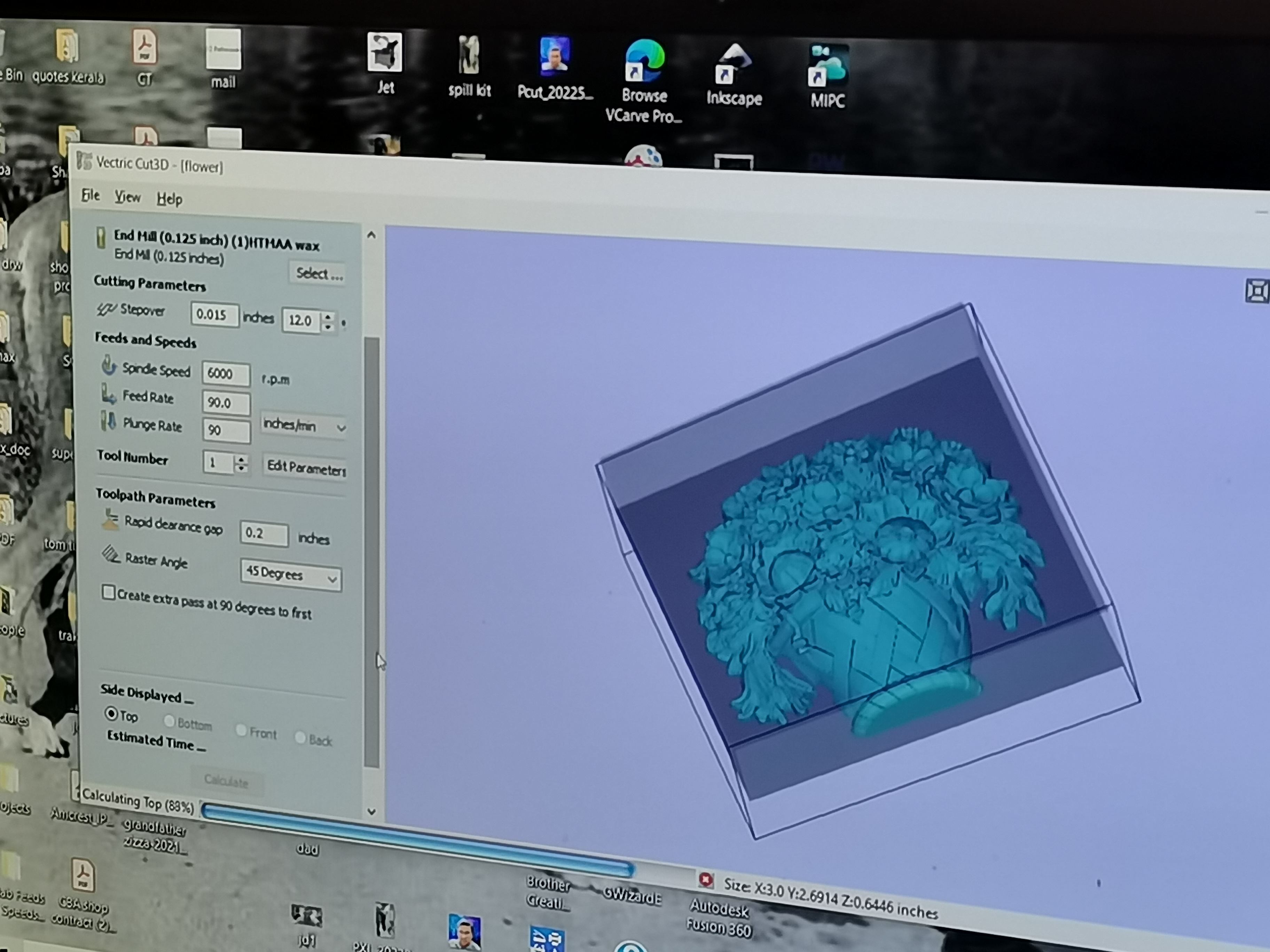

Toolpath generation

I then used VCarve to generate the toolpath of the designed 3D model.

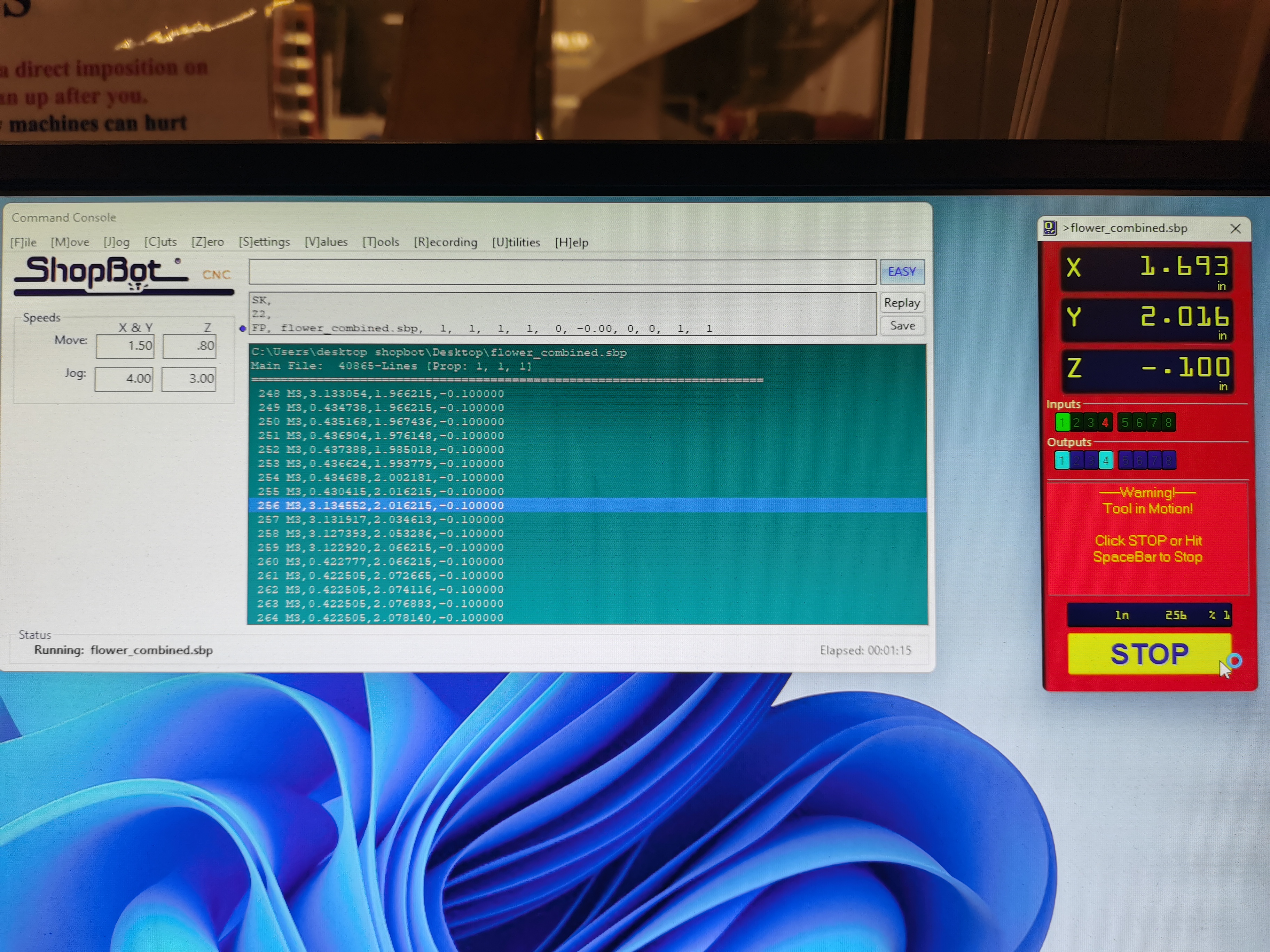

Shopbot Setting

Then I used software to prepare and start the ShopBot CNC machines. For the preparation, after adjusting the x and y position with button, I use the manual method to To set the Z zero location. After setting the xyz position, I start the machine.

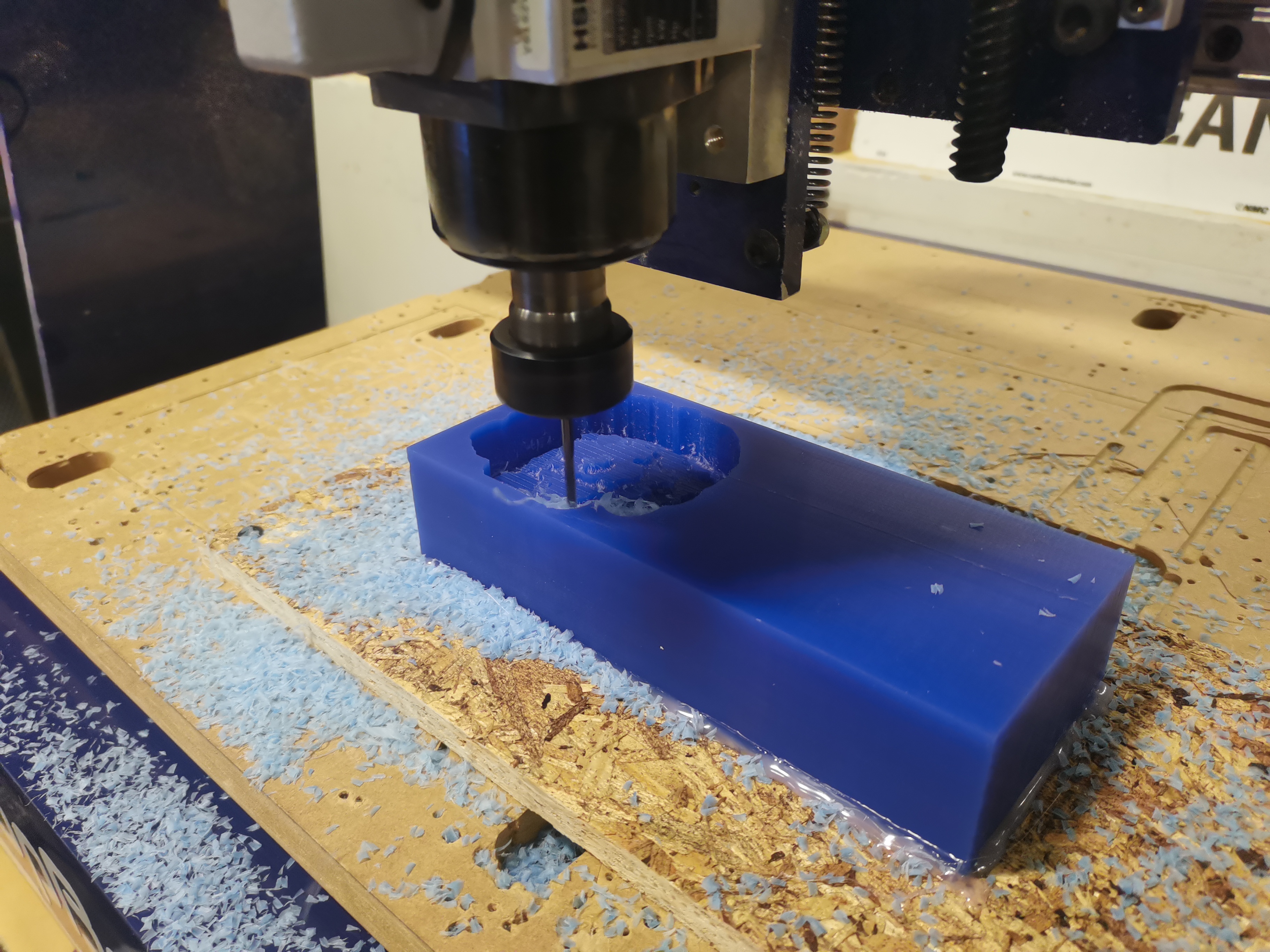

Milling

Then I wait the machine milling the mold. At the beginning, I used the round mill, but TA told me that my pattern is a little complex, maybe I can try the flat mill. Then Tom helped me stop the machine, swith the mill, and re-start the machine.

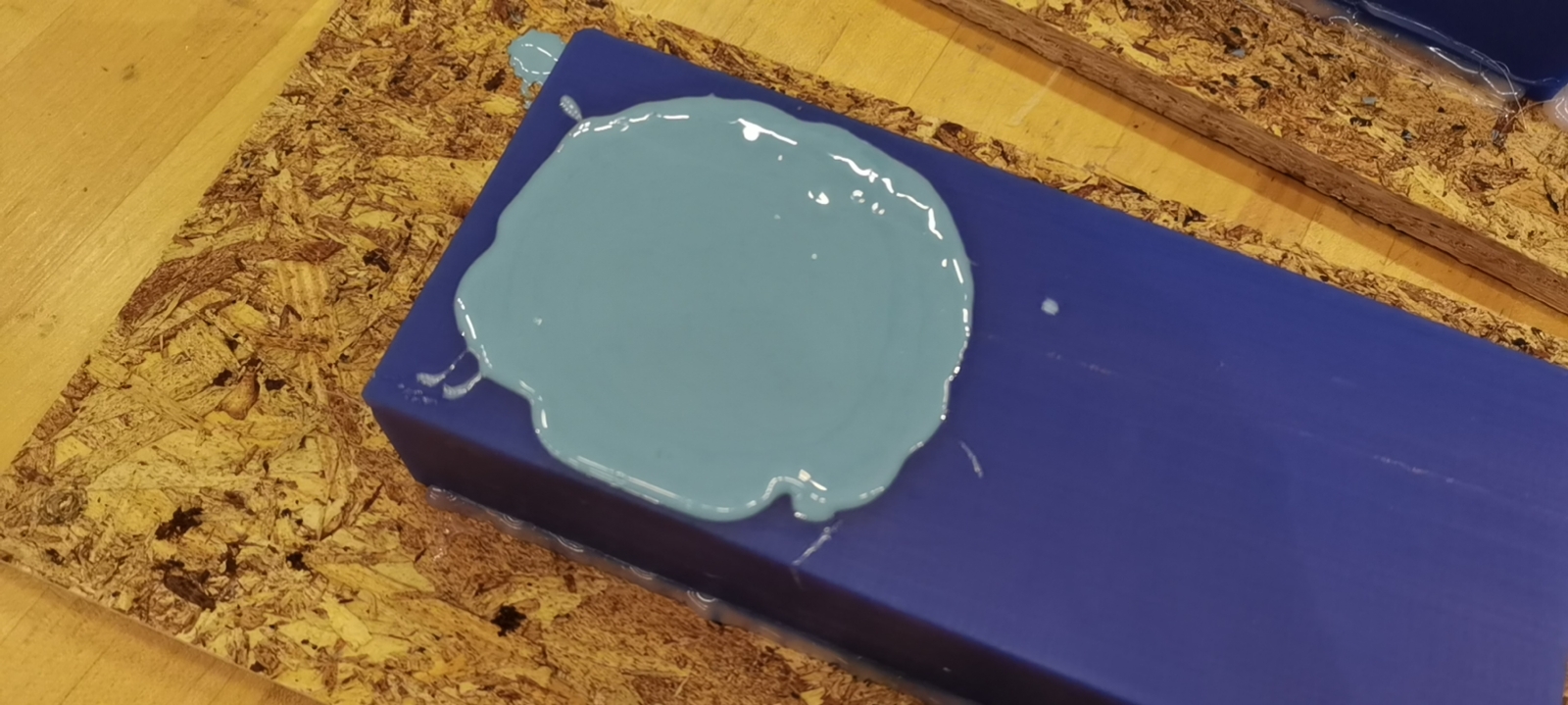

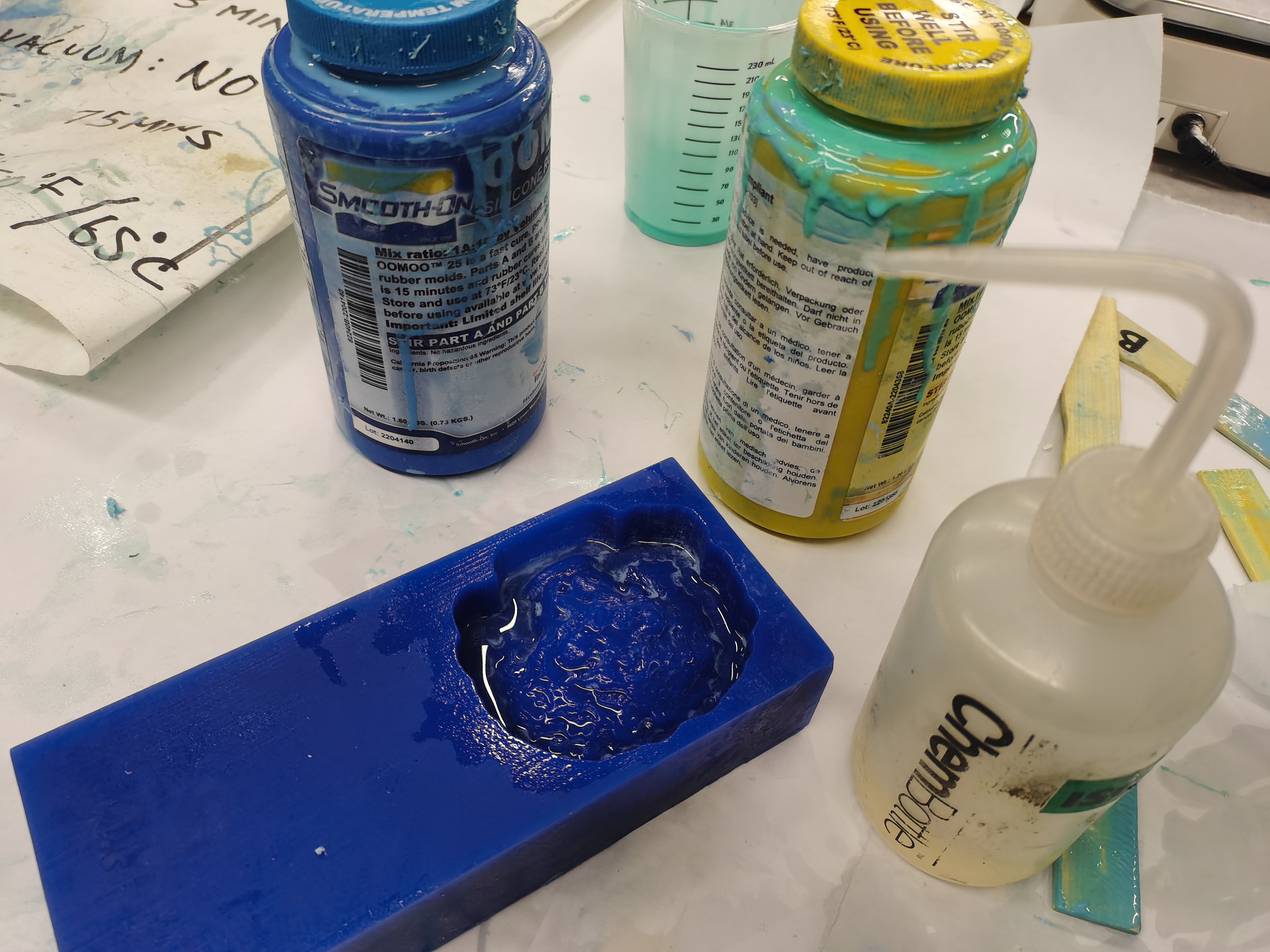

Silicon Casting

I used 1A:1B OOMOO and mixed both individually before combining and mixing again for 3 minutes. Then I poured the liquid into the mold and let it sit overnight.

A failed attempt

It is worth mentioning that I did not mix AB OOMOO in a 1:1 ratio at the beginning, so the liquid did not solidify despite sitting for a long time. I removed the remaining OOMOO with alcohol and did the silcon casting again

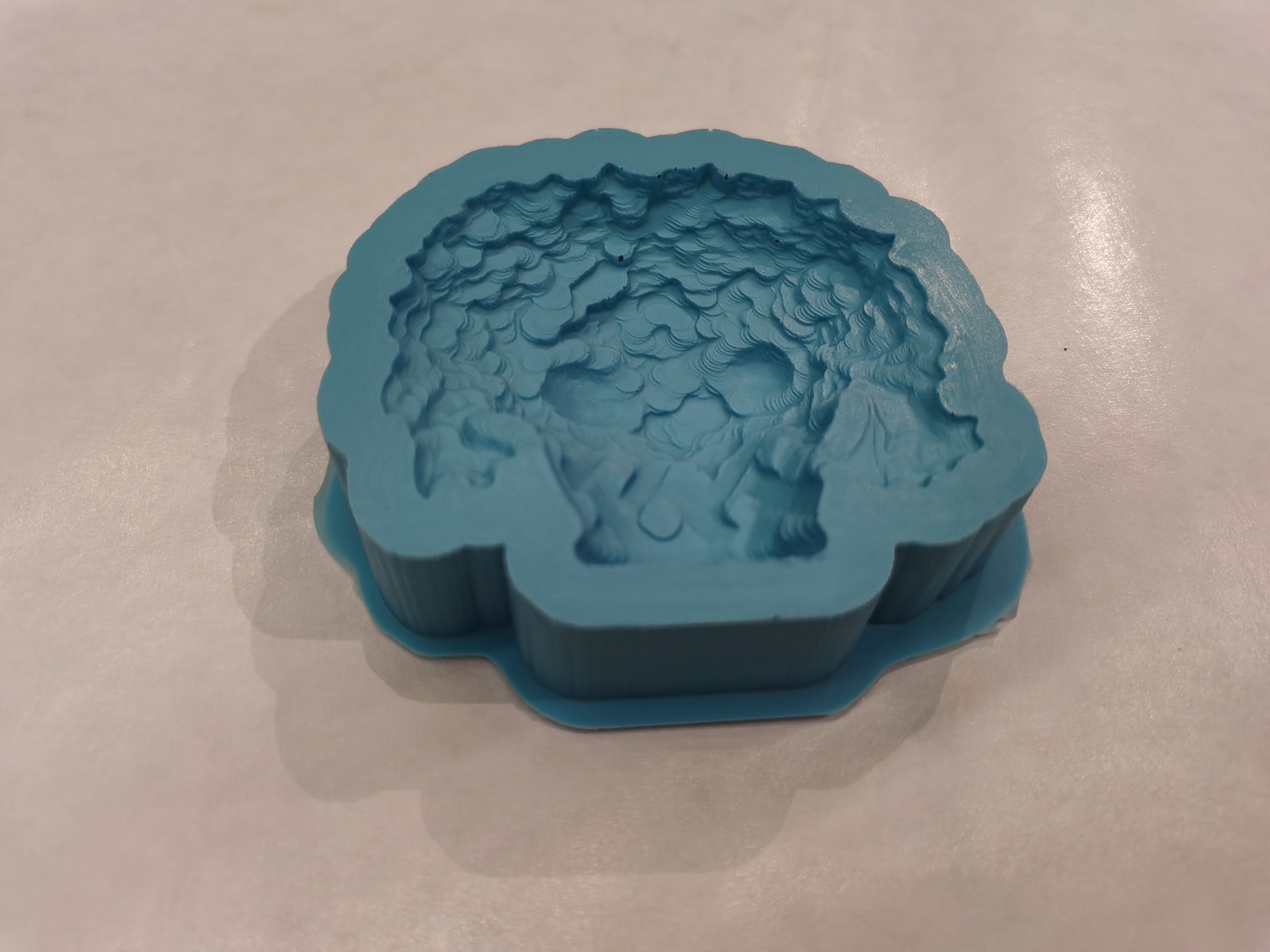

The silicone mold

After a night, my mold was super sticky but I peeled them out of the wax mould. I got my mold! How happy I am!

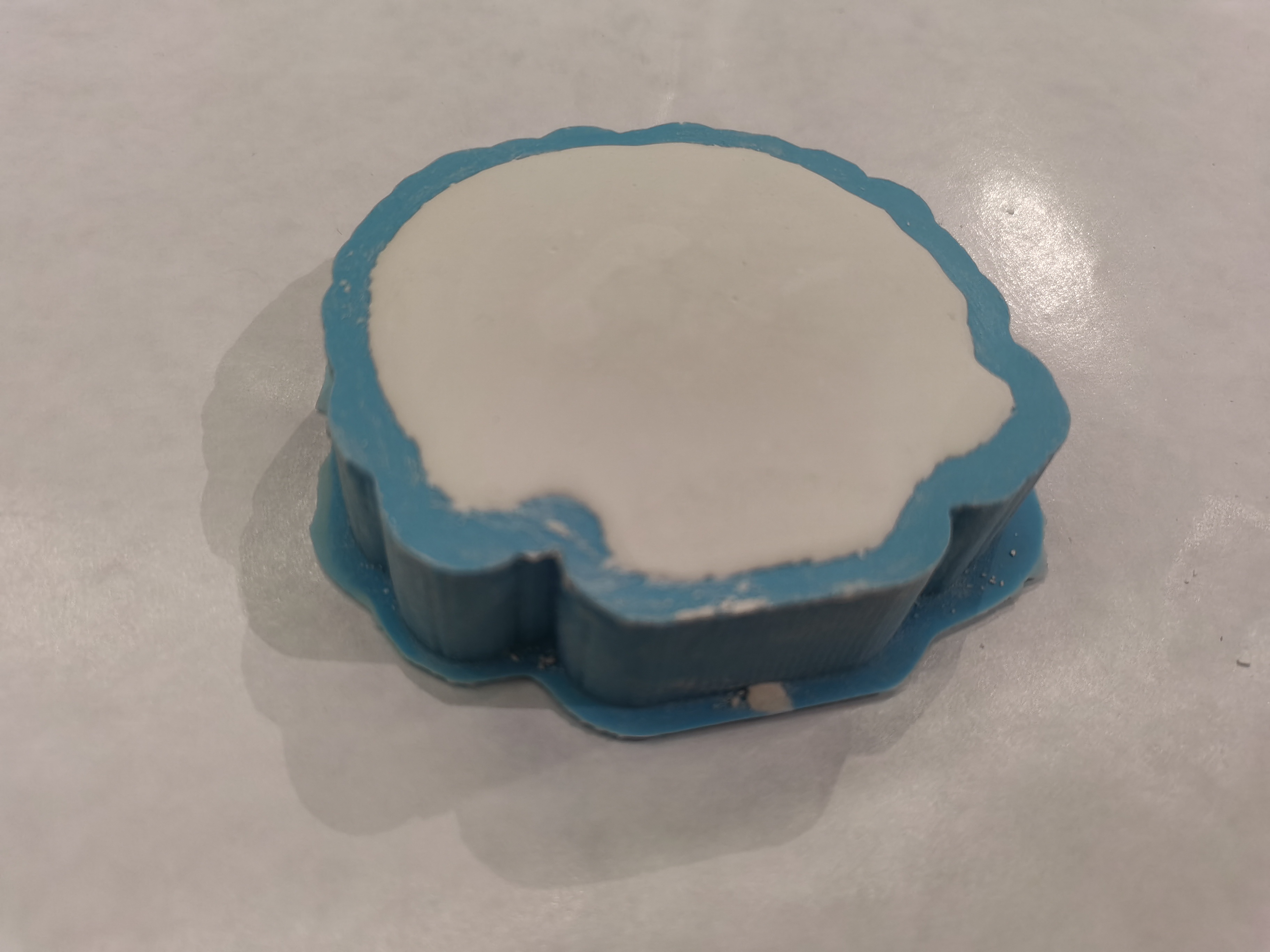

Hydrostone Casting

Then I tried hydrostone casting. I mixed together 40g water to 200g hydrostone and slowly poured it into my mold. But while pouring the liquid, I realized that the hyrdostone mixture was not watery enough to fill all the way. Then I added a little more water and then re-fill my mold.

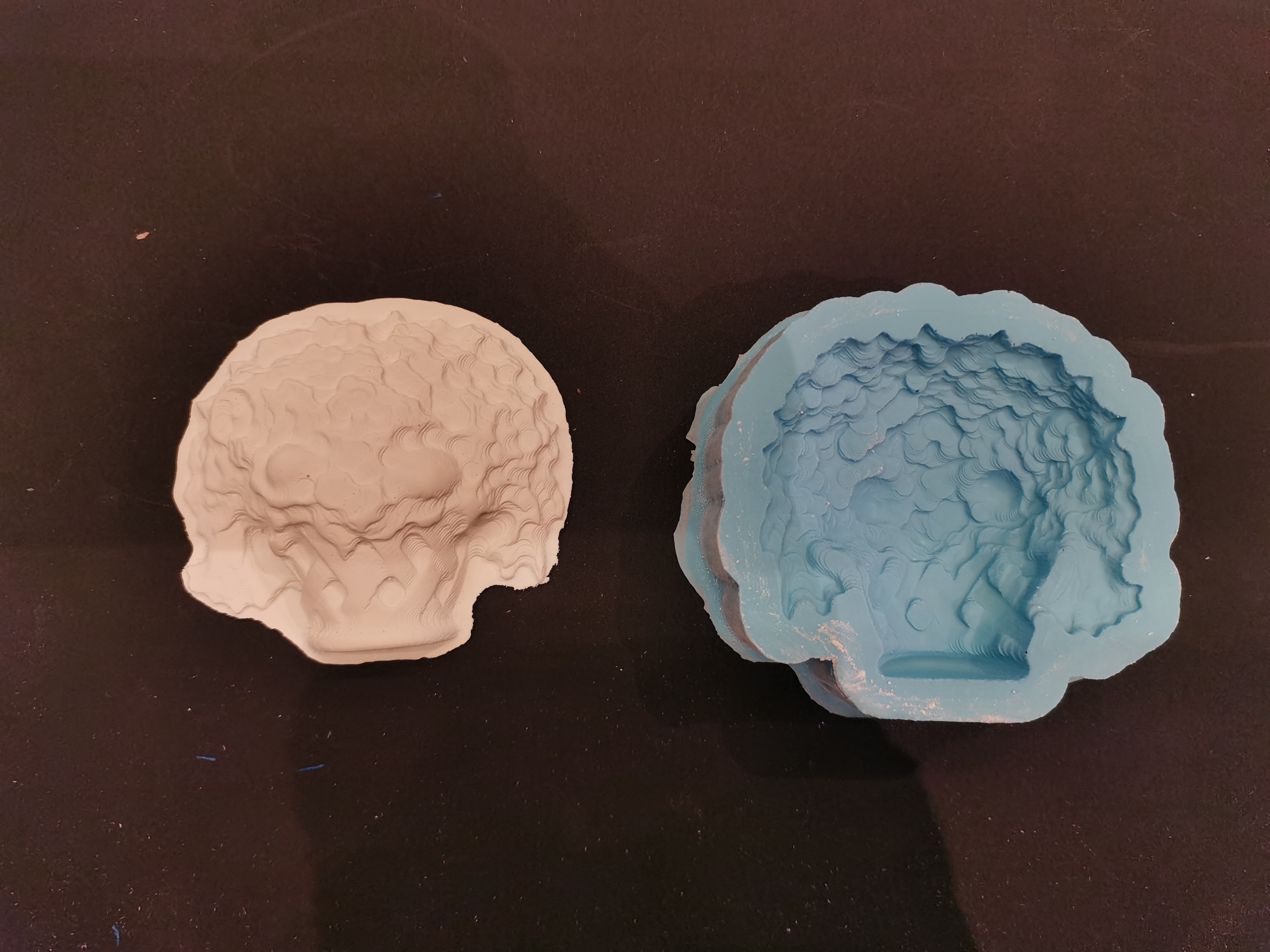

Final Product

This is my final flower!