Week 2

Getting comfortable with asking for help.

This week we were tasked with milling, soldering and flashing a circuit board. All unfamiliar concepts to me.

I began by going to the shop to see what others were doing. Apparently, we had to mill the board first.

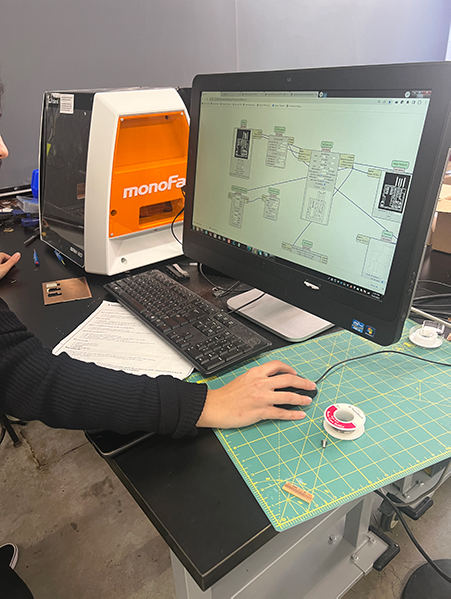

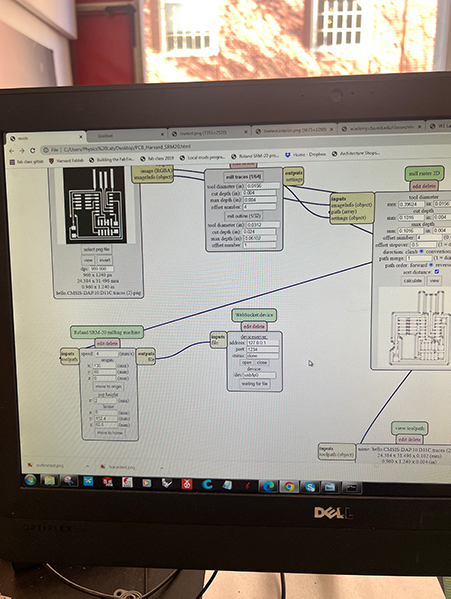

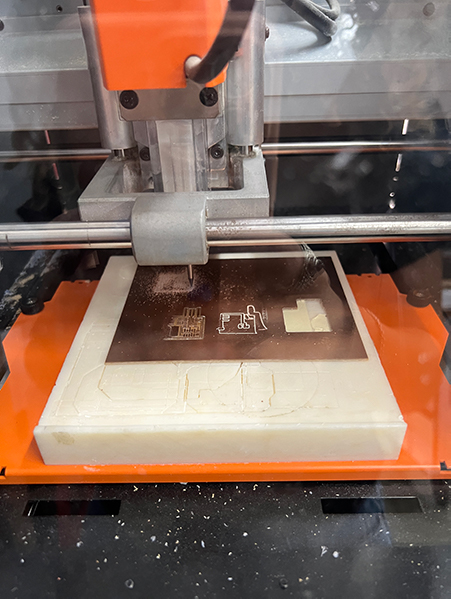

Milling the board consisted of 3 hours of simply waiting to use the notoriously volatile SRM-20 milling machine. Every person ahead of me had to try about 4-5 times before getting it right. Pro tip: go to the shop extra early to mill. By the time it was my turn we had pretty much perfected the system. Play with z axis until its in the right spot. 1/64 endbit for traces, 1/32 endbit for cutting. On the mod- hit mill traces, calculate, then send to printer. WAIT AT LEAST 5 SECONDS BEFORE LIFTING THE LID.

So many f*ck ups the poor sacrificial board was screaming.

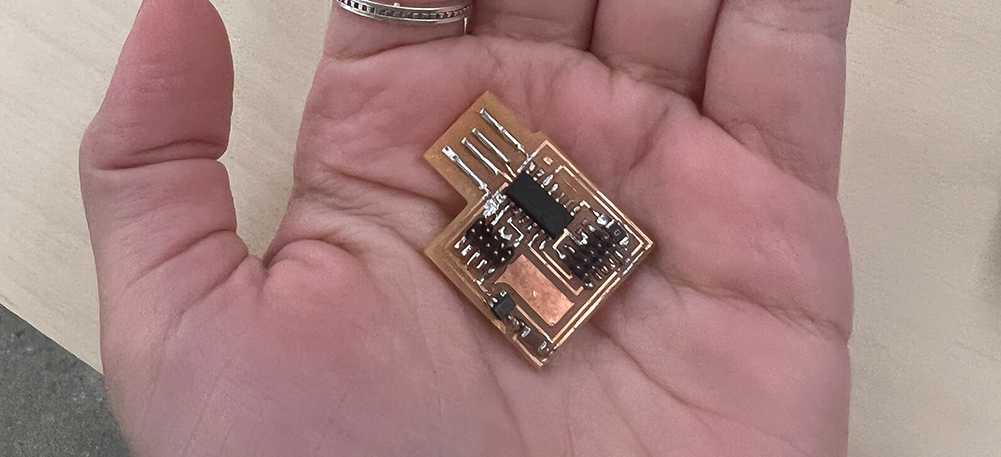

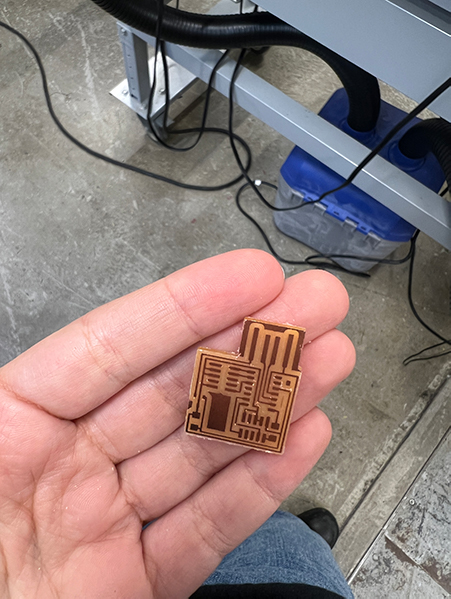

I finally milled my board! So proud. Next up is soldering.

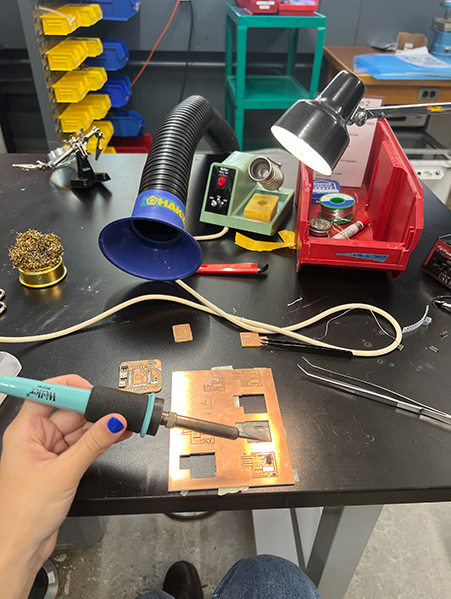

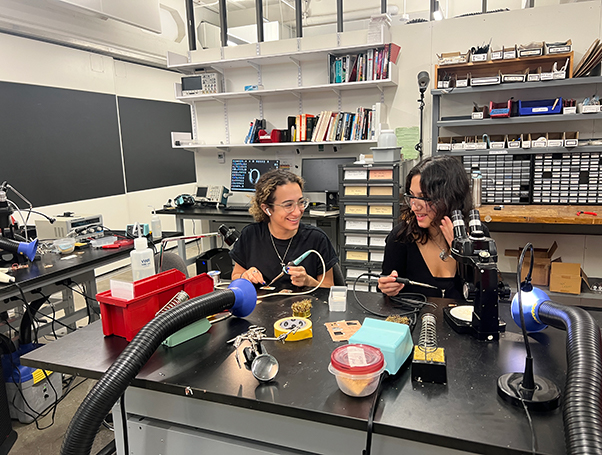

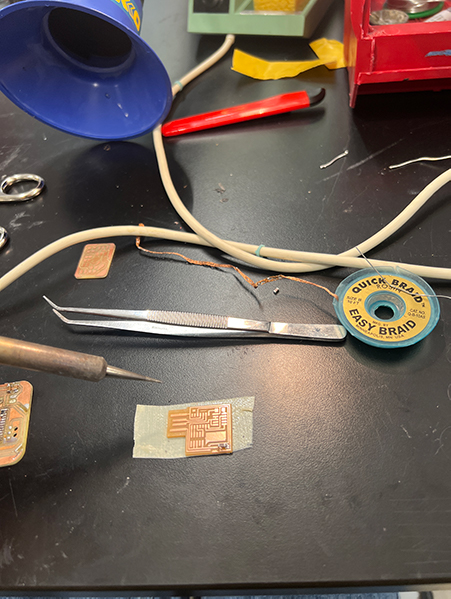

Before soldering the circuit board I just spent 3 hours milling, I decided to practice on a throw away board. I quickly learned that I have bad eyesight and am a poor solderer. What I found most difficult was using the soldering braid to pick up the lead and start over. I discovered the right technique was to not use the braid.

However, with lots of encouragement and assistance from my lovely classmates, I was able to make a *first pass* at soldering the parts to the board. Now it was time to program the thing.

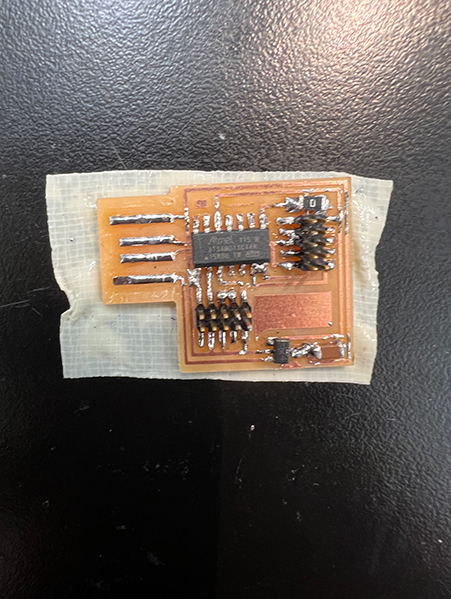

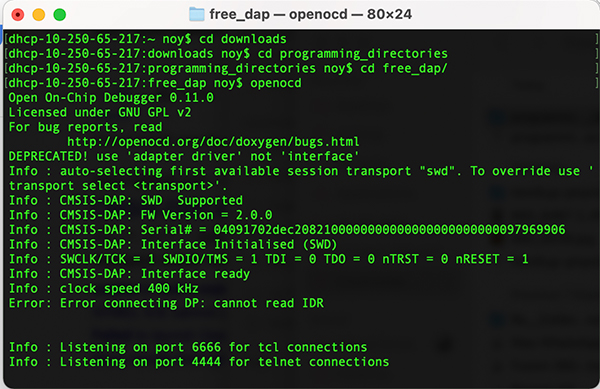

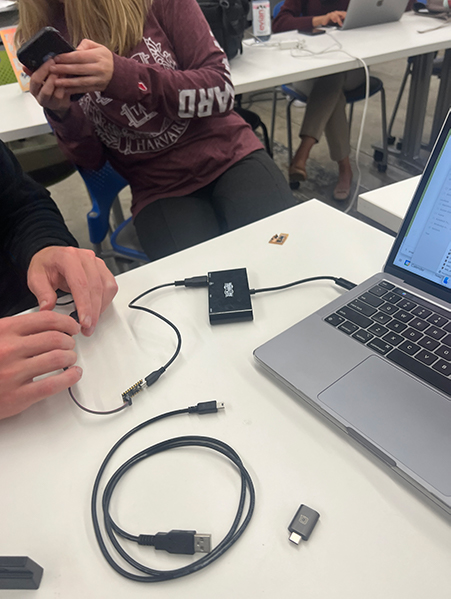

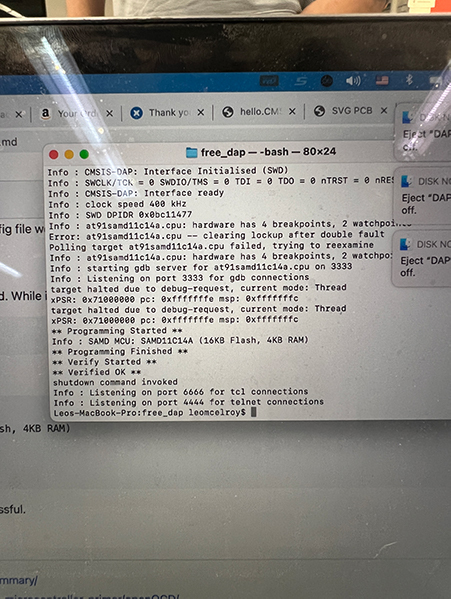

I installed Homebrew, then Openocd, I plugged in the board and began a series of plugging and unplugging and resoldering for the next 4 hours or so until I (Leo) got it to work (Bless you Leo).

My PCB was able to be programmed but did not work as a programmer to other boards. I will keep tinkering with it in the coming weeks until it works.