Week 5: Make Something Big

"Don't get lost in the sauce" -Claire

I was very excited about this week's assignment because I love playing with scales . I wanted to make something I could place in my apartment, specifically, a record player stand/vinyl holder. In addition, as a member of the Harvard GSD Halloween Party Planning Committee, I volunteered to build the installation that will hang from the ceiling (don't tell anyone).

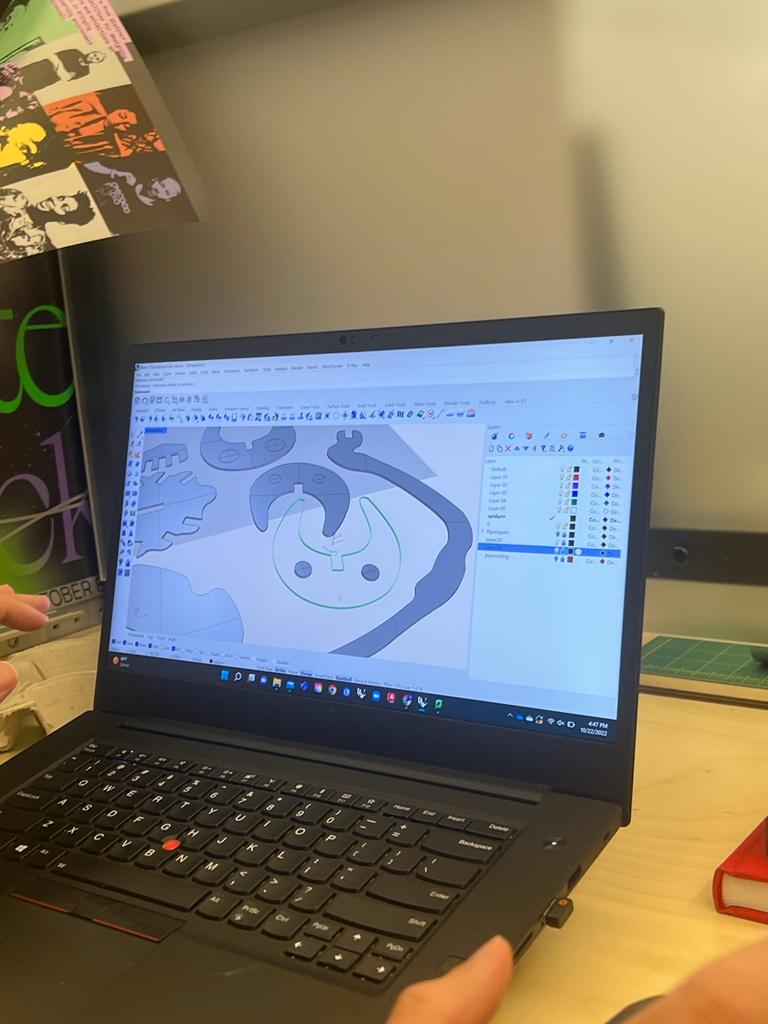

When using illustrator to design my plans, I had the artboard set to exactly 24x18 in (the dimensions of the piece of OSB I was cutting. I literally created a rectangle with a width of 0.5 in (the width of the OSB we were using) and subtracted it from the slots.

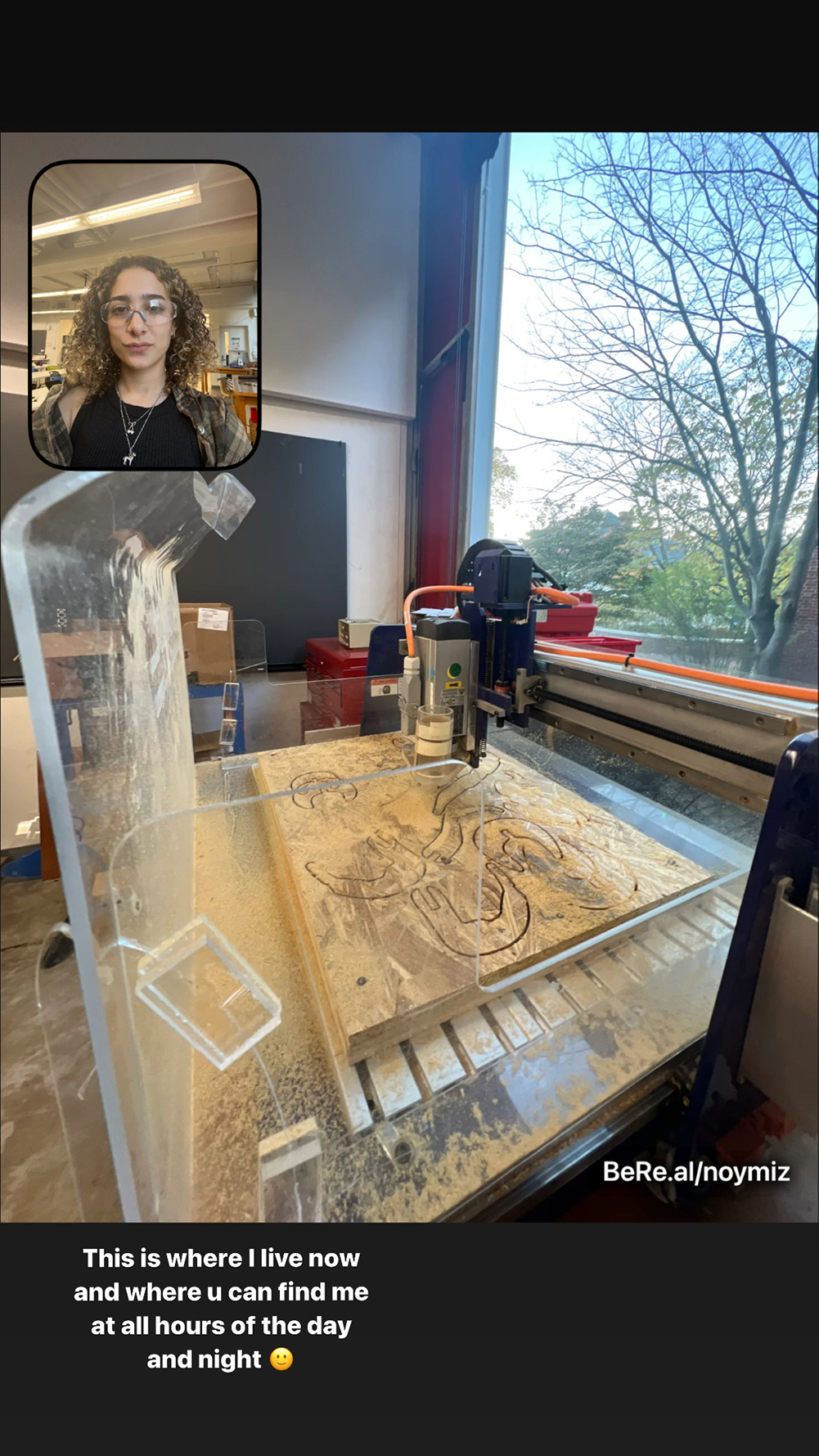

On Saturday I woke up, saw the gorgeous foliage outside of my window, and thought to myself "I have the best way to spend this perfect day! Another 12 hours in the fablab inhaling sawdust and lead." I went to the science center. Thankfully Leo (TA) was there and repeatedly showed me how to use aspire and the small shopbot upstairs until it clicked. I am now an expert. (follow me on BeReal)

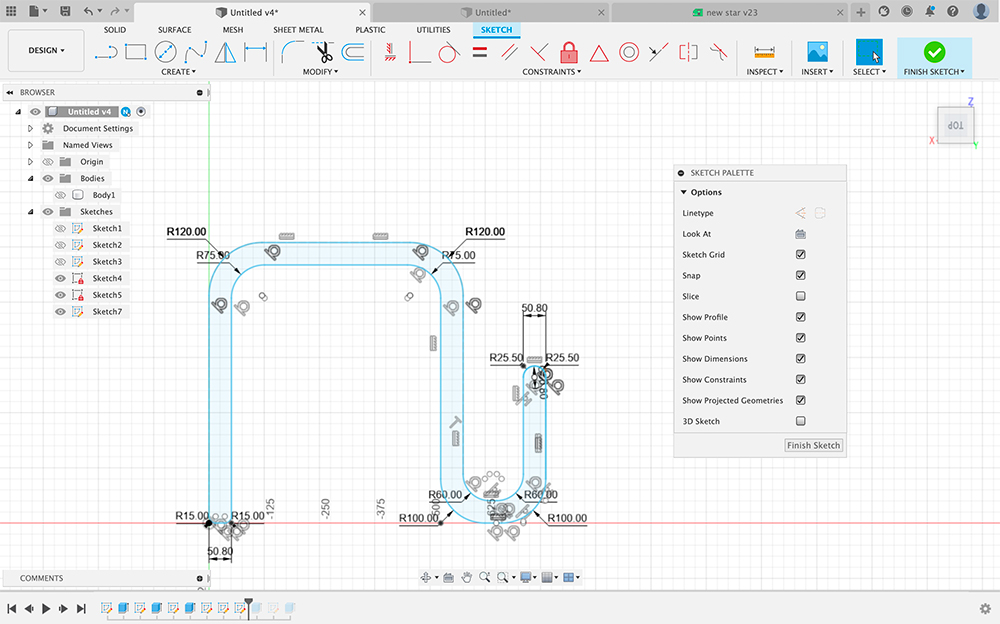

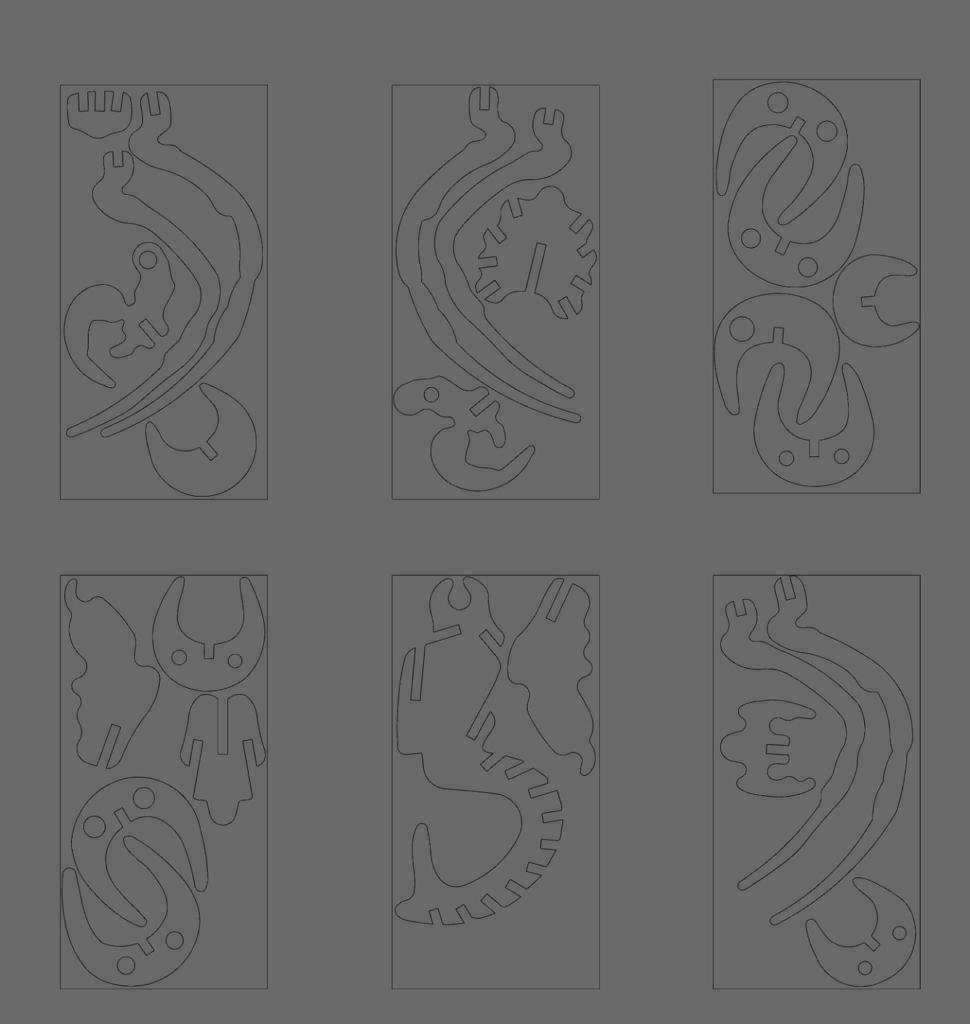

The rest are pictures.. I'm running out of time. Basically I also wanted to make something I designed and built from scratch. I made a squiggly sketch in fusion, added rough parameters that corresponded to the size of a standard record player, extruded and sliced.

Thank you Jessica + Tyler for help with transport < 3

One week later...

It was the week before Halloween, and I was dealing with a very spooky predicament. I volunteered to make something big for the Harvard GSD Annual Halloween party. I had originally a model of the spider to gain some inspo/gauge my skills with CNC. However, when I showed the model to the planning committee they decided to run with it. The party was now spider themed. (eek)

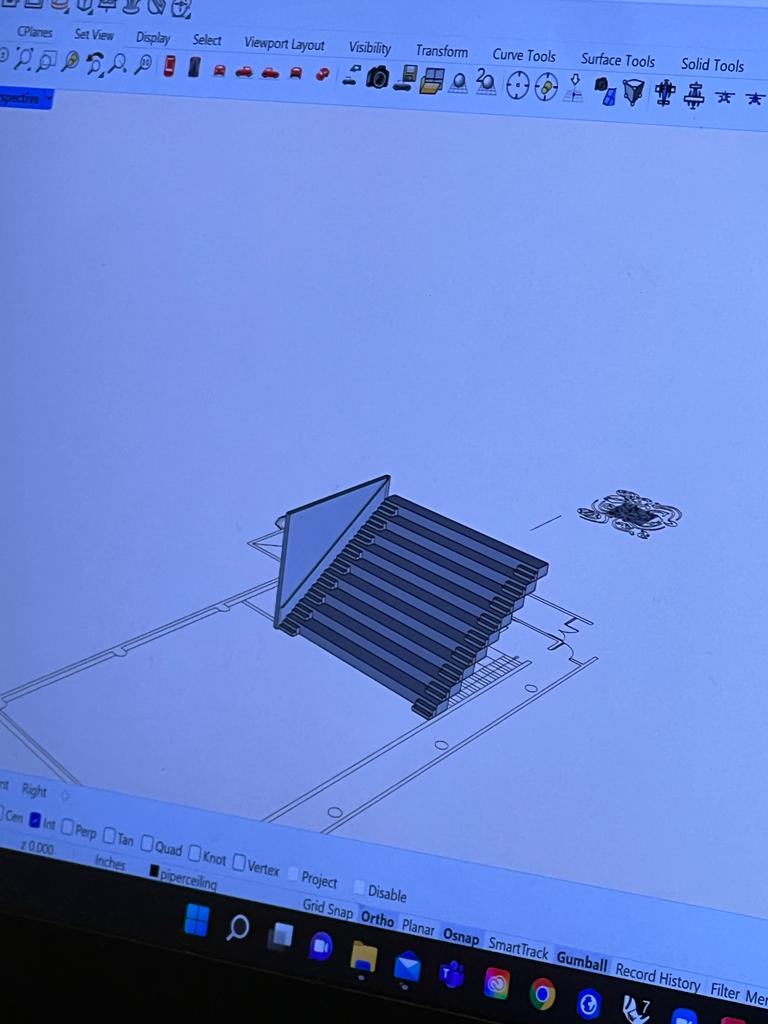

I was asked by the planning committee to prepare my cut files in Rhino. However, when trying out my rudimentary rhino skills to scale up the spider pieces, I realized I would have to model Piper Auditorium so that the legs of the spiders would be custom to each stair they sit on. This is important, because I wanted to avoid a 15-foot spider barreling down the auditorium stairs toward my peers at the school halloween party. Thankfully I go to architecture school. On Friday night my lovely friend, Nick agreed to help me. We went into Piper and took loads of measurements to see how we big the spider should be, Keeping in mind out constraints. At this point the omnly constraint was the max size the CNC machine in GSD's fablab could cut, which is 4x8 ft. that's Nick looking very confused as he modeled the Piper Auditorium stairs in 5 seconds (???).

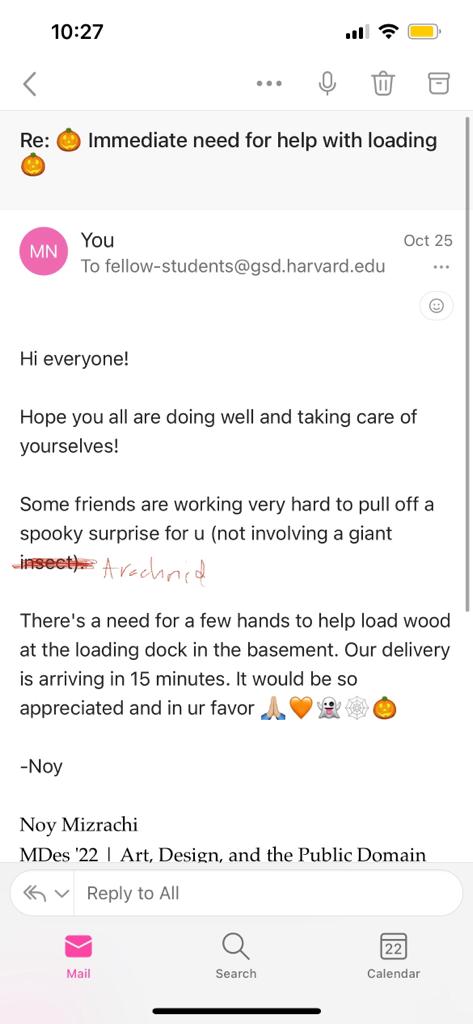

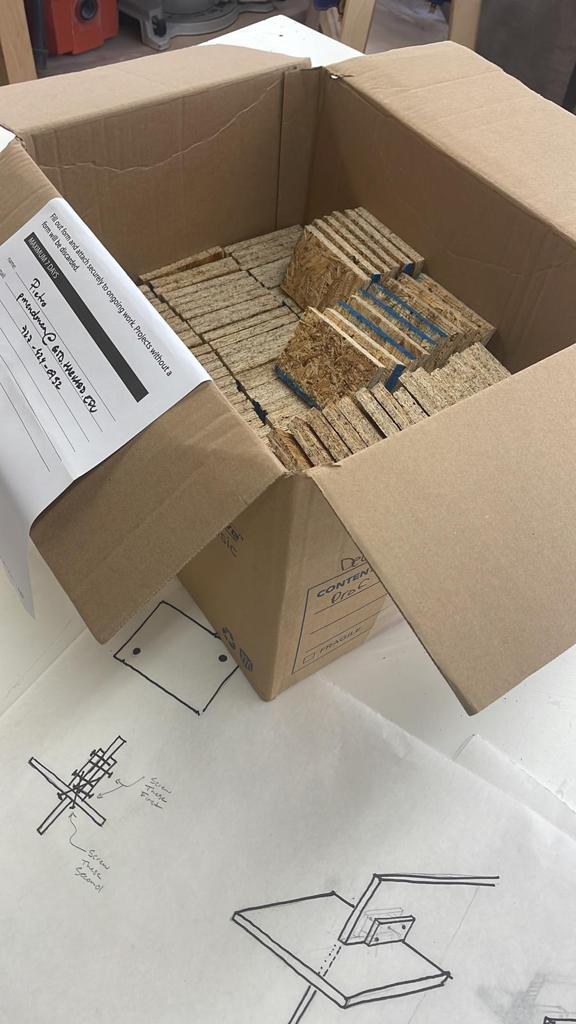

We then scaled up each of the spider pieces, the most important part was scaling each joint the width of the OSB I was using which is 7/16 inch. Acquiring the wood was another story, I needed 13 panels of OSB. 13!!! The GSD agreed to budget in the wood for the party. My fellow Halloween party planning committee members took a Uhaul to Home Depot while I prepared the loading dock for them. We needed hands for the wood, so I sent out a desperate email to the school. Our prayers were answered and we got a lot of help to carry the wood inside.

I took the file to the GSD Fablab, Where fablab student employee and all around wonderful person, Tobi, who immediately told me the spider was way too big to handle once cut. She helped to scale the spider down and set up the cut files. We also dog-boned the joints and added some shapes to the body of the spider for handling purposes (Tobi's great idea). The file was sent to machine! And we were ahead of schedule! While the pieces were being cut, I needed to figure out where to store them. This consisted of me begging the wonderful folks at building services for a spot in the basement. The issue was the basement was stuffed. Eventually, my desperation got through to Barry at building services, and he kindly lent me an A-frame and made space for the wood by the loading dock. The incredible GSD Fablab team rallied together to help with cutting the giant spider pieces. THANK YOU GSD FABLAB <3

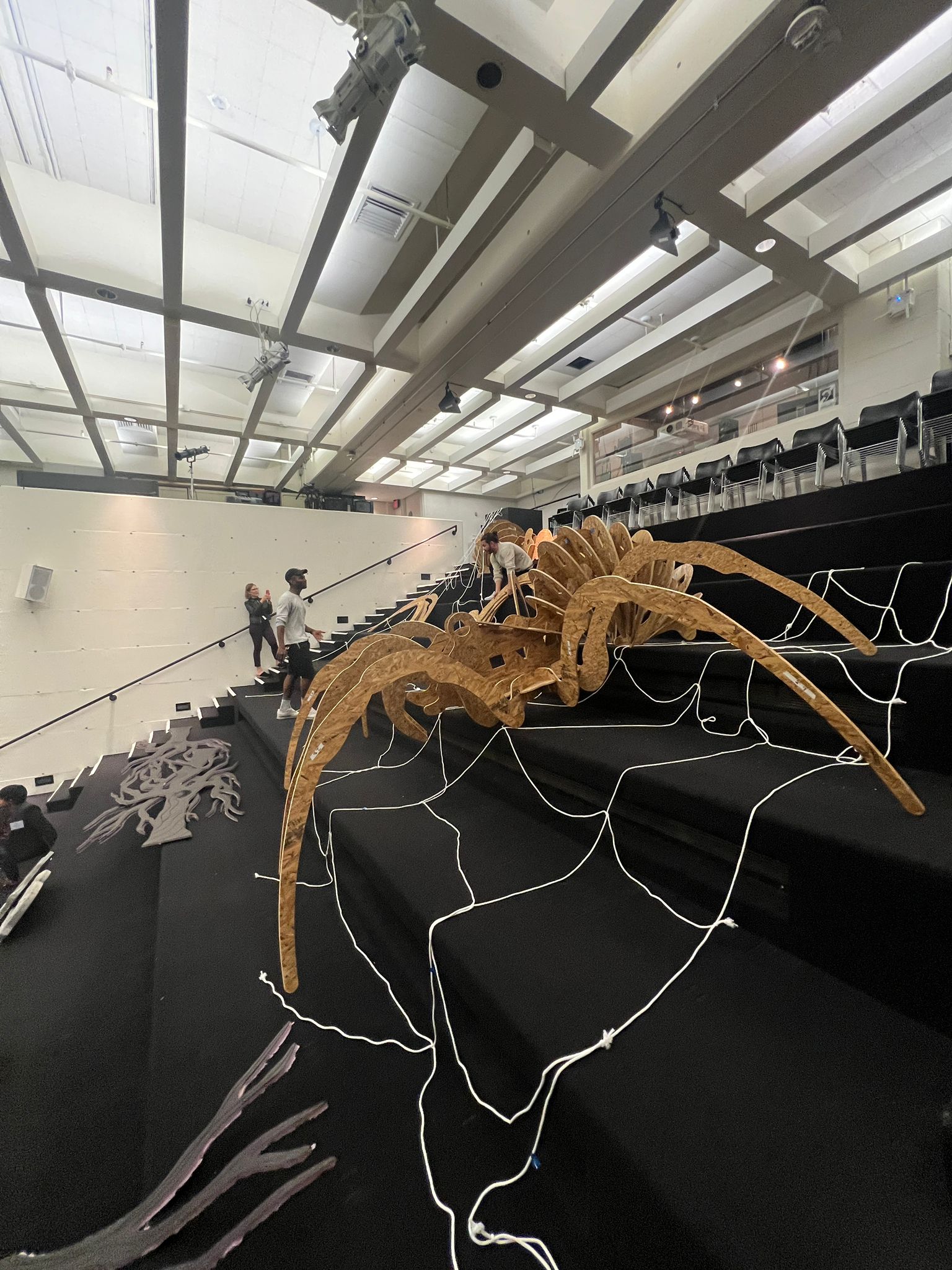

Now that we had those pieces cut, It was time to begin the clunky and splintery process of putting the pieces together. This process was made even more difficult due to a whole other swarm of issues. Mainly, I only had an hour to assemble the spider in Piper Auditorium, as Harvard was having a donor event in the auditorium right before the Halloween party. They REALLY did not want a giant spider hanging out on the stairs during their donor event. Thankfully, some friends noticed my distress and panic and I had volunteered to help me with assembly. I want to take this moment to thank Pietro and Jono so so so much! Their help was necessary for the execution of this project. We brainstormed ways to put the spider together in the most structurally sound way. Since we didn't have any L shaped brackets for drilling. I had the idea to drill OSB scraps to the 90 degree connection points of each piece. We drilled the two spiders bodies and left the leg assembly to be done in the auditorium before the party.

This really started to feel like a military operation. Sneaking around the Harvard billionaire donor event to put together giant wooden spiders was a thrill I never knew I needed. We placed the semi-assembled spiders in the balcony of the auditorium the night before the party.

THE DAY OF THE PARTY...

In full costume (I went as Pearl from the movie Pearl (2022)), We brought down the spider bodies to the spidersa and began connecting the legs.

I was still so fearful the spider would fall apart, however it ended up being quite sturdy standing on the stairs! I was so happy to avoid being a GSD legend who ended

up crushing my classmates. Although, the Harvard Halloween Spider killer does have a ring to it. At least I'll have a legacy...

Once assembled, I began adding LED light strips to the bottom of the legs. The light strips I used environmentally sync with music through a mic to pulse light with the beat.

The Spiders were ready to party.