Brian's HTMAA Diary 2024

Week 03: 3D Printing & Scanning

Group Assignment

We got our training from Jack Forman.

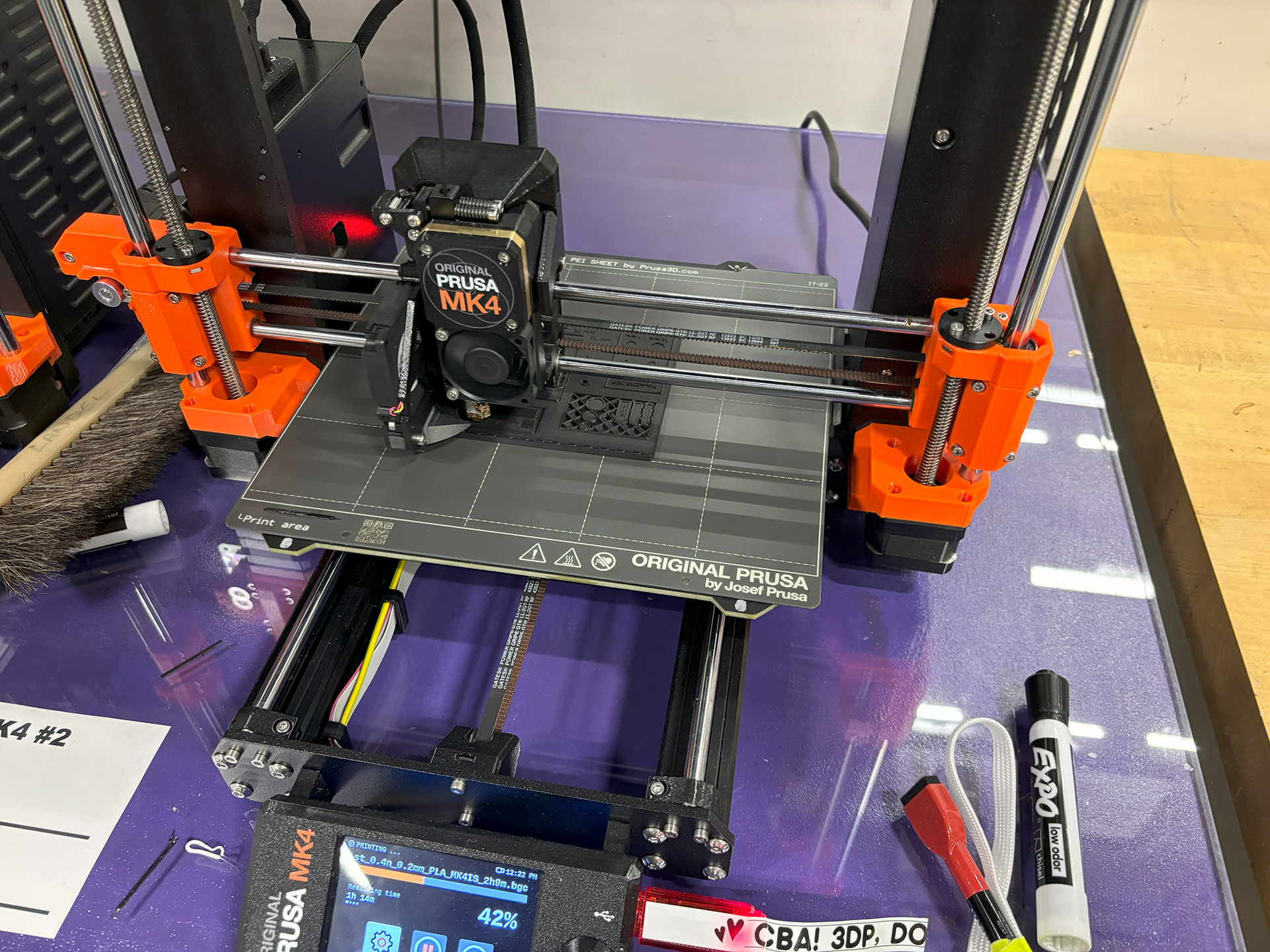

We focused on the PRUSA 3D printers and learned how to edit our prints in slicer software, specifically PrusaSlicer. We then exported the sliced print as gcode and loaded it into the 3D printer. Jack also spoke briefly about the bambu lab, formlabs, and stratasys printers.

Jack then trained us on the 3D scanner.

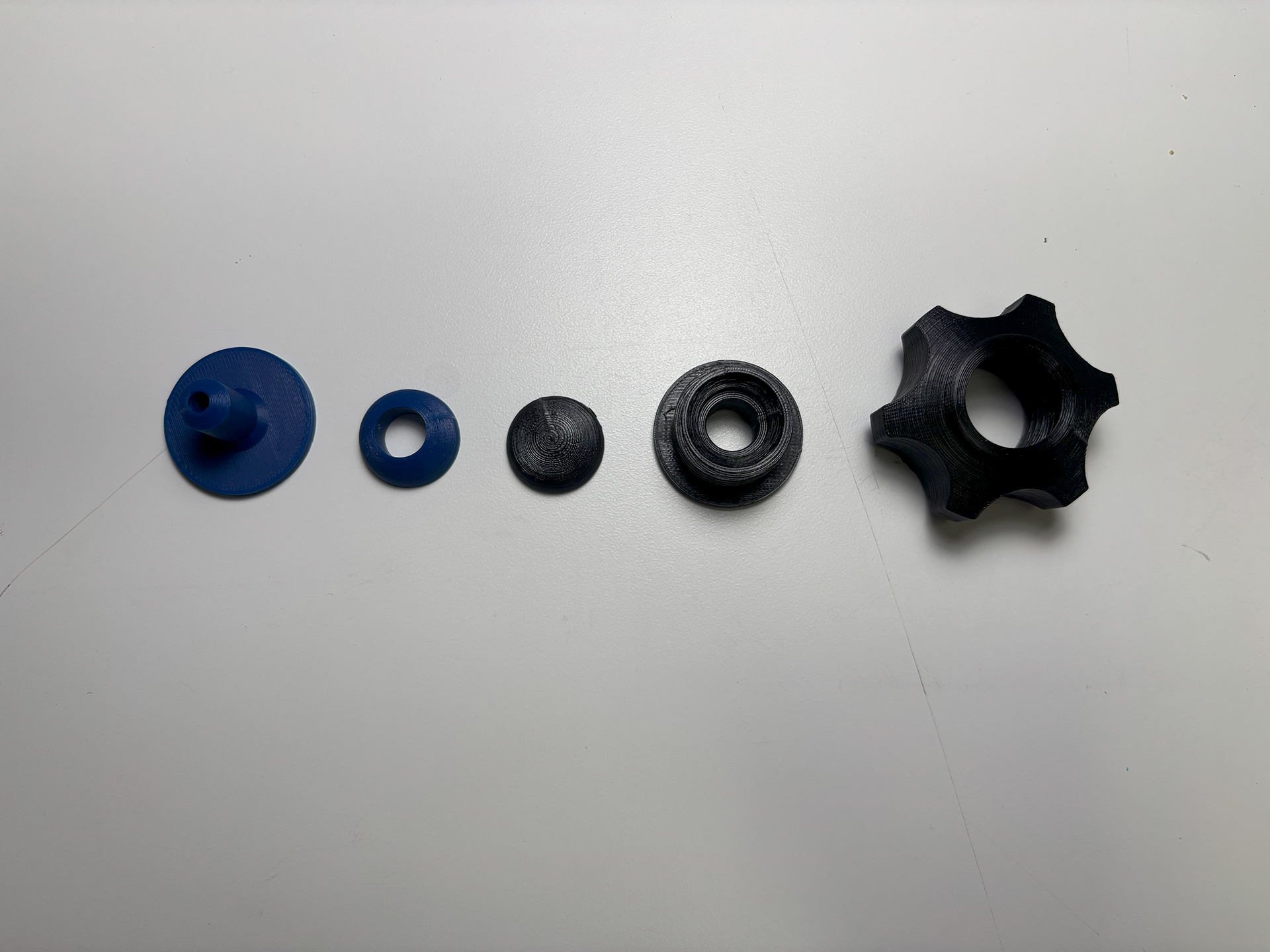

By the end of the training session our group assignment was done printing:

Individual Assignment

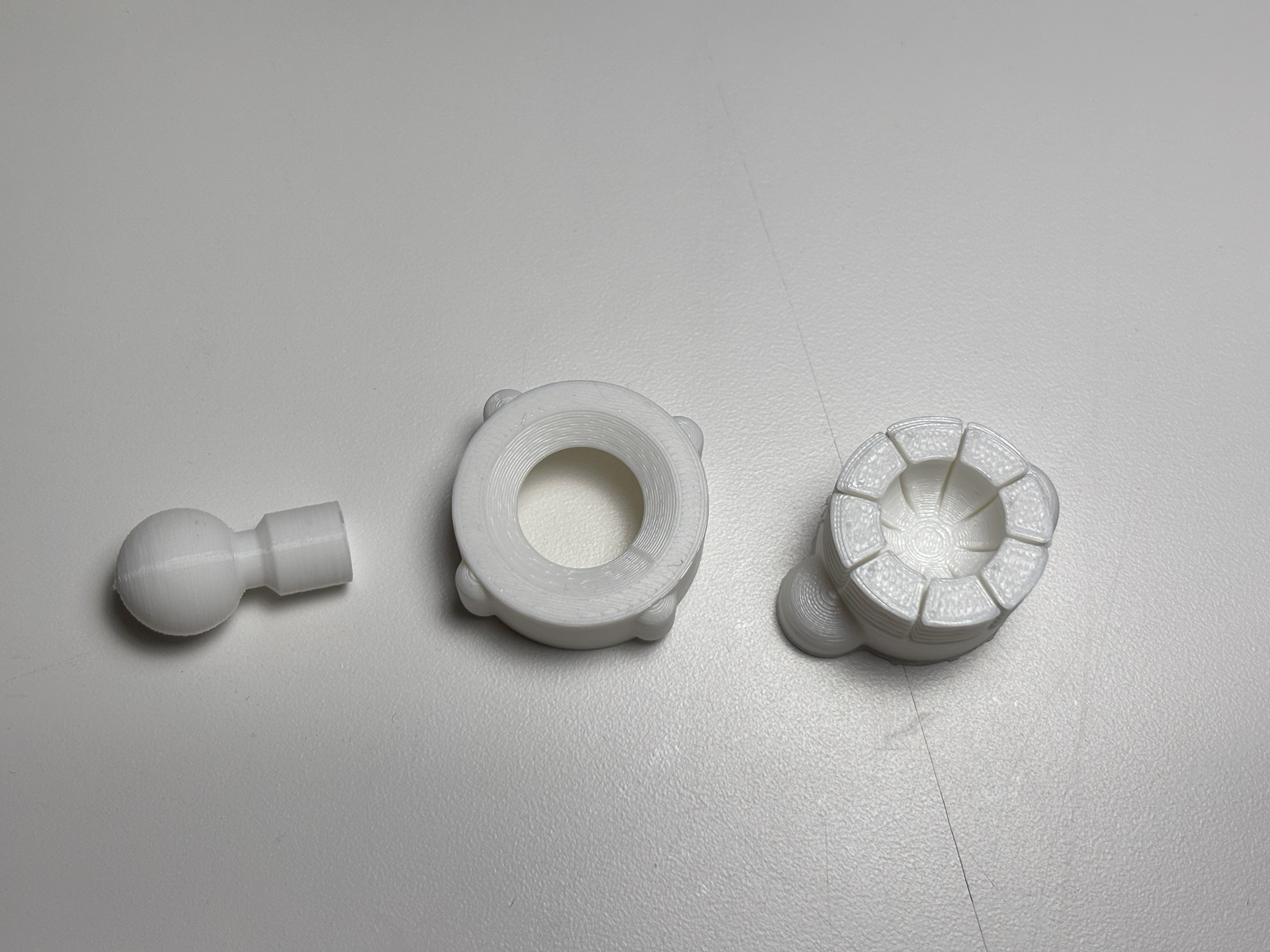

I was interested in 3D printing joints that could give the largest range of manipulation, and looked into universal joints like the ball and socket. I found some interesting ones and printed some to test out what works the best when I design my own ball and socket joint.

the first joint lacked a locking system:

The second joint has a locking system to hold the position:

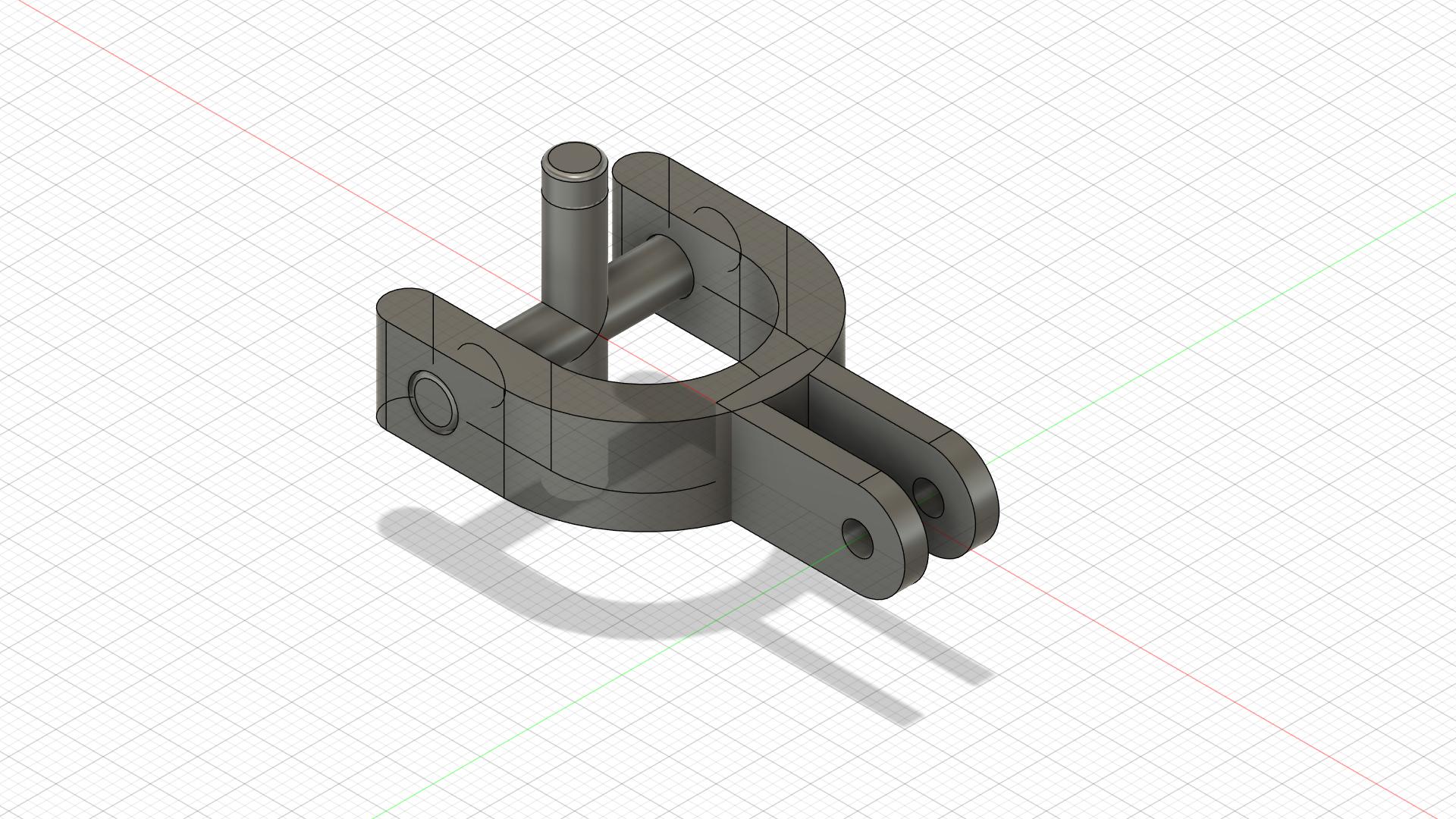

I then tried my hand and designing and 3D printing a joint based on the design of universal coupling/gimbal joints: