Brian's HTMAA Diary 2024

Week 09: Computer-Controlled Machining

Group Assignment

Individual Assignment

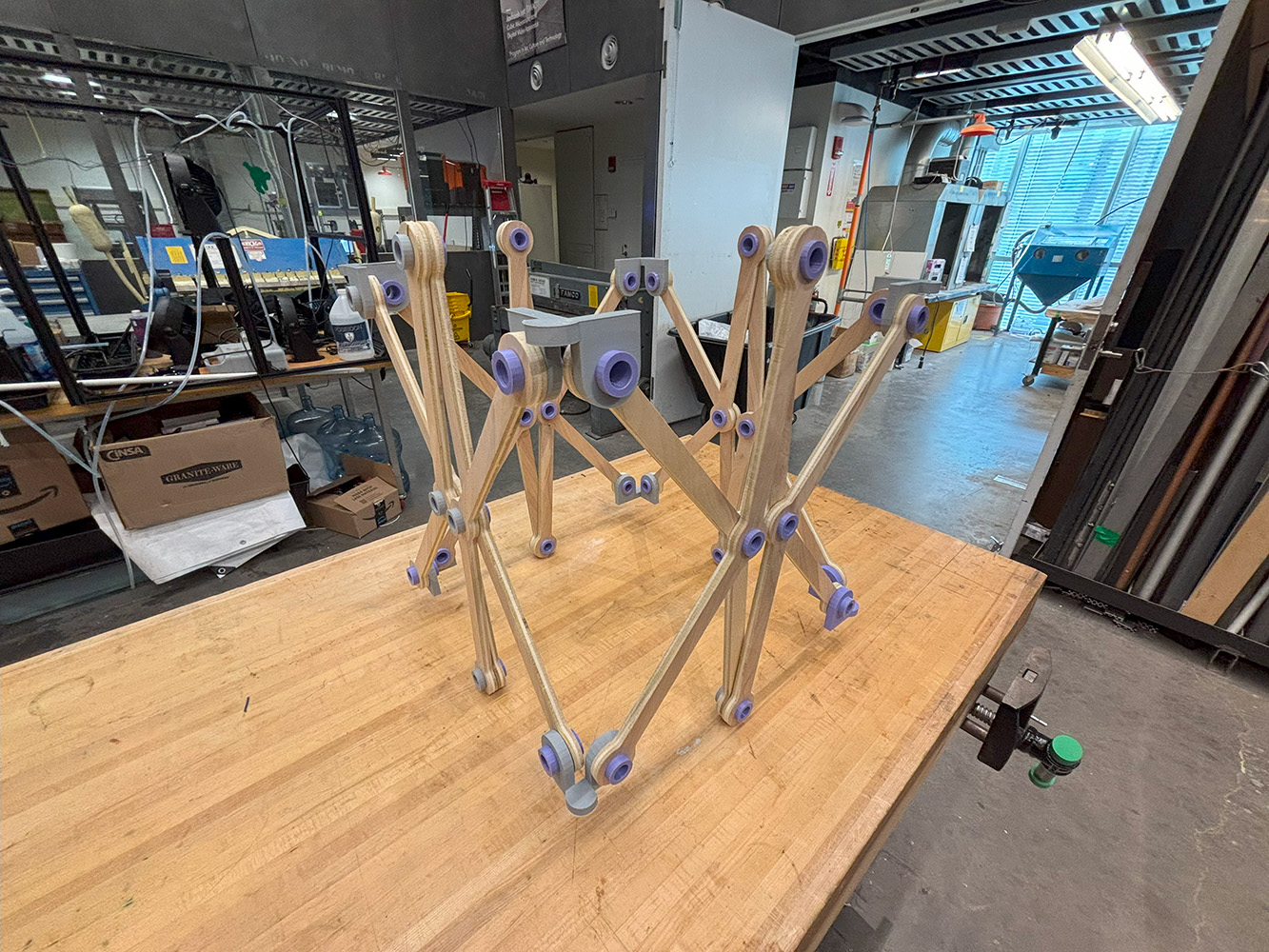

The individual assignment is to make something big, so I was thinking a lot about objects that could expand in space while still utilizing a limited amount of materials. I landed on the mechanics of the Hoberman sphere, which exapnds and contracts with the scissor-like action of there joints. I modeled up some joints and 3D printed them to test that they work before possibly ruining a piece of stock.

CNC milling started off with the downcut pass, but we found that it took to long: the estimated 8 minuted job ended up taking 40 minutes.

I ran into the first serious problem during the upcut pass, and a piece got stuck on the brush head. Although I did select the cuts from inside to outside in Fusion, I forgot to turn on the preserve order setting. The tabs were not strong enough to hold onto the piece I was milling.

I exported a new version where the preserve order setting was on, but another person had to use the Shopbot after me, so I lost the origin coordinates of my first job. Alfonso graciously helped me approximate the original coordinates, the wood pieces came out decent.

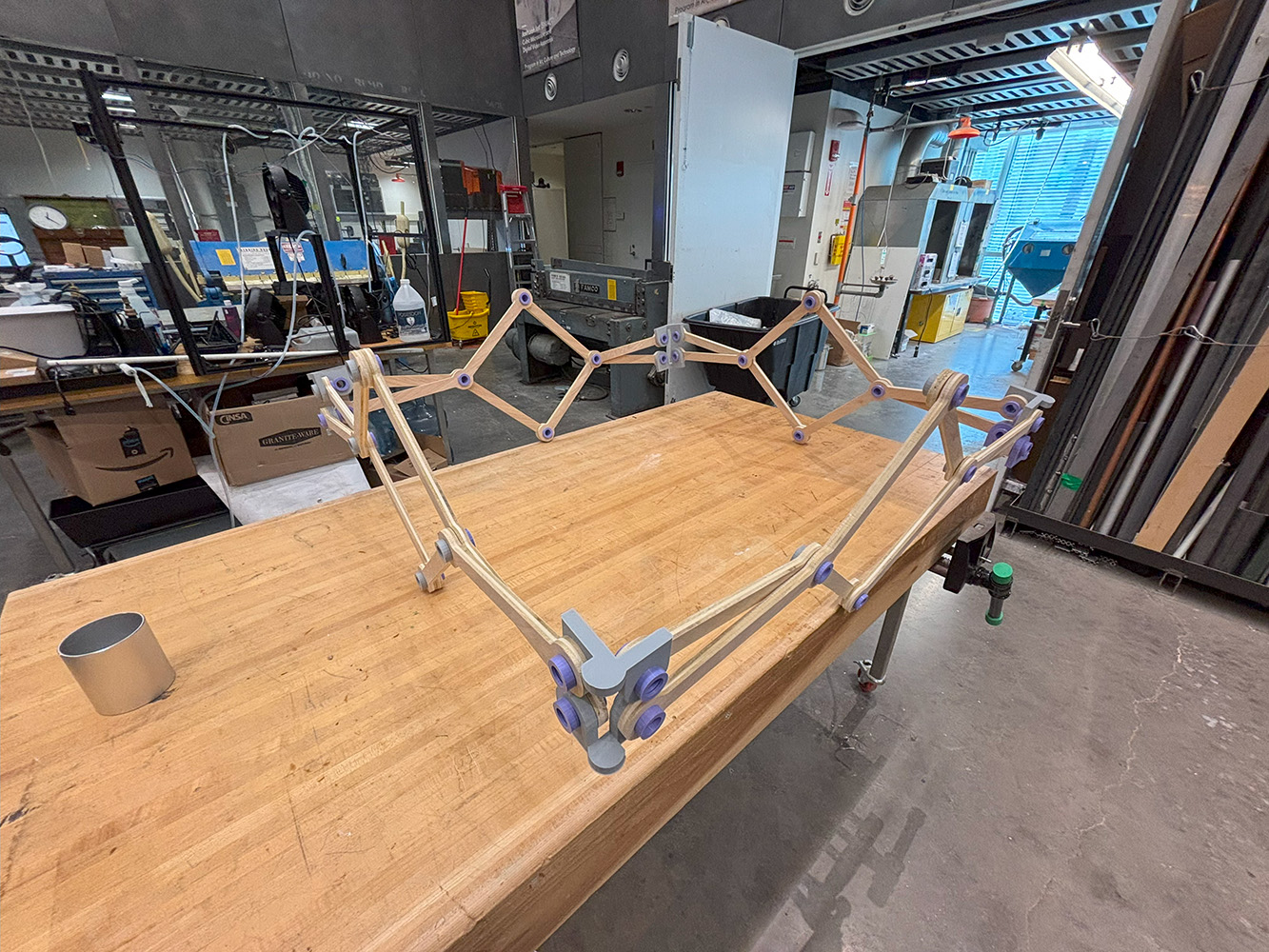

I then connected the pieces with 3D printed parts. Here is an image of the shape closed:

And one of it open: