week4

assignment - 3d print and 3d scan

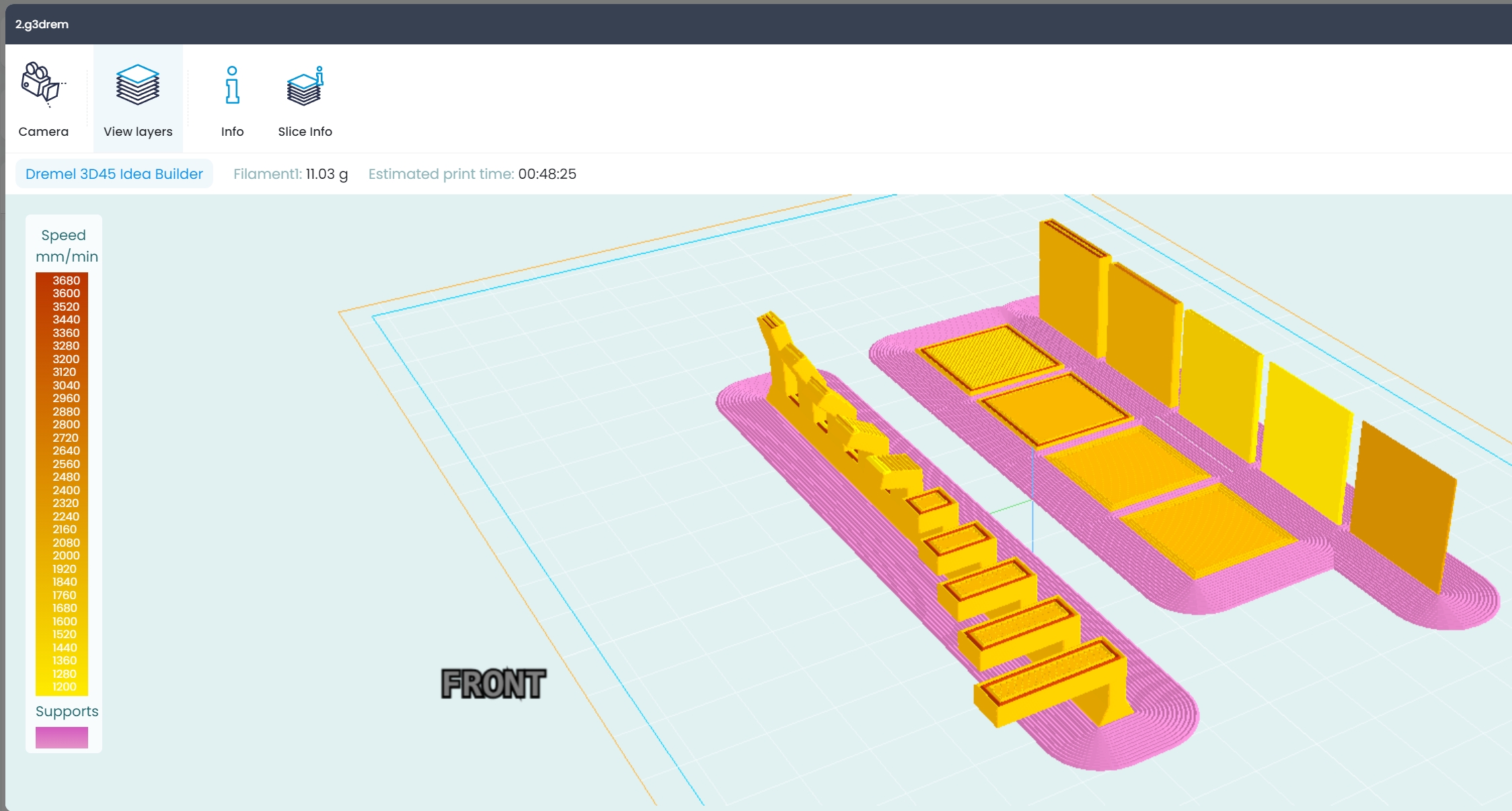

for the week4 project, i started by testing the print limits of the machine

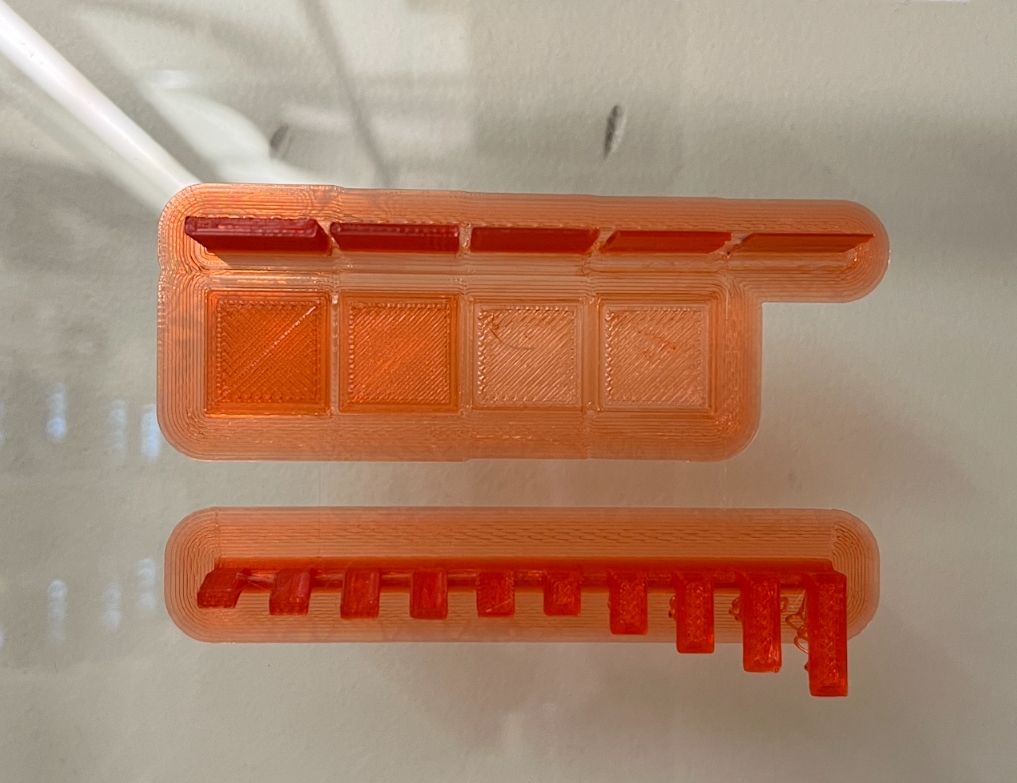

i tested three different factors:

1. wall thickness: i experimented with five different thicknesses: 3mm, 2mm, 1.5mm, 1mm, and 0.5mm

2. plate thickness: i tested four different thicknesses: 0.8mm, 0.4mm, 0.2mm, 0.1mm, and 0.05mm

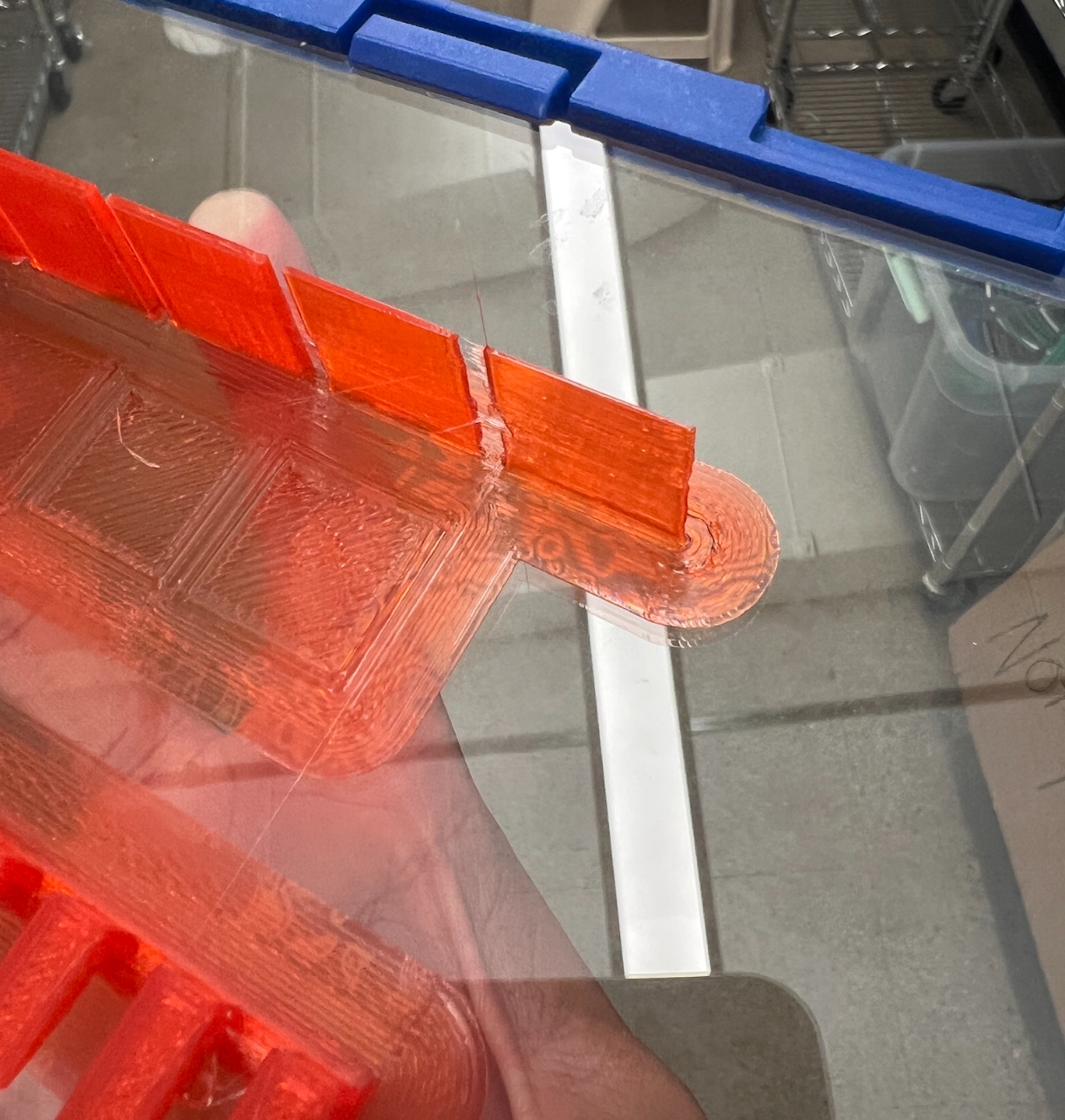

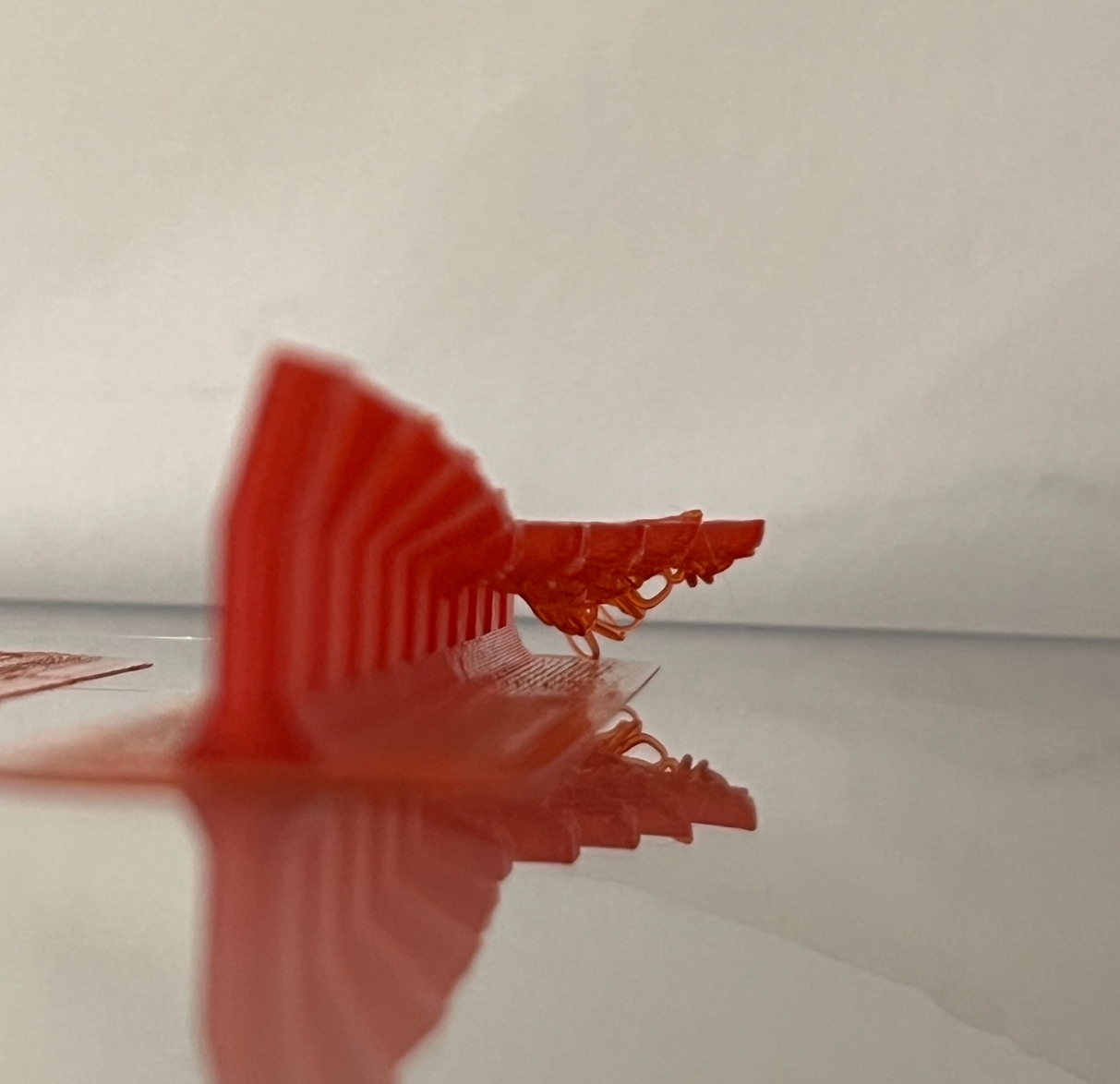

3. overhang without support: i bent a bar at various angles in 15-degree intervals up to 90 degrees and extended the overhang at 4mm, 7mm, 10mm, 13mm, and 16mm to see at what point the print would become unstable, where "spaghetti" started to show up

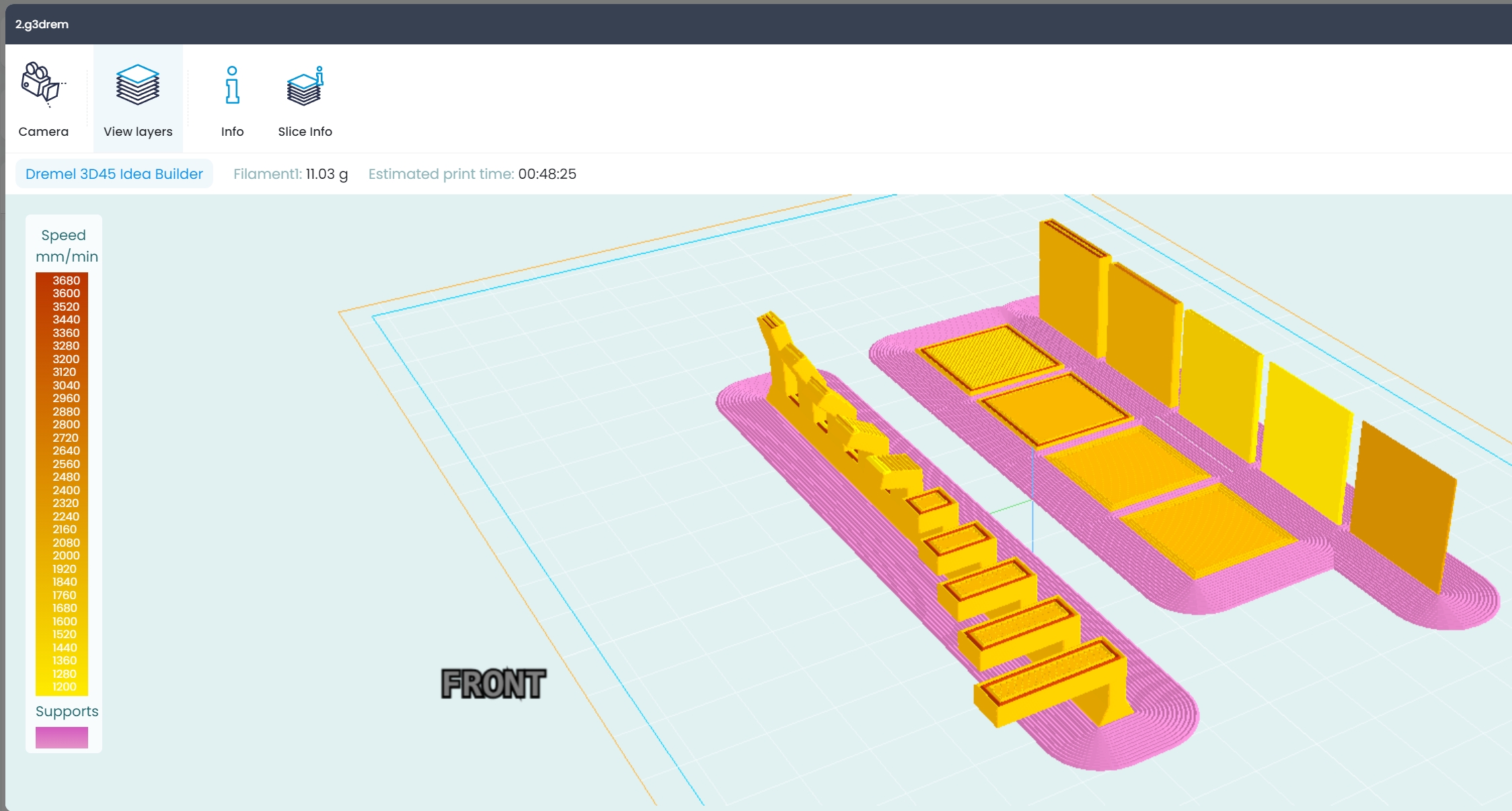

for the printer, i used Dremel 3D printer becasue it was available at the architecture school

i converted the rhino file into stl and imported into the 3D print system

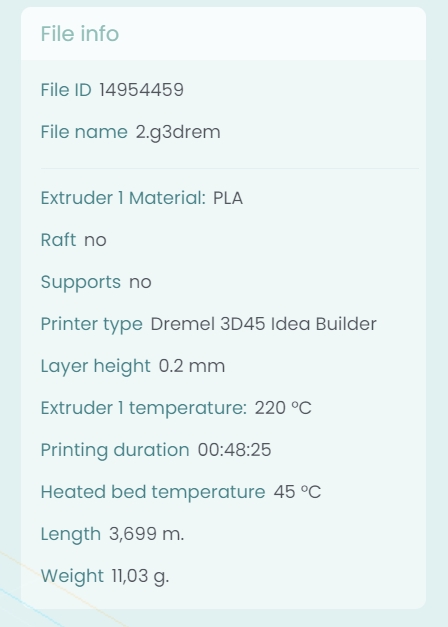

with a layer height of 0.2mm, it is estimated to use around 50 min

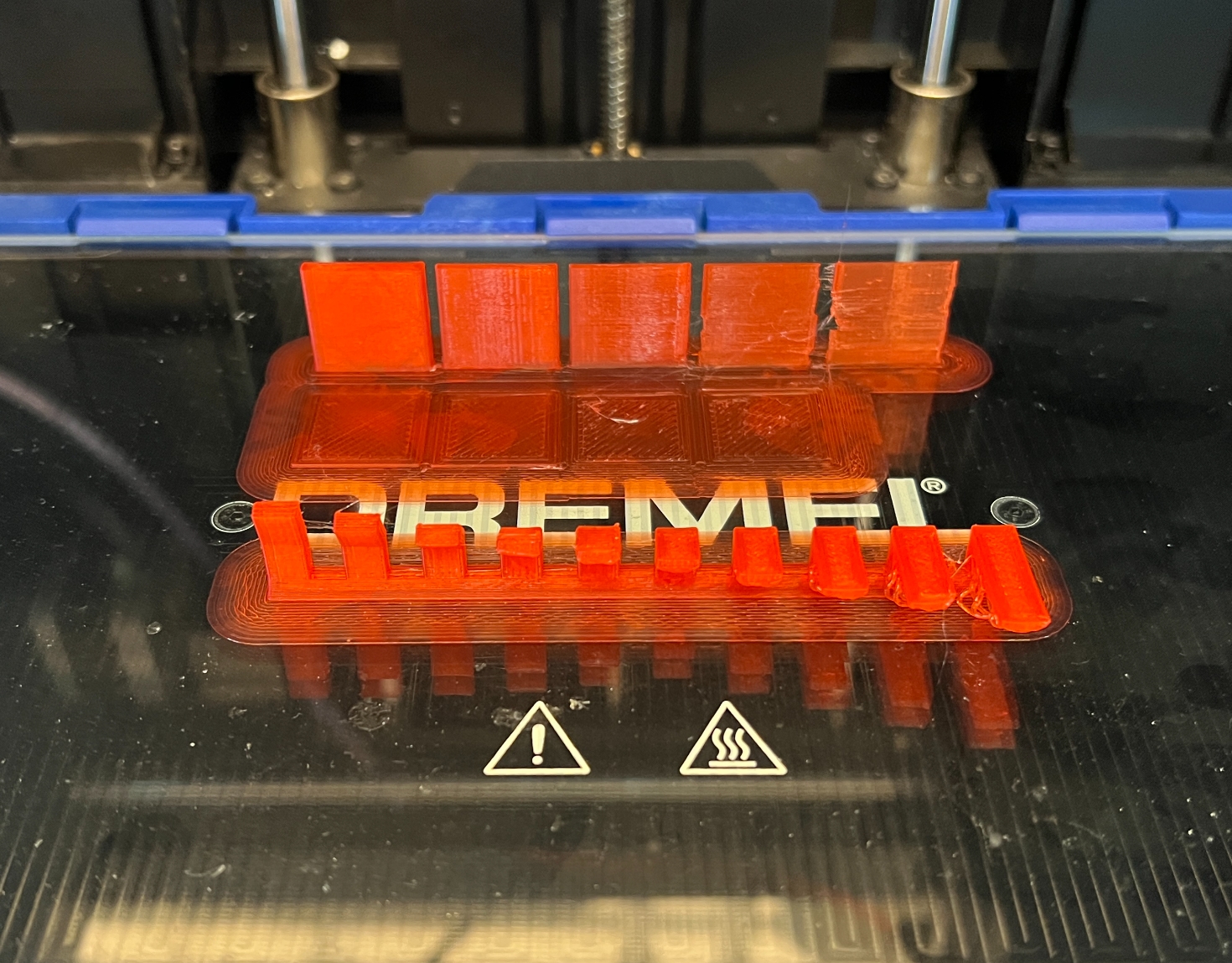

first five layers

fortunately, after 50 min, the print finished on time

what i learned about the machine

1. walls remain strong down to 1mm thickness, but they start getting weak at 0.5mm and break easily

2. all thicknesses can be printed, but anything thinner than the layer height (0.2mm) becomes impossible to remove from the support and cannot be printed accurately

3. the printer struggled with overhangs without support. chaos started at the first overhang (4mm), and by 17mm, the print became very unstable

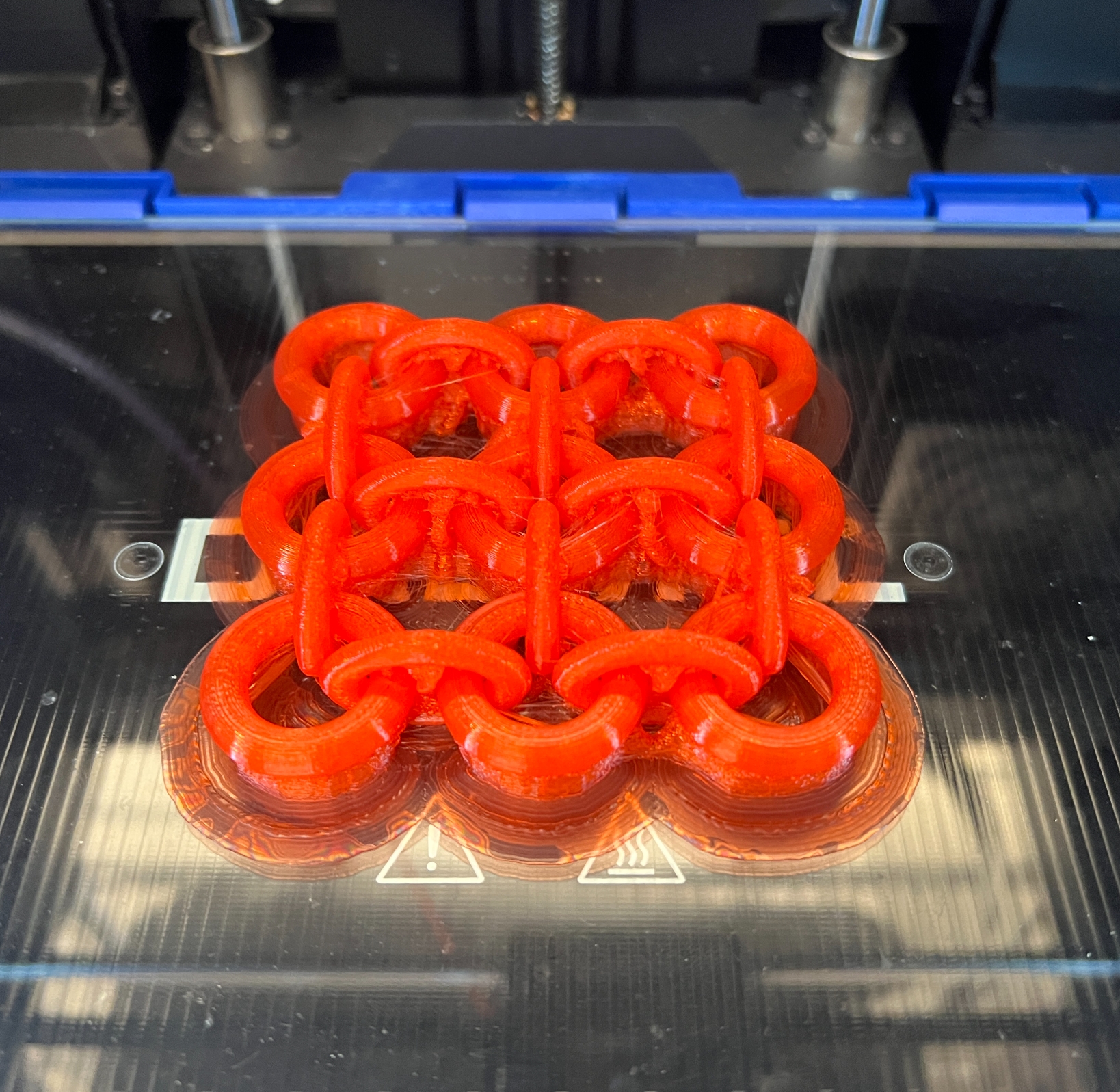

i designed a wire mesh in rhino

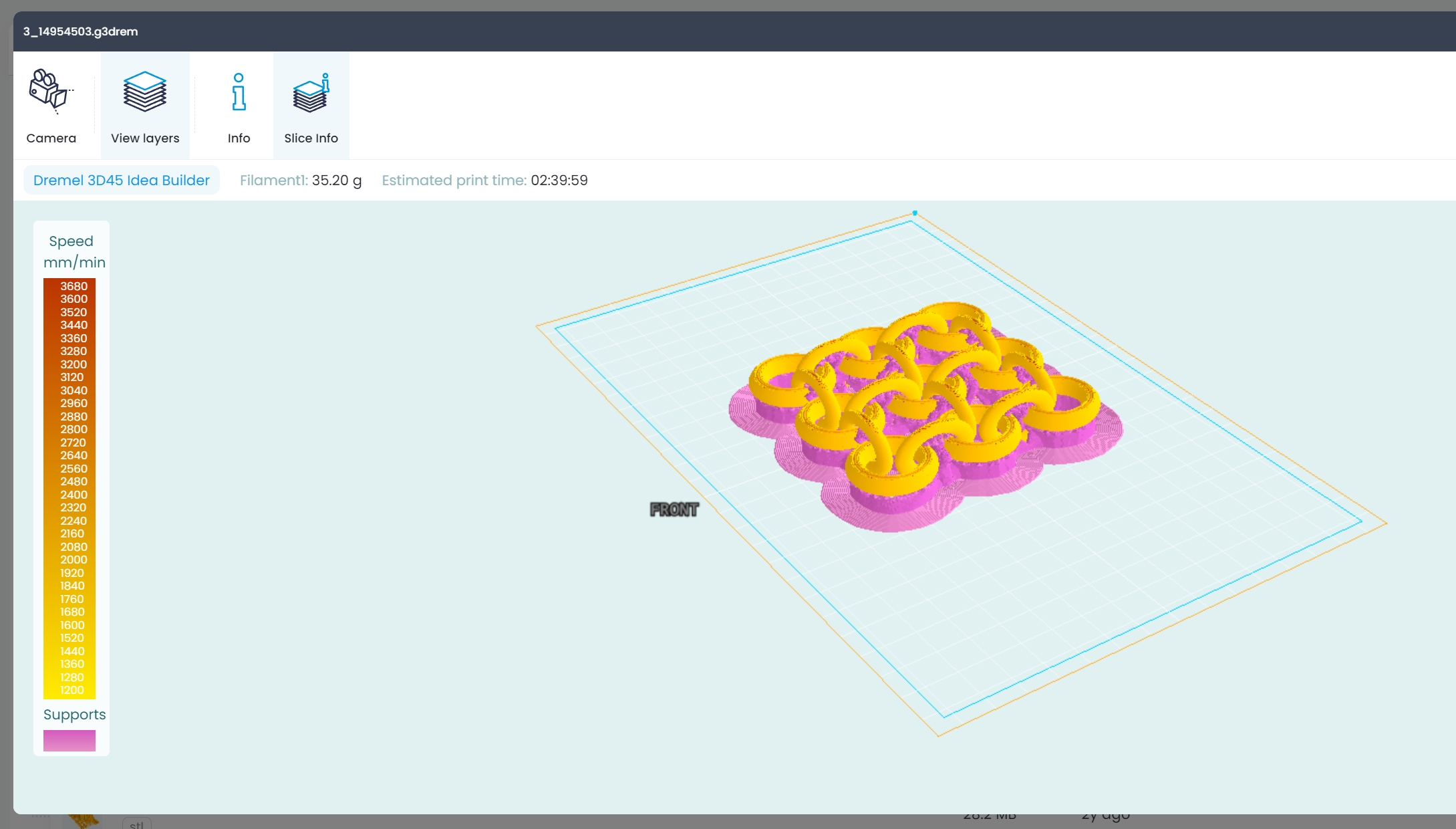

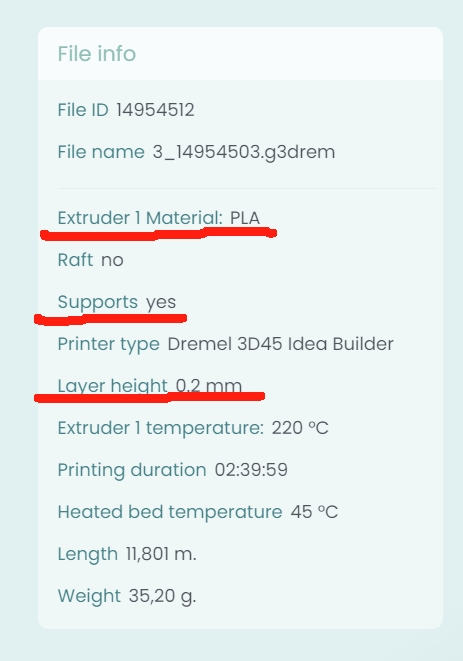

i used a setting that i found trustworthy from the test

i decided to use PLA with supports at a layer height of 0.2mm, it was estimated to take 2 hours 40 min

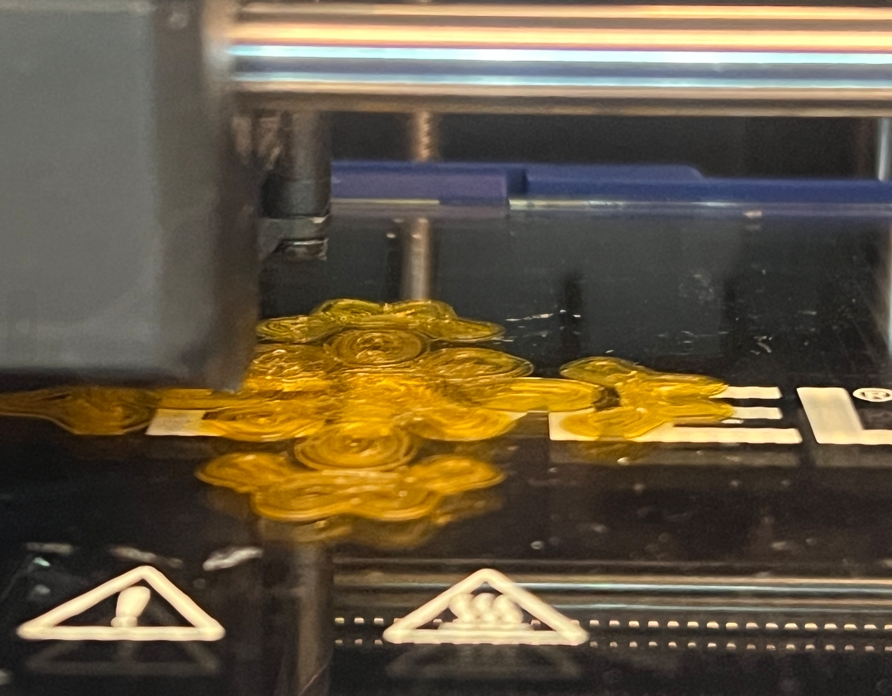

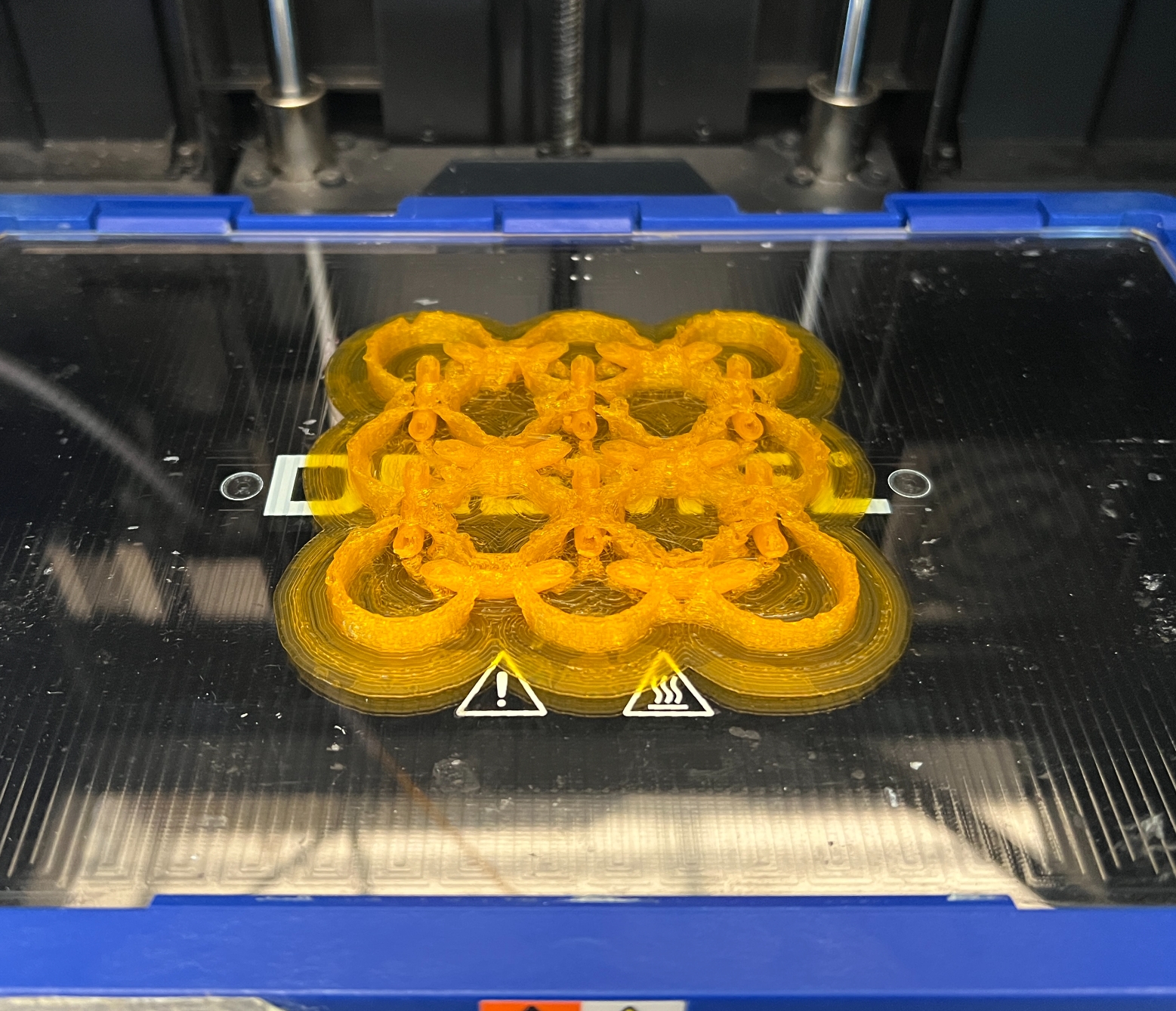

first layer

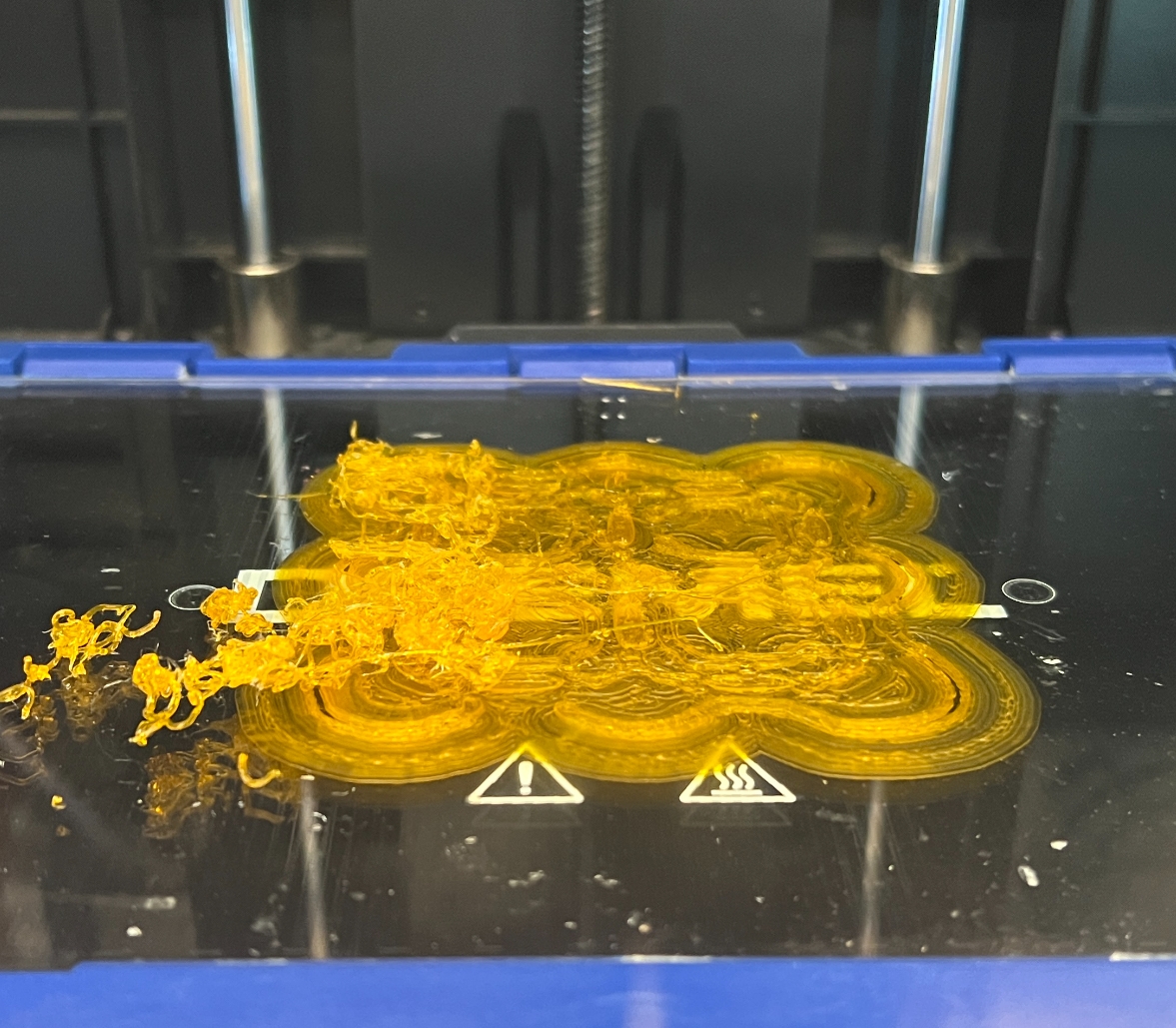

:( the print failed after 25 minutes because the filament got stuck. The printer continued moving, but no filament was being extruded

a second attempt failed, I switched to a different machine and filament

i switched a machine and also switched the filament

3 hours later

what i learned:

1. failure rate - the failure rate was about 50%. Out of four attempts, only two were successful

2. give yourself more time - 3D printing is not 100% reliable. you need to check on the print regularly to ensure it's progressing correctly

3. layer height - it becomes complicated and risky when the model's thickness approaches the print layer height

4. overhang - overhangs without supports are tricky, so it’s best to avoid them if possible

3d scan

i experimented with 3D scanning by using the iOS app scaniverse to scan myself and my friends

what i learned:

1. steadiness - the quality of the scan highly depends on the steadiness of your hands, making it difficult to achieve a good scan

2. detail - while the app can capture small texture details, it struggles to capture fine geometric details