week7

assignment - mold and cast

design a mold and make a cast

i wanted to make a sake cup, and the design went through multiple rounds of changes due to practical challenges.

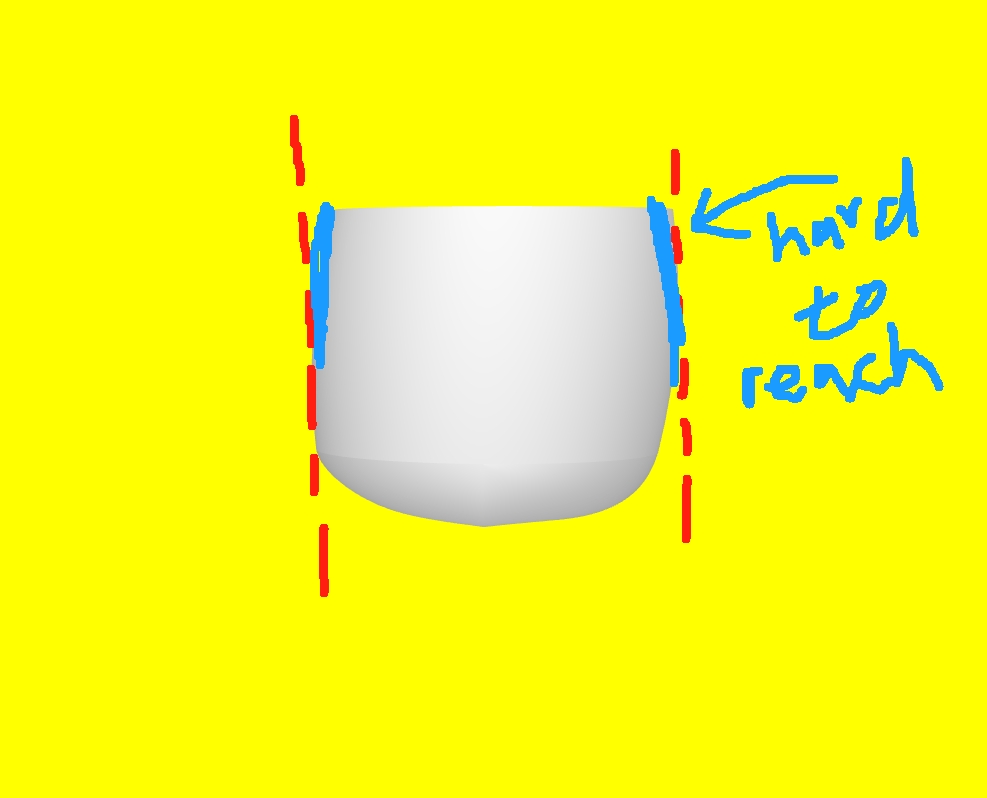

initially, i aimed to retain a handmade quality by giving the cup an irregular shape.

however, as i began designing the mold, i realized it was impossible for the Roland SRM-20 machine, which is the only option at the REEF maker space to mill the wax, because the bit couldn't reach certain areas. So, I modified the shape to make it more regular.

however, when i was at the shop with Leo (a big shoutout), he explained the size constraints of the bit, which can hardly go deeper than 1 inch.

as a result, the cup had to become smaller again.

a big lesson from this experience is that many products we see today are the result of compromises due to manufacturing processes, transportation limits, equipment constraints, and more. in the end, the cup took on this final shape.

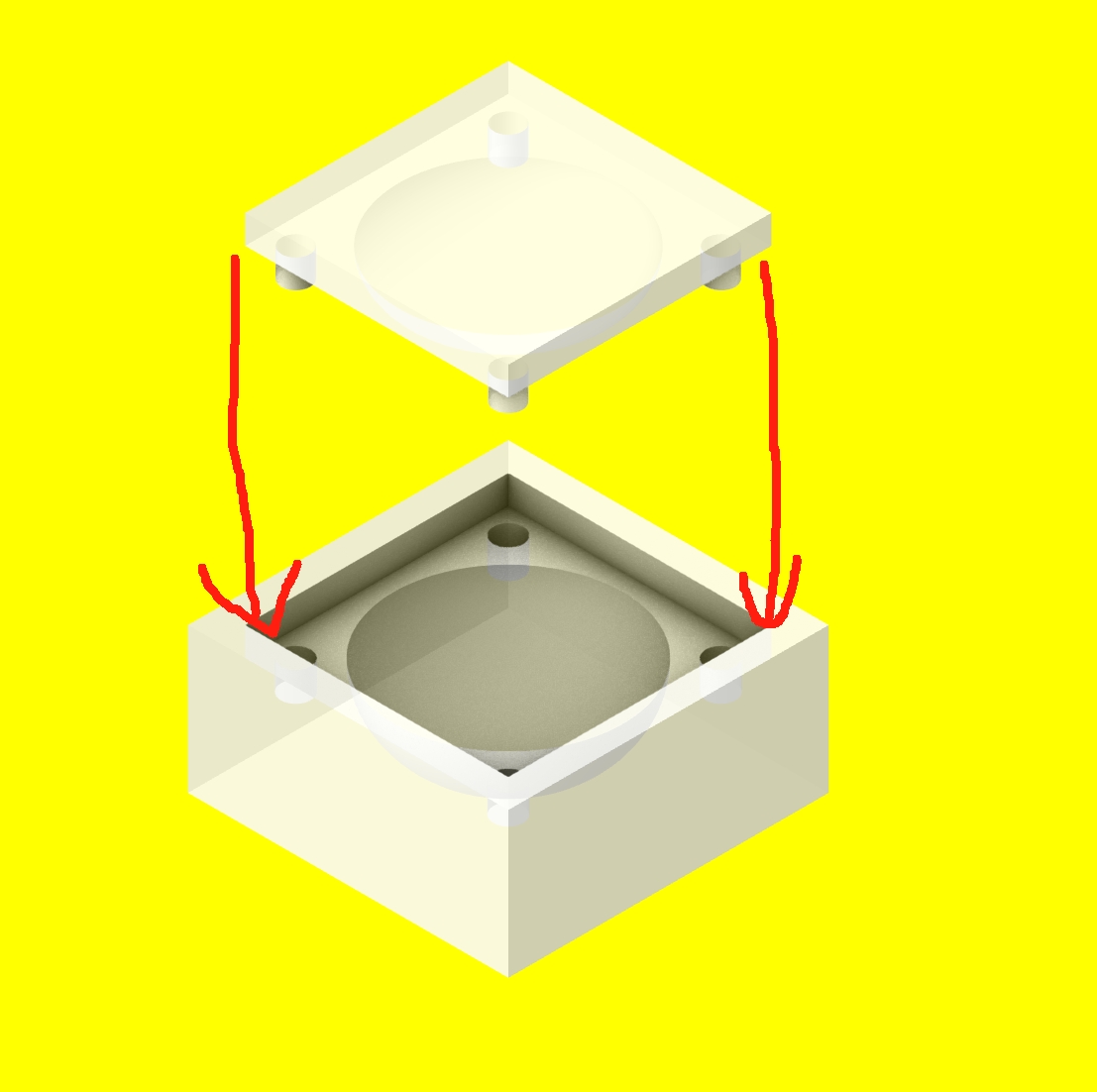

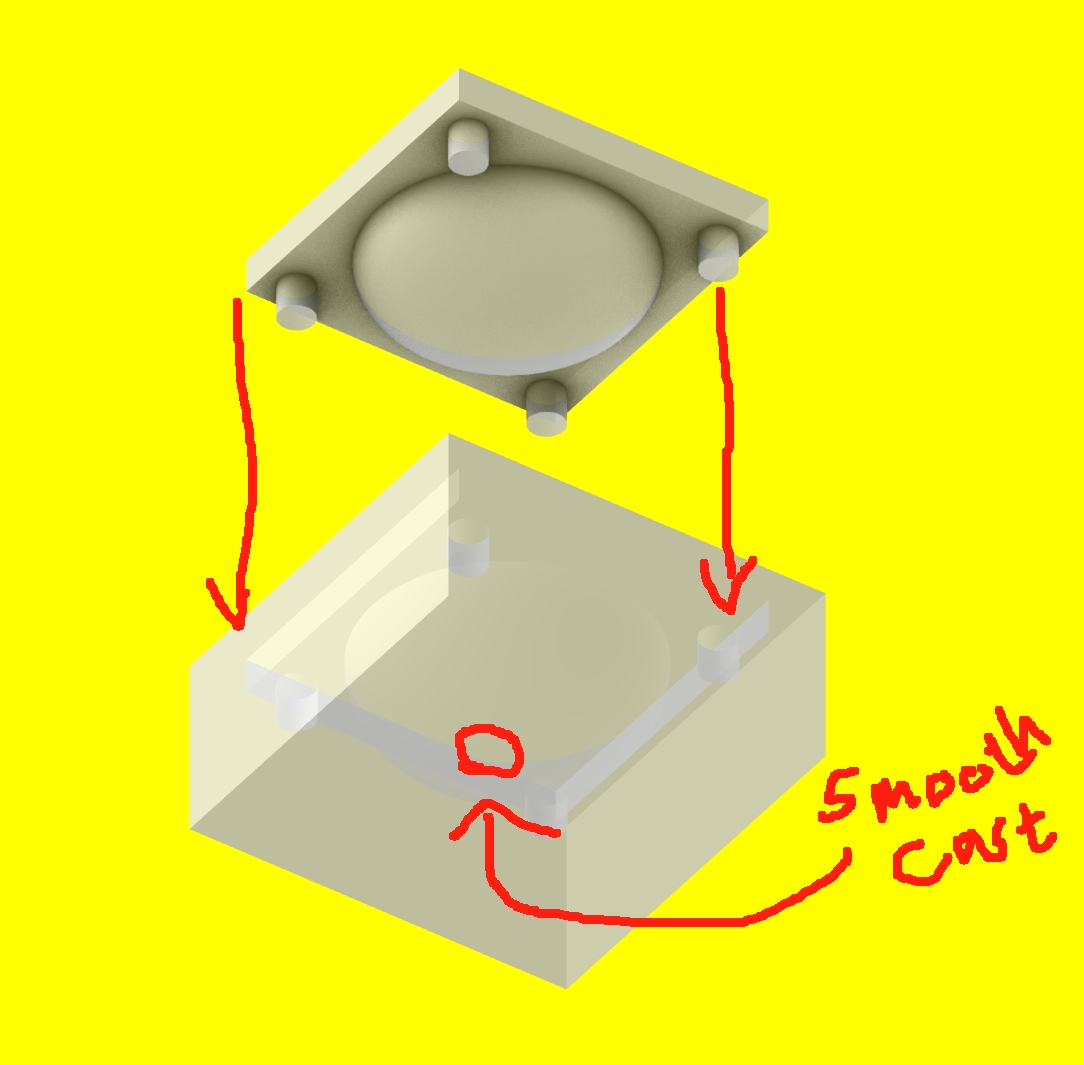

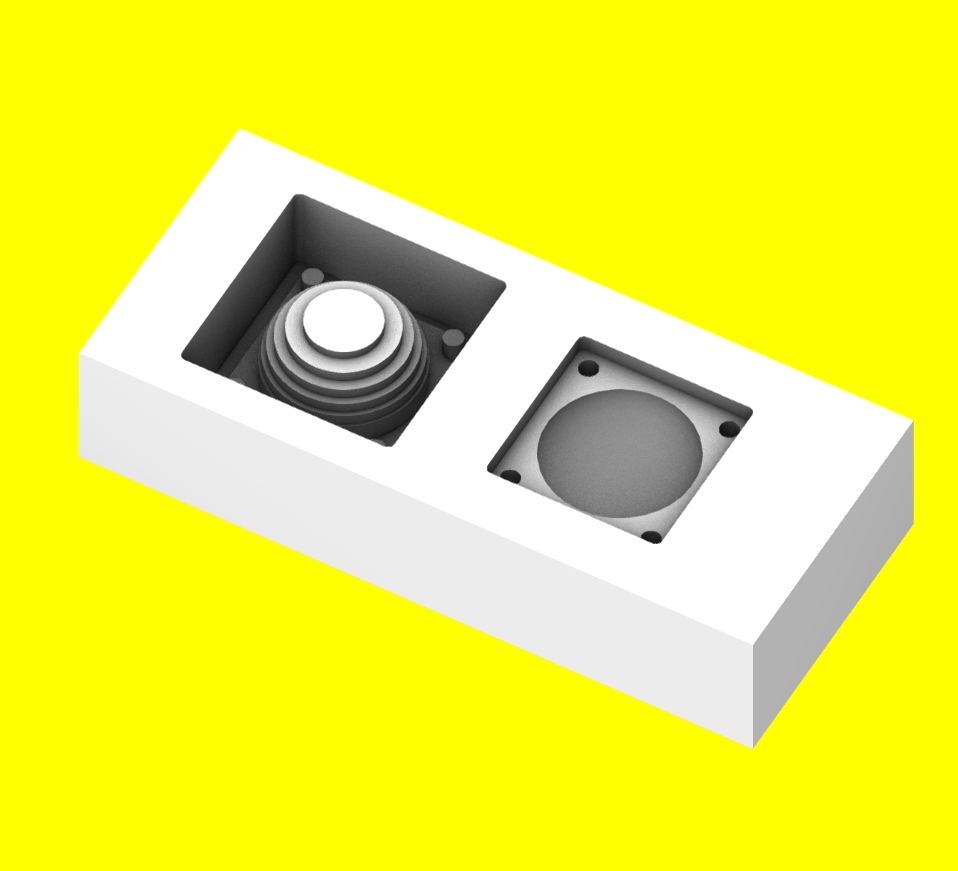

i designed a two-part mold for casting: the top part plunges into the bottom, and a hole in the bottom allows me to inject Smooth-Cast for the final cup.

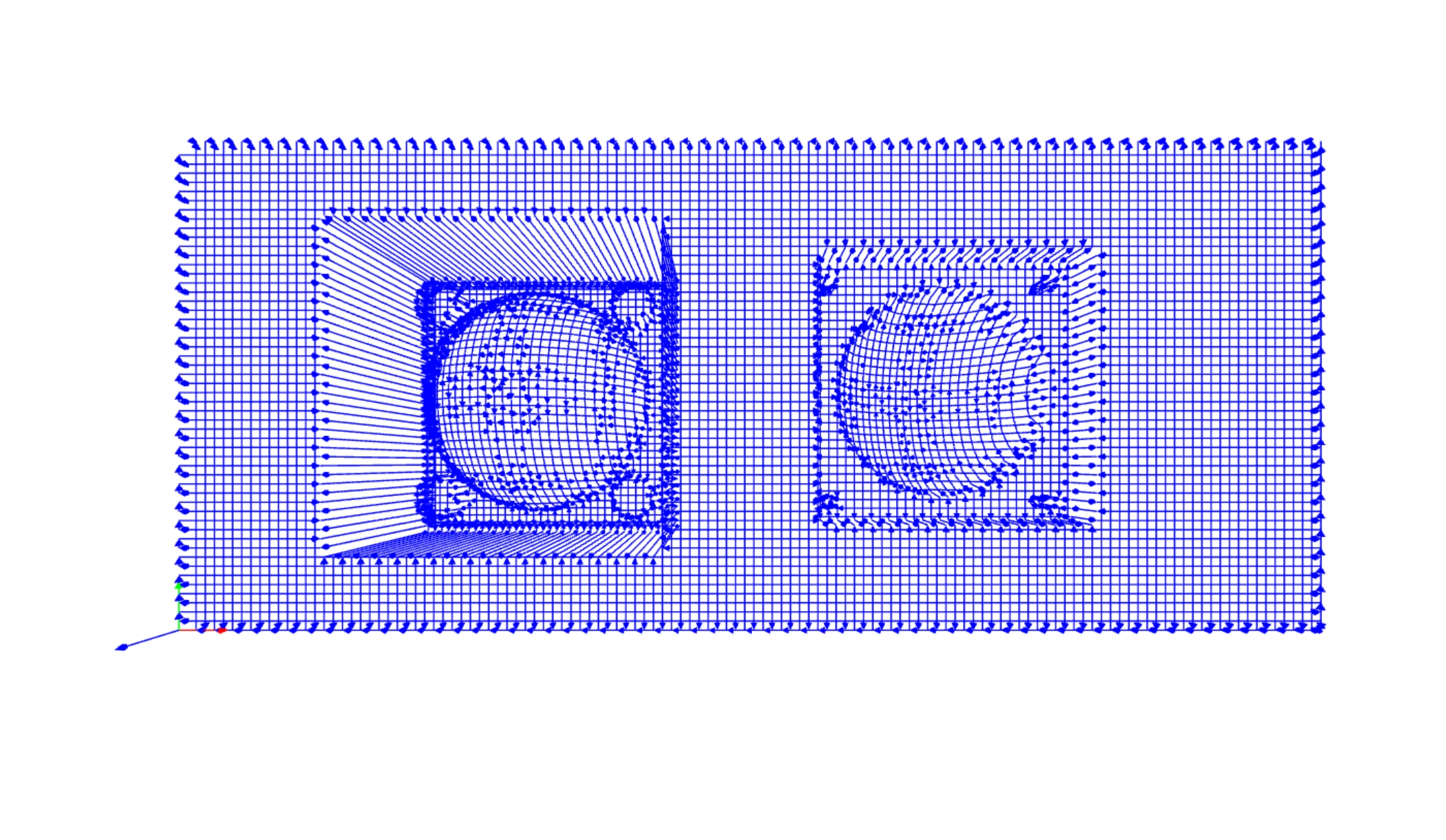

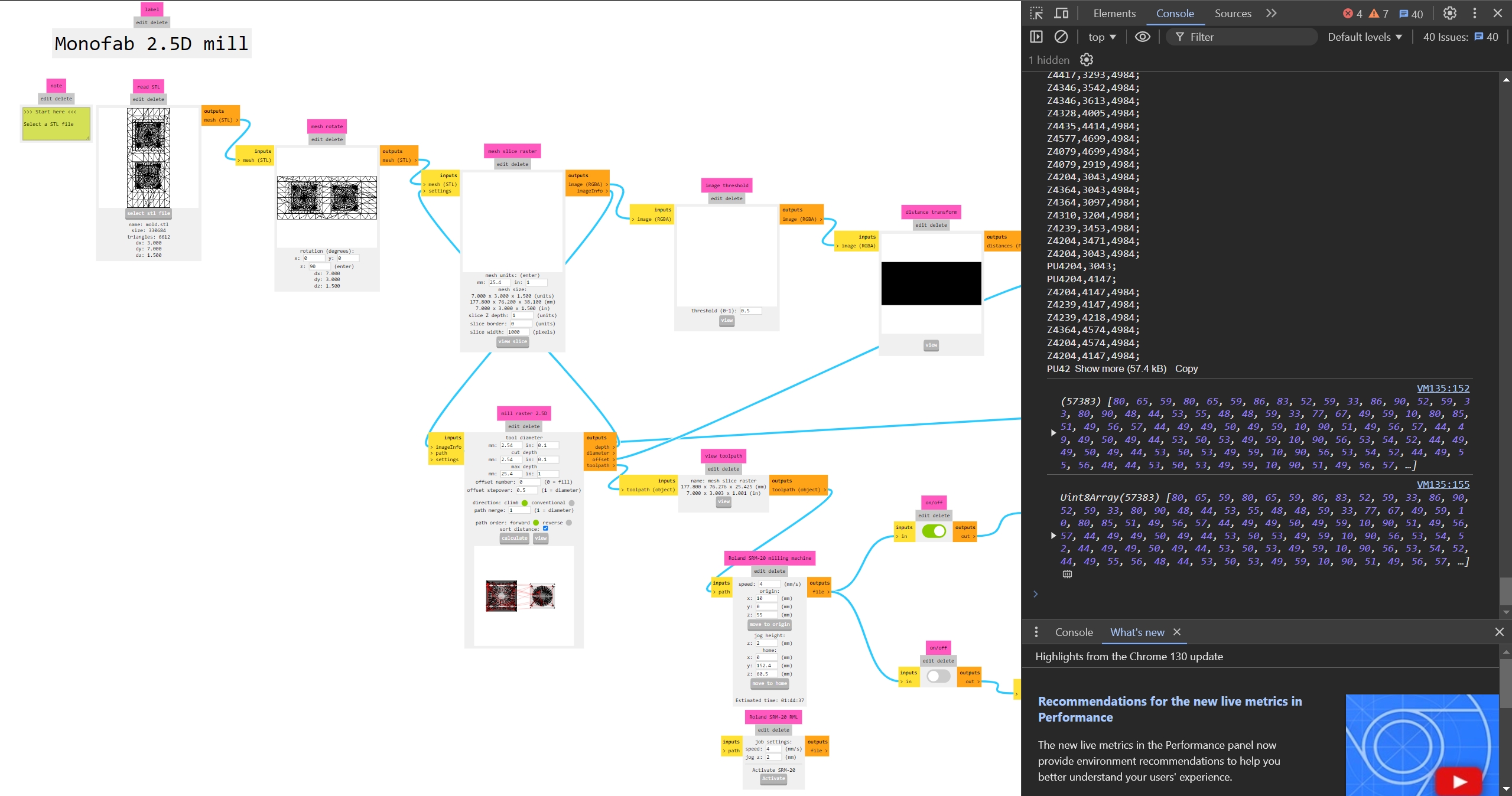

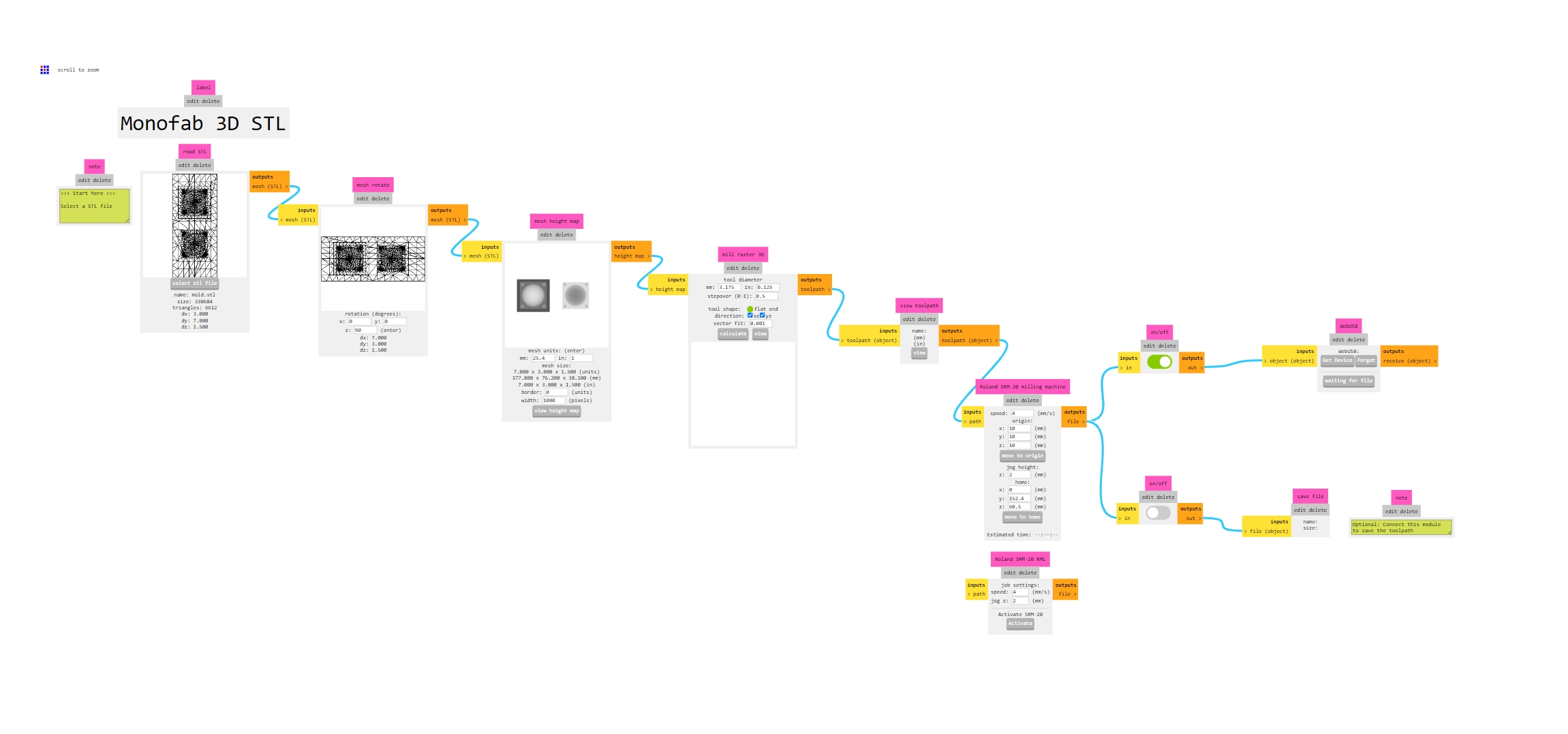

after finalizing the mold design, I followed Leo's MOD CE instructions and sent the STL file to generate the job.

there was a bug where Windows computers couldn’t communicate with the Roland machine, but Leo helped me fix it.

the roughing process took 1 hour, and the finishing was expected to take 2 hours.

unfortunately, halfway through the finishing, the machine stopped unexpectedly, and i had to rerun the job :(

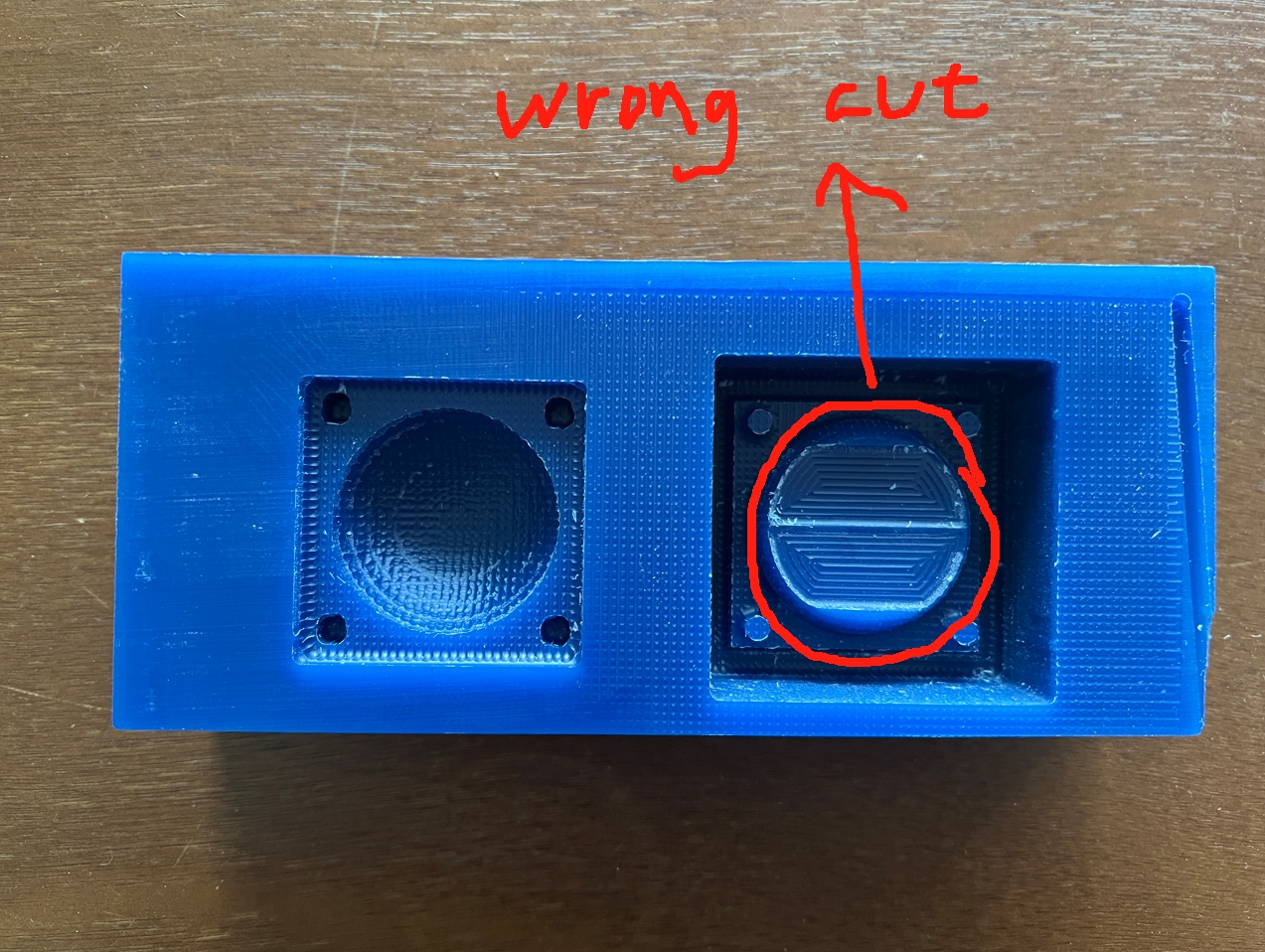

after 4 hours, the mill was done, however i noticed some mistake cuts

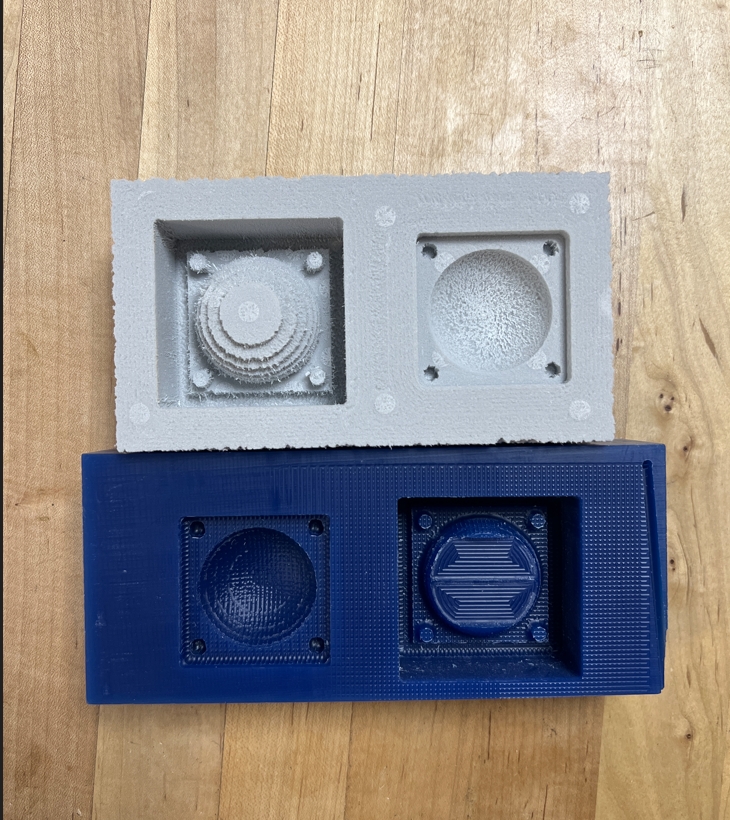

that was frustrating :( i decided to mill a new mold, changing the design this time. the outside of the cup now has a staggered section to enhance the layered machining effect

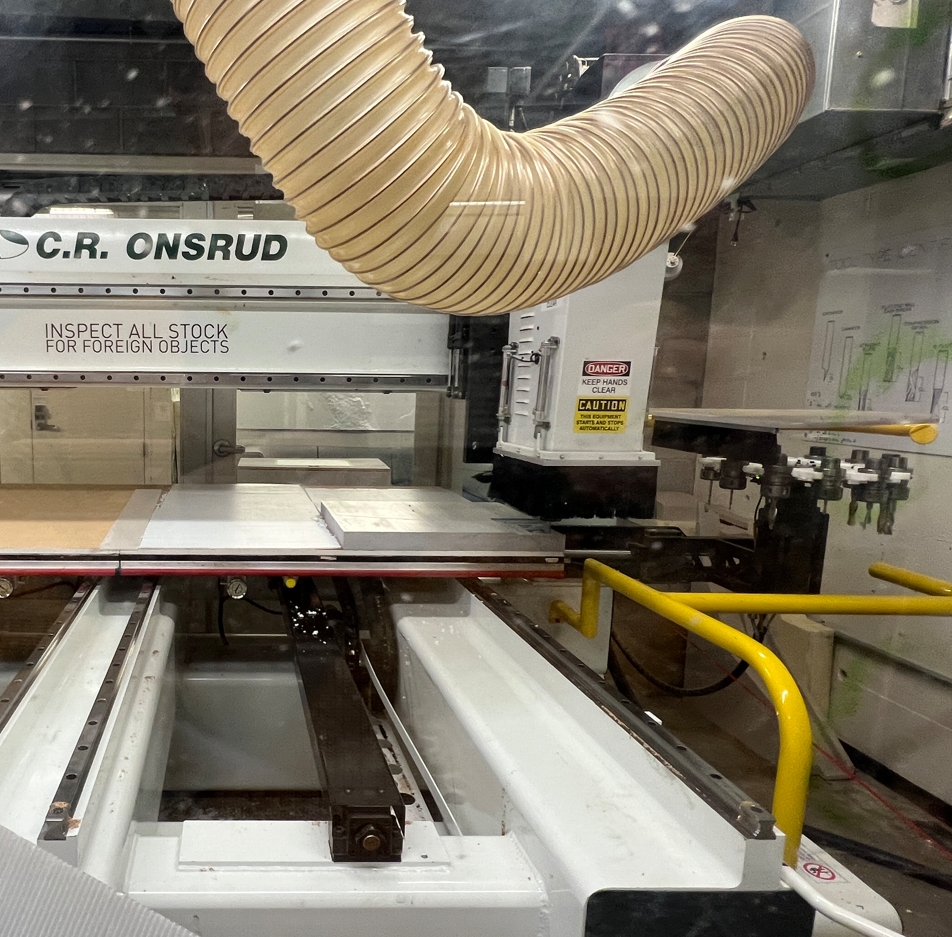

this time i chose the bigger CNC machine at GSD and with Rigid Polyurethane Foam to save time. The entire milling took 15 minutes.

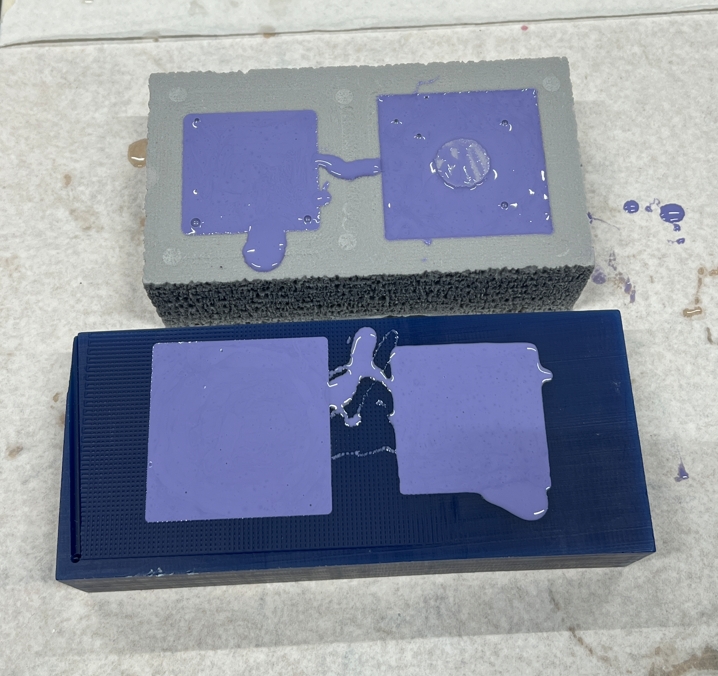

with help from Jeff (REEF Maker space staff), i poured oomoo into it

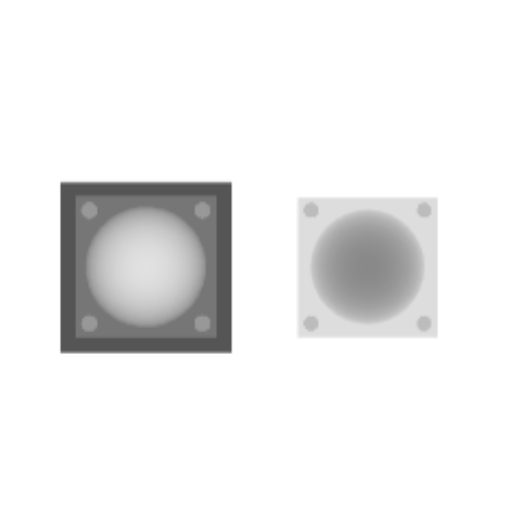

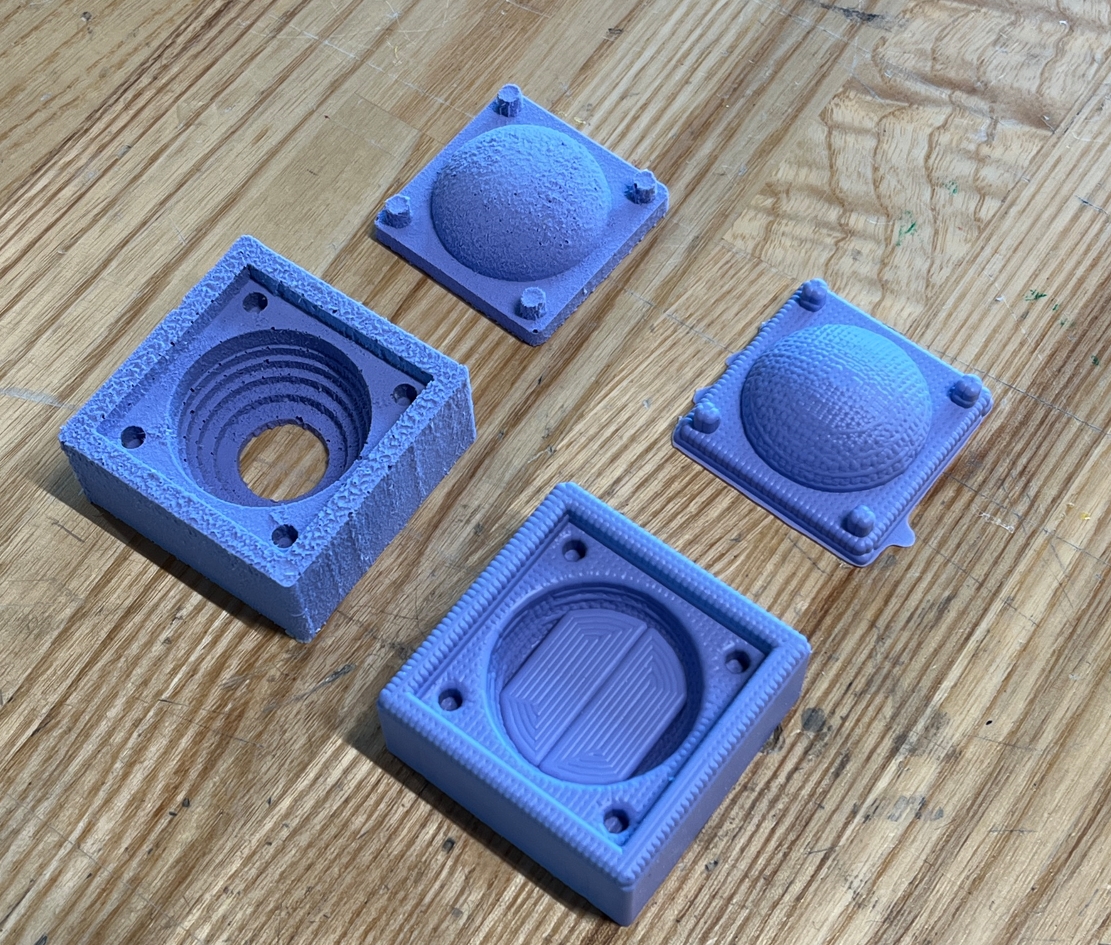

i let it cure overnight. the results are very interesting, the one from Roland machine with wax looks drastically different from the one from CNC with Polyurethane Foam

i casted with concrete, i always want to drink sake with concrete