week6

assignment - electronics production

make and test a microcontroller development board that you designed

following last week's assignment, i tried to produce my very first PCB board

i went to Lingdong's office hour at REEF on Saturday, and i also met Bobby there. he is working on a cool digital puzzle!

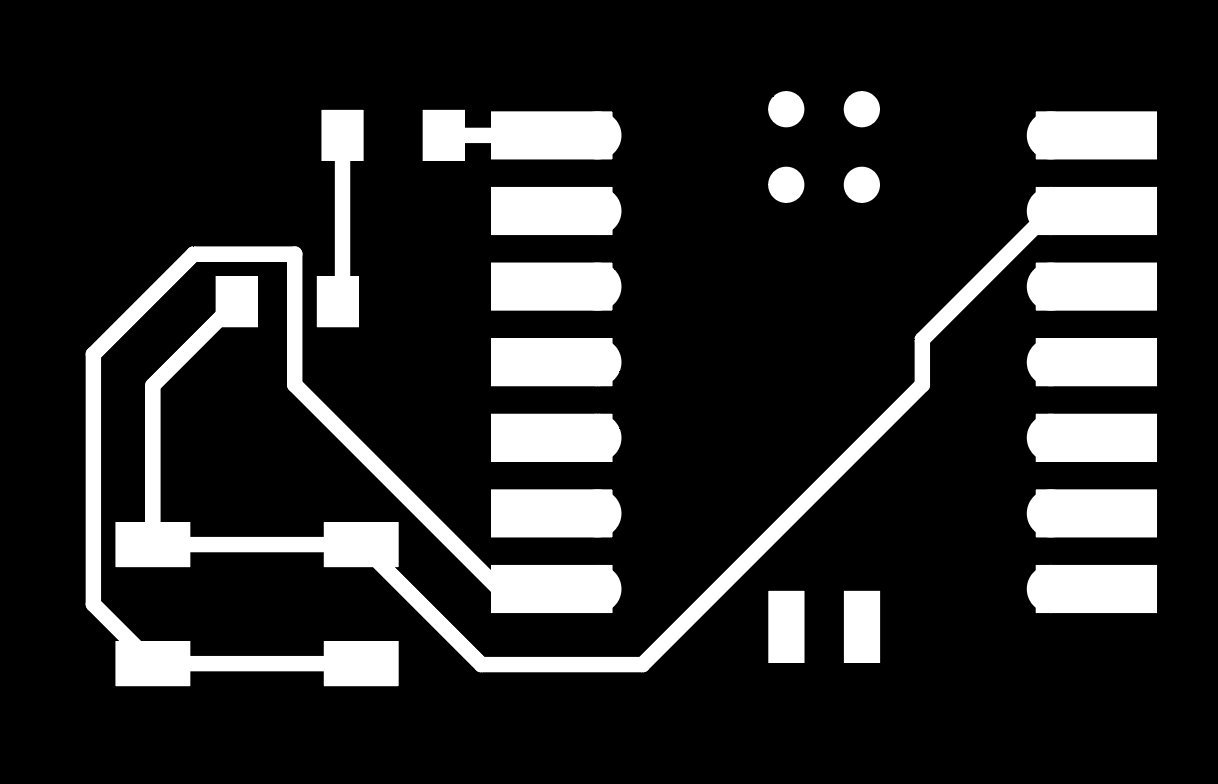

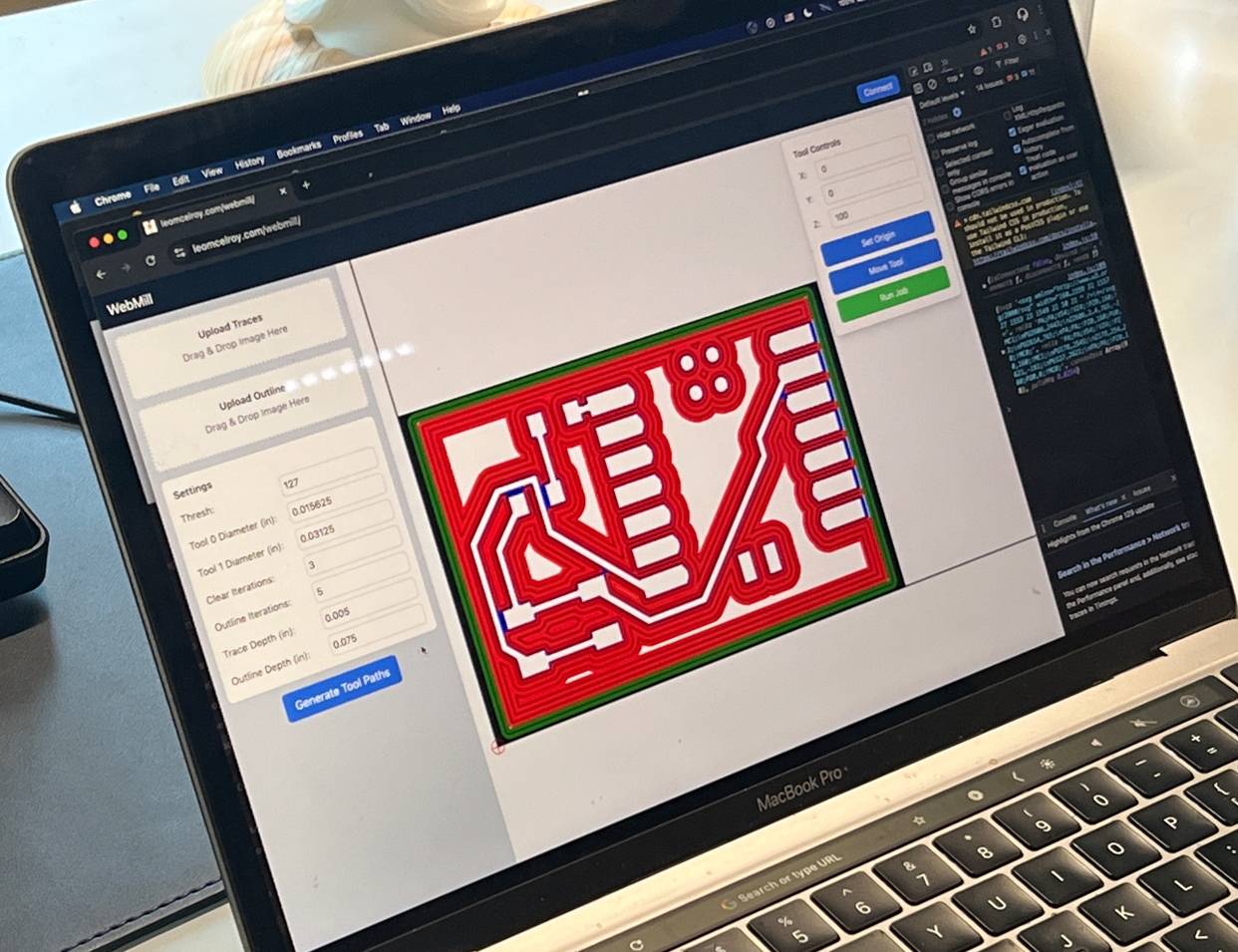

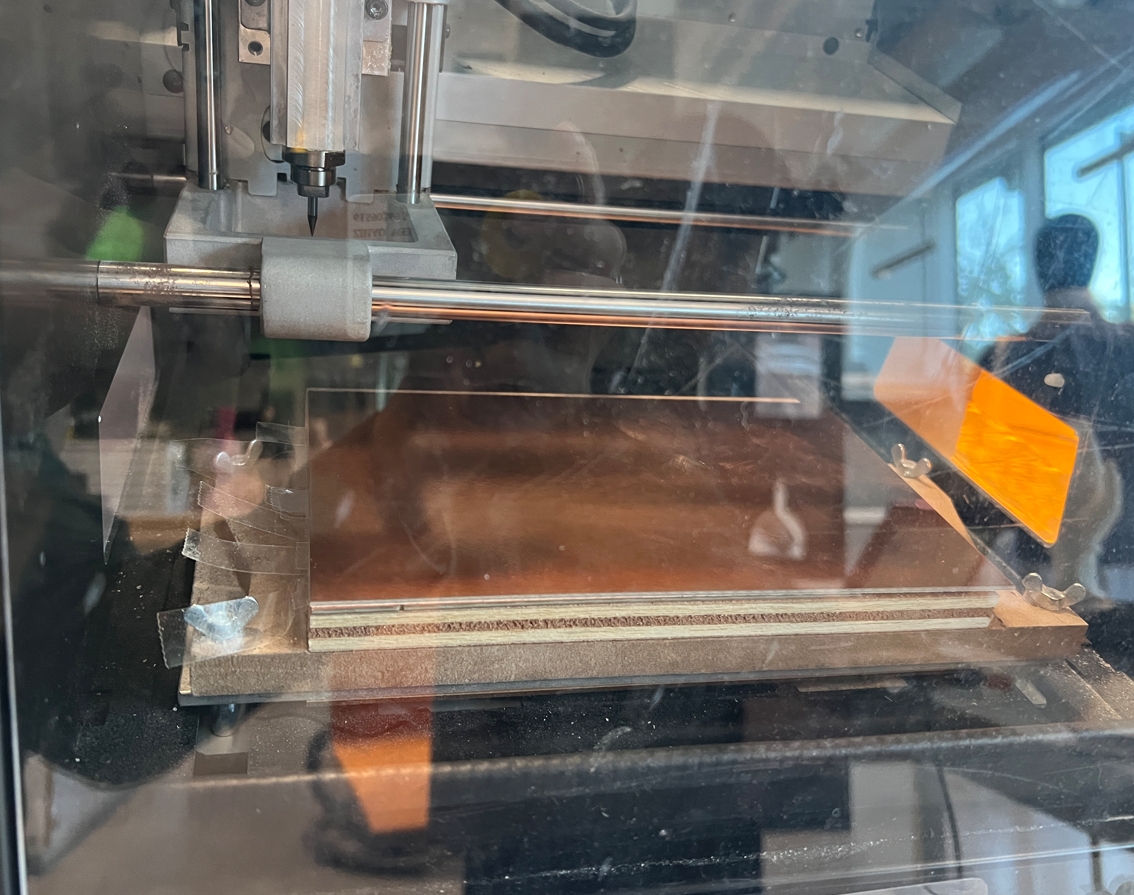

i gave my exported SVG files to Lingdong, and he used a software that he and Leo apparently just wrote last week to prepare the routing process

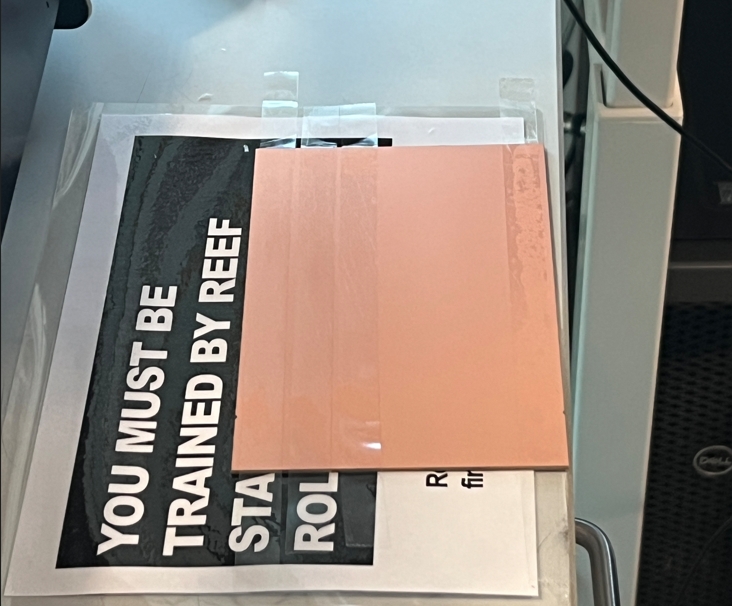

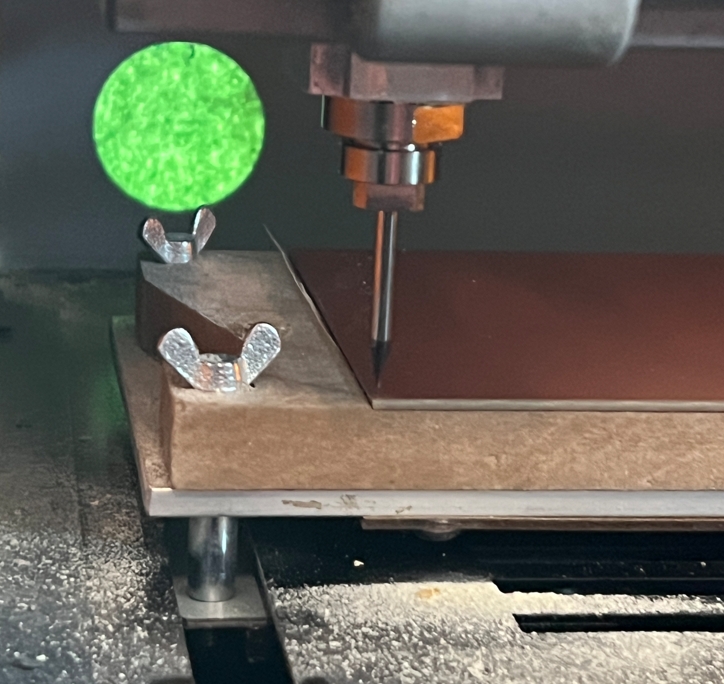

the machine uses a 1/64" tool. one thing that was quite interesting is that despite all the high-tech happening within the machine, we used common techniques like double-sided adhesive to adhere the board to the base board.

however, just before we were about to start cutting, we found the tool couldn't reach as low as we had hoped.

we searched around the maker space and found a piece of 1/2" plywood that came in handy, hoping it was flat. we placed it underneath, and it seemed to work fine.

here we go — cutting!

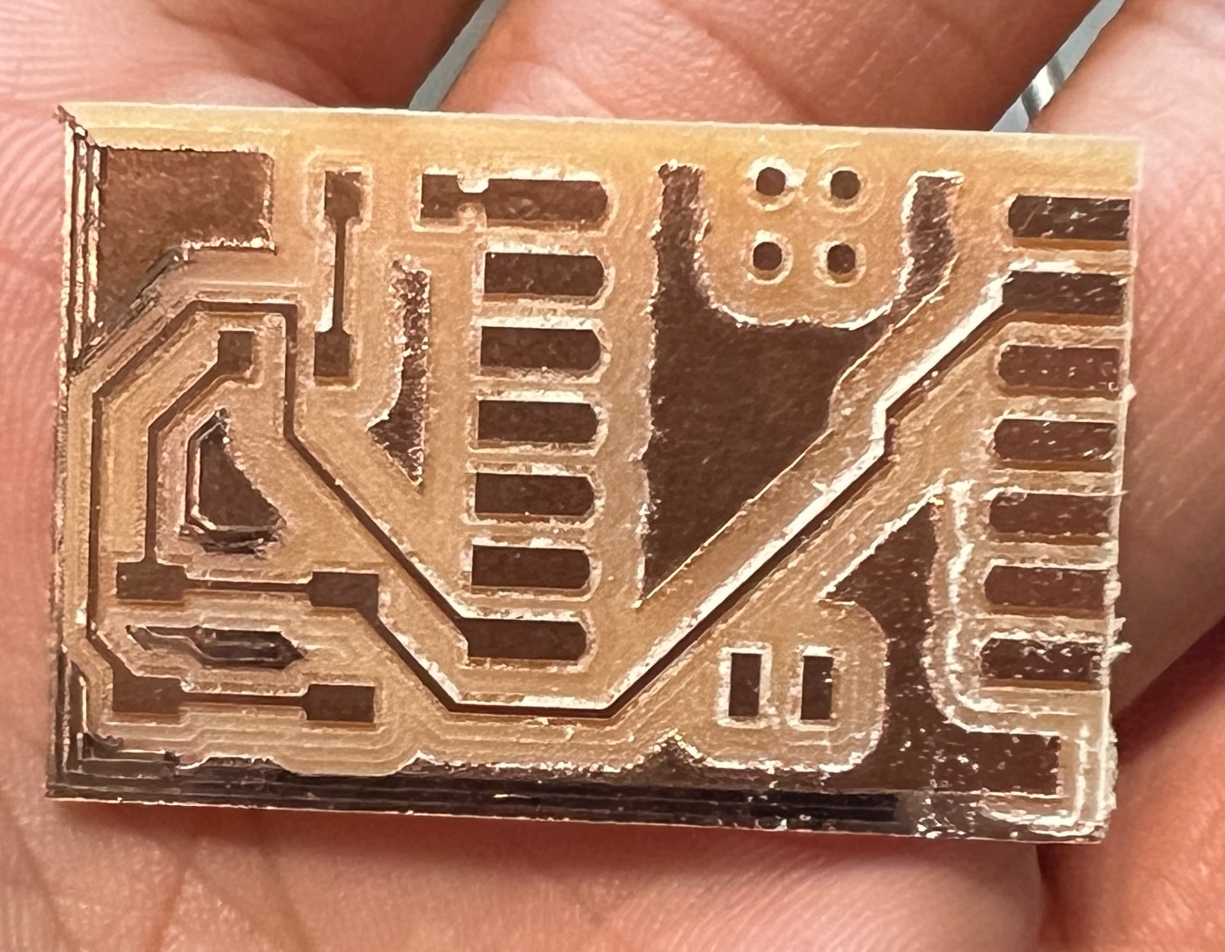

reveal

my first PCB board!

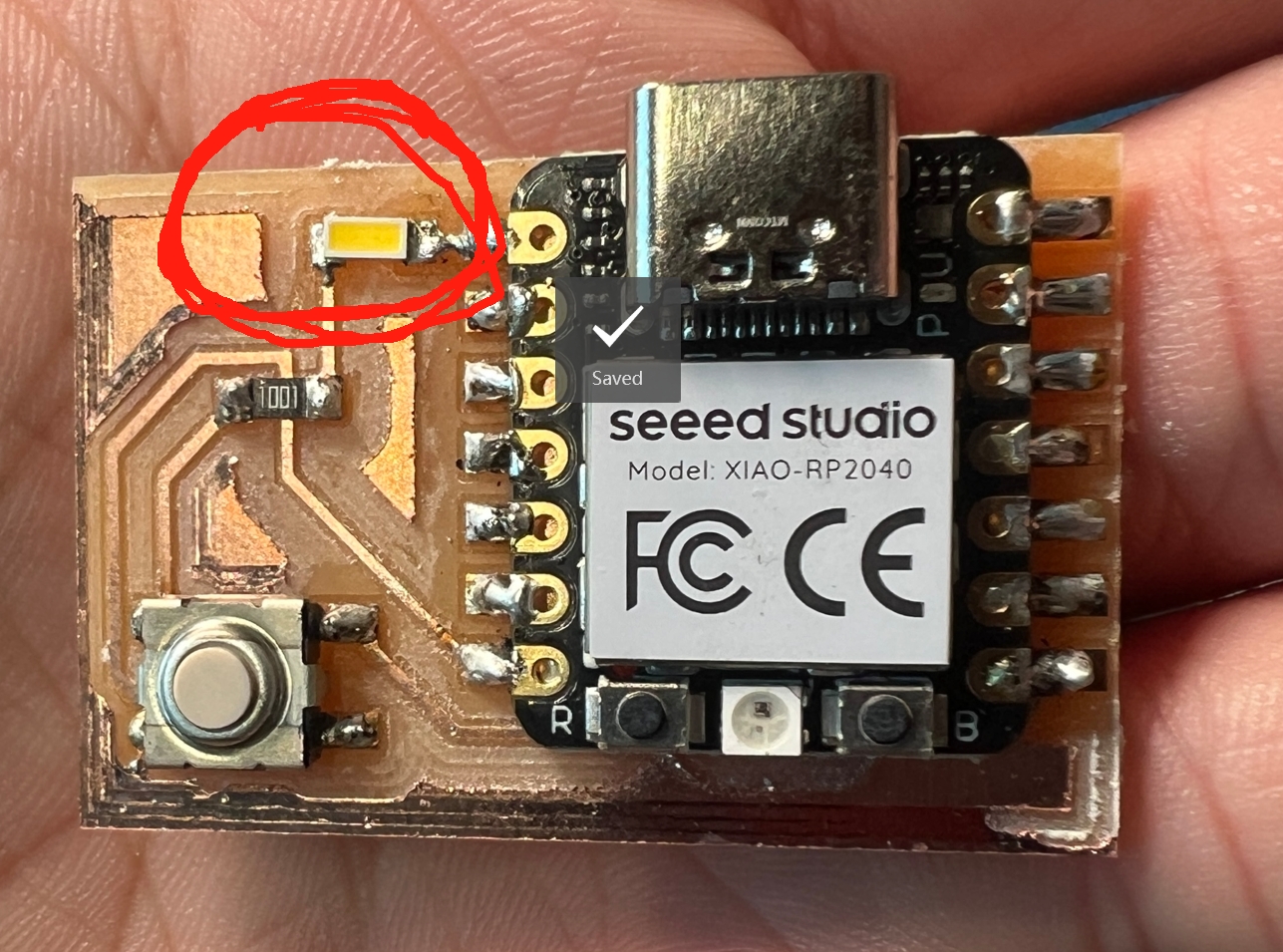

next, i had the components that i needed to solder together.

after several tests and about 30 minutes, i successfully put them together.

a couple of things i learned during the process:

1. try to avoid smelling or inhaling anything—these fumes can be very toxic.

2. always wear goggles during the process. While we were milling, a piece of the glass partition wall in the maker space shattered somehow, so please always wear safety glasses.

however, after we uploaded the code in Arduino, the LED didn not light up. We tried to debug it:

1. there might be something wrong with the soldering.

2. the LED has a + and -, and i might have soldered it backwards.

3. here could be a code issue.

after rounds of debugging, Lingdong (a big shoutout!) helped me identify the issue with the LED component:

1. it needed to be soldered on the backside—tricky!

2. it was soldered backwards.

3. the + side wasn't soldered at all.

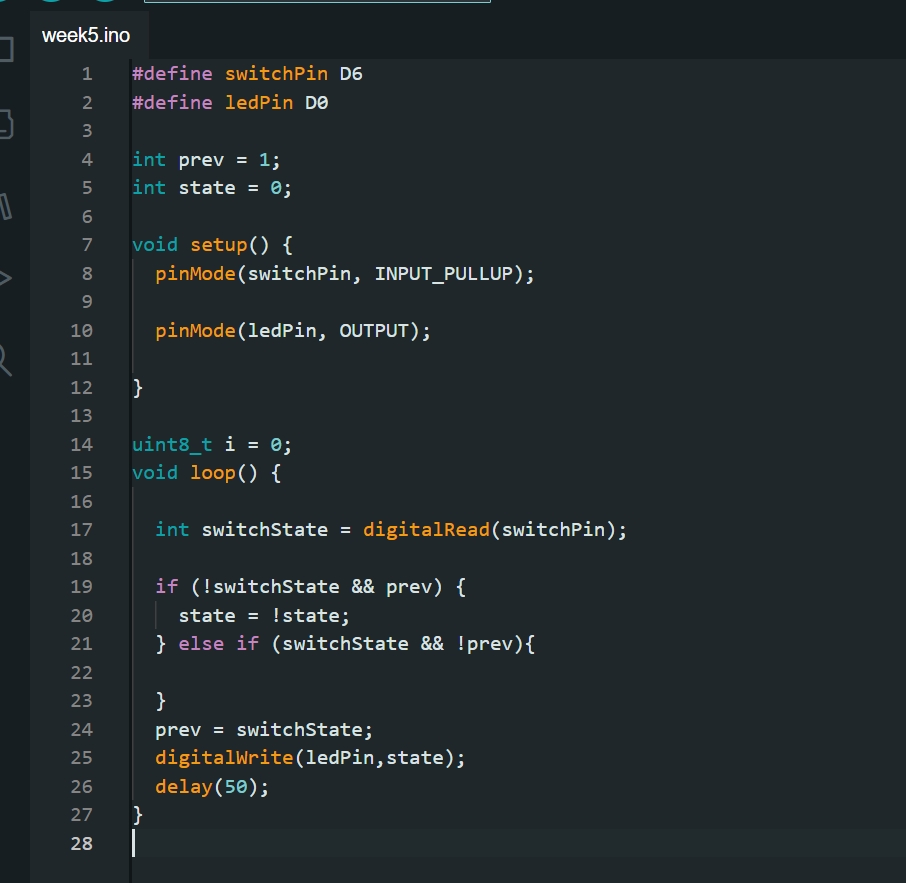

we de-soldered it, switched to another LED, and fixed the issue. updated the code in Arduino

someone needs to turn on the light!

Lingdong showed me how to make the light come in waves :)

although my project is simple, i found the overall process to be incredibly empowering.

initially, i felt quite frustrated last week because i struggled to get started with designing my PCB board. However, Anthony and Quentin’s tutorials were a big help in breaking down the steps, and Lingdong’s office hours were also super helpful in guiding me through the challenges I faced. meeting and talking with Bobby was also inspiring - it reminded me how important it is to connect with peers who are working on different projects, as their experiences can spark new ideas and approaches.

Here are a few key things I learned from this experience:

1. find and work with resources as possible: before jumping in and risking failure, it’s essential to digest the materials and resources available - tutorials, documentation, and advice can make the process much smoother

2. talk to peers and TAs: engaging with others is extremely valuable. Peers and TAs provide insights and perspectives that can broaden your understanding. One of the best parts of this class is the wide range of expertise and backgrounds everyone brings.

3. start with easy tasks and build up: starting with simple tasks was important. i also realize now that i need to push myself more and take on greater challenges in the coming weeks, cheers :)