Week 10

Goal

For this week, I wanted to mold a boot. My final project will walk around on many feet, which all need to have traction. Molding is a great way to use materials with high traction and it is a great way to make 100 of something. So, this week was a good opportunity to prototype for my final project.

I decided to do a two-stage mold just to practice, even though my end product was supposed to be soft.

Design

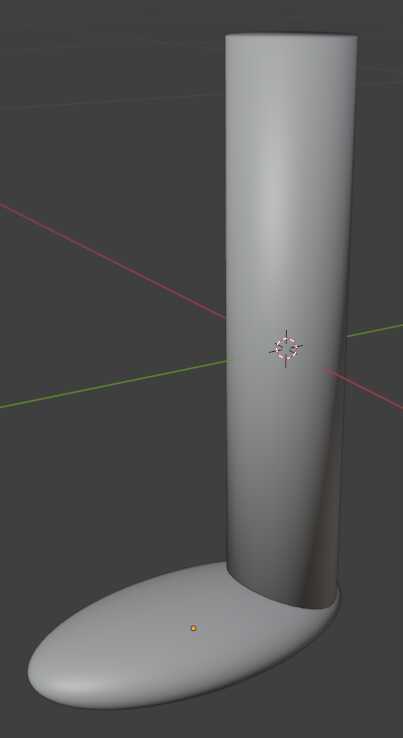

I decided to use Blender to design my boot, because I have never used Blender. The boot I designed is below:

I figured out how to sculpt, but in the interest of time, I ended up keeping the two starting shapes for the design. I uploaded the design here.

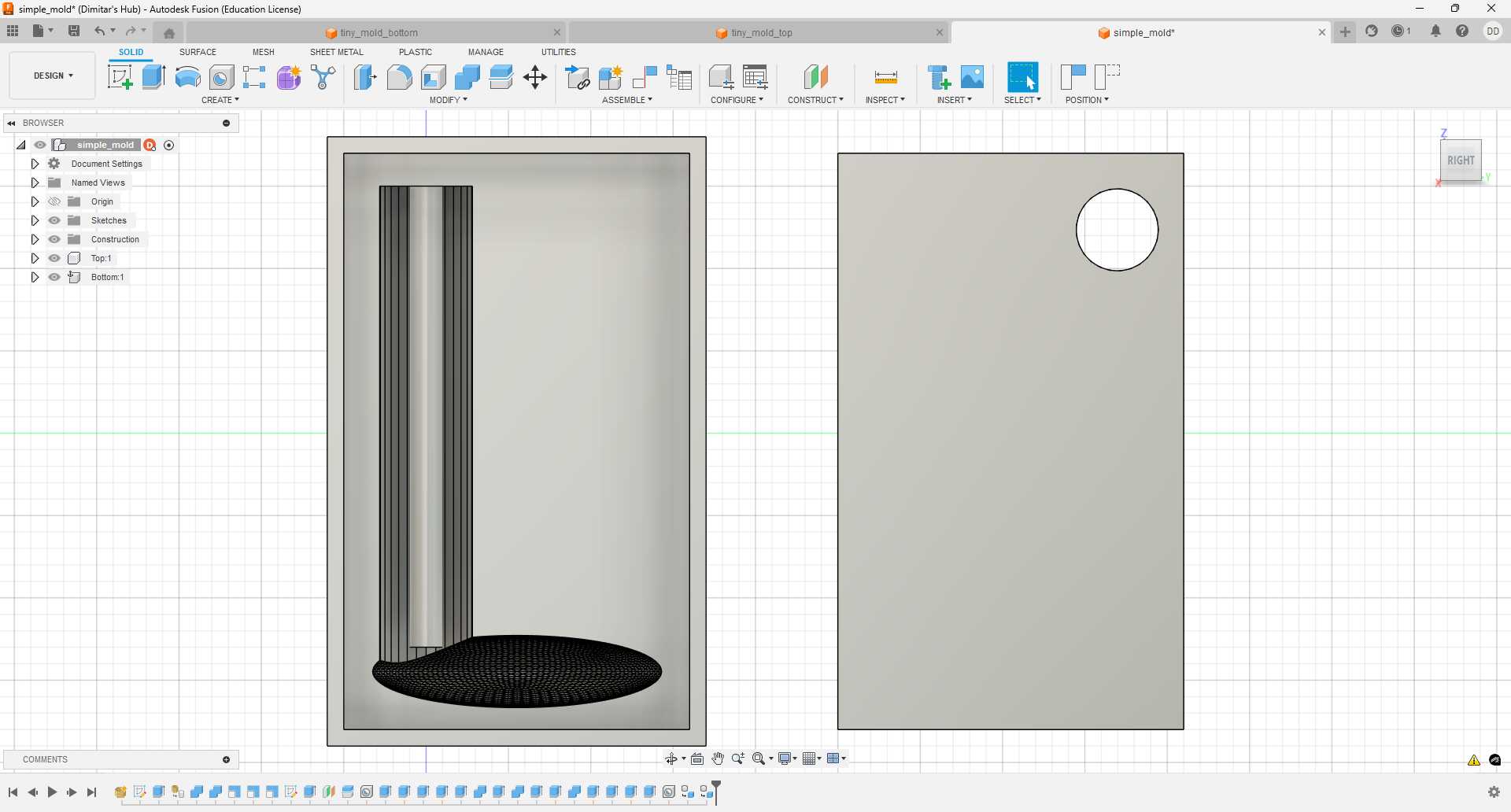

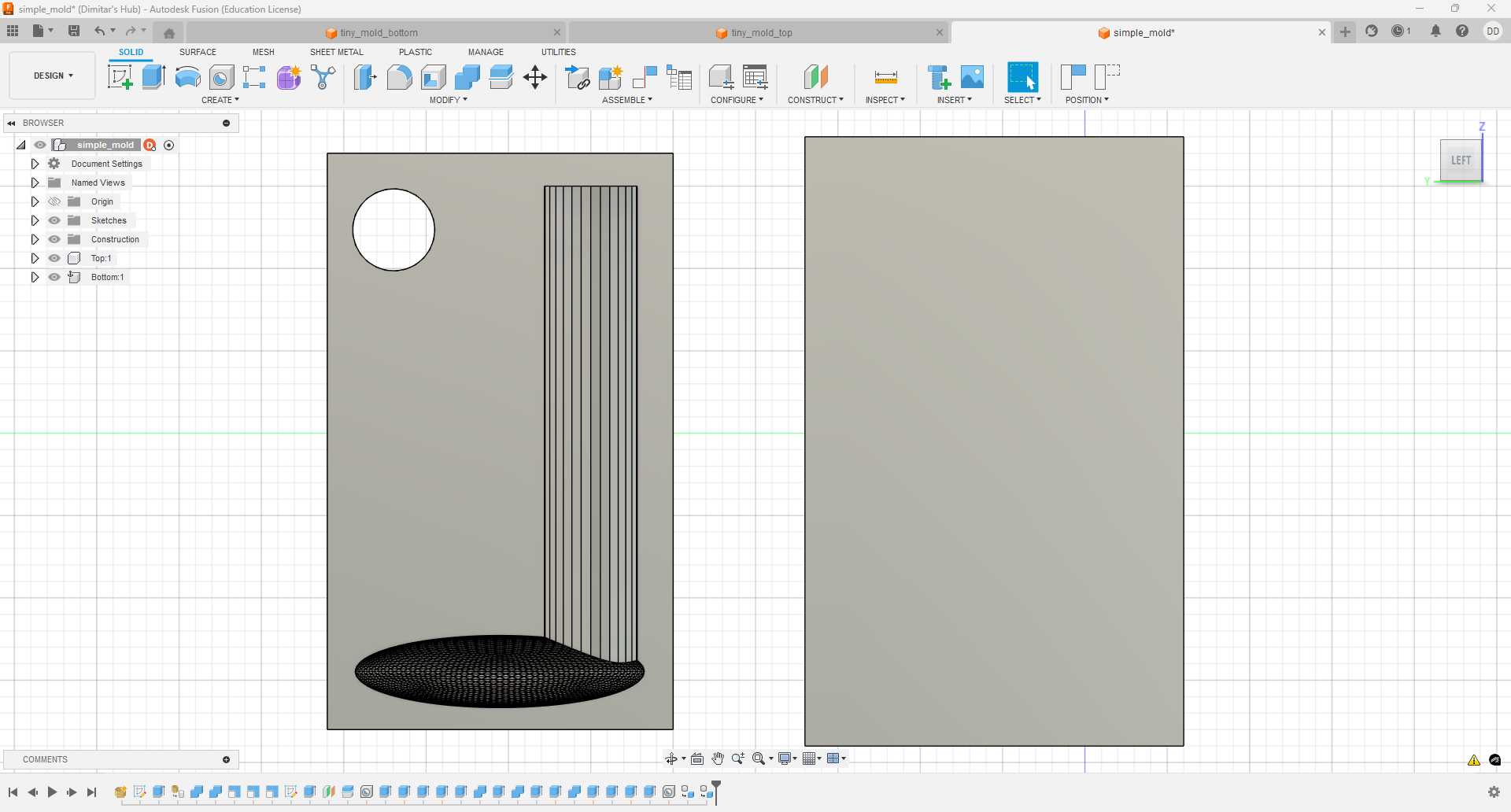

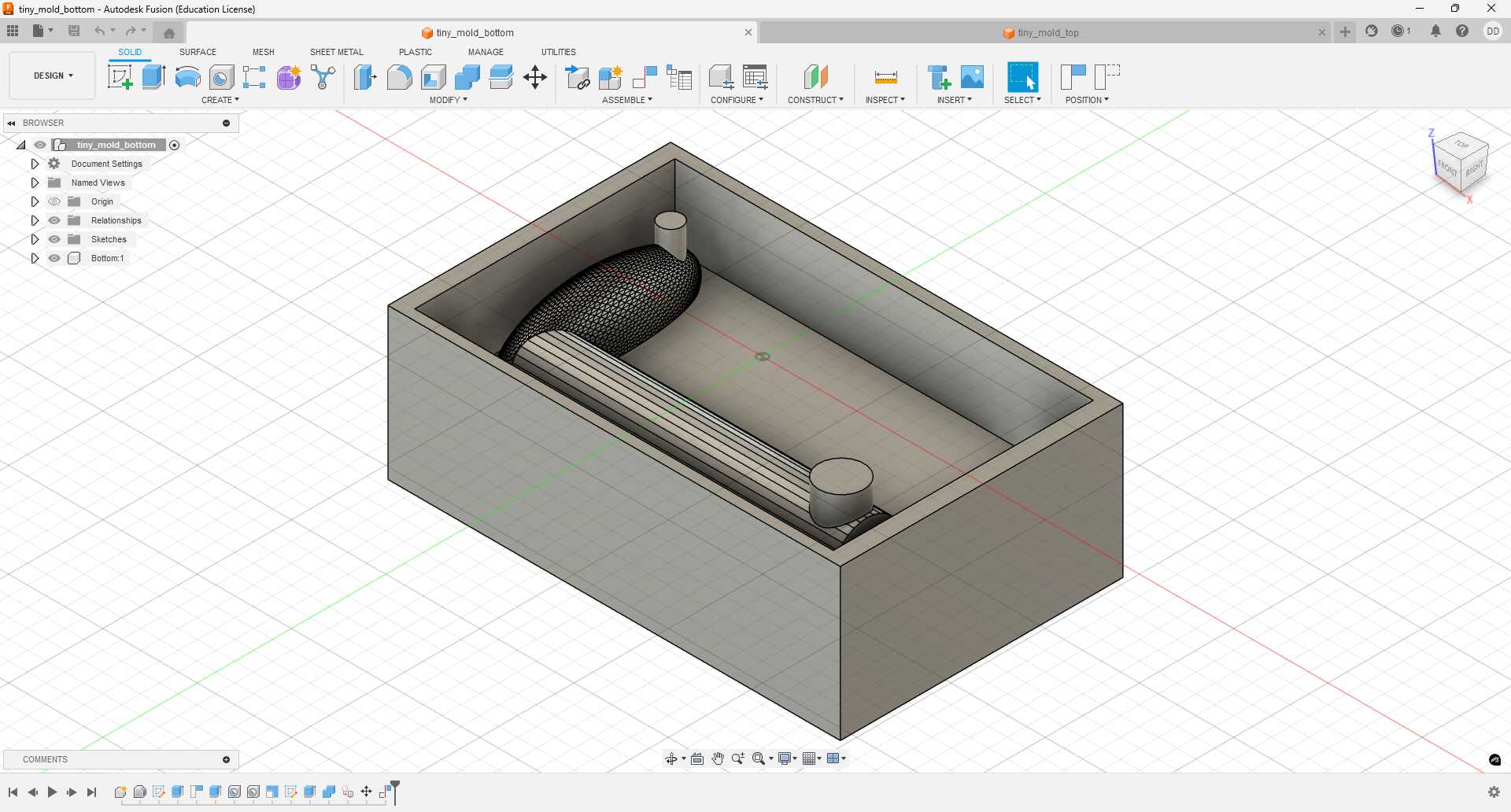

I exported the STL file and imported it into Fusion, where I designed a two-part mold. (It quickly became apparent that I had not exported with enough shapes for the cylinder, which I should have addressed earlier.)

The “second” mold is a negative of the boot,

and includes walls for registration (instead of bumps) and a hole to help separate the pieces.

It is shown in Figures 2-3.

It is also accessible at https://a360.co/48CY09l

and embedded below (so long as autodesk360.com continues to host it):

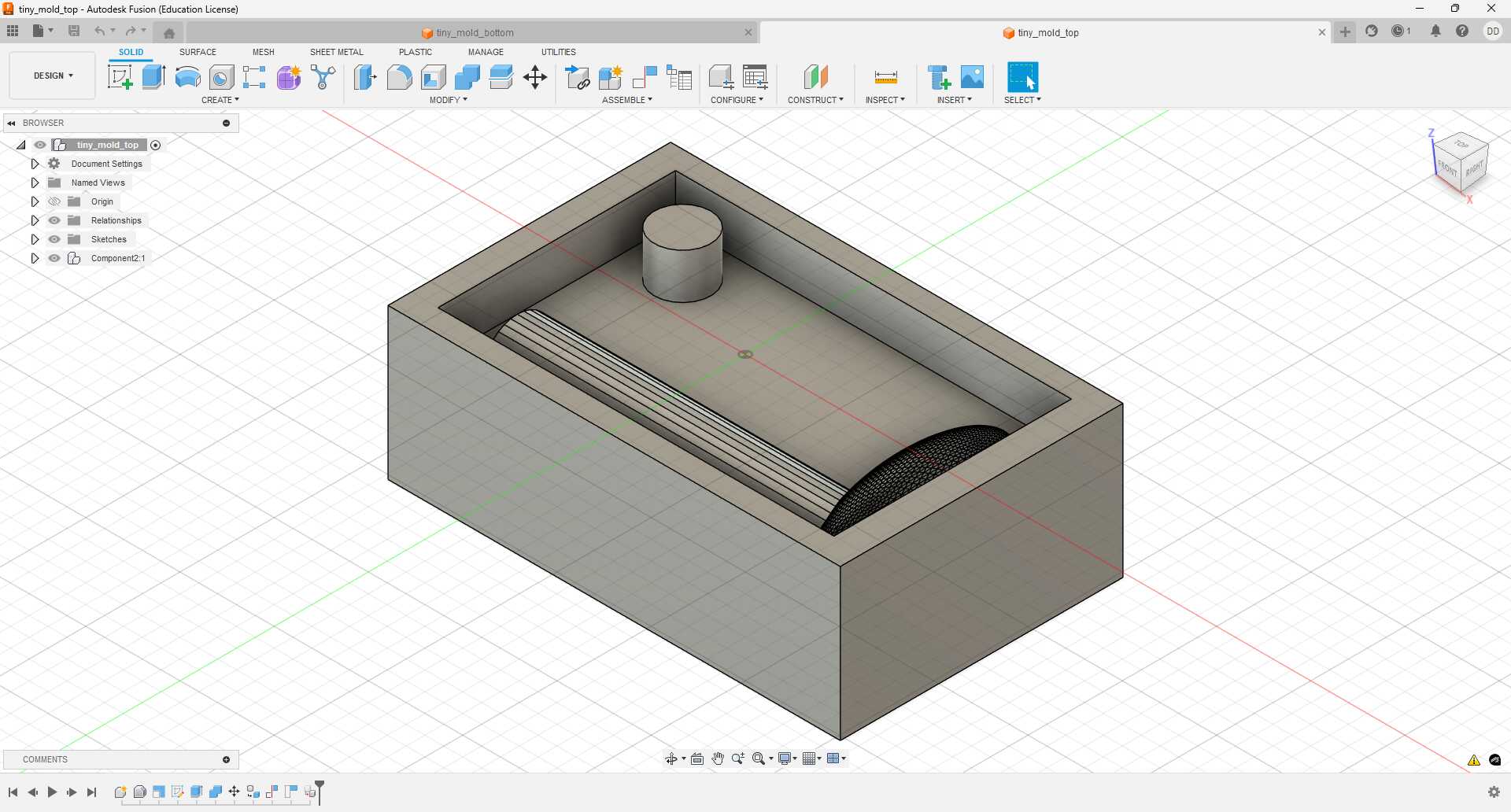

The “first” mold is a negative of the second mold.

I moved and resized the pour hole and added an air hole, which I had omitted in the second mold originally

(in the interest of time, I did not got back and edit the first CAD).

I made each side the same size as the provided wax stock.

They are shown in Figures 4-5.

They are also accessible at https://a360.co/4pnFSrg and https://a360.co/4rG3yso

and embedded below (so long as autodesk360.com continues to host them):

Making the First Molds

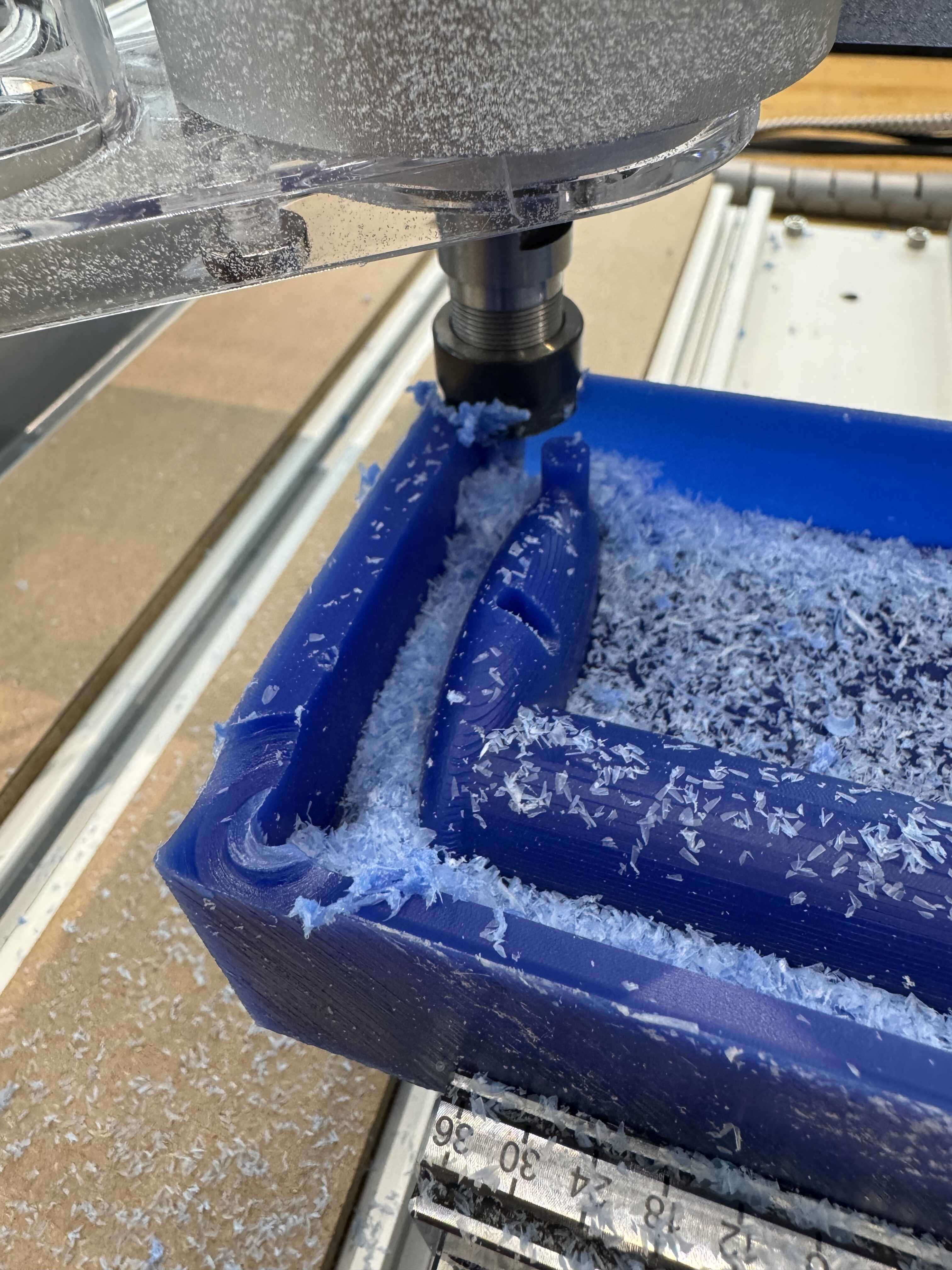

I made two versions of the first mold: one out of wax on the Genmitsu, and one out of resin on the Formlabs SLA printer.

The wax mold presented significantly more challenges, and I made a few mistakes. I had not used the Genmitsu before, and I found that learning to use it made me understand G-code a lot better. However, it did have a few quirks. Most notable was that its travel in Z was severely limited, but I did not find a way to make Fusion aware of that when generating toolpaths. So, some manual tweaks of the G-code were required. For every missed tweak, the machine would hit a limit switch, and require repeated resets and jogs to get it out of that state.

Another challenge for me were the toolpaths. The coarse run was straightforward, but I did not do a great job with the fine run. I suspect I should have split it up by areas. This is definitely something I hope to get better at in the future.

Most critically, however, I was not able to drill the walls of the larger second mold. When I created the corresponding first mold, the walls created high-aspect-ratio trenches. When the machine got to them, the collar prevented the cuts from completing (Figure 6). I decided not to fix this, since even small walls allowed for registration, but this is something else I will improve the next time I do this. I simply stopped the run and fixed the first occurrence with some tape.

Also, after one of the Z-axis stalls, the machine suddenly moved in the X direction and took a small chunk out of the mold. It’s unclear to me why it did this, but it’s a good reminder to never make assumptions about where the machine is going. I stopped and reset it after which it continued normally.

The final product is shown in Figure 7.

The SLA printing was painless and high-quality (despite using the Fast material). Alan walked me through it on the Formlabs printers in 015. The mistake I made there was printing the entire design, which I had made to include the wax stock to make toolpath planning easier for the milled version. Next time, I will not only not do that, but modify the mold to further reduce material.

The final product is shown in Figure 9. The guck in the picture is from making the second mold - the print itself turned out pristine!

Molding the Second Molds

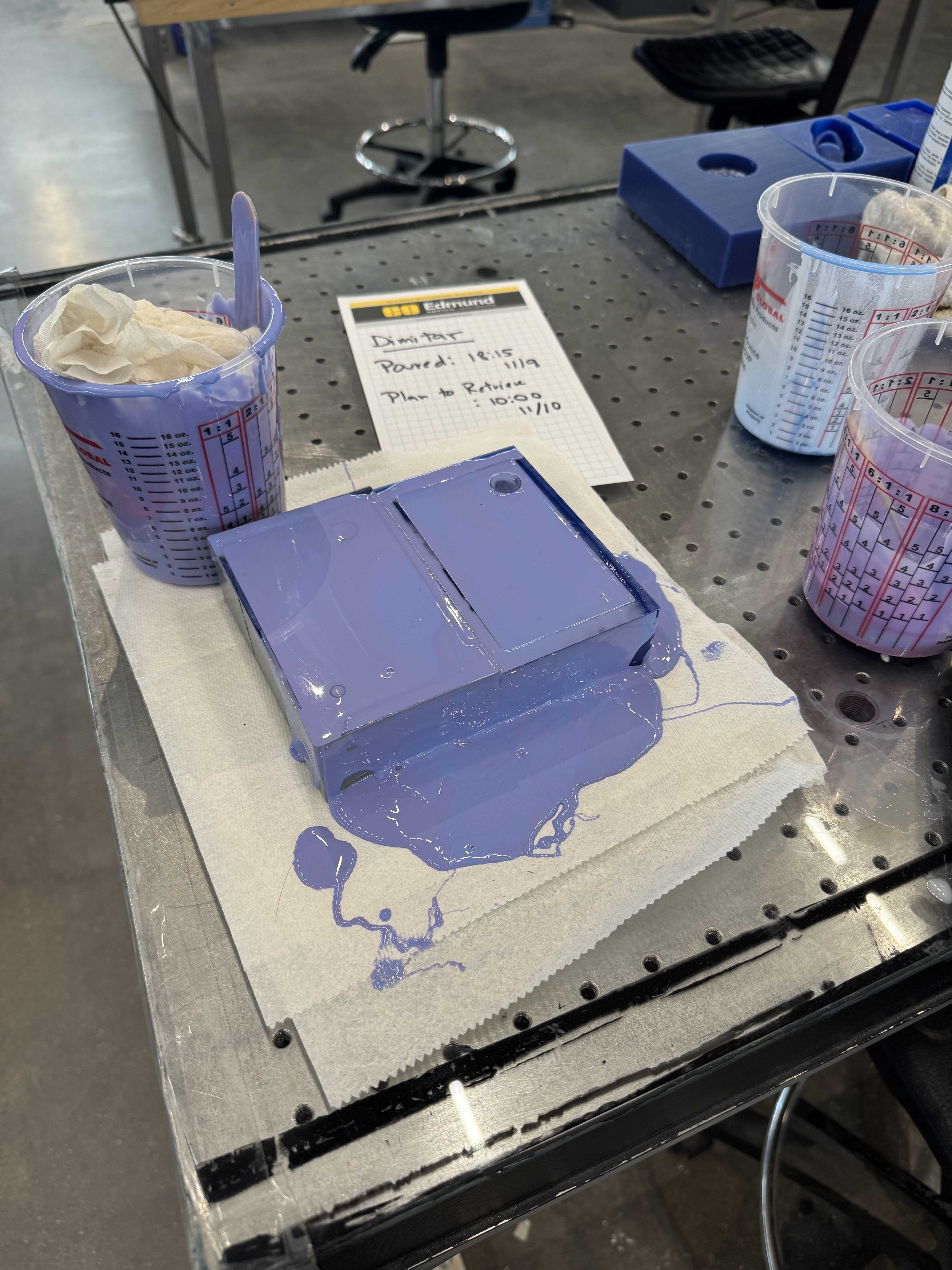

For each of the two first molds, I made two sets of second molds using two types of silicone rubber: OOMOO 30 and the “food-safe stuff”. For both materials, I used vacuum to remove all bubbles each time I made a new batch.

First, I used OOMOO in the wax molds (while the SLA molds were printing). That worked great!

Then, I mixed the food-safe stuff (Figure 13) by weight and made a set of second molds with that (while simultaneously molding boots in the first set; more on that later). Simultaneously, I molded OOMOO in the SLA print. Both turned out well (Figure 15). The SLA version had the nice walls, as expected.

Finally, I molded the food-safe stuff in the SLA molds. (I also re-molded OOMOO in the wax, because my first set of boots had made a mess, and the first mold was idle.) The food-safe stuff did not cure in the SLA molds. I left it in overnight (much longer than necessary, but when I checked in the morning, it was a gooey mess.

In summary, out of the four combinations, three worked well (or, as well as the original mold allowed), but the food-safe stuff did not cure properly in the Fast SLA. All five attempts are shown in Figure 16:

- OOMOO in wax

- Food-safe stuff in wax

- OOMOO in SLA

- Food-safe stuff in SLA

- OOMOO in wax again

Molding the Boots

Pipelined with molding the second molds, I was molding boots in the second molds that were already molded. This stage was a lot less successful.

Based on faulty intuition, I started by molding in the opposite material. The food-safe stuff boots in OOMOO cured for the same amount of time as the food-safe stuff in wax (Figure 14), but they did not fully cure (Figure 17).

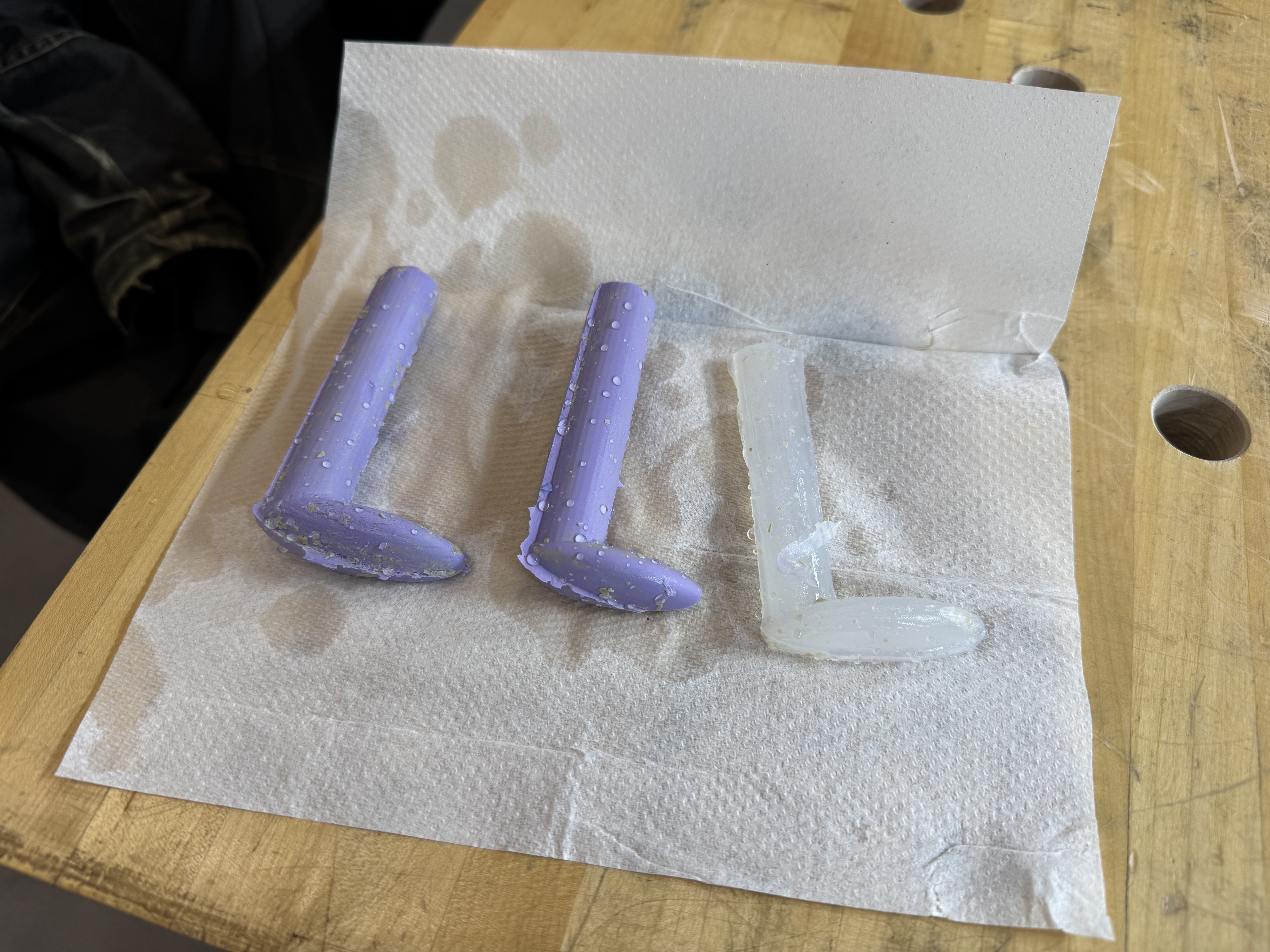

I then molded the opposite material in each second mold except for the food-safe stuff SLA one. The OOMOO-in-food-safe-stuff boot was almost okay, but also didn’t cure completely. The results are show in Figure 18:

- Food-safe stuff in OOMOO in wax

- Food-safe stuff in OOMOO in wax

- Food-safe stuff in OOMOO in SLA

- OOMOO in food-safe stuff in wax

(One of the attempts had some other issues as well.)

After these failed attempts, Kat suggested I do like-in-like and use mold release. I washed two of the OOMOO’s and both food-safe-stuff molds, and lined them with SC Johnson Paste Wax. I then molded OOMOO in the OOMOO ones and food-safe stuff in the food-safe-stuff ones. The food-safe-stuff mold that had been made from the SLA mold turned into a solid block of silicone, but the other three turned out okay (Figure 19).

Final Thoughts

This week was simultaneously my least successful week, and the week in which I learned the most (perhaps those go hand-in-hand). I learned:

- how to create 3D toolpaths

- how to use a table-top mill

- how to use an SLA printer

- how to mold

I didn’t get to do any casting, but I imagine a lot of my learning in molding will transfer. I knew going in that a two-stage mold was unnecessary for my final product, but I learned that it’s actually significantly more difficult than a one-stage mold because of cure inhibition.

As is the case with most weeks, there is a lot more I would have tried with more time. This week was especially tight with machine week ramping up in parallel. If I were to redo this experiment, I would go in with a much clearer plan. But, my main goal was to learn how to mold for my final project. The good news is that the first stage mold worked well, so I am confident I will be able to execute successfully. Based on my experience, I plan to use the SLA printer with OOMOO 30.

Sources

- Blender file, Boot: https://gitlab.cba.mit.edu/dimitar/kitchen-sink/-/blob/main/boot/boot.blend

- CAD, “Second” mold: https://a360.co/48CY09l

- CAD, “First” mold, part 1: https://a360.co/4pnFSrg

- CAD, “First” mold, part 2: https://a360.co/4rG3yso