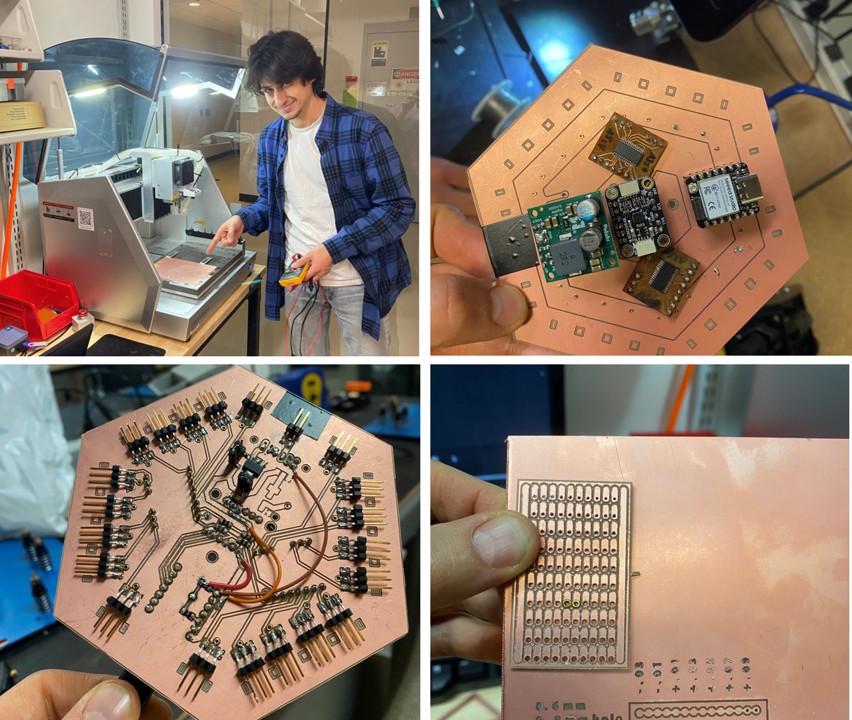

Week 11

Week 11 was Machine Week.

I was on the Electronics team, along with

Ben

and

Tyler.

I made some initial prototypes for the firmware team.

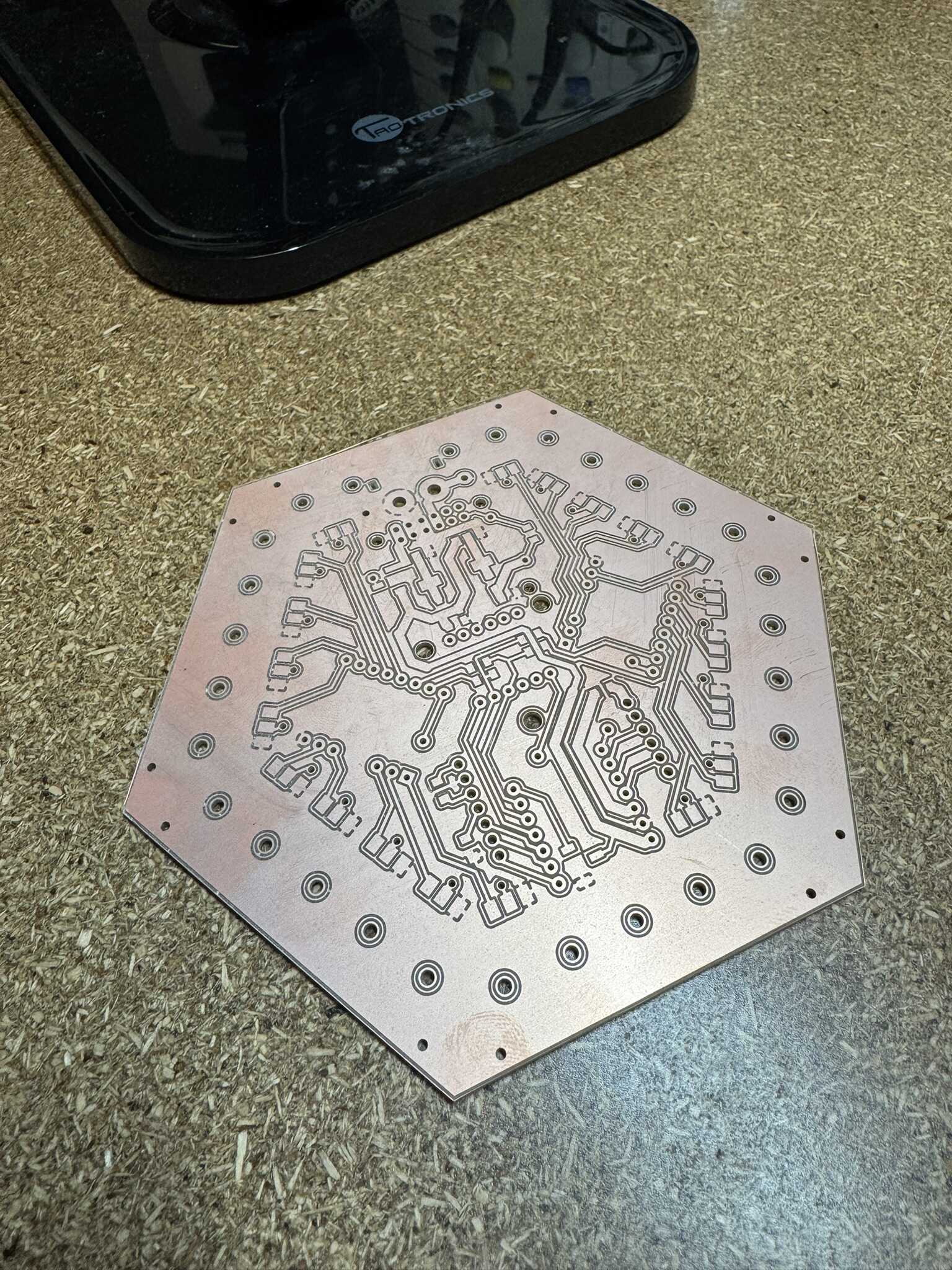

Then, I worked with Ben to developed the v2 board,

shown below in pictures taken by Ben:

Key challenges included:

- agreeing on a form factory and mounting scheme with the mechanical team

- alignment of a two-sided PCB with through holes (I did this by engraving the back first, mirrored and rotated by 90 degrees, then using the corner of the Carvera bed to register the sides with each other; I also ensured that the back side annular rings were large, so that alignment requirements were relaxed)

- using rivets (I made a test board for this – the winner was 1.1mm holes for 0.9x2.5 rivets)

- actually engraving the two sided stock (we needed to increase cut depth from .12mm to .36mm, a lesson I re-learned for v2.1 the hard way)

I then improved the board to a v2.1 version fixing minor bugs and adding better connectors.

The source for both is here. More extensive documentation can be found in the README.

We initially used the 3D v3 board for integration,

but v2 made a second appearance at 9AM of demo day,

one we were done rebuilding the ball following disaster at 4AM.

Sources

- KiCad Project, v2.x board: https://gitlab.cba.mit.edu/classes/863.25/CBA/cba-machine/-/tree/main/hardware/main

- KiCad Project, rivet test: https://gitlab.cba.mit.edu/dimitar/kitchen-sink/-/tree/main/rivet_test_board