Week 5: Electronics Production

This week has been slightly particular because I got sick early in the week (something seems to be passing around on campus), and this impacted my productivity a lot. This, combined with a few technical diffulties that I'll describe later, has led me to miss the chance to obtain a fully functional board as I had hopde to. However, I did make a lot of progress and I hope that I can get the board ready for the end of this week!

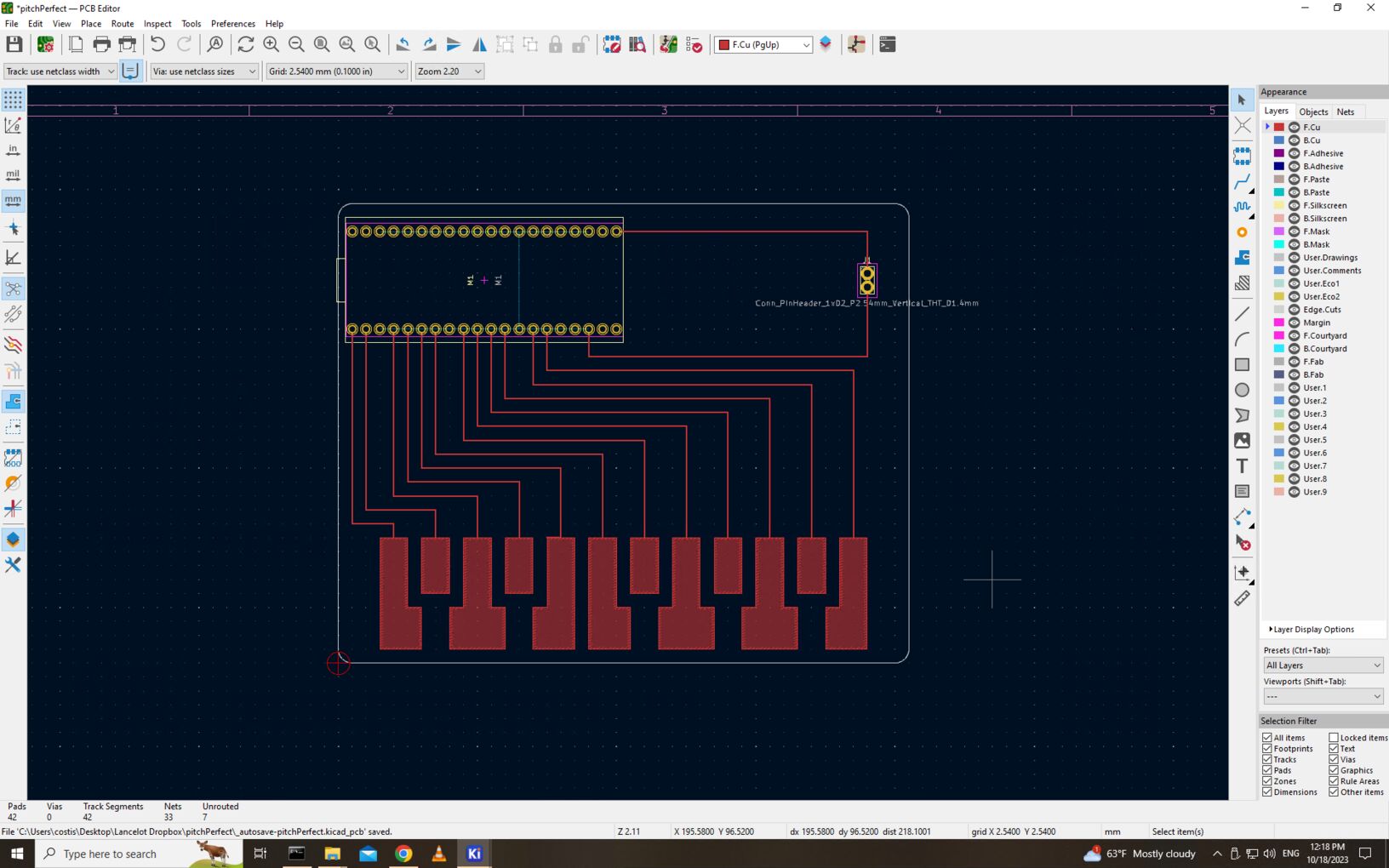

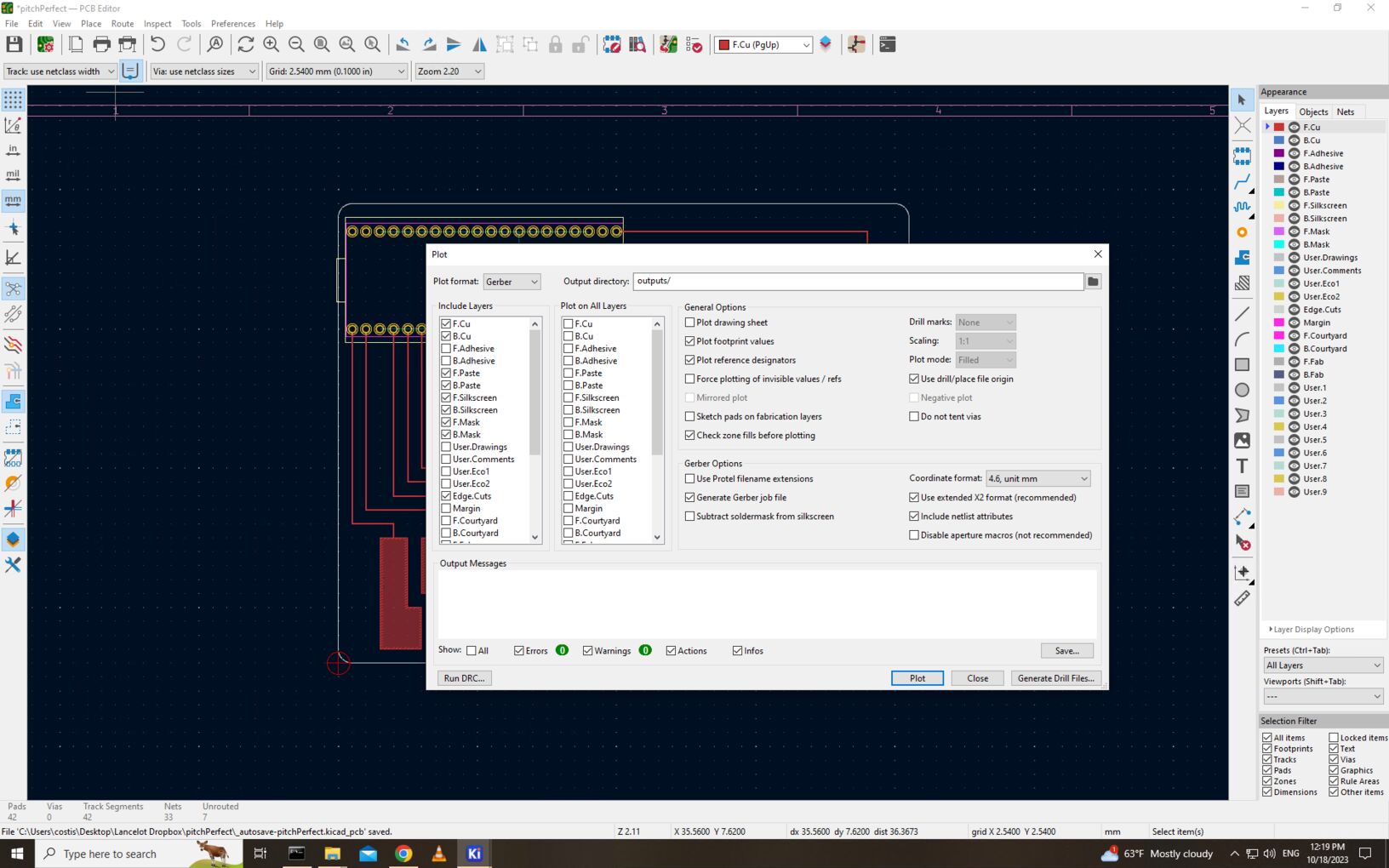

Still on KiCad, I continued the design of my synth/board and quickly realised that something was wrong with my previous design from last week. As a matter of fact, my keys were only graphics in the PCB file, and, as such, were not being exported properly when exporting the entire board. I then realised that I needed to use the "filled copper zone" tool in order to design pads that would be considered when exporting the board to Gerber files. An additional thing that I realised that the speaker part that I got did not corresponding to the footprint that I had used previously. In particular, the speaker I have cannot be directly mounted on a PCB. I have therefore been advised to use a 2x1 connector with through-holes and followed these instructions. After making sure that my Pico was on the edge of the board, I was happy with my design. I exported all the necessary layers (Front Copper, Edge Cuts, and PTH) and obtained 3 Gerber files.

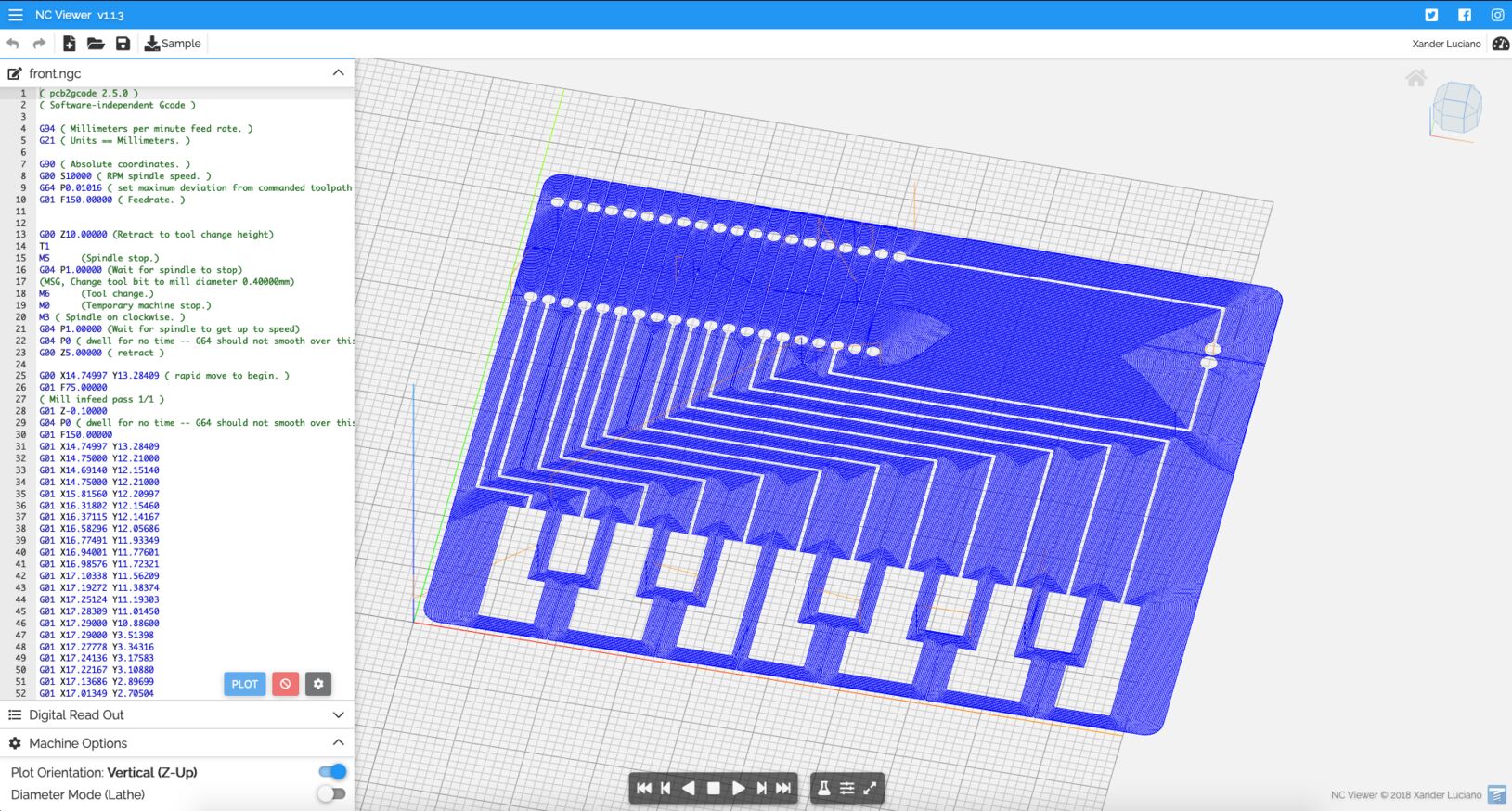

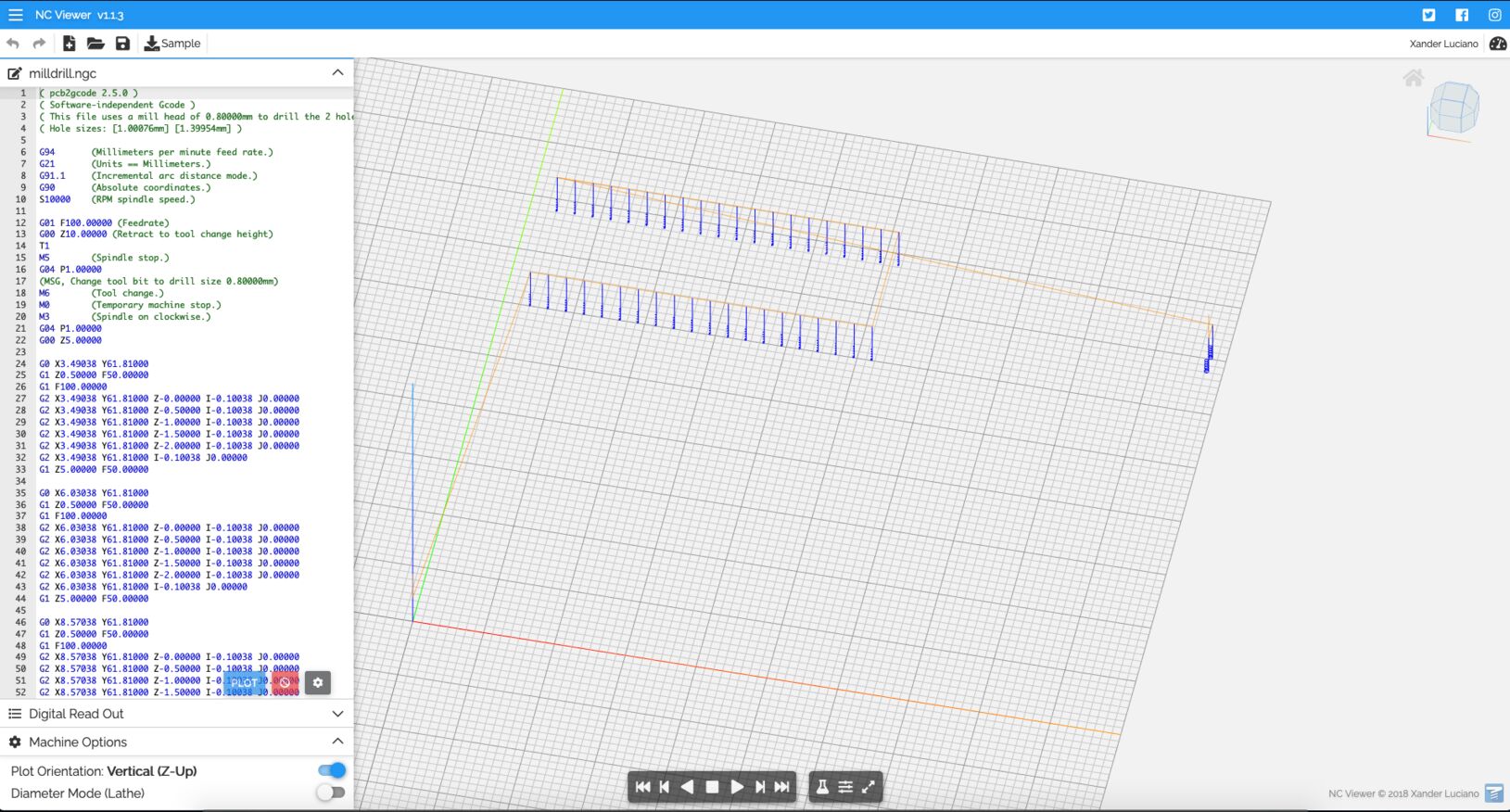

Once I obtained the corresponding Gcode files (front.ngc, milldrill.ngc, and outline.ngc), I was able to visualise the corresponding paths that the CNC machine will be following using the online tool NCViewer.

As I mentioned, I got sick pretty early in the week, which stopped me from being able to go to the lab as soon as I wanted to. Additionally, a few technical problems arised with the CNC machine, which resulted in a few endmills being broken and large queues of students accumulating to use the machine. When I tried to mill my PCB, the estimated time rose up to almost 5 hours!

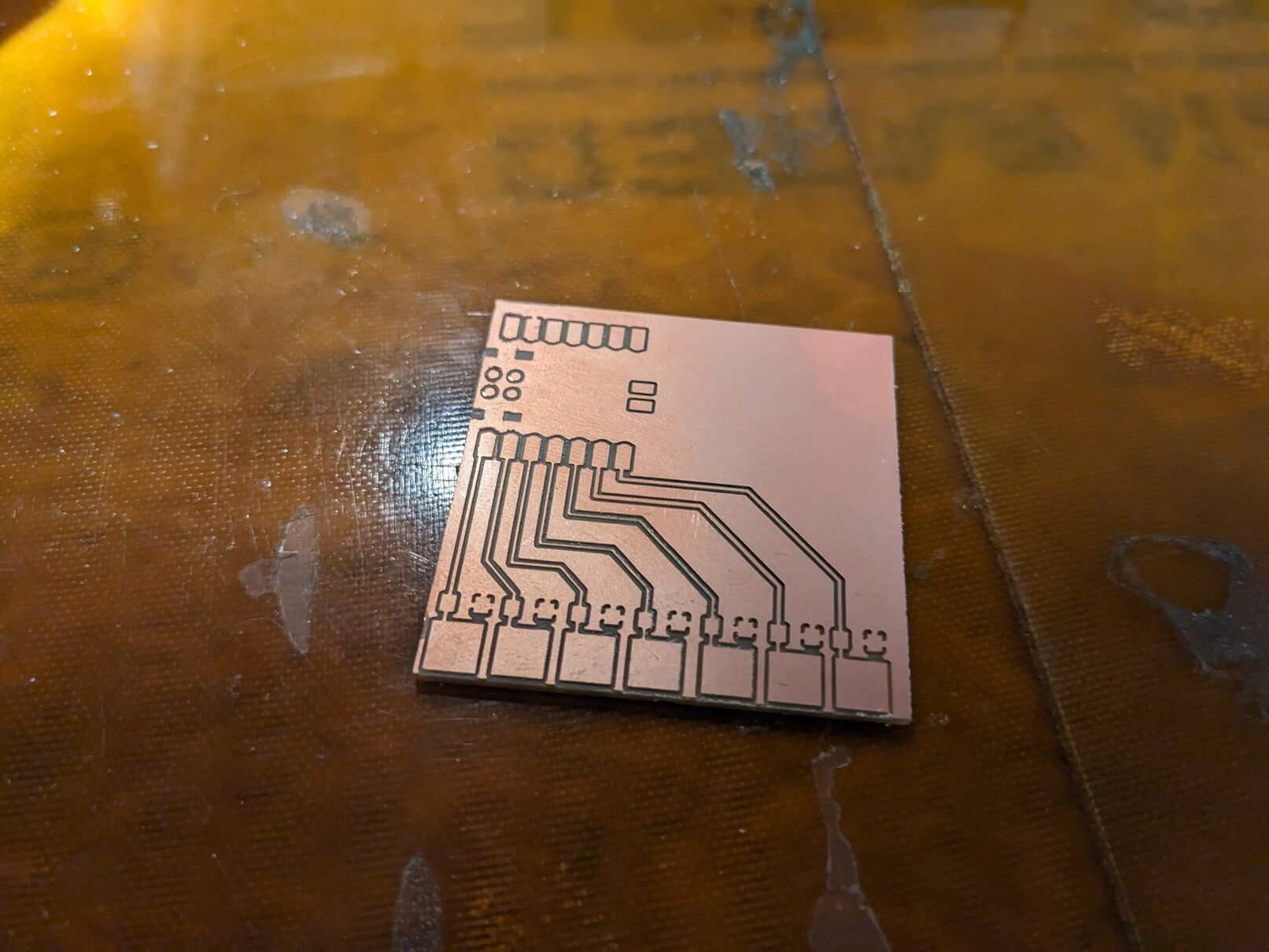

I therefore had to delay my PCB milling to Week 8. Eventually, I managed to mill a synthesizer using a ground pour, which heavily reduced the milling time, and I obtained the following PCB:

Notes to a future me (learning outcomes):

- Fangzheng's advice on using pcb2gcode was very useful: always trust your elders!

- Time management is even more important in the winter, because who knows when you'll be sick and everyone wants to use the same resources than you?