3D Scanning & 3D Printing

FormLab 1+

I created the model using Solid Works that I learn over the weekend. I called it “Second Glass”, like an hourglass, it only takes a second to drop the “sand”. I printed several models with Formlab 1+. It is a very slow and messy process and results could be very disappointing, sometime it printing nothing out. This is the only printer that prints clear and hi-res 3D model in the shop. I think the resin contributes to the high failure rate. We don’t know if the leftover resin is good in the resin tank. Often times people forgot to shake the solution before pouring into the tank.

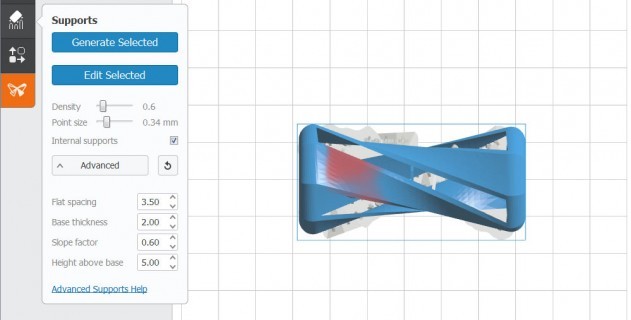

When I print for the first time with the Formlab, I did not know what the red highlight meant on the model, but later I learned that it means the “lake of support”. It just means that we need to either rotate the model, add more supporting density or make the walls thicker.

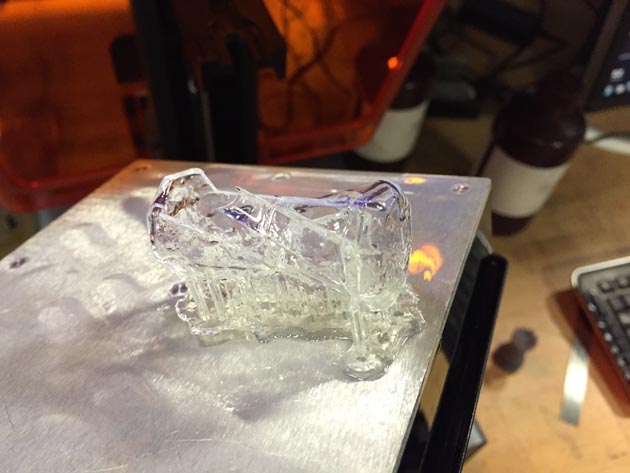

The weak/red spots of the 3D Model as shown above translates to the 3D print below.

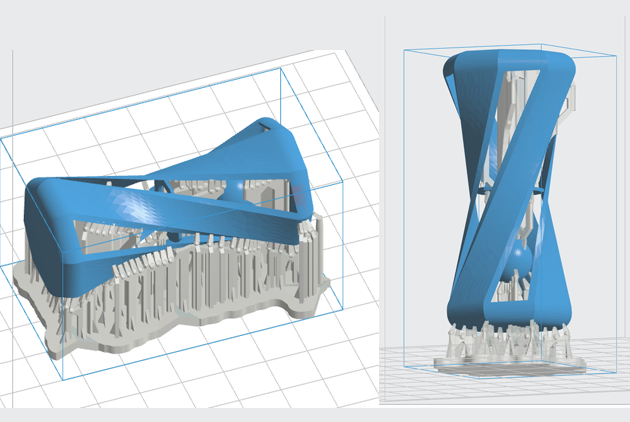

I tweaked the settings and rotations to make sure that there are no red spots on the model before I print.

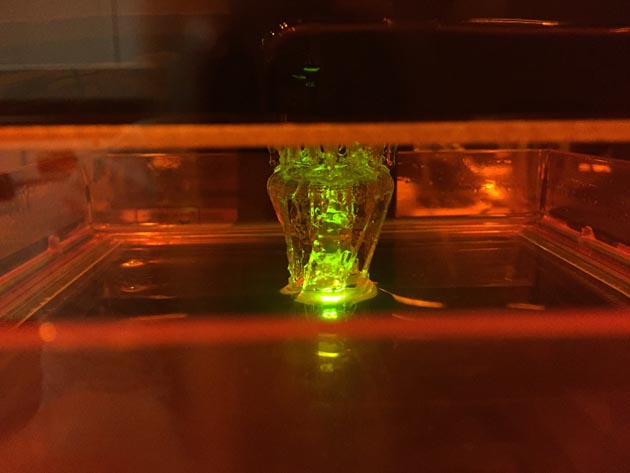

This is a picture + Video of the Formlab printing.

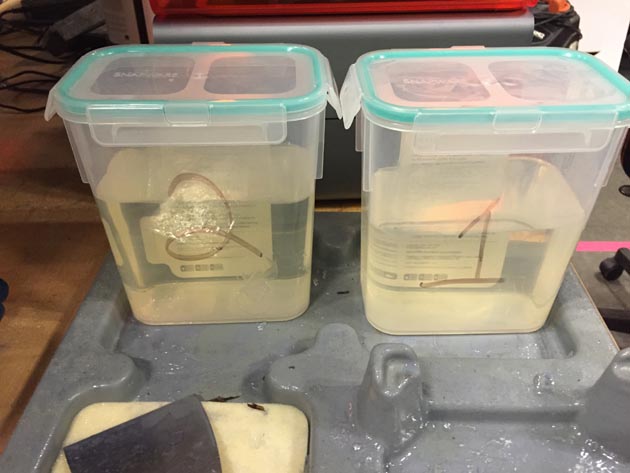

The prints then goes through solution 1 for 3 minutes, soaked for 3 minutes, and the same with solution 2.

The top and the bottom of the parts are still very soft to the touch. The inside supporting materials makes it very hard to take it out.

The print is far from perfect, some of the parts “melted” away.

Final Print with formal. I printed this one in high-resolution and it turns out pretty well.

Maker Bot

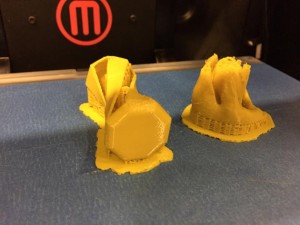

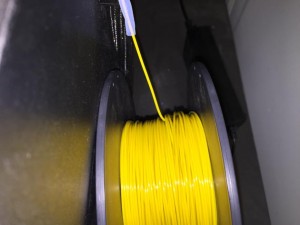

Maker bot is more reliable than the Formlab. When I tried my first print with the Maker Bot, it failed a couple time due to the tangled up filament. Make sure you check the feeding mechanism before printing. Here are pictures of my parts printed half way.

The left model below has a bad mesh in it, it did’t print correctly. The error in the right model below was caused by printing without filament.

Once I figured out the filament problem, I was able to print with very little problem. The left model shows supporting element, and the right shows the supporting elements been removed.

Dimension Elite

I made the wheel in Solid Works. Similar to my first laser cut project, the 2 wheels forms H shape profile, connected via a cylinder on the inside.

I was able to turn the wheel freely, however one of the wheel was in the bath for too long, it was deformed slightly.

Sense 3D Scanner

3D Scan of the cordless drill. This was pretty easy to scan, probably due to its’ bright color and high contrast.

Hand selfie of my hand. This is not easy to do with just one hand, but doable. The bottom surface details are often lost with the scanner.

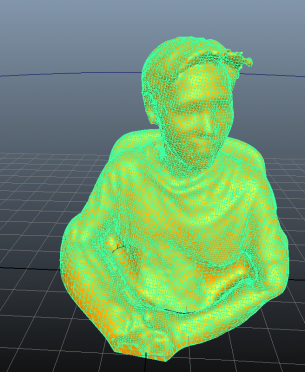

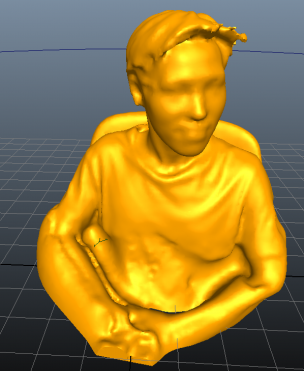

3D Portrait. With my classmates’ help, I was able to get this portrait scanned. I then exported .Obj File opened in MeshLab for some detailing.

Exported .Obj File opened in Maya. It does not retain the color.

Sketch Fab allows you to embed 3D Models online like Youtube videos.