Casting

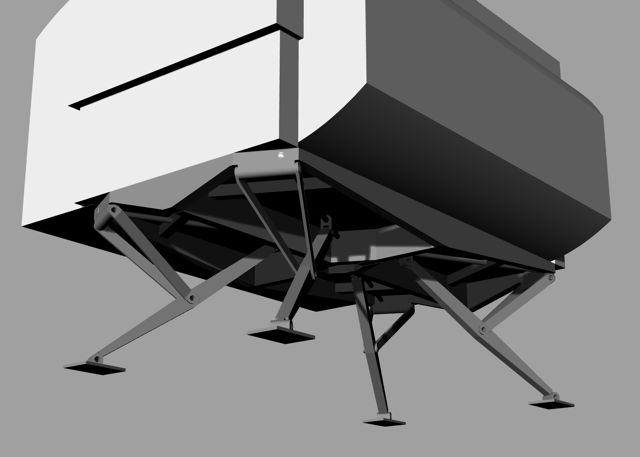

I am working on an architecture project with a lot of moving parts and linkages, so I set about to casting the various fittings needed to make the building work. essentially I want to make a set of legs that can be adjusted with a linear actuator. they look like this.

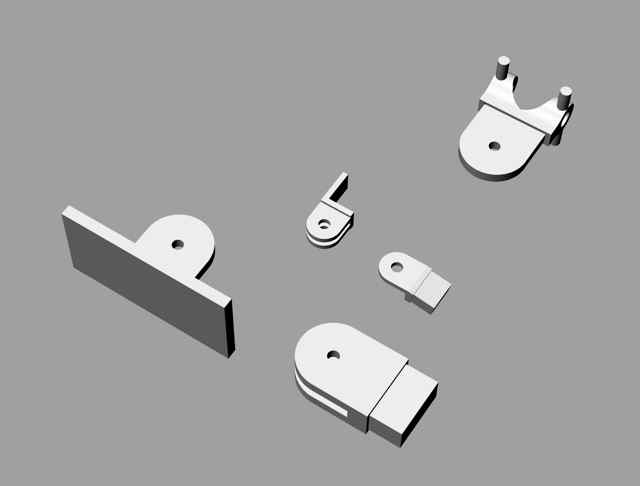

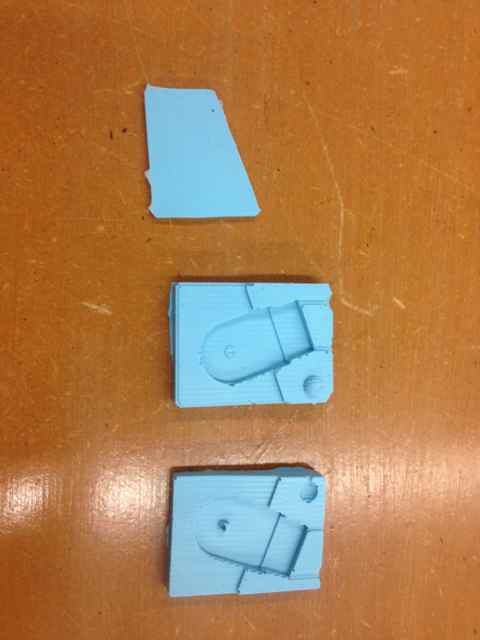

The parts look like this, they are designed to mate with 3/4" x 3/8" , and 3/8"x 3/16 rectangular brass tubing.

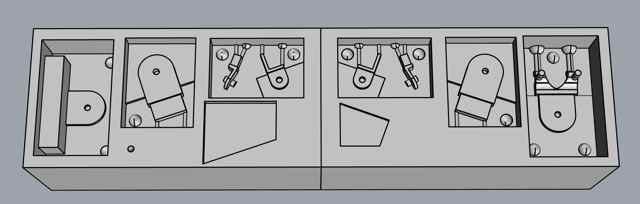

This is my mill model. I have put in pour holes and vents, and there are several places that require plugs, both flat and round. The trapezoids in the middle are flat plugs.

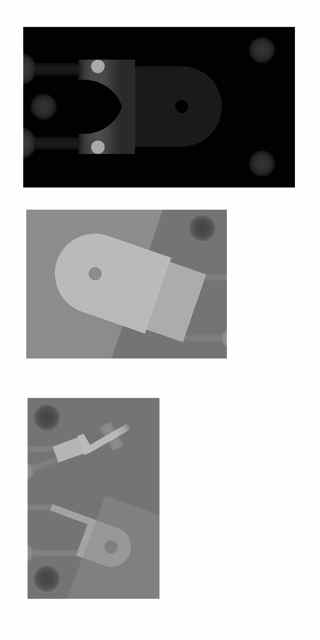

Next I mill. We used Neil's fab tool to convert .stl into .png, each side was a 26MB whopper that looks something like this!

I ran the rough cut on the mill with an 1/8" flat end mill. I had to first adjust the colors in photoshop so that the darkest color would be pure black and the lightest color true white. Then in the FabModule, I had to set the cut depth to the deepest point on my model, about 19mm. After the rough cut, I offset the top white surface inward 1/16", so that when I ran a smaller bit, the shank would not hit the side wall. I did a final cut with the 1/16" mill and got pretty good results.

I was hoping to cast my pieces out of the babbitt metal, but when I discovered that the MoldMax 60 needed 24 hours to cure, and I had milled molds on both sides of my wax block(meaning I couldn't cast them all at once), I decided to just do a test run in oomoo and Hydrostone. oomoo was a bit more viscous than I thought, may have some spots that don't get covered.

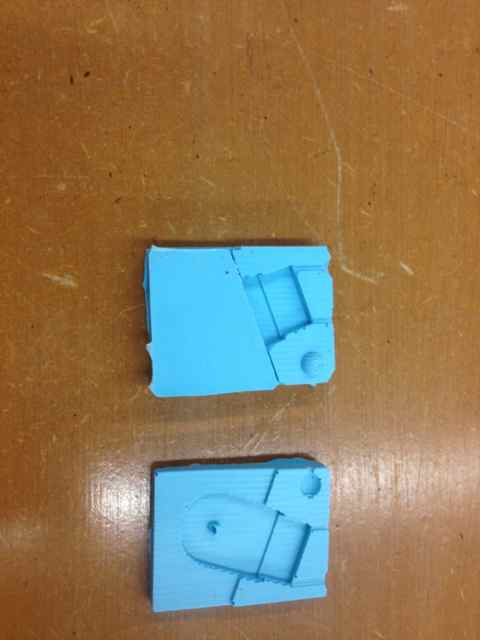

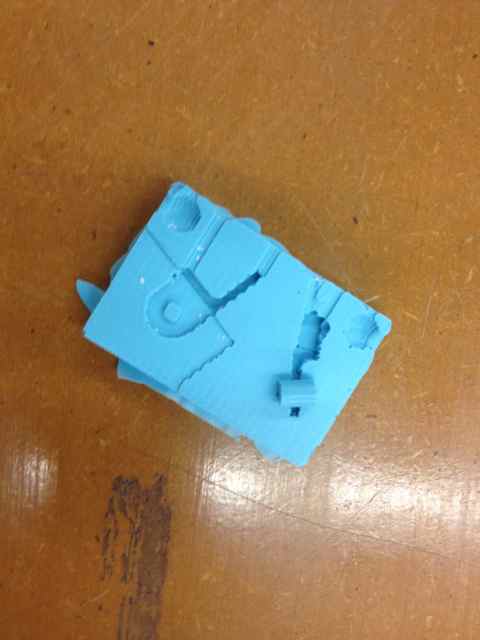

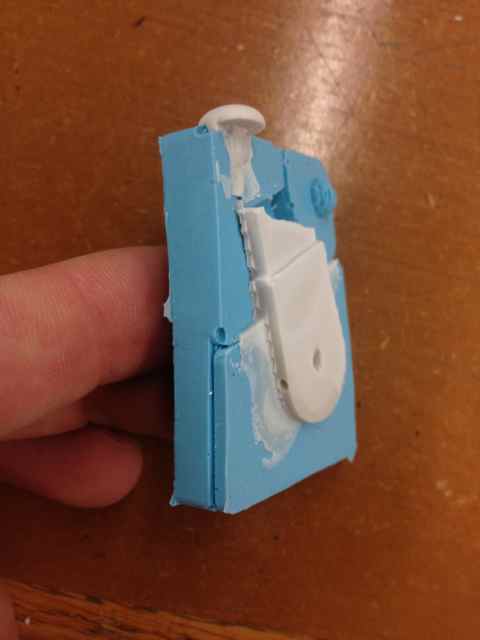

this shows the molds and plugs going together. The round plug for the piece on the bottom right did not fit either.

this shows the molds and plugs going together. The round plug for the piece on the bottom right did not fit either.

All taped up!

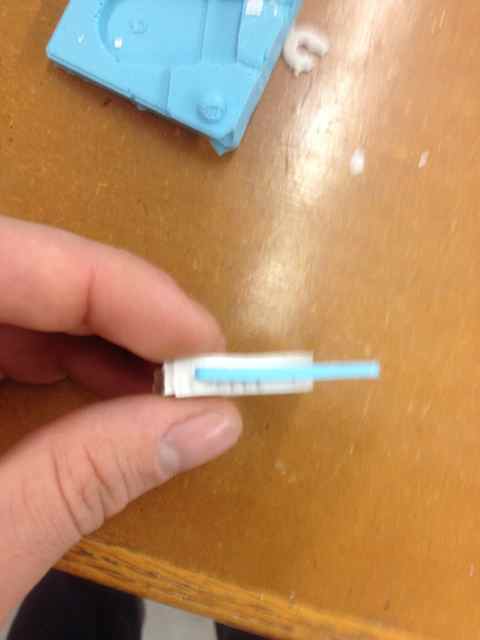

Since my pieces are so fine, I used a syringe to inject Hydrostone into the mold. Doctah doctah!

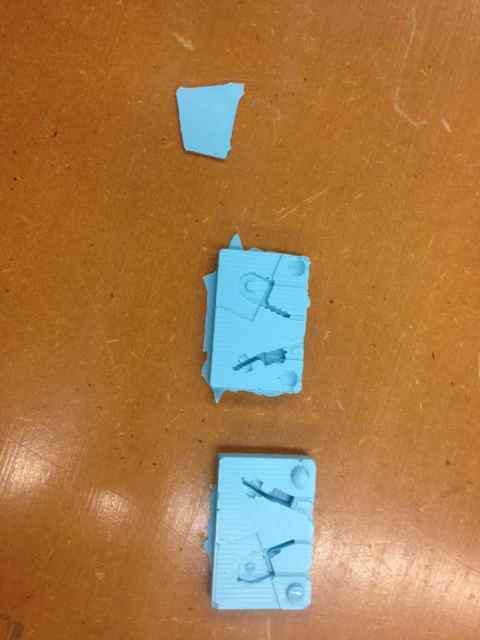

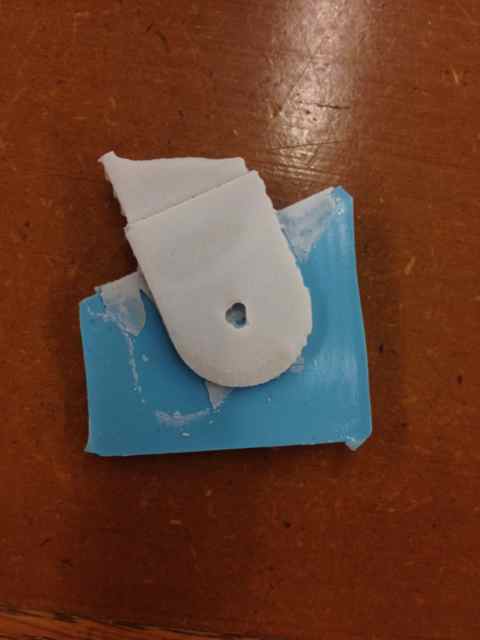

Excavating was a delicate process. I didn't have good flow in some areas, so the final cast pieces are pretty rough. The first one I broke. It was the smallest and had wimpy plaster penetration.

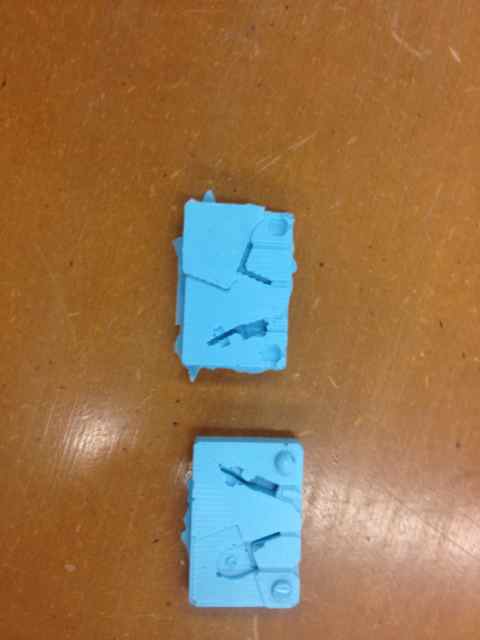

The larger one came out much better, but it doesn't look like my vent worked. It also appears that the mold was a little bit floppy. The larger fork is twisted nright in the middle, which would make it not function as a pivot, it does look cool though.

tadaa! Kinda janky, but hopefully with thicker molds or some rigid support for them, and metal instead of plaster, they would come out a little better.